Steel band bale breaker

A technology of unbundling machine and steel belt, applied in the directions of packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of inconvenient handling, low production safety, long steel belt, etc., and achieve simple and quick adjustment of length and mechanical precision. High, fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

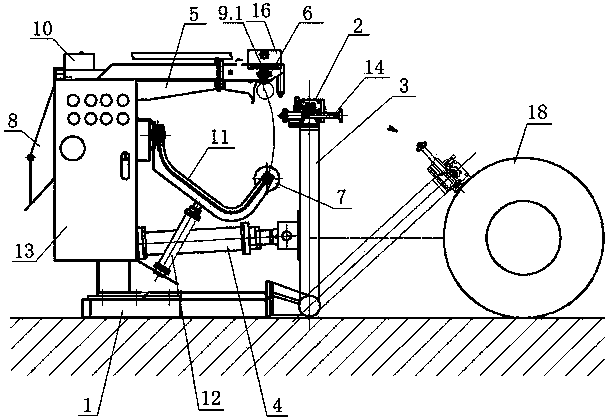

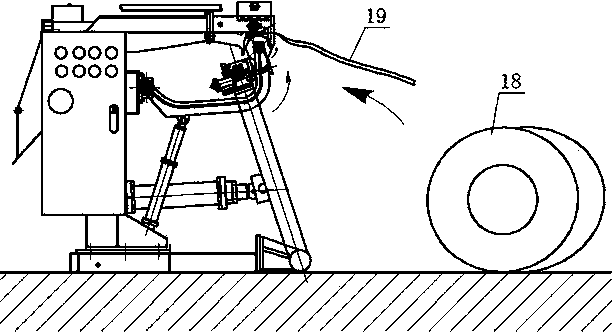

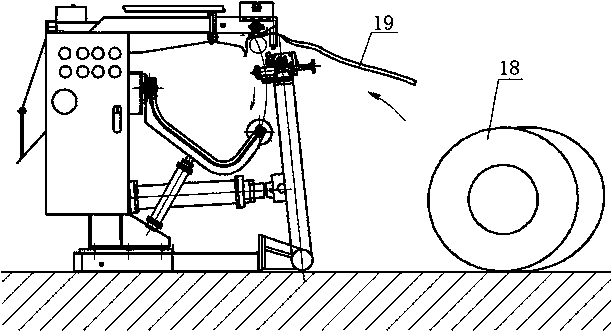

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The present embodiment provides a kind of strip unbundling machine, as Figure 1~Figure 3 As shown, it includes a frame 1 with a shearing mechanism 2, the shearing mechanism 2 is arranged on one end of the rotating arm 3, and the other end of the rotating arm 3 is hinged with the bottom of the frame 1; one end of the rotating arm cylinder 4 is connected to the rotating arm 3. The other end is connected to the waist of the frame 1; the upper part of the frame 1 is provided with a belt feeding hopper 5, such as Figure 4 As shown, a fixed entrainment roller 6 is set at the entrance of the belt delivery hopper 5, and the end of the belt delivery hopper 5 is connected to the discharge bin 8, and a belt delivery mechanism 9 is set between the entrance of the belt delivery hopper 5 and the fixed entrainment roller 6, and the belt delivery hopper 5 A t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com