A flying probe testing machine and its flying probe module

A flying probe testing machine and module technology, applied in conveyors, measuring electricity, measuring devices, etc., can solve the problems of loose pins and solder, reduced pressure by impact force, low efficiency of manual plate layout, etc., to reduce friction, Increase the speed of feeding and the effect of fast feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

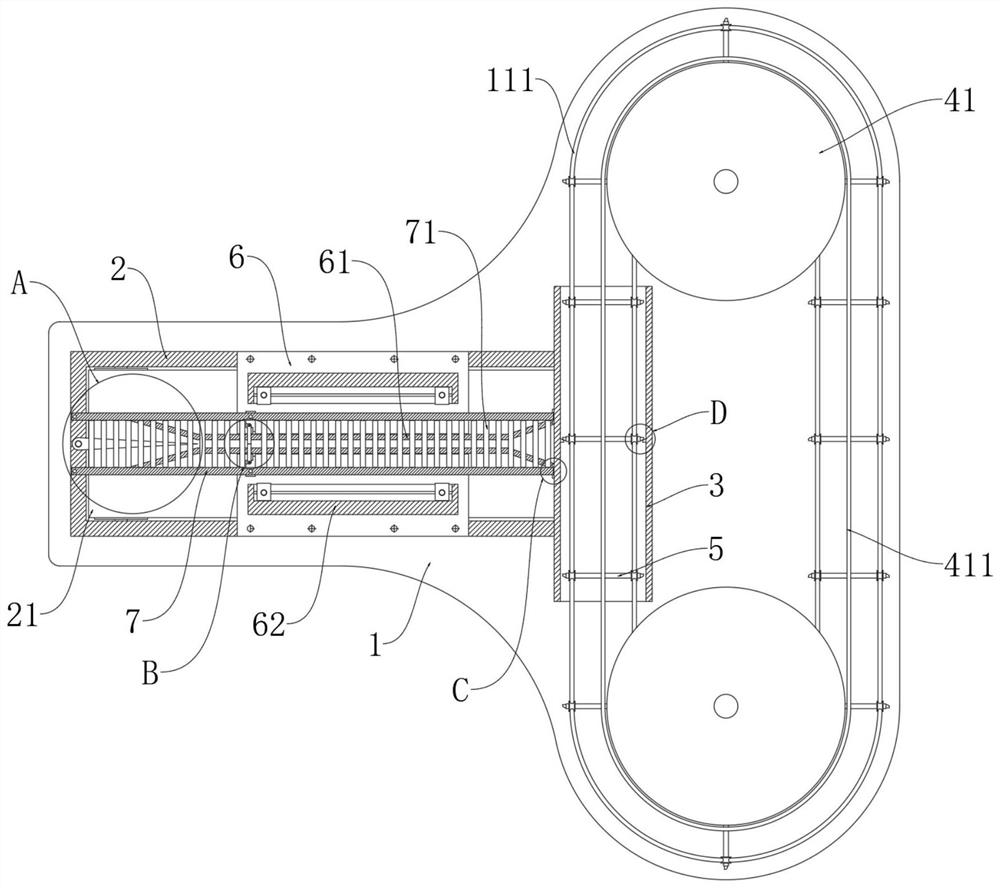

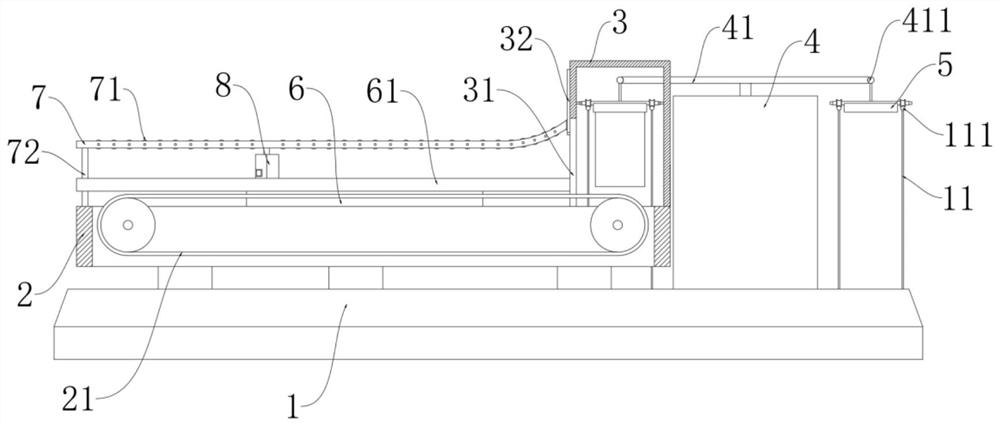

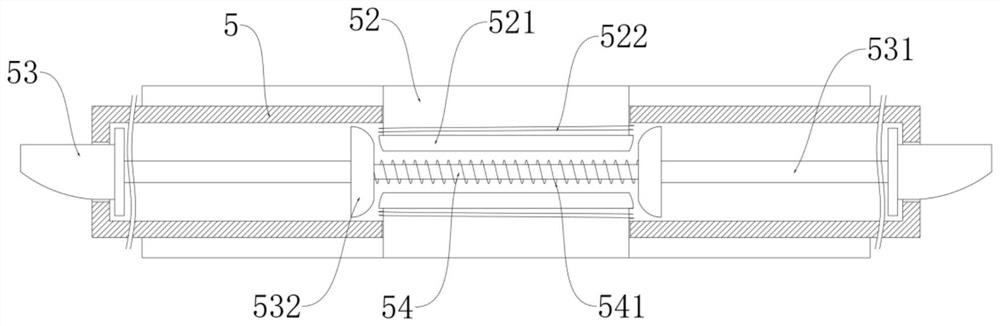

[0039] refer to Figure 1-9 , a flying probe tester, comprising a base 1, a plurality of support rods 11 are installed equidistantly and symmetrically on one side of the base 1, and the upper ends of the plurality of support rods 11 are jointly installed with a double surrounding track 111, on the base 1 A transport frame 2 is installed, a belt conveyor 21 is installed in the transport frame 2, a limit shield 3 is installed on the side of the transport frame 2 close to the double surrounding track 111, and a section of the double surrounding track 111 passes through the limit shield 3, and the machine A control host 4 is installed on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com