Rounding device for automobile spokes

A technology of automobile wheel and cooling mechanism, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of inconvenient cooling of workpiece, inconvenient wheel angle and position, and increase labor intensity of workers, so as to improve cooling speed and reduce The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

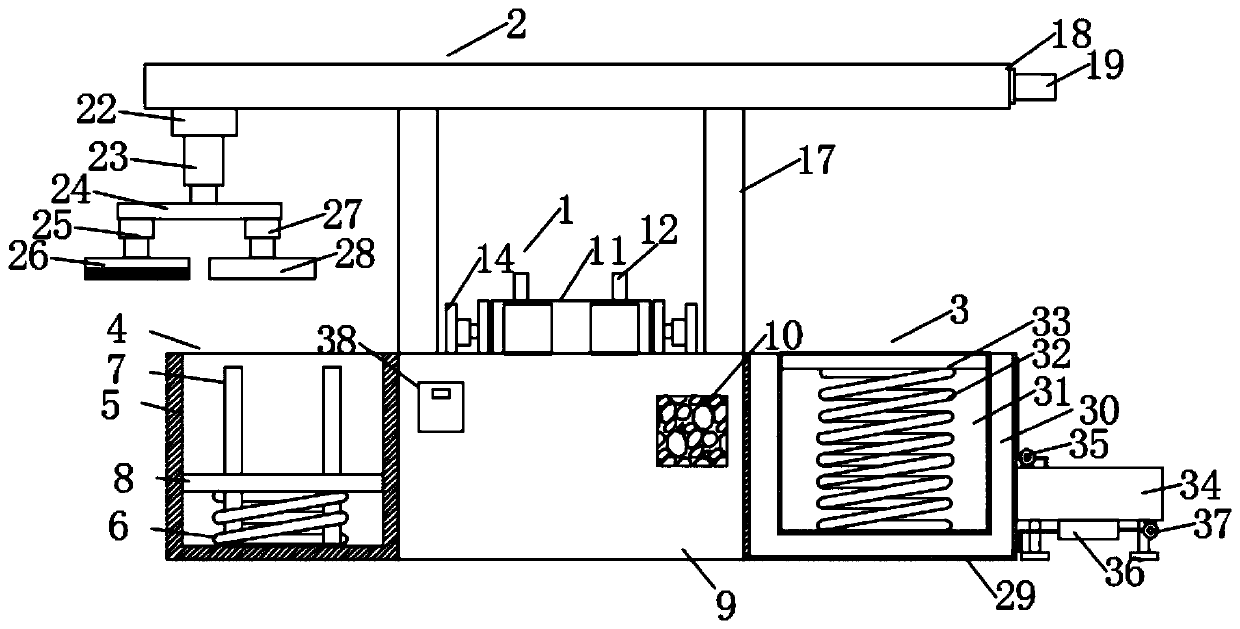

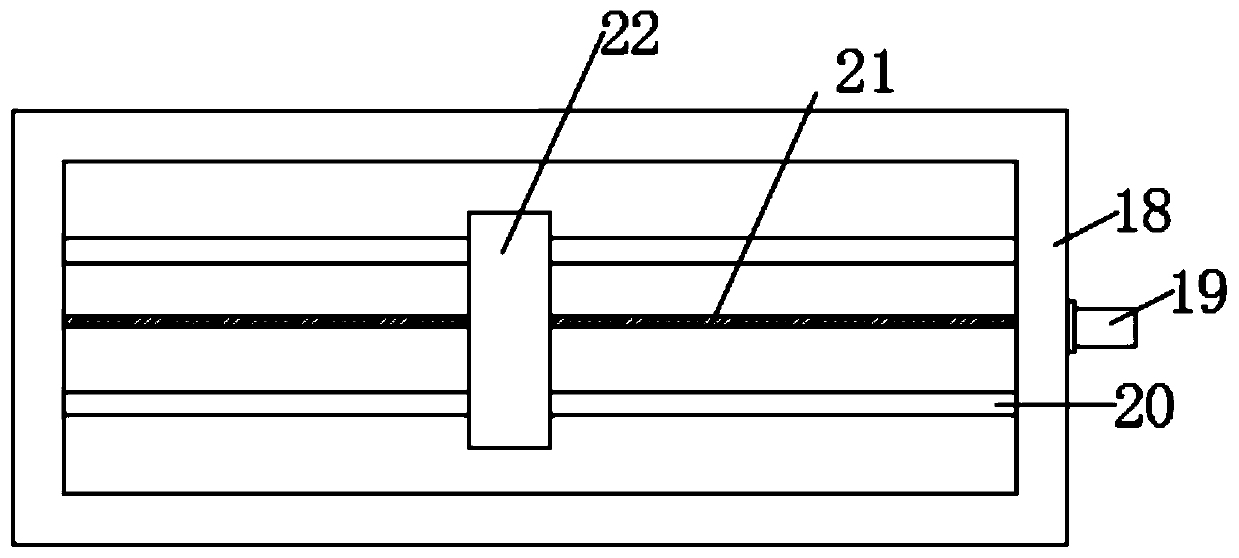

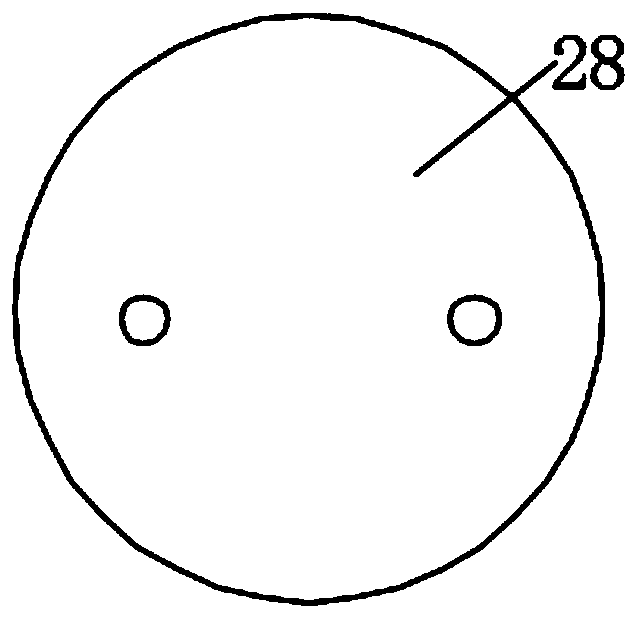

[0025] Such as Figure 1-4 As shown, the specific embodiment adopts the following technical scheme for a rounding device of a car wheel spoke, including a rounding mechanism 1, a feeding mechanism 2, a cooling mechanism 3 and a stocking mechanism 4, and the top of the rounding mechanism 1 is provided with Feeding mechanism 2, one end of described full-circle mechanism 1 is provided with cooling mechanism 3, and described full-circle mechanism 1 is provided with storage mechanism 4 at an end away from cooling mechanism 3, and described storage mechanism 4 is reset by storage box 5, The spring 6 is composed of a positioning rod 7 and a reset top plate 8. The bottom of the inner wall of the storage box 5 is fixedly connected with two positioning rods 7, and the bottom of the inner wall of the storage box 5 is fixedly connected with the reset spring 6. The top of the reset spring 6 Fixedly connected with a reset top plate 8, the outside of the reset top plate 8 is slidably connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com