Visual feeding manipulator

A robotic arm and vision technology, applied in the field of automated production, can solve the problems of inconvenient management of trays, large labor costs, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

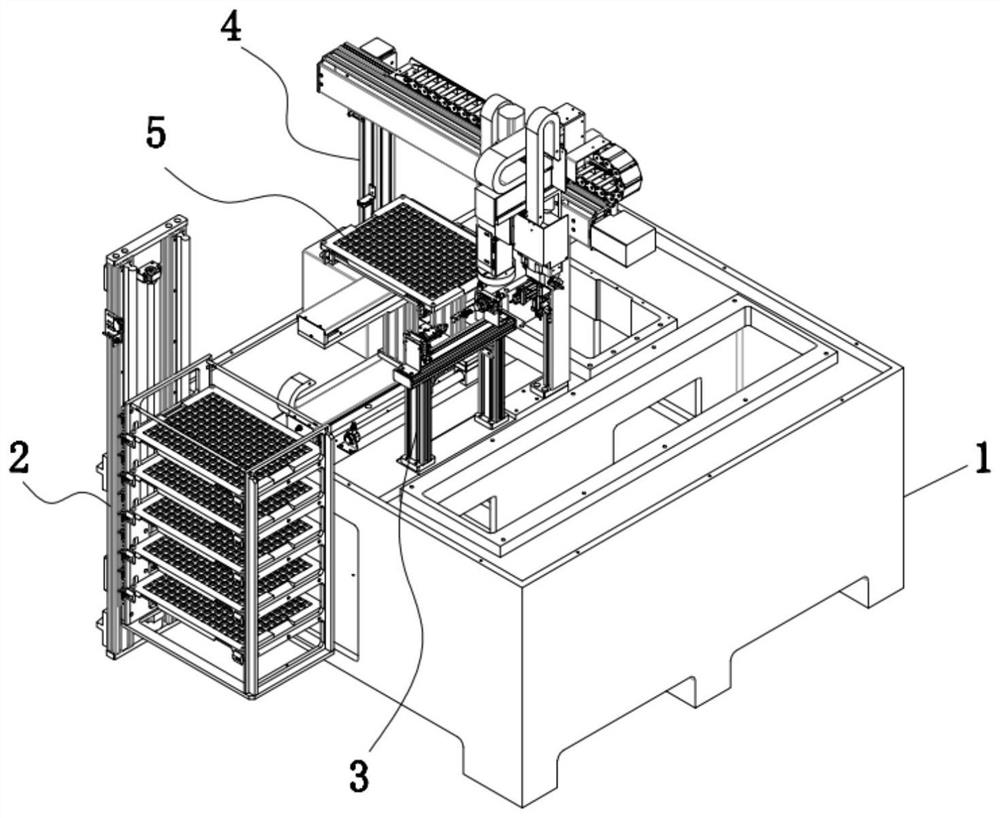

[0059] Please refer to Figure 1-Figure 20 , with vision feeding robotic arm including:

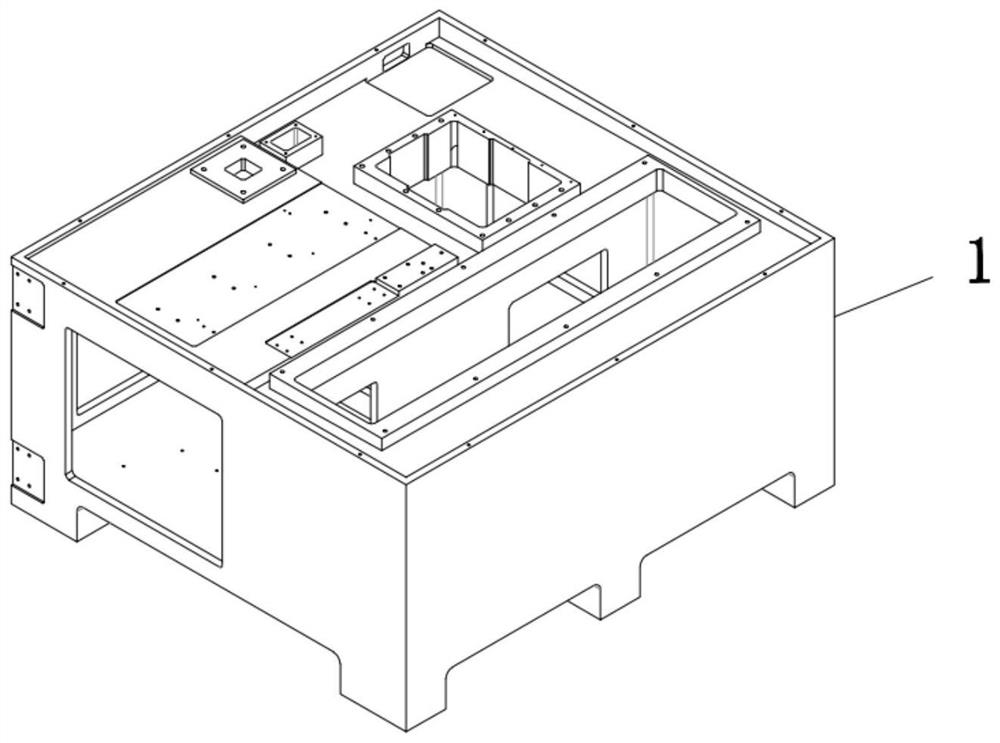

[0060] Installing the base 1, the installing base 1 is used to install each functional part, and is used to fix and connect each functional block;

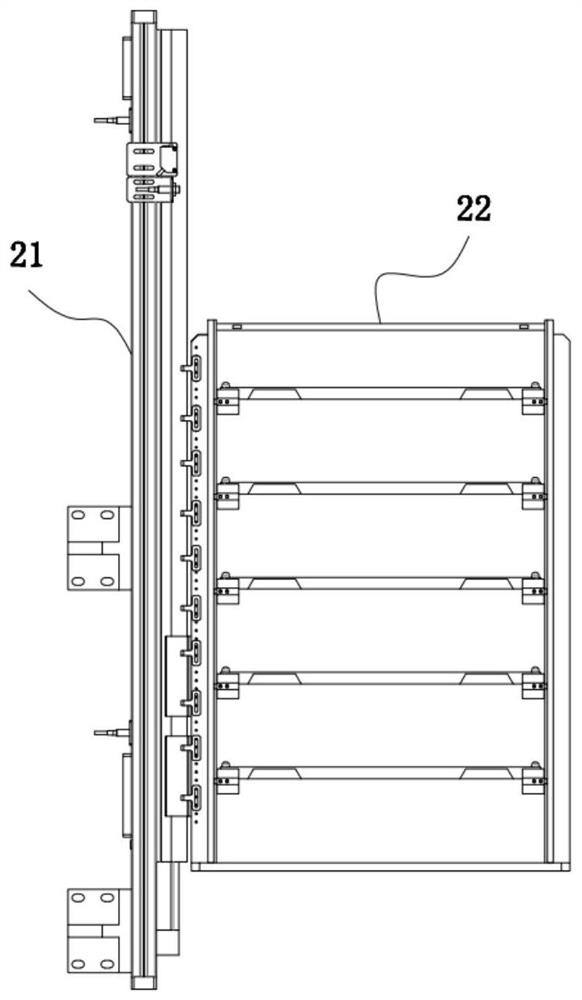

[0061] The feeding table part 2, the feeding table part 2 is installed on one side of the installation base 1, the feeding table part 2 includes a tray moving shaft 21 and a tray supply box 22, and the tray supply box 22 is slidably installed on the moving shaft 21 of the tray;

[0062] Blade turning part 3, described blade turning part 3 is installed on the top side of described installation base 1, and described blade turning part 3 comprises bracket base plate 33, blade turning part 31 and blade corner part 32, and described blade turning part The part 31 and the blade corner part 32 are all installed on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com