Automatic manufacturing all-in-one machine of paster for mobile terminal decoration and control method of all-in-one machine

A mobile terminal and control method technology, applied in typewriters, printing devices, printing, etc., can solve the problems of low production efficiency of mobile phone decoration stickers, time-consuming calibration of printing and cutting origins, and unguaranteed product quality. The effect of manual workload, reduction of manual participation, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

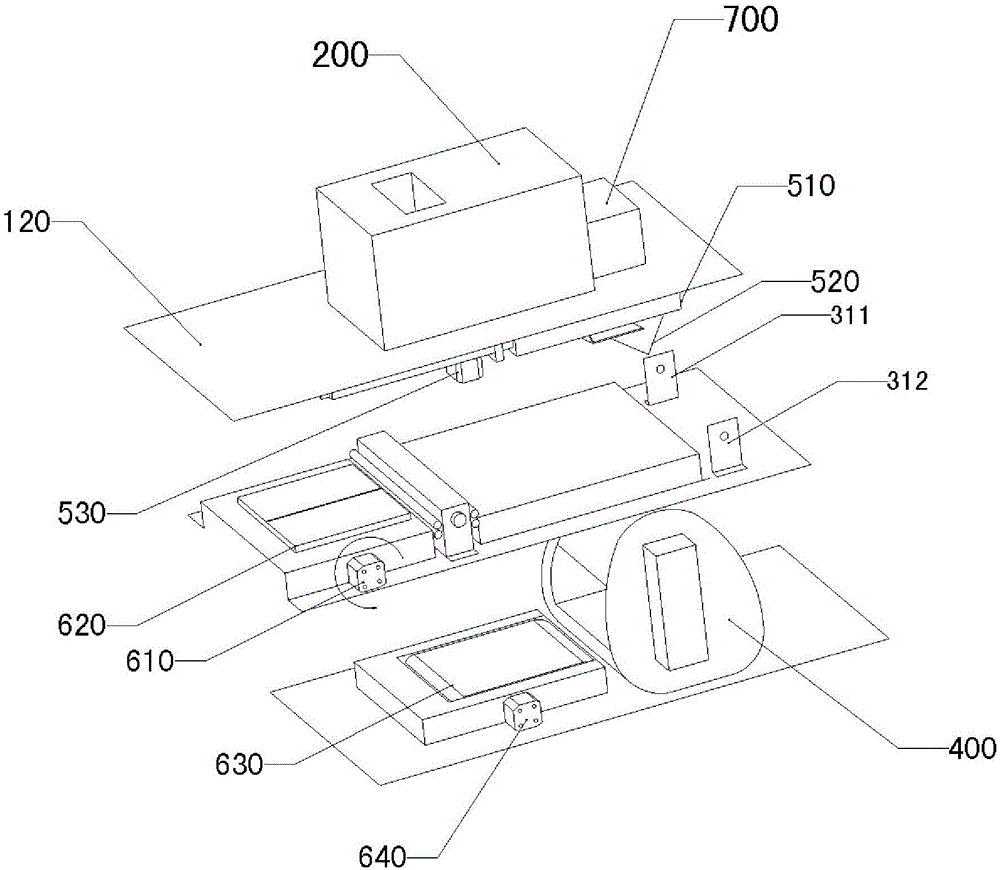

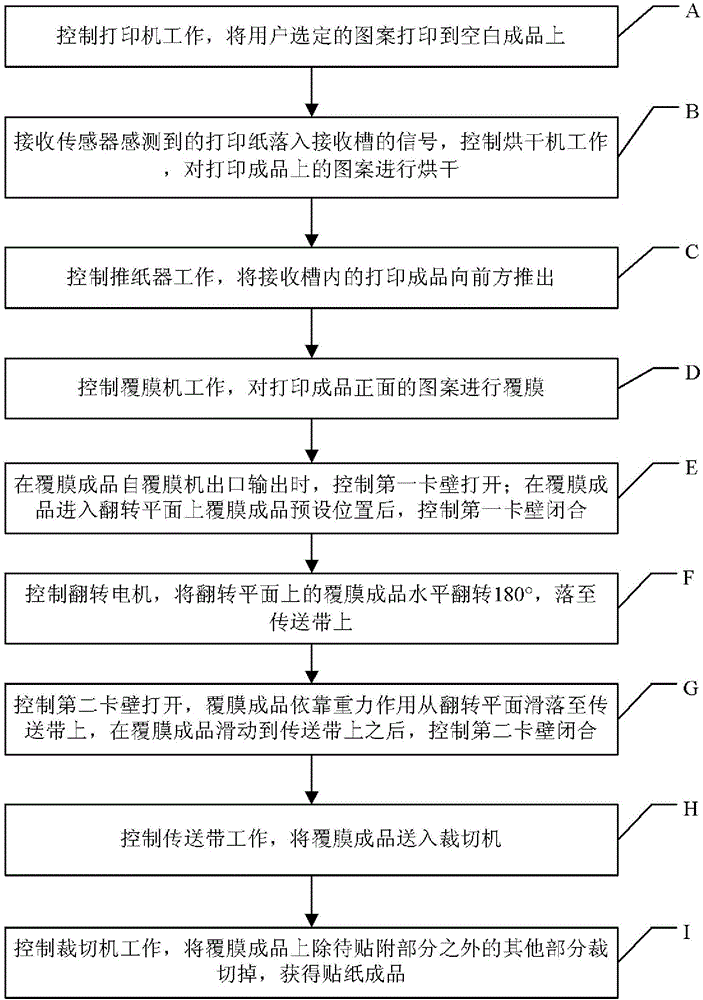

[0051] Through the organic organization of each machine, the present invention realizes the assembly line completion of printing, heating, film covering and cutting of stickers for mobile terminal decoration, improves efficiency and improves product quality.

[0052] Hereinafter, for the convenience of description, the film with no pattern printed is called blank printed film, the film with pattern printed is called printed product, and the semi-finished product after film coating is called film-coated finished product. Among them, printed finished products and laminated finished products are collectively referred to as semi-finished stickers.

[0053] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

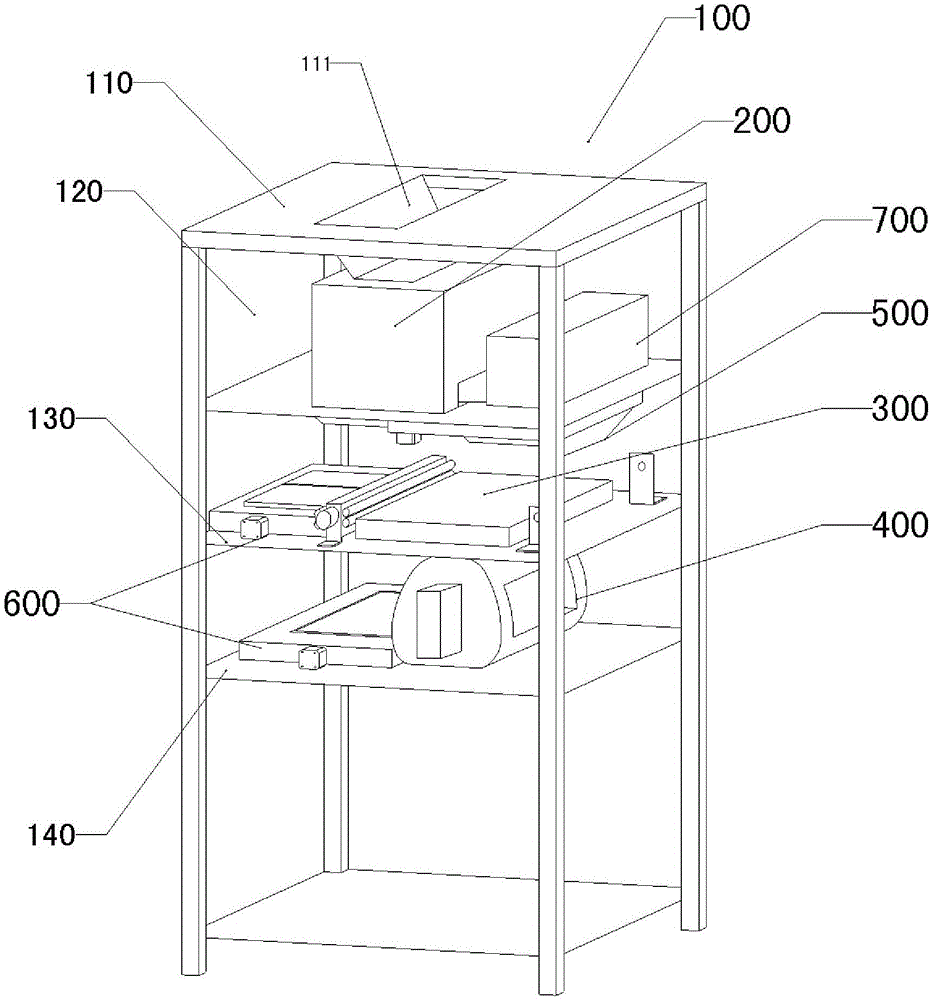

[0054] In an exemplary embodiment of the present invention, an automatic prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com