Patents

Literature

108results about How to "Improve drilling ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

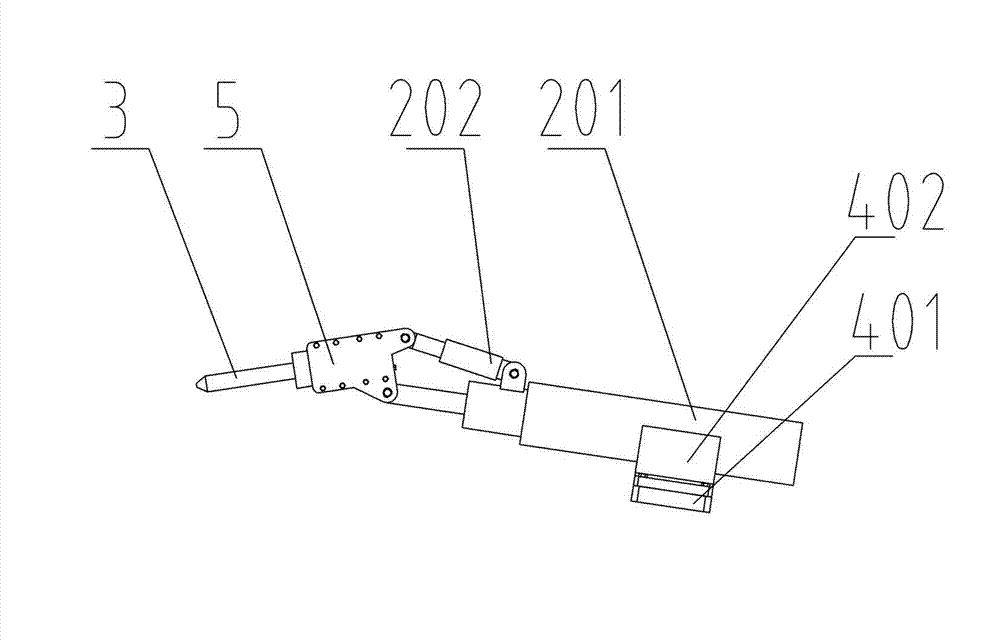

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

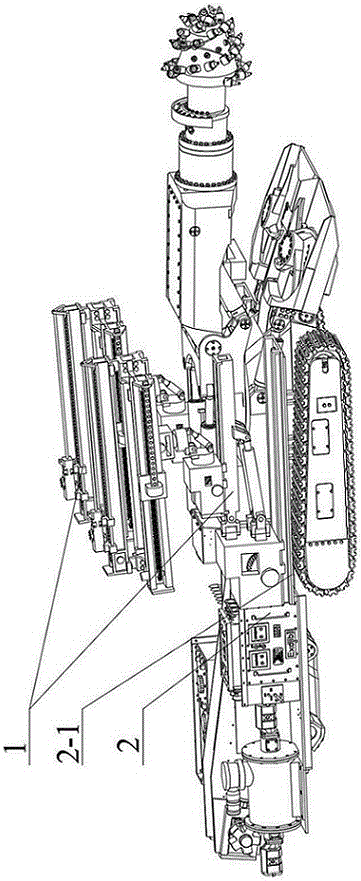

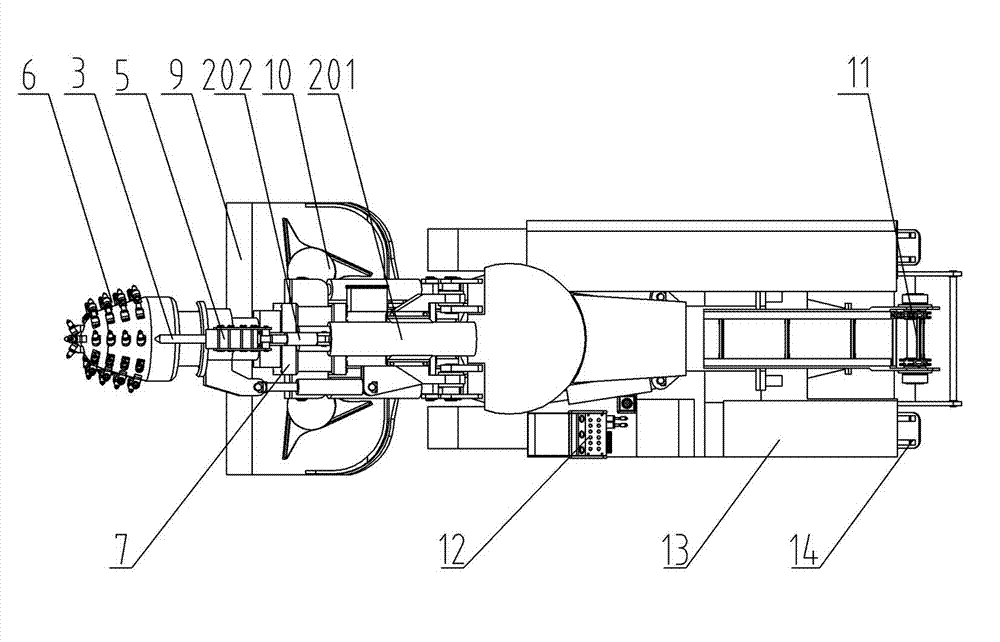

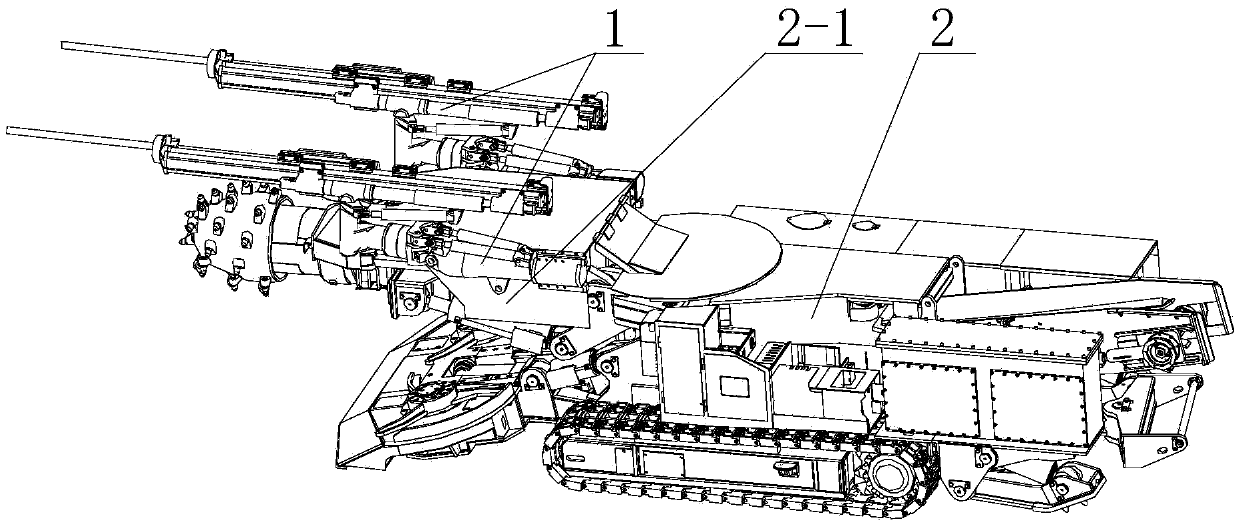

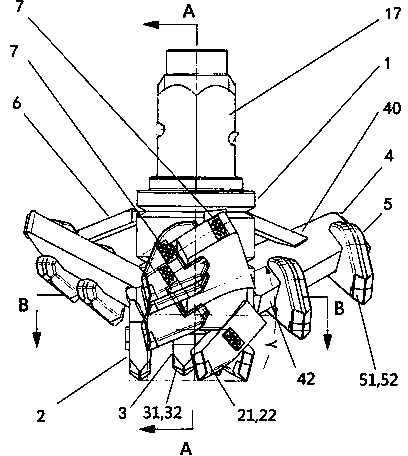

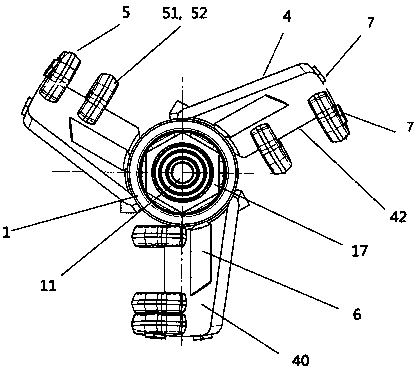

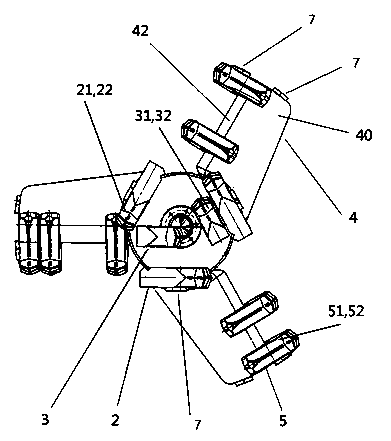

Compound cantilever excavator

InactiveCN102733803AImprove drilling abilityImprove work efficiencySlitting machinesCutting machinesHydraulic cylinderClassical mechanics

The invention relates to an excavating machine, and especially relates to a compound cantilever excavator. The excavator comprises an excavator body, an excavating mechanism, a travelling mechanism, a hydraulic system, an electrical system, a conveying mechanism and a dedusting system, wherein the excavating mechanism comprises cutting heads and a cutting arm, the cutting heads are positioned on the top of the cutting arm, and the lower part of the cutting arm is movably fixed on the body of the excavator; the travelling mechanism comprises a power machine and a crawler belt positioned under two sides the body of the excavator; and the upper part of the excavating mechanism is provided with an impact fragmenting mechanism, and the impact fragmenting mechanism comprises a hydraulic cylinder and a fragmenting hammer positioned on the top of the hydraulic cylinder. According to the compound cantilever excavator of the invention, service lives of cutting teeth can be prolonged, so the cost of the whole excavator is reduced; the working environment of workers is improved, so the body health of the workers is protected; and the application range of the cantilever excavator is substantially widened, so the cantilever excavator has a wide market prospect.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Drilling device applied to graphite mold production

InactiveCN105414599ASolving Drilling ProblemsStrong targetingWorkpiecesTurning toolsElectric machineryReducer

The invention discloses a drilling device applied to graphite mold production. The drilling device comprises a frame and a drilling table; drilling longitudinal frames and a drilling transverse frame are arranged on the frame; the drilling longitudinal frames are positioned at the two sides of the frame; the drilling transverse frame is positioned between the drilling longitudinal frames, and is provided with a lifting driving mechanism and a lifting mechanism; the lifting mechanism includes lifting platforms and lifting lead screws; the lifting lead screws are mounted in the drilling longitudinal frames, and are connected with lifting lead screw connecting bases; the lifting lead screw connecting bases are connected with the lifting platforms; drilling mechanisms are arranged on the lifting platforms, and include drilling motors and drilling lead screws; the drilling motors are connected with drilling motor output shafts; the drilling motor output shafts are connected with drilling speed reducers; the drilling speed reducers are connected with the drilling lead screws; the drilling lead screws are connected with drilling bases; and the drilling bases are connected with drill rods. The machine is simple in structure, strong in pertinency, precise in positioning and excellent in drilling effect, and preferably solves the drilling problem in the graphite mold production.

Owner:SHENGZHOU SIGMA TECH

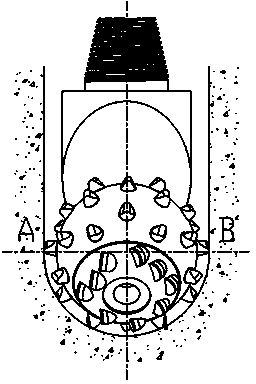

Roller type cutter rectangular pipe jacking machine

The invention relates to a roller type cutter rectangular pipe jacking machine, which comprises a cutter, a cutter driving system, a spiral mechanical unearthing system, a hydraulic propulsion system and a rectangular shell. The cutter adopts a composite formation roller type cutter, is sleeved on the cutter driving system and is driven by the cutter driving system to rotate, the composite formation roller type cutter comprises a plurality of ordinary tools, a swinging tool and an over-excavation tool, a cutter shell adopts a round tubular component, the inner wall of the cutter shell is provided with a separating wall vertical to the axial line of the cutter shell, the ordinary tools are uniformly and fixedly arranged on the outer wall of the cutter shell, the swinging tool is hinged on the inner side of the outer wall of the cutter shell through a pin shaft and can rotate around the pin shaft, and the over-excavation tool is fixedly arranged on the outer side of the outer wall of the cutter shell. The invention has the advantages of high adaptability to formations and high tunneling efficiency. Meanwhile, construction risks can be reduced greatly, construction safety can be ensured, and the machine can adapt to construction of slightly weathered rock formations, composite formations, backfilled formations, continuous walls through the ground, pile foundations and other complex formations and working conditions.

Owner:上海盾构设计试验研究中心有限公司 +1

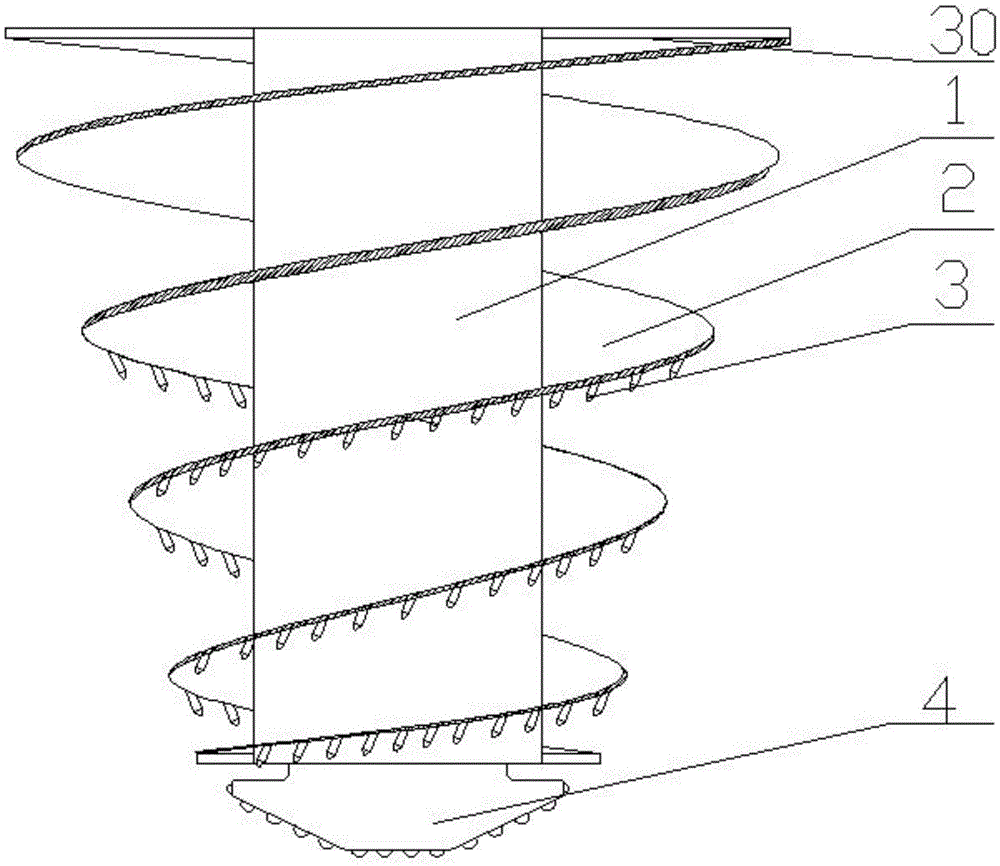

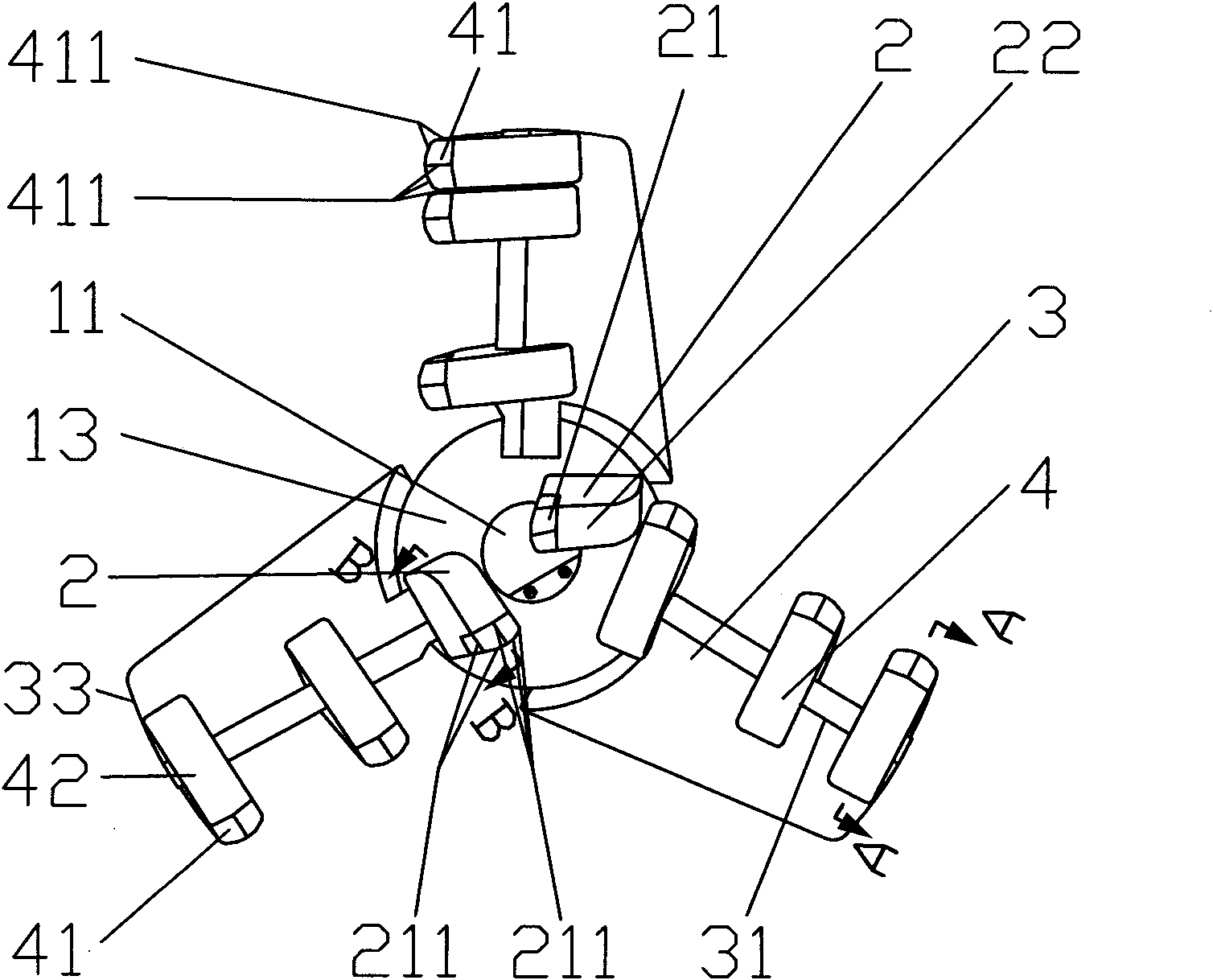

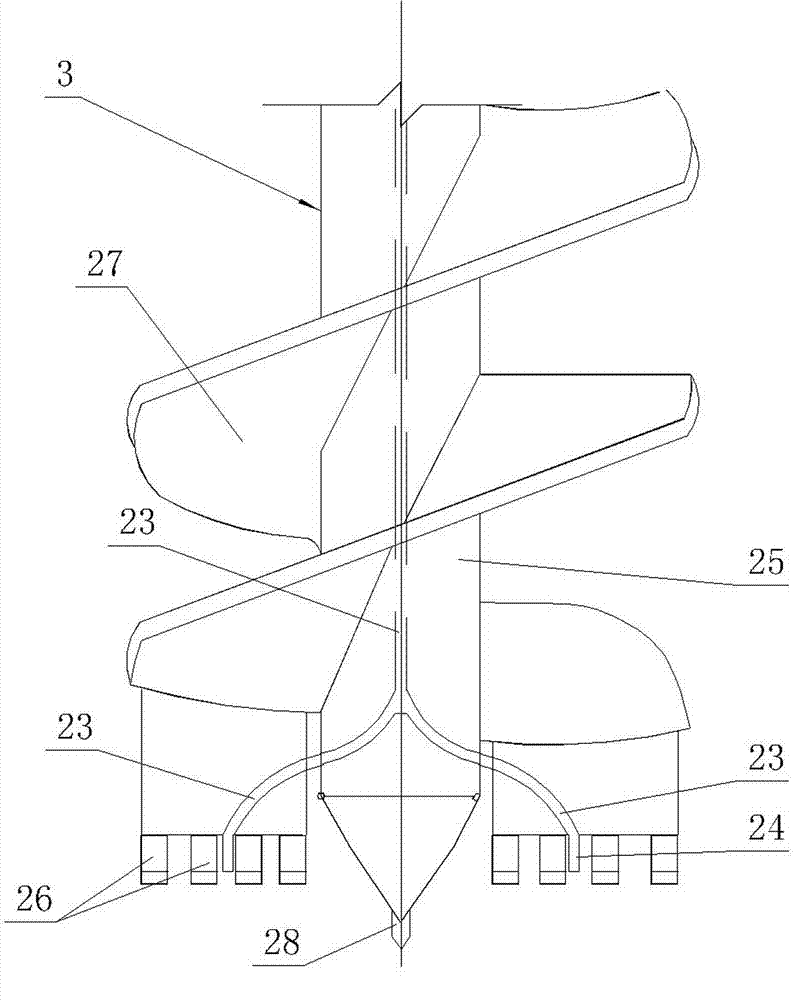

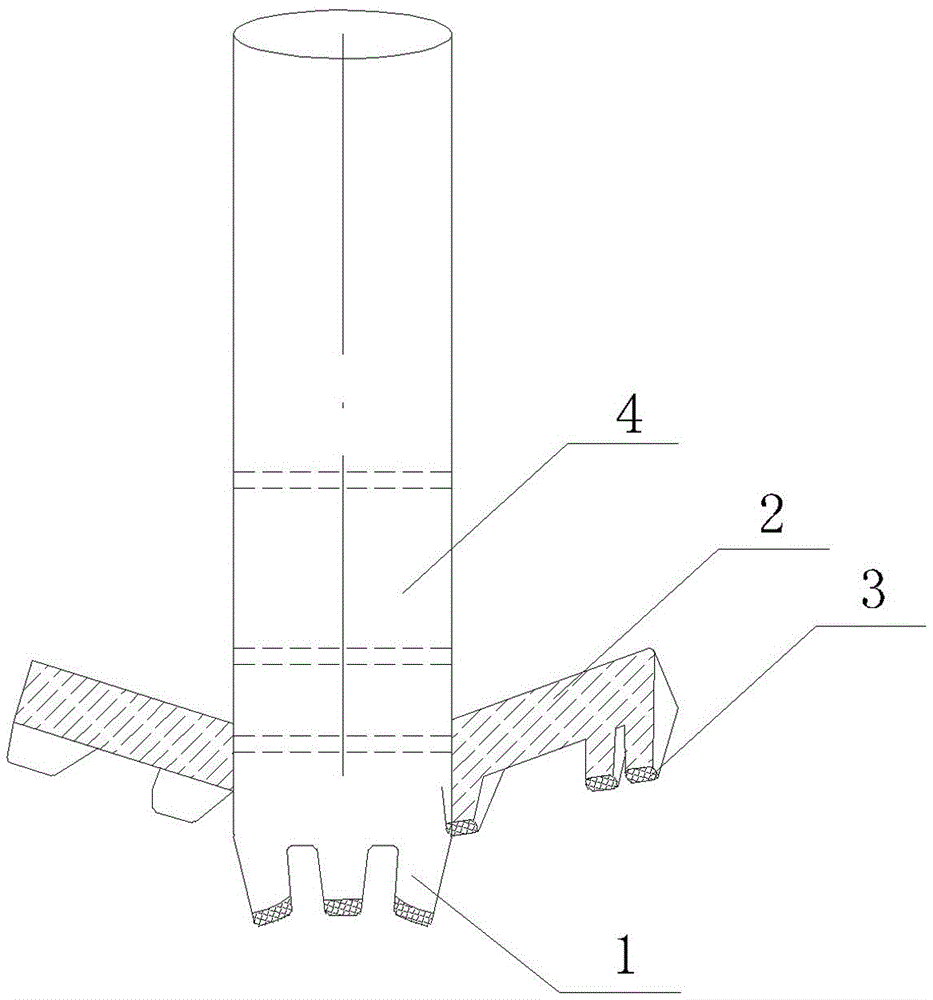

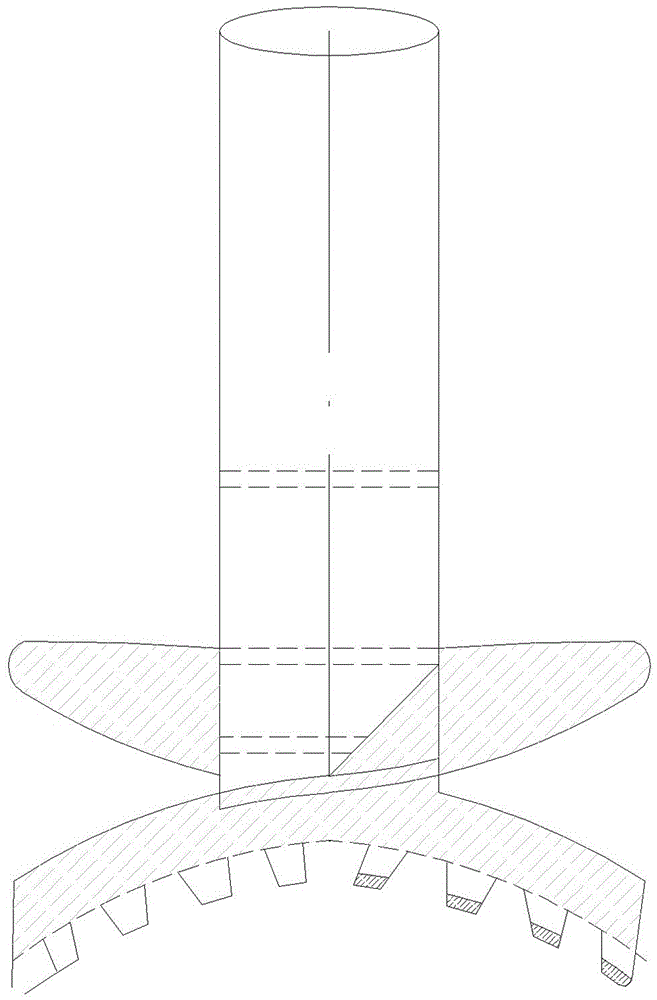

Rotary drilling rig bit capable of impact drilling

InactiveCN105569563AImprove applicabilityImprove work efficiencyDrill bitsDrilling rodsFlangeDrill bit

The invention provides a rotary drilling rig bit capable of impact drilling, which is reasonable in design, applicable to different strata and capable of improving working performance. The rotary drilling rig bit comprises a flange for connecting the machine body, a drill rod arranged on the flange, a double-screw blade arranged on the outer side of the drill rod, and a down-the-hole hammer which extends from the drill rod housing head of the drill rod and is in sliding arrangement, wherein a plurality of bullet-like cutting picks arranged on the edge of the double-screw blade; a propulsion mechanism connected with the down-the-hole hammer is arranged inside the drill rod housing. According to the invention, the advantages of the spiral drill rod and the down-the-hole hammer are combined to play, then the drill rod can perform impact grinding and further bring debris and soil out of the hole through rotation, the working efficiency is greatly improved, and the drill bit is good in applicability for the complicated stratum. The structure that the down-the-hole hammer is combined with the double-screw blade can perform impacting while drilling, so that the efficiency is greatly improved; the double-screw blade can bring the debris or soil out of the hole, so that the drill bit is not required to be changed frequently.

Owner:CHANGAN UNIV

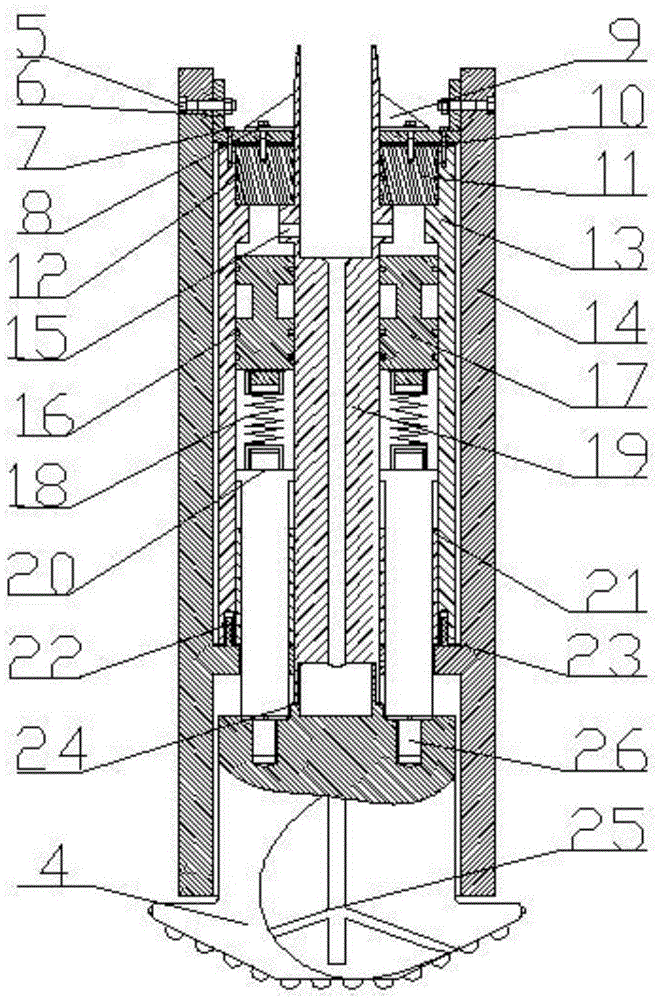

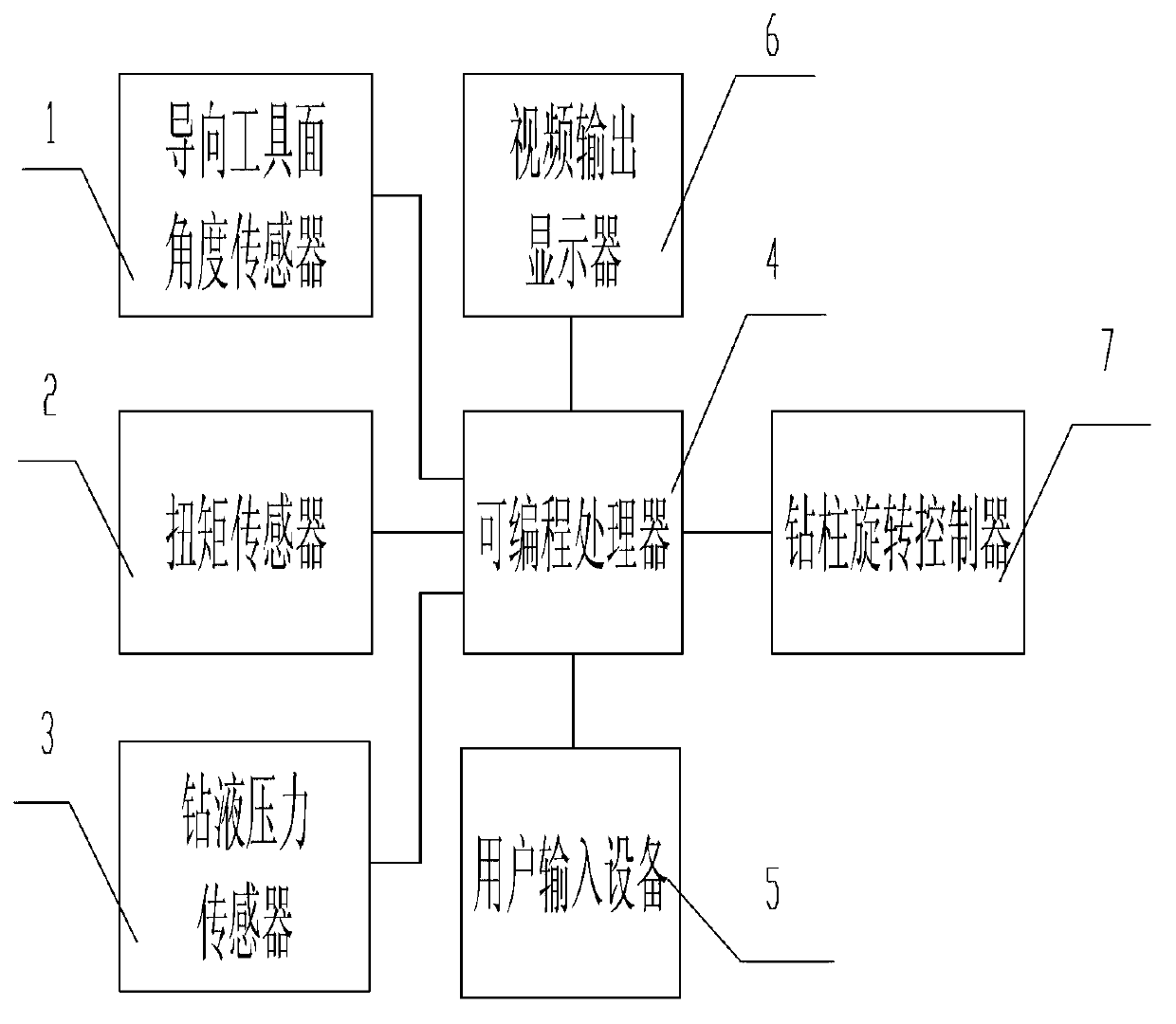

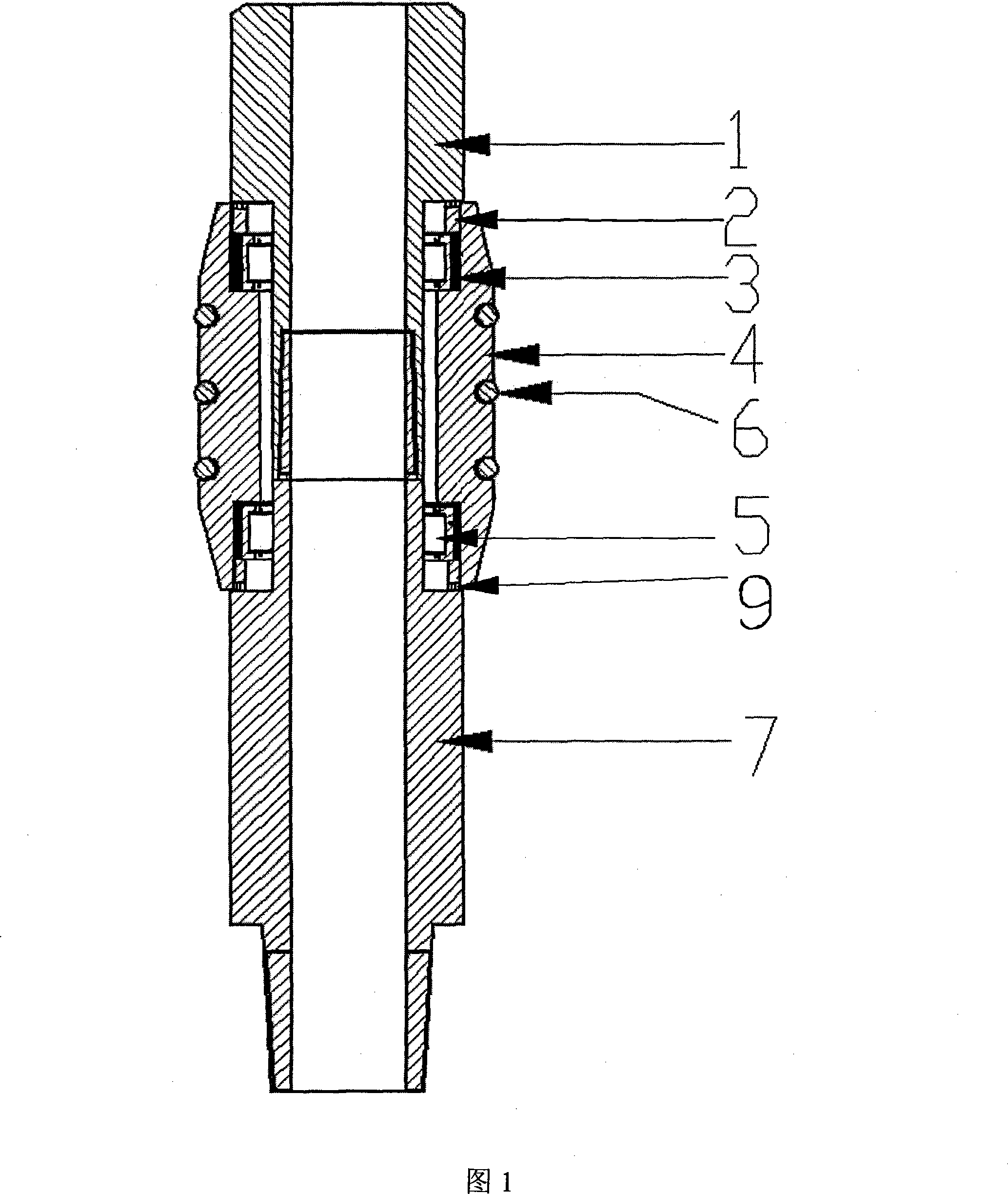

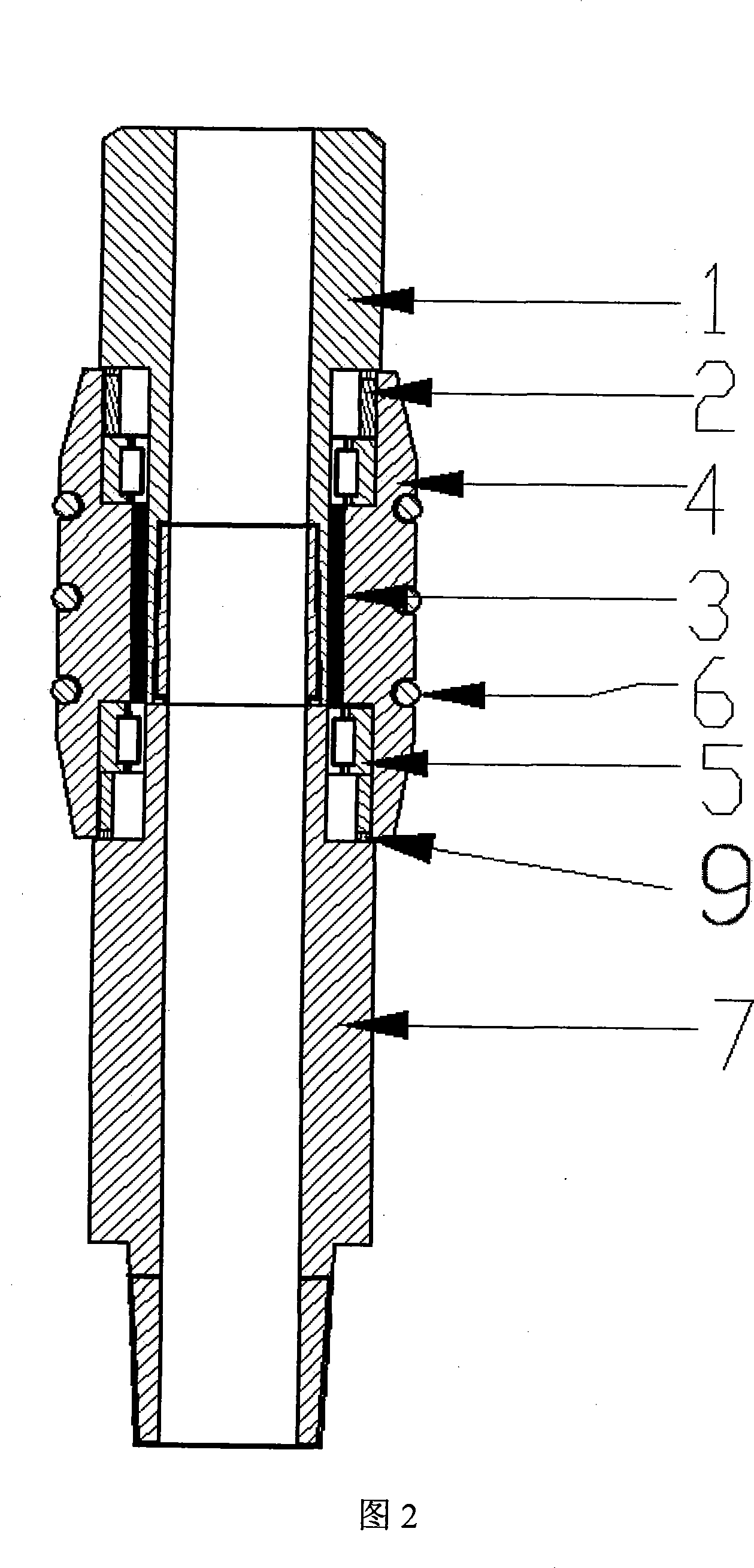

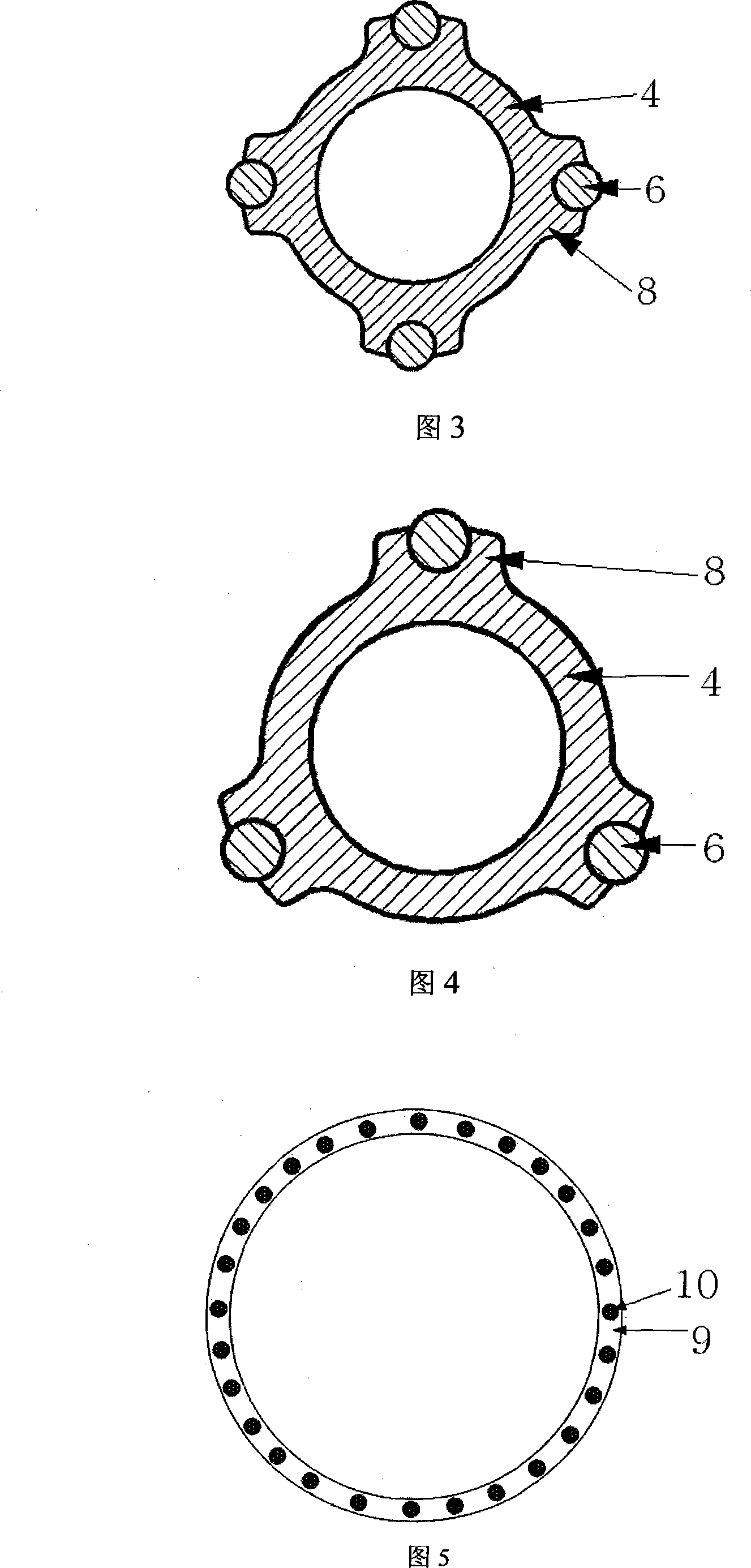

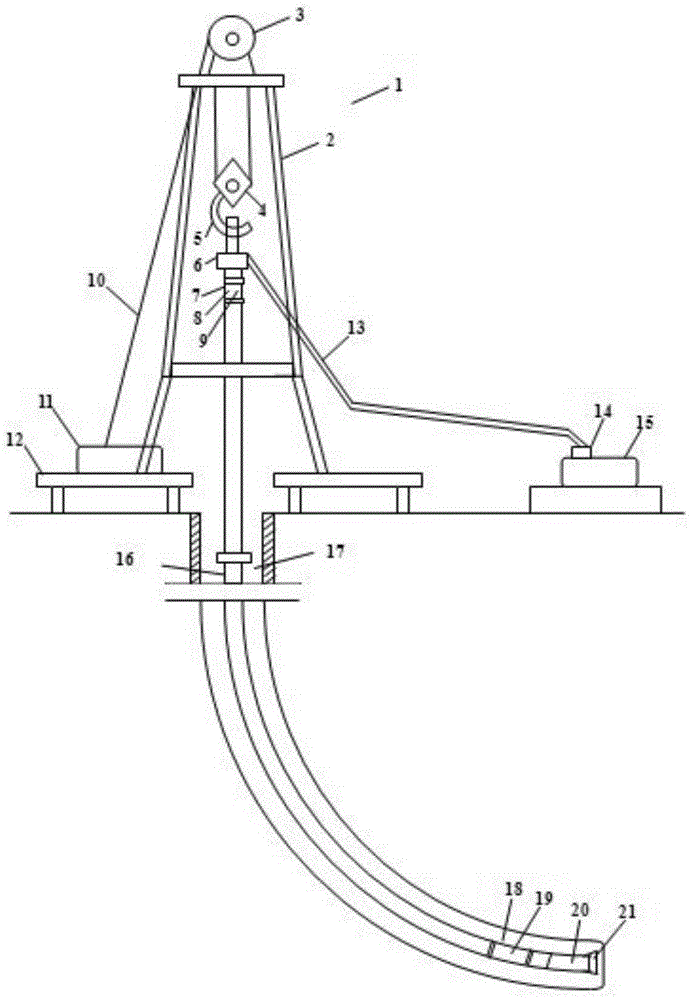

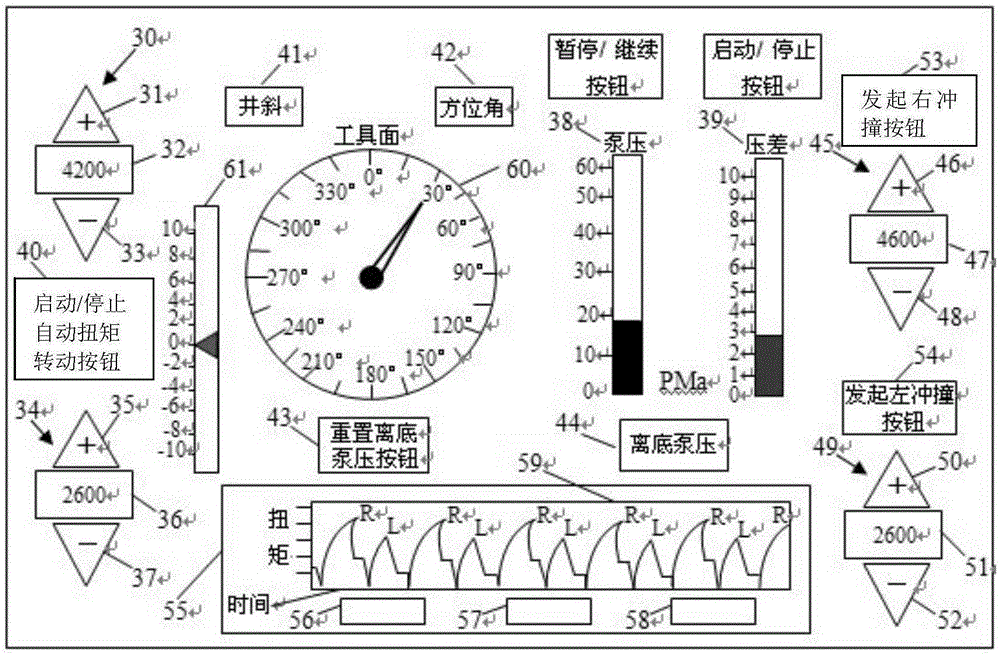

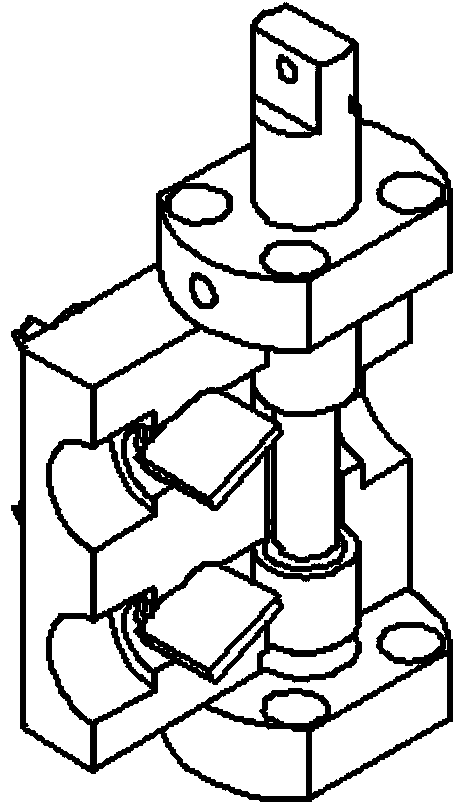

Automatic sliding well drilling control device

InactiveCN103277048AReduce work pressureImprove track qualityDirectional drillingAutomatic control for drillingWell drillingUser input

The invention relates to an automatic sliding well drilling control device, and belongs to the technical field of oil drilling tool design. The automatic sliding well drilling control device is characterized by being composed of a guiding tool face angle sensor (1), a toque sensor (2), a drilling fluid pressure sensor (3), a programmable processor (4), a user input device (5), a video output displayer (6) and a drill column rotating controller (7). The programmable processor (4) is used for receiving output signals form the guiding tool face angle sensor (1), the toque sensor (2) and the drilling fluid pressure sensor (3), the output signals is processed by the programmable processor (4) and the received information and a processing result are displayed on the video output displayer (6). After the programmable processor (4) processes the received information, the programmable processor (4) outputs a control instruction to the drill column rotating controller (7) and controls the drill column rotating controller (7). According to the automatic sliding well drilling control device, a tool face can be modified and oriented fast and accurately, the conversion between the sliding and the rotating drilling is fast, the drilling ability in a horizontal section is enhanced, and the automatic sliding well drilling control device has the advantages that mechanical drilling speed is increased, well track quality is improved, and the service life of a motor under a well is prolonged.

Owner:YANGTZE UNIVERSITY

Reduction-resistant vibration-damping break-proof righting coupling for gas drilling

InactiveCN101220732AReduce wearReduced torque transfer lossesDrilling rodsDrilling casingsCasing wearRolling-element bearing

The invention provides an antidrag, vibration-damping, break-proof and strengthening coupling which is utilized in the oil-gas field which has a gas drilling which has strong vibration, high frictional resistance, erosion and is easy to be inoperative. The technical proposal is that: the upper and lower joints are coupled by threads and is positioned by a shaft shoulder; a radial rolling bearing is consist of an upper set and a lower set of cylindrical roller bearings without inner ring, wherein one set is arranged between the shell and the upper adapter, and the other set is arranged between the shell and the lower adapter and positioned by a sleeve; three posing belts are symmetrically distributed on the outer surface of the shell, and the two ends of the posing belt is plagiohedral and the posing belt is provided with a groove; an axial rolling bearing consists of three sets of drum-shaped rollers which are respectively arranged in the grooves of the posing belts on the outer surface of the shell and touch against the borehole wall or the sleeve; a shock-absorbing rubber sleeve is arranged between the upper and lower radial rolling bearings without inner ring and the shell and is positioned by a sleeve. This invention has good shock-absorbing performance, strong vibration-absorbing capacity and can relieve the abrasion of the drill stem / sleeve, reduce torque and increase drilling capacity; furthermore, the structure is simple and the cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

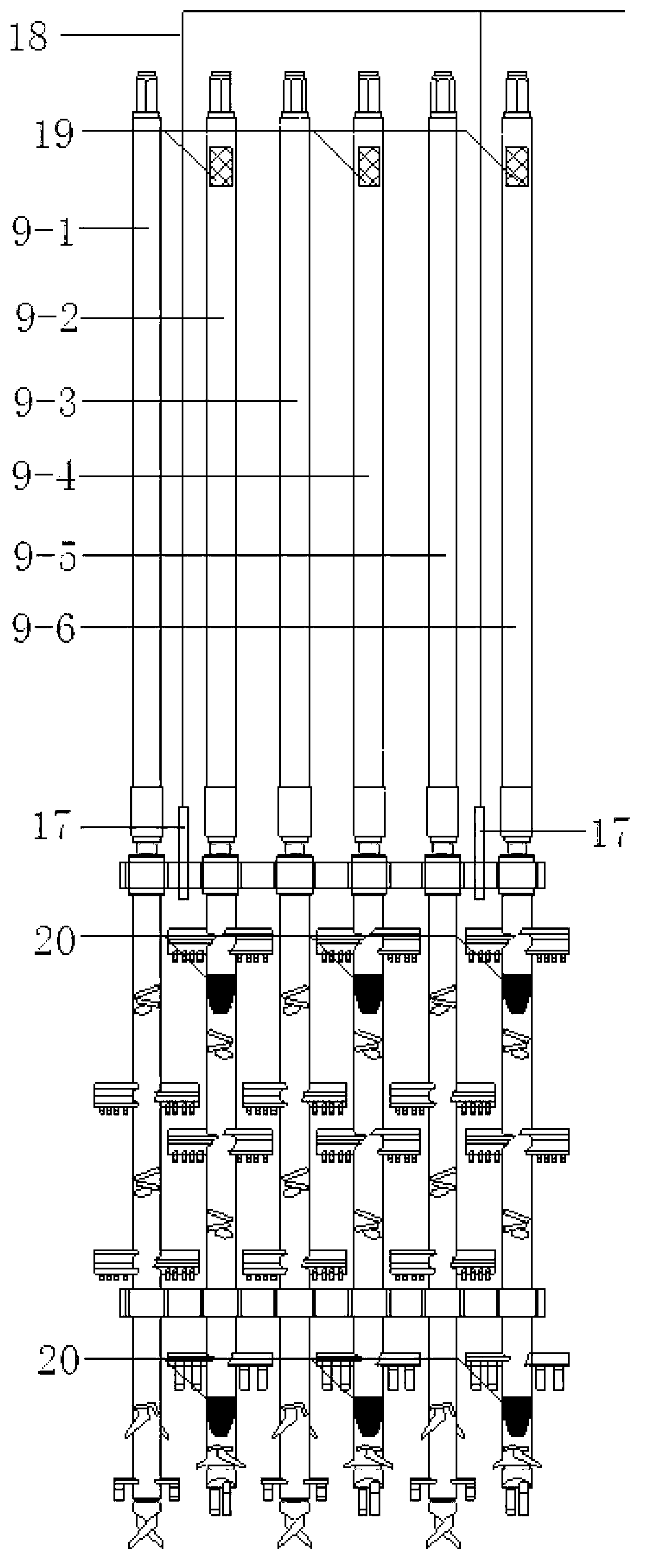

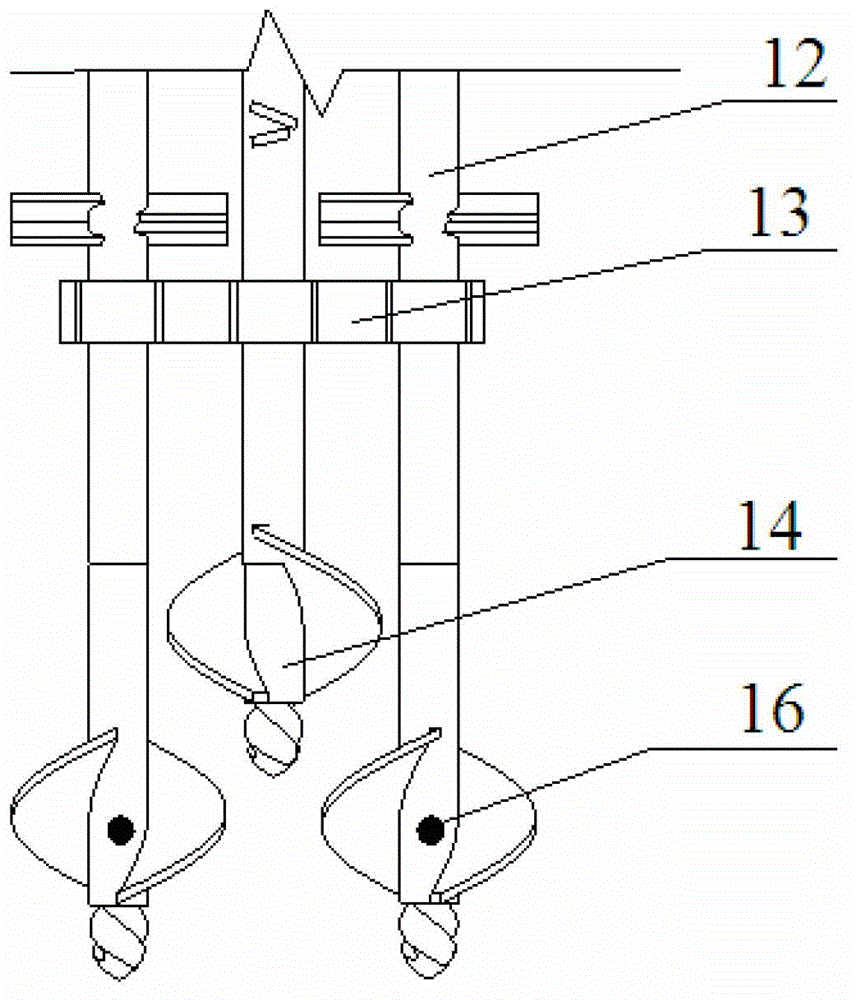

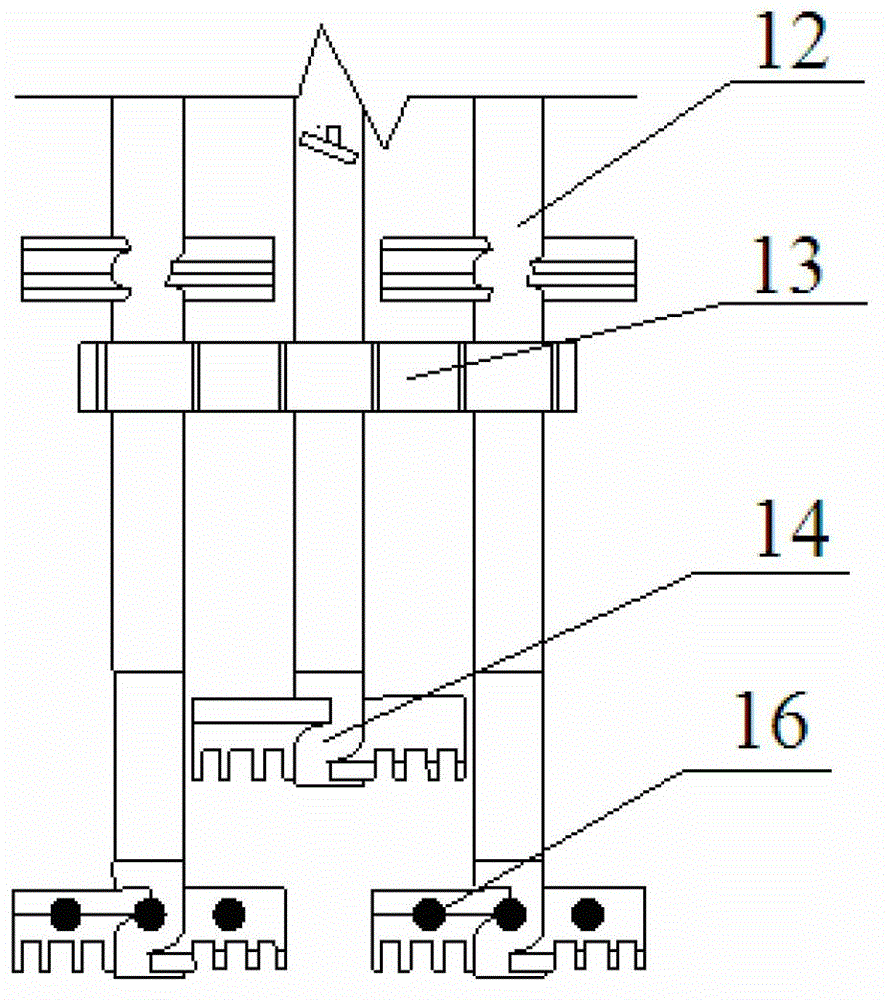

Two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and construction method thereof

ActiveCN103074892AReduce the number of lapsImprove the water-stop effectSurveyDirectional drillingCement slurrySoil cement

The invention relates to a two-shaft, four-shaft and six-shaft interchanging type cement and soil stirring pile device and a construction method thereof. The device comprises a host, a guide rod, a power assembly, a plurality of drill pipes, drill pipes with wings, multifunction drill bits, a background cement slurry stirring system, flow meters, a soil penetrating depth sensor and verticality real-time monitors, wherein the power assembly is connected with the drill pipes, the lower end of each drill pipe with the wing is connected with each multifunction drill bit, the top part of each drill pipe is provided with a slurry inlet, the middle part of each drill pipe is provided with a middle bearing bracket, each flow meter is arranged on a slurry spraying port, the penetrating depth sensor is arranged on a slide rail of the guide rod, each verticality real-time monitor is arranged on each middle bearing bracket, the flow meters, the soil penetrating depth sensor and the verticality real-time monitors are respectively connected with the host, and detachable drill pipes are adopted as the drill pipes. Compared with the prior art, the device has the advantages that the pile forming function is versatile, the cost is saved, the verticality is controllable, the pile forming effect is good, and the like.

Owner:SHANGHAI CHENGDI CONSTR

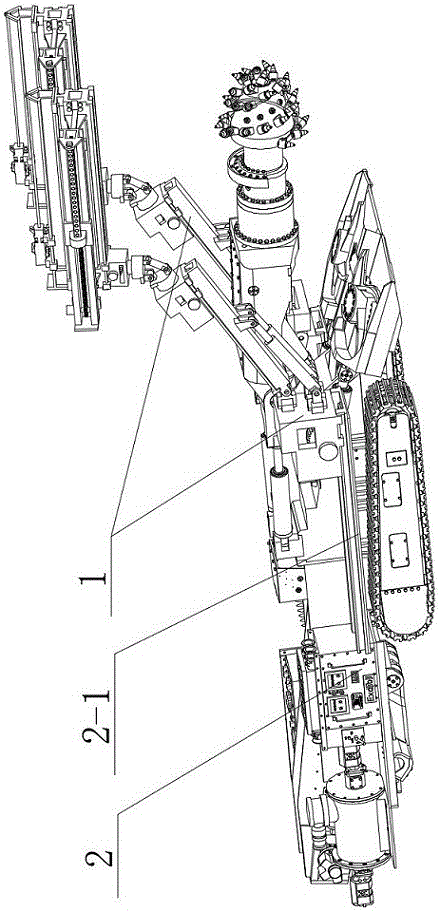

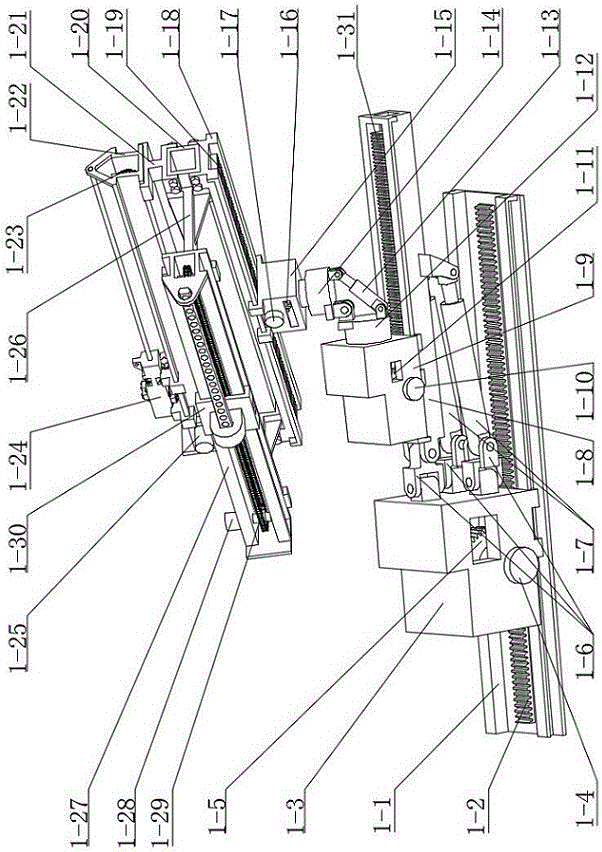

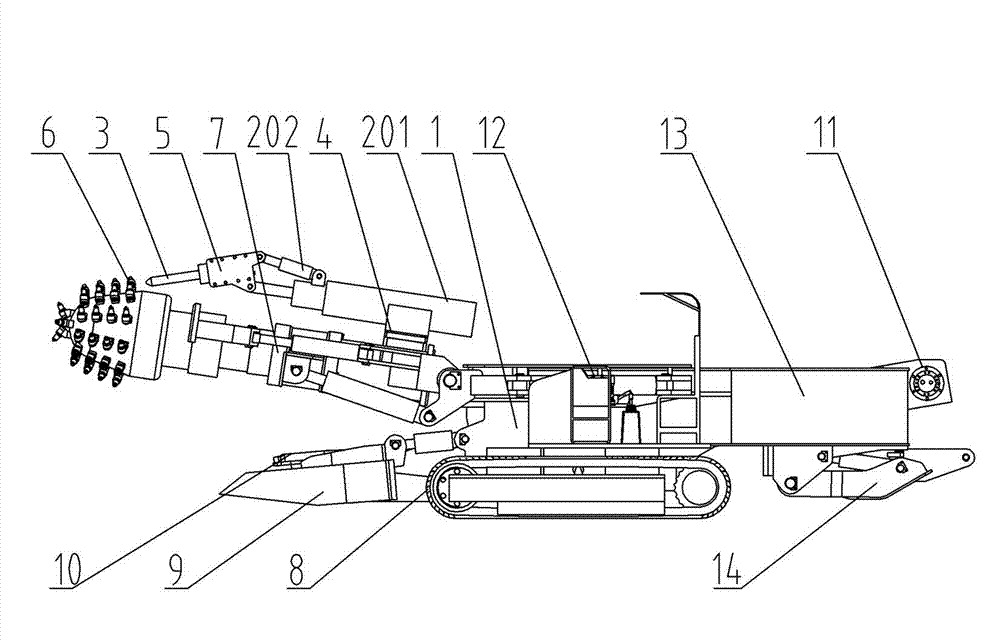

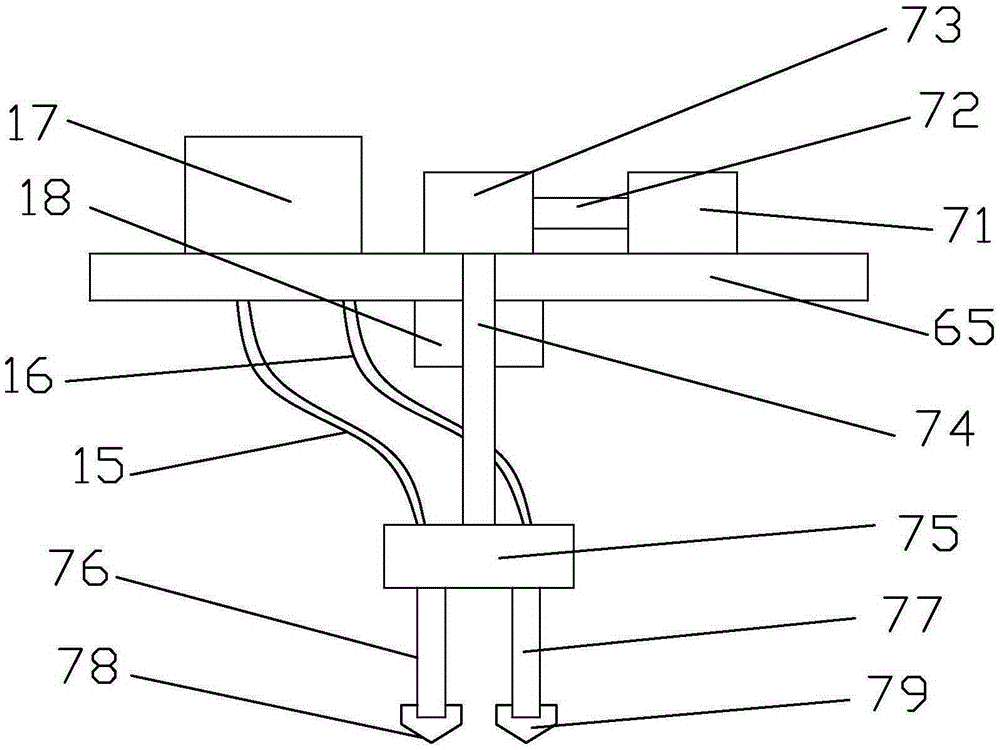

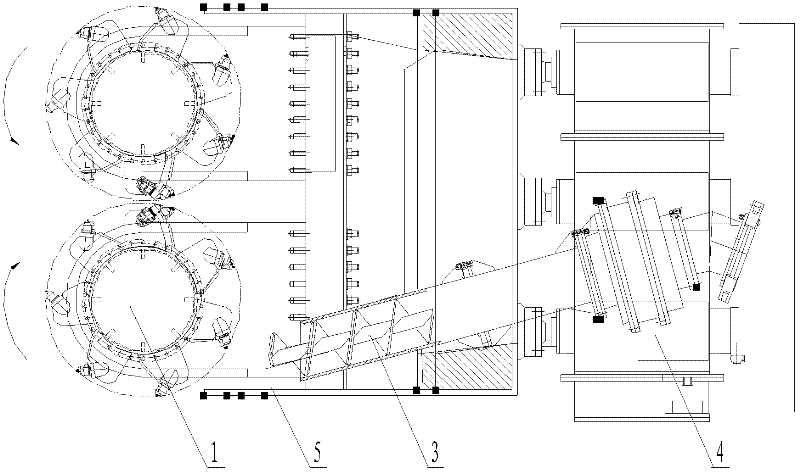

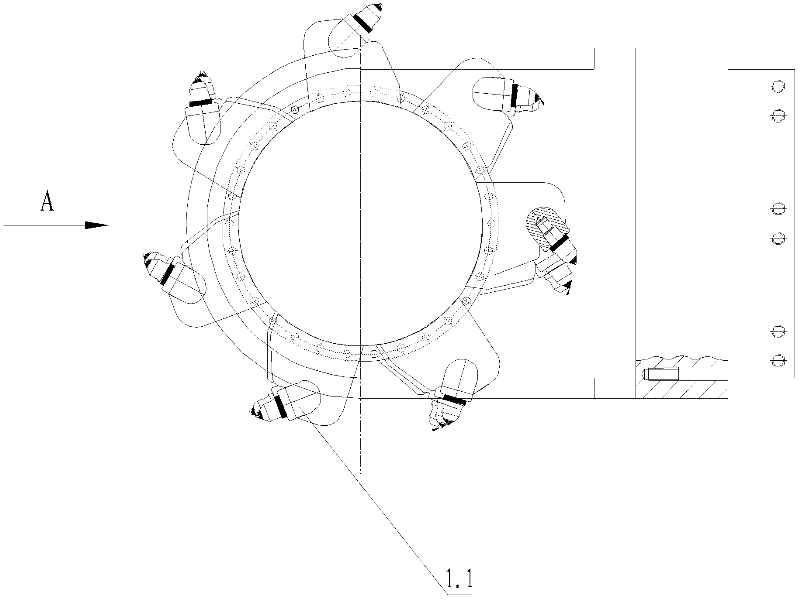

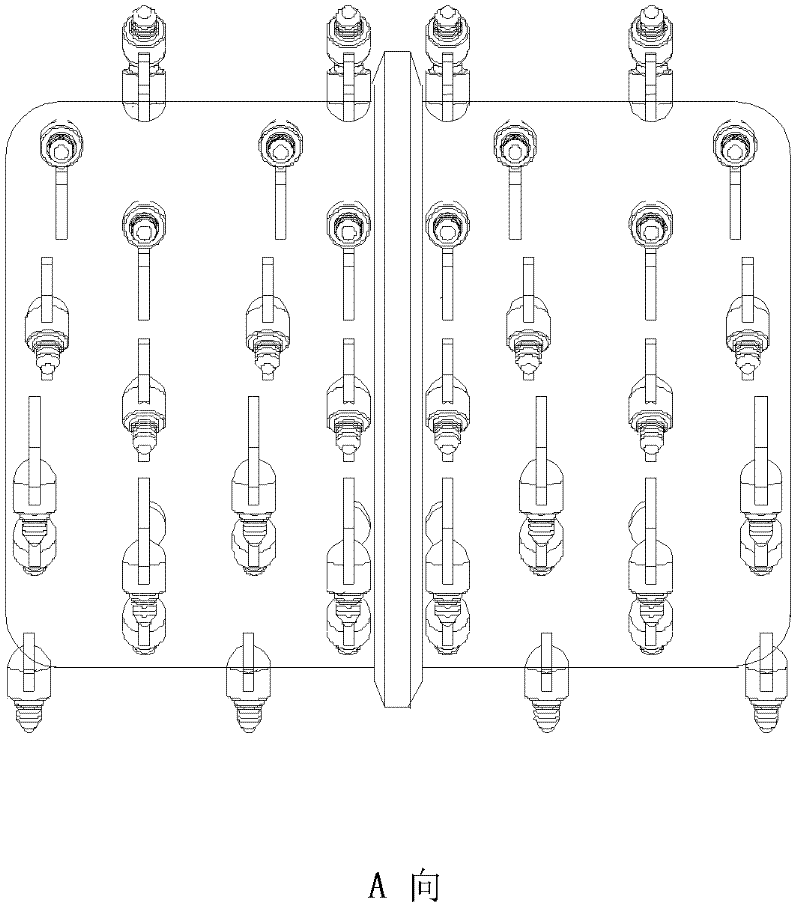

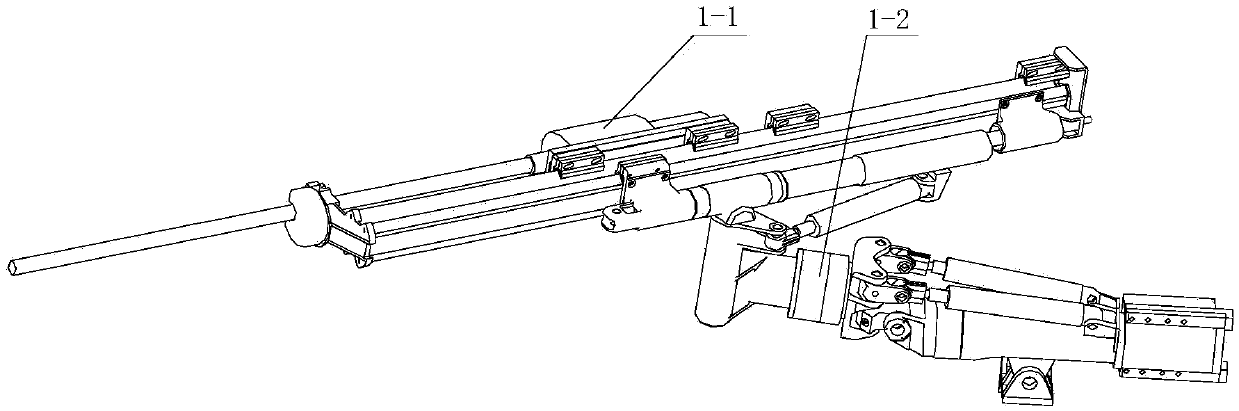

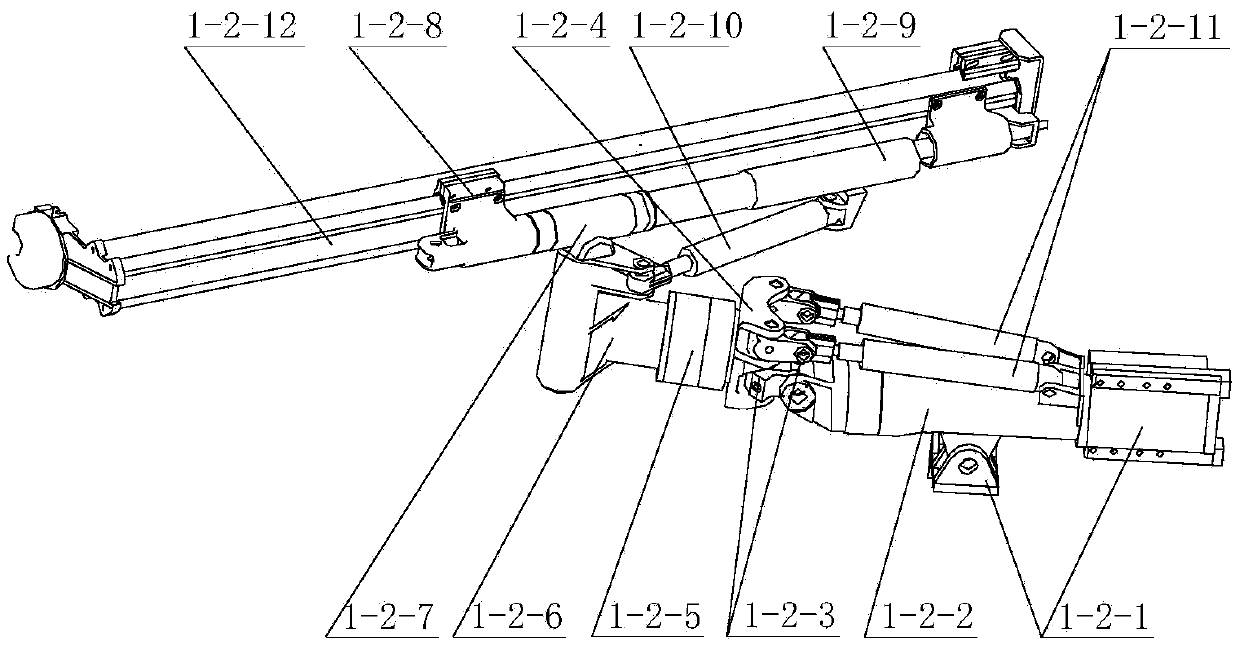

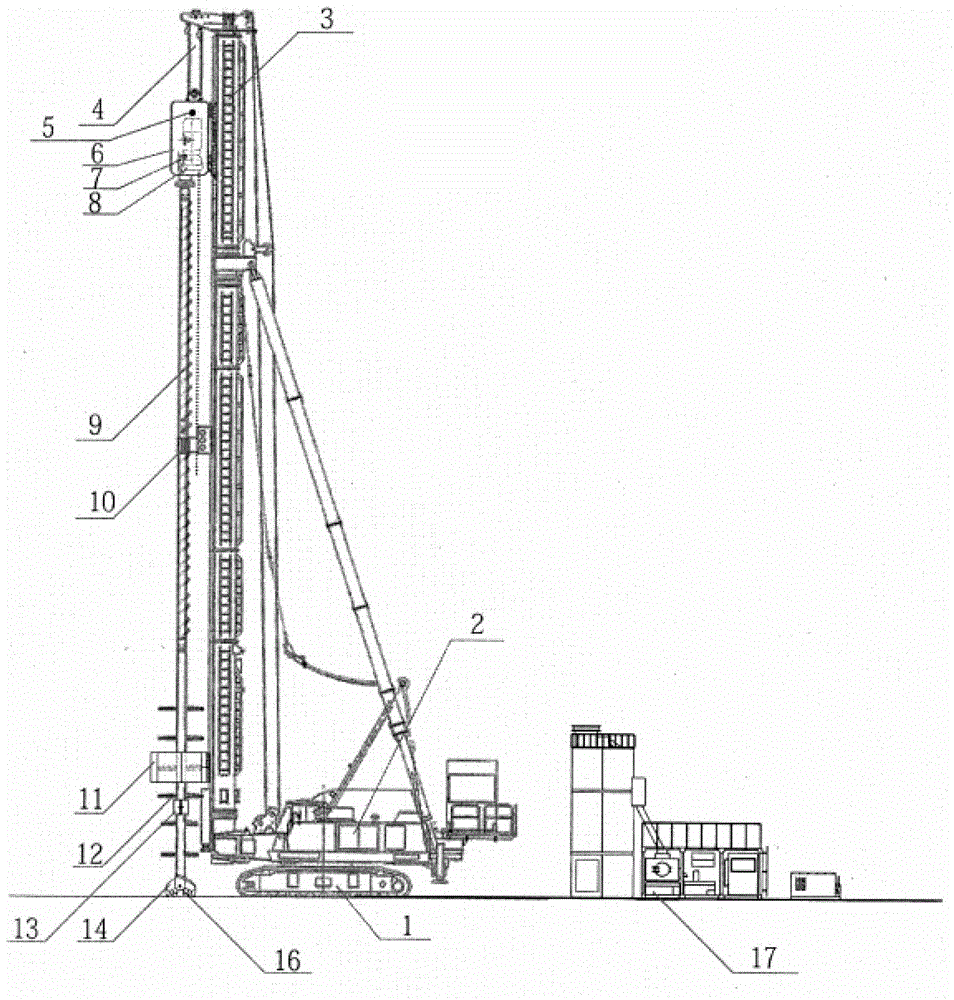

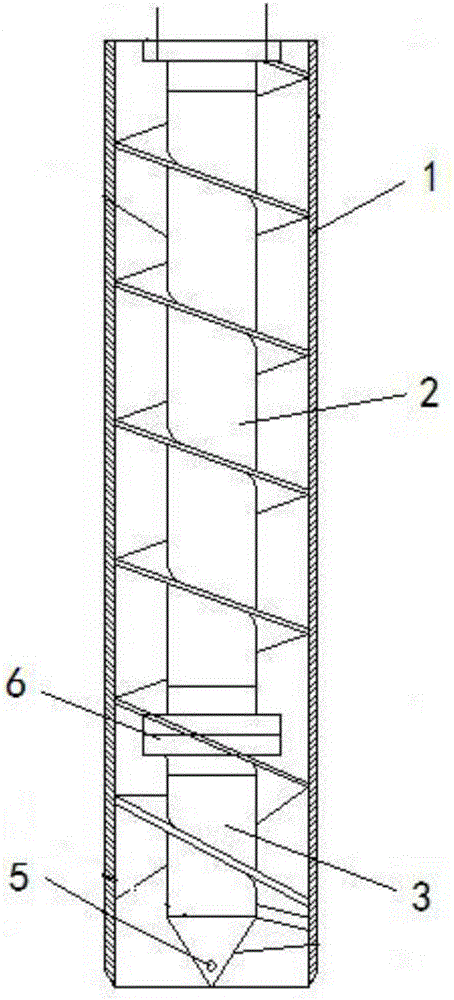

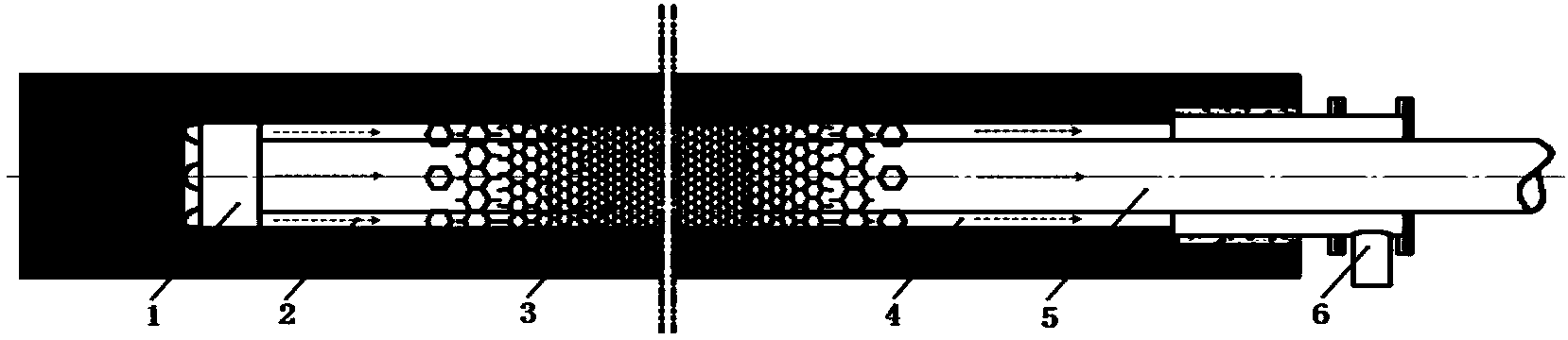

Drilling type boring machine

ActiveCN105370294AImprove drilling efficiencyImprove efficiencyTunnelsThree degrees of freedomEngineering

A drilling type boring machine is most suitable for digging a rock laneway of which the hardness f>8. The drilling type boring machine comprises a drilling mechanism and a boring machine. The drilling mechanism is fixed to a boring machine cantilever, and swings up and down and left and right along the boring machine cantilever. The drilling mechanism comprises a drilling mechanism main propulsion mechanism and a drilling mechanism attitude adjusting mechanism connected with the drilling mechanism main propulsion mechanism. For the rock drilling mechanisms of the same drilling type boring machine, three-degrees-of-freedom movement can be realized, the need for punching at all angles, in all positions and at all attitudes is satisfied, the two rock drilling mechanisms can work simultaneously, and the drilling efficiency is improved greatly. By reasonably integrating two rock drilling mechanisms on the boring machine, the boring machine has the functions of two rock drilling machines and one boring machine, and the drilling type boring machine greatly helps to save the roadway development cost. When an ordinary boring machine cannot conduct boring normally, a drilling work part drills a hole in the section of a roadway first to increase the free face of the rock so as to reduce the damage strength of the rock, and then, a boring machine cutting part develops the roadway.

Owner:CHINA UNIV OF MINING & TECH

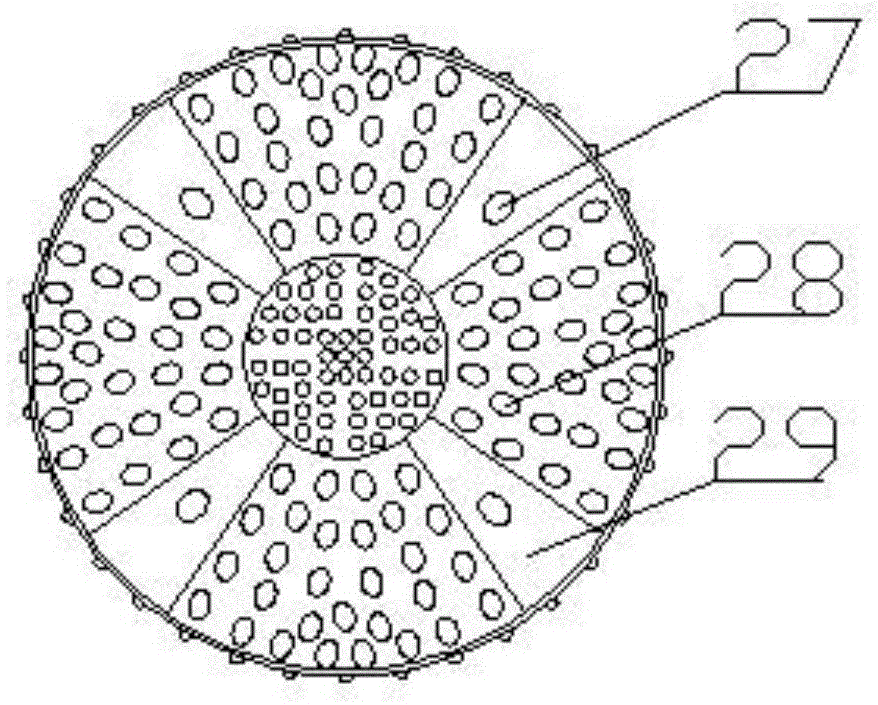

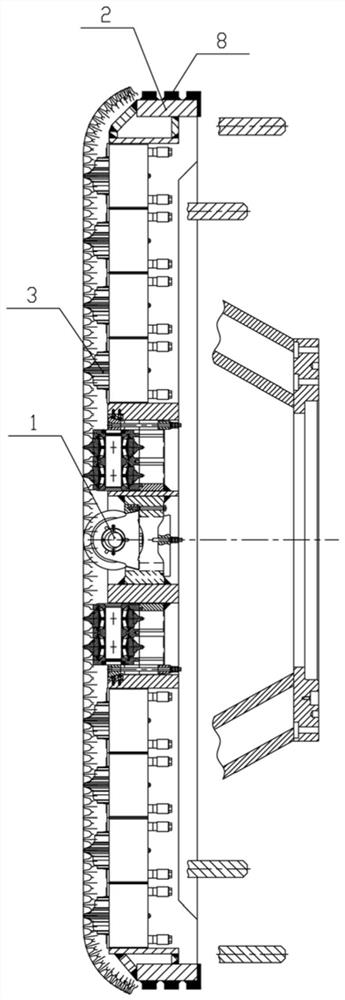

Variable-diameter ordinary pressure tool changing cutter and shield tunneling machine using the same

PendingCN108104827AImprove drilling abilityImprove construction efficiencyTunnelsShield tunnelingMechanical engineering

The invention provides a variable-diameter ordinary pressure tool changing cutter and a shield tunneling machine using the same. the variable-diameter ordinary pressure tool changing cutter and the shield tunneling machine using the same can not only adapt to the complex geological conditions safely and reliably, but also the excavation diameter of the cutter can be adjusted according to the construction needs, and the use ratio of an opposite side hob is high. The variable-diameter ordinary pressure tool changing cutter comprises a cutter, primary beams, and secondary beams; the primary beamsand the secondary beams are arranged on the cutter in a alternate mode; the edges of the front faces of the secondary beams are provided with welding seats; the lower portions of the welding seats are provided with upper sealing seats; the lower portions of the upper sealing seats are internally provided with tool changing support barrels; the outer sides of the upper sealing seats are provided with gate oil cylinders; the gate oil cylinder is connected with gate plates; the tool changing support barrels are internally provided with tool barrels; the top portions of the inner walls of the tool barrels are provided with tool seats; and the tool seats are internally provided with side hobs. The variable diameter of the variable-diameter ordinary pressure tool changing cutter can be realized, and the diameter of the cutter head can be enlarged and reduced quickly, conveniently and safely.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

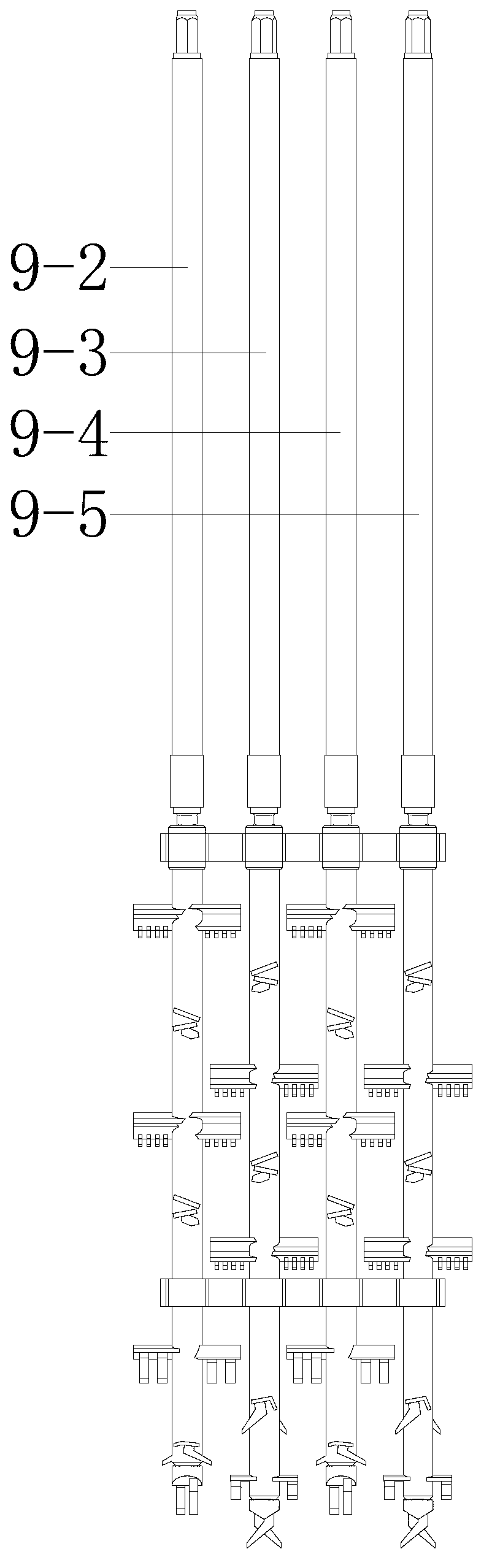

Multi-axial mixing pile device capable of reducing soil extrusion and application thereof

InactiveCN102943468AReduce the crowding effectGood drilling stabilityDrill bitsDerricks/mastsEngineeringReducer

The invention relates to a multi-axial mixing pile device capable of reducing soil extrusion and an application thereof. The device comprises a host, a hoist, a guide rod, a power head, a gearbox, a reducer and a drill pipe, wherein the hoist and the guide rod are fixed on the host; the power head, the gearbox and the reducer are arranged on the guide rod from top to bottom; the power head is connected with a pulley at the top of the guide rod through a steel wire rope which drives the power head to lift; the power head drives 1-9 drill pipes to rotate through the gearbox and the reducer sequentially, the rotation directions of the drill pipes are positive-reverse stagger, a grout inlet is arranged at the upper end of each drill pipe, the lower end of the drill pipe is connected with a winged drill pipe, the lower end of the winged drill pipe is connected with a multifunctional drill in a replaceable mode, and a grout nozzle and an air nozzle are arranged on the multifunctional drill. Compared with the prior art, the mixing pile device has the advantages of capable of reducing soil extrusion effect, better in drill forming, higher in cement use ratio, smaller in influence on surroundings and the like.

Owner:SHANGHAI CHENGDI CONSTR

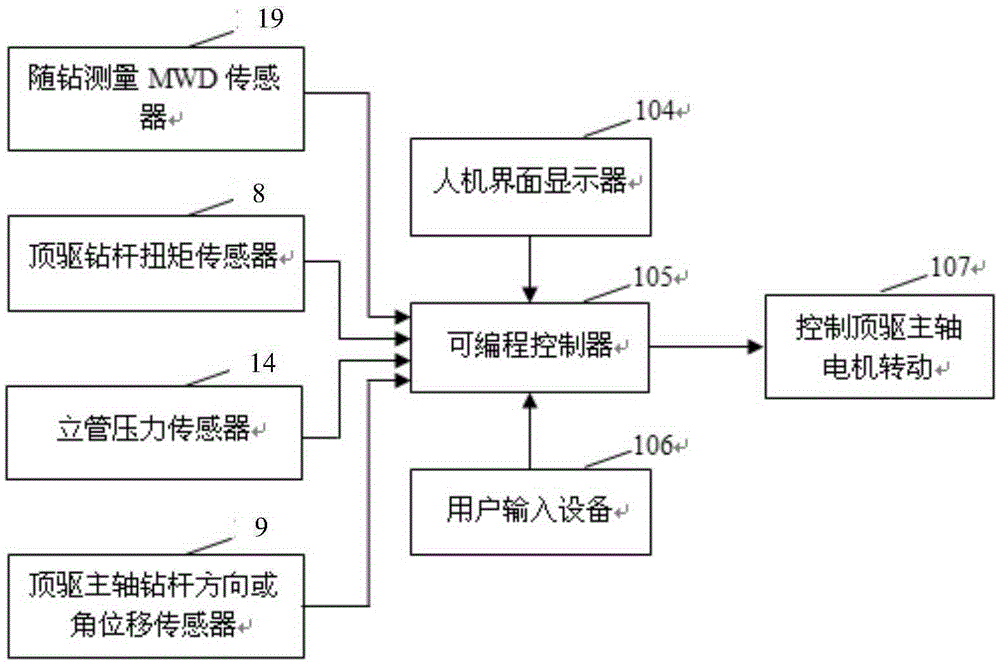

Ground control method of directional drilling adopting mud motor

InactiveCN105332688AImprove the correction effectEasy to controlAutomatic control for drillingTop driveMud motor

The invention discloses a ground control method of directional drilling adopting a mud motor. The ground control method includes: using signals collected by four sensors which are underground and overground as input and control variables, wherein the sensors include a measurement while drilling (MWD) tool face angle sensor, a top drive drilling rod torque sensor, a pump pressure or standpipe pressure sensor and a top drive spindle drilling rod direction or angle displacement sensor; through feedback information displayed overground, adopting a computer system and a user intervention mode to monitor directional drilling process overground in real time; executing a drilling rod rotating program, and controlling a drilling rod rotating controller to control a top drive spindle motor to act. A ground assisting system controlling directional drilling by a computer has obvious effect, the ground control method is an optimal choice adopting the mud motor for directional drilling currently, except for a rotating guide system, and drilling efficiency of slide drilling can be improved remarkably by using the ground control method.

Owner:CNPC BOHAI DRILLING ENG

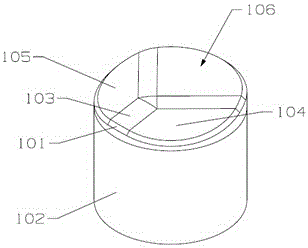

Diamond compact

InactiveCN106089089AStrong plowing actionImprove crushing drilling performanceDrill bitsShock resistanceCemented carbide

The invention relates to a diamond compact which comprises a cemented carbide substrate and a diamond composite layer. The diamond compact is characterized in that a boss and strip-shaped flanges protruding upwards are arranged on the end face of the diamond composite layer, and each strip-shaped flange extends upwards to the edge of the boss in an inclined mode from the edge of the diamond composite layer. According to the diamond compact, multiple strip-shaped flanges are arranged, the cutting face has a high ploughing effect, the crushing and drilling performance of the compact is improved, the drilling cutting resistance is reduced, and the penetration speed of a diamond drill bit is increased; meanwhile, the cutting face composed of the strip-shaped flanges, the lateral inclined plane and the boss has high shock resistance; the effect of guiding downhole debris to be discharged can be achieved, and the penetration speed of the diamond drill bit is increased. The cutting face of the compact is larger, abrasion resistance of the compact is further improved, and the service life of the diamond drill bit is further prolonged.

Owner:KINGDREAM PLC CO +1

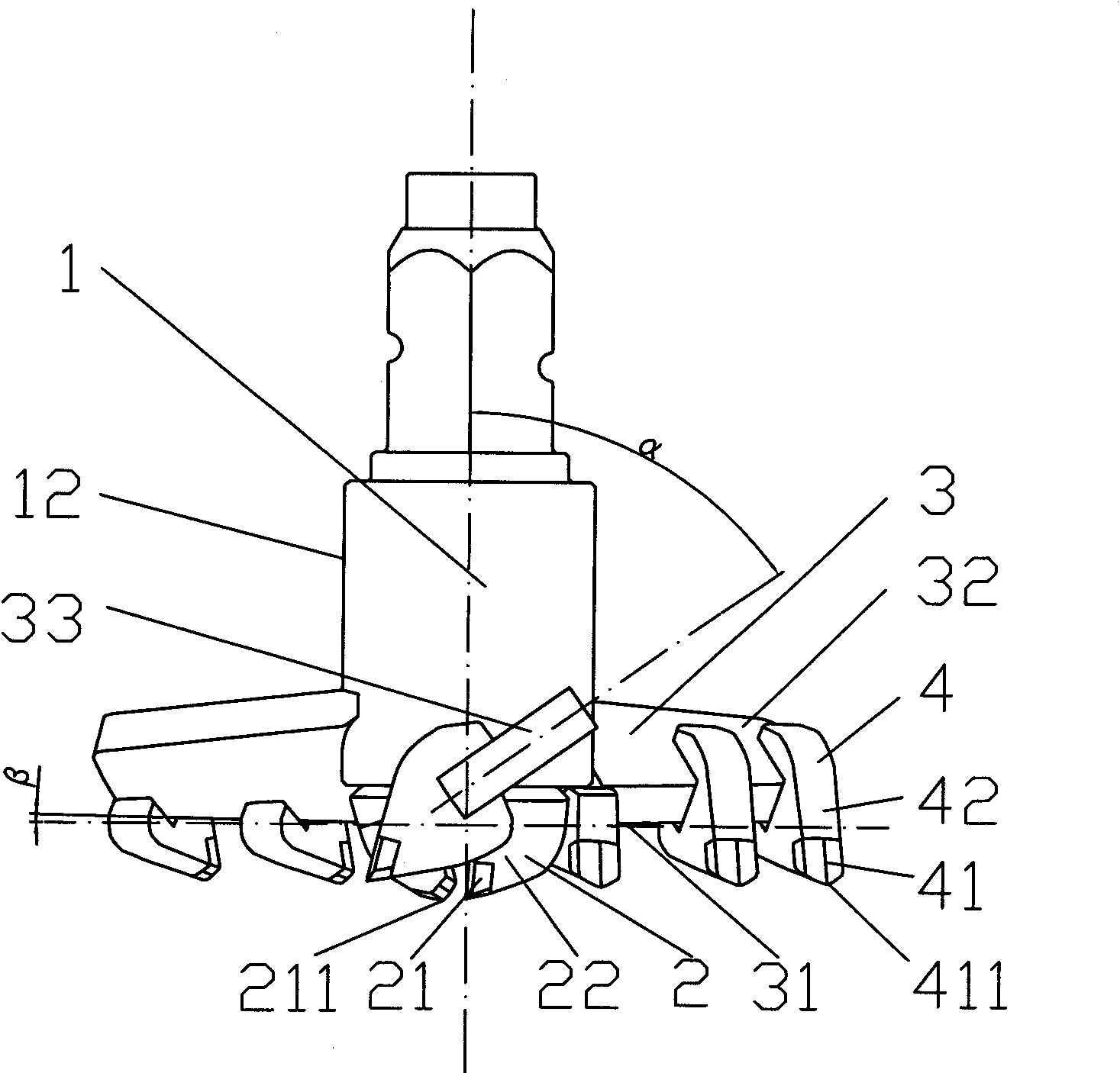

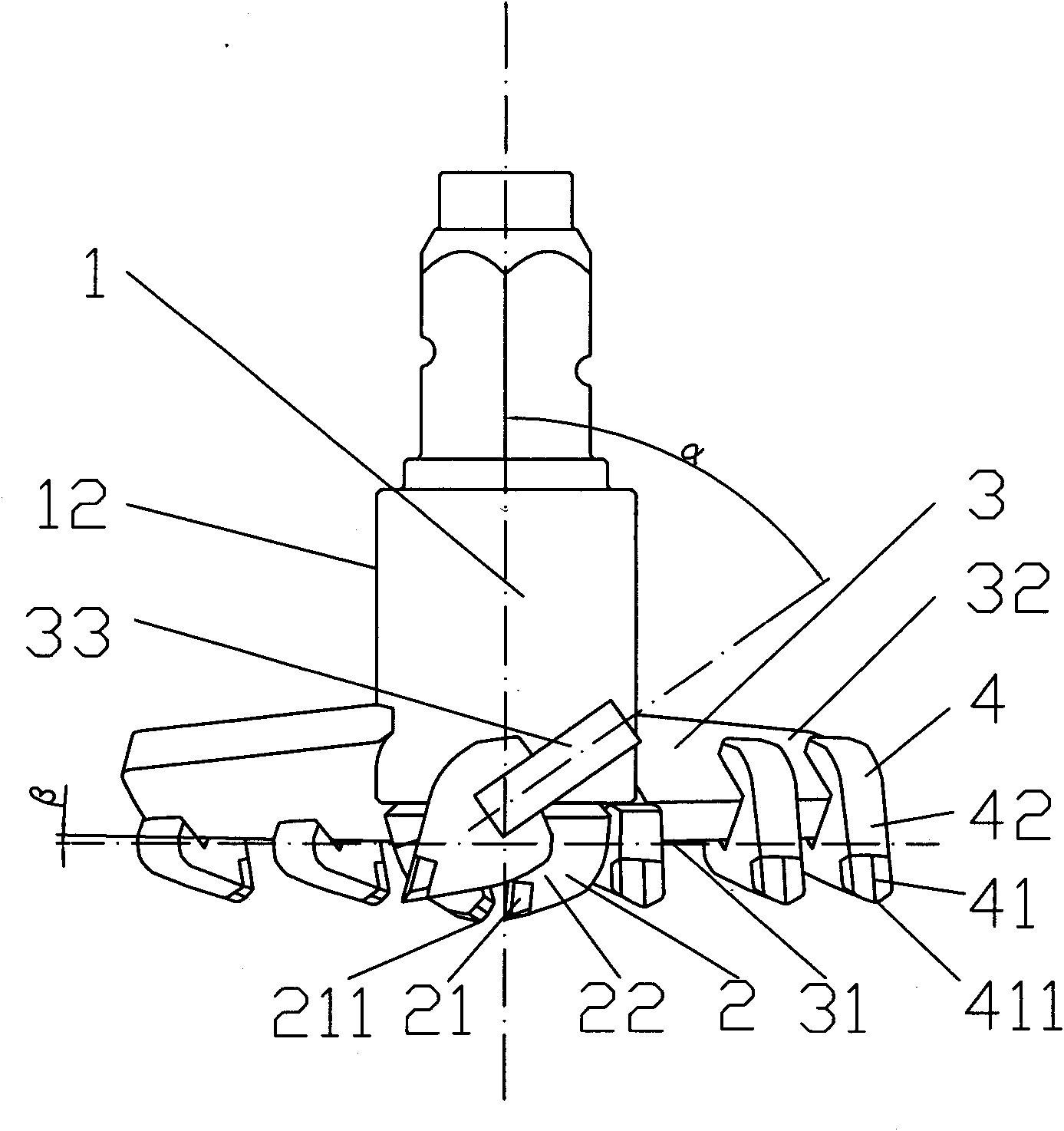

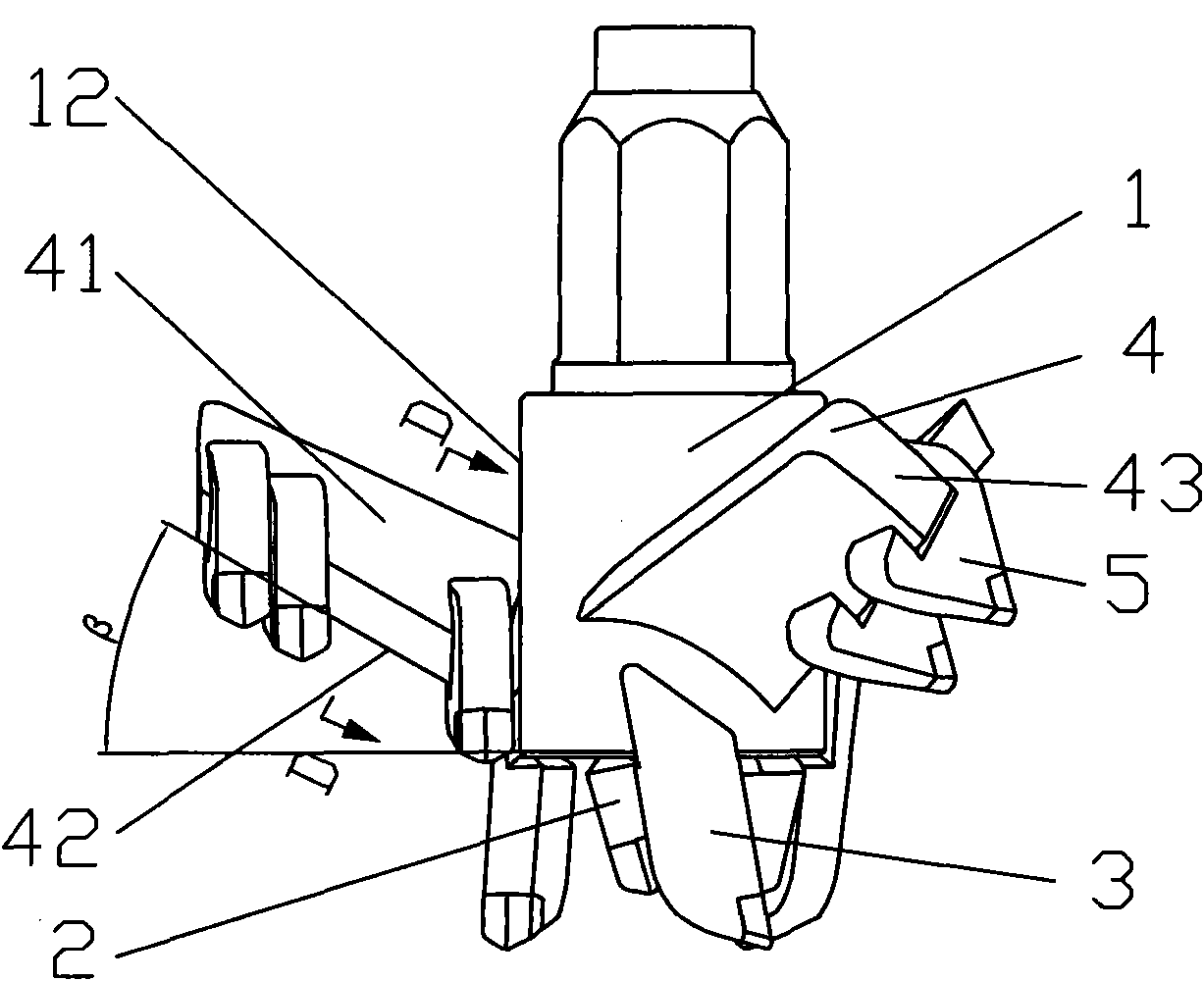

Combined bit

InactiveCN101812971AImprove drilling abilityHigh strengthDrill bitsConstructionsEngineeringMechanical engineering

The invention relates to a combined bit, comprising a rod body, an inner cutter body consisting of an inner cutter head and an inner cutter handle, wings and an outer cutter body consisting of an outer cutter body and an outer cutter handle, wherein the middle part of the rod body is provided with a grouting channel, and the inner cutter body is fixed at the lower end part of the rod body; the number of the wings is 2-6 and are uniformly distributed and fixed on the peripheral surface of the lower part of the rod body along the length direction thereof vertical to the direction of an axial central line of the rod body, and the outer cutter body is fixed on the wings; the inner cutter head in the inner cutter body and the outer cutter head in the outer cutter body are respectively welded the inner cutter handle with the outer cutter handle into a whole; the front ends of the inner cutter head and the outer cutter head are respectively provided with an inner cutting edge and an outer cutting edge; and the installation directions of the inner cutter body and the outer cutter body are rotating directions leading the inner cutter head and the outer cutter head to be installed toward the rod body. The combined bit realizes synchronous drilling and cutting of the inner cutter head and the outer cutter head, improves the operating efficiency multiply, has high bonding strength of the cutter heads and the cutter handles, reduces the wear condition of the cutter heads and the wings, and guarantees the quality of continuous walls after drilling holes.

Owner:上海工程机械厂有限公司

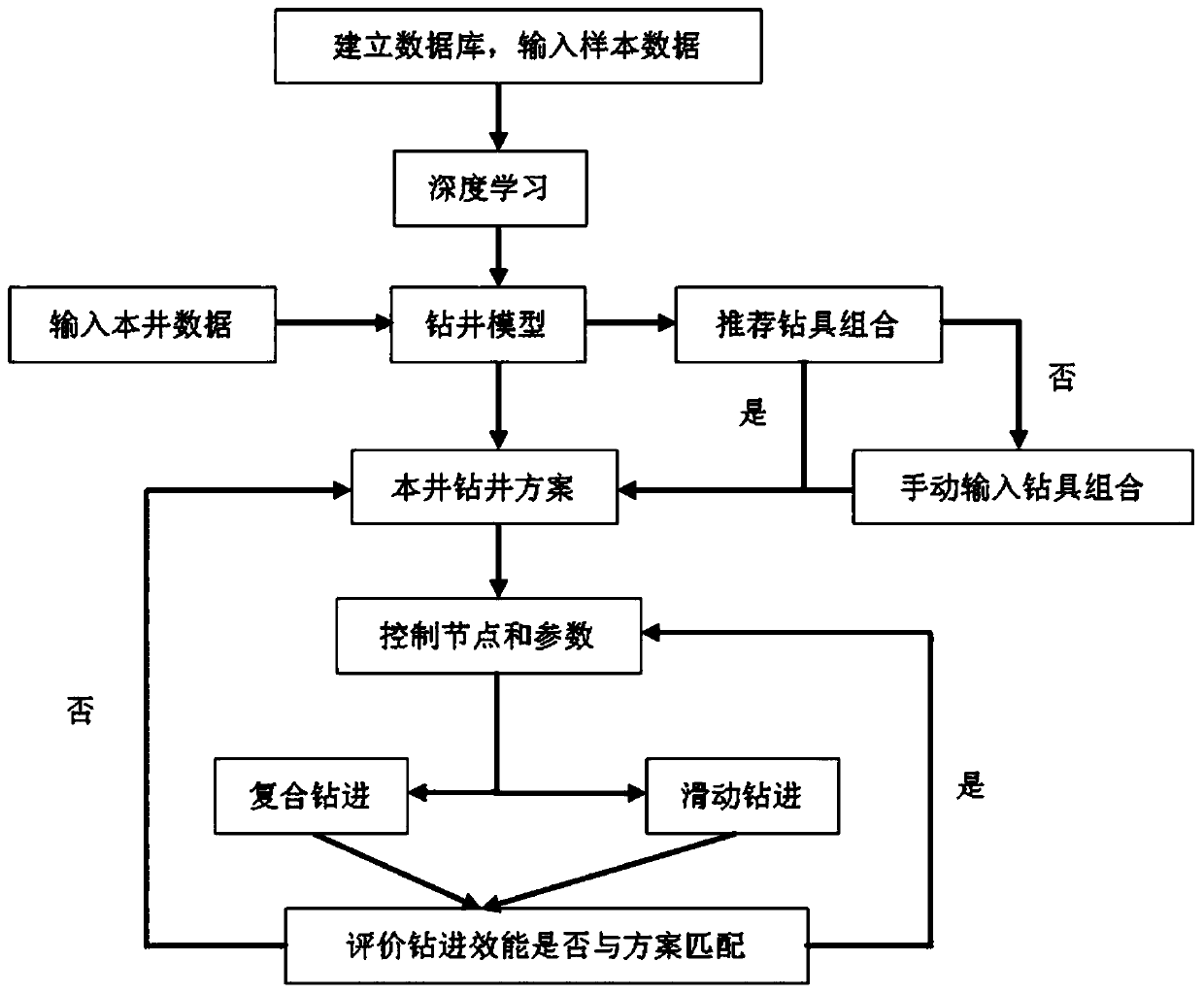

Automatic drilling method based on deep learning

ActiveCN110500081AAdjust drilling parametersImprove control efficiencySpecial data processing applicationsAutomatic control for drillingWell drillingHigh intensity

The invention provides an automatic drilling method based on deep learning. The method can comprise the following steps of building a drilling database; forming a drilling model on the basis of the drilling database; inputting basic information of a well to be operated, designed well hole track data and drilling tool combinations into a drilling tool model, wherein the drilling tool model can simulate the drilling efficiency and output a drilling scheme; performing drilling operation on the basis of the drilling scheme; and measuring the well hole track data in real time. The drilling model performs real-time evaluation on the basis of the measured data. Under the condition that the evaluation is not qualified, the drilling model plans the drilling scheme again, and the drilling operationis continuously performed according to the planned drilling scheme. Compared with the prior art, the automatic drilling method based on deep learning has the beneficial effects that the goal of intelligently controlling the well hole track and the drilling efficiency can be achieved; and engineers can be liberated from high-intensity brainwork and work through the reasonable plan on a control mode.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

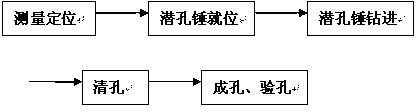

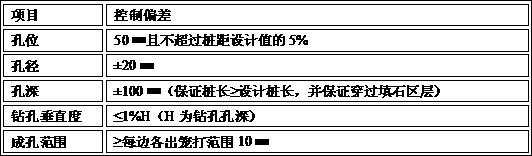

Pipe pile leading-hole construction method under boulder cluster geological condition

ActiveCN103277037AHigh selectivityPrevent buried drilling phenomenonReciprocating drilling machinesConstructionsLandslideInstability

The invention relates to a pipe pile construction method, in particular to a pipe pile leading-hole construction method under the boulder cluster geological condition. The pipe pile leading-hole construction method adopts a down-hole hammer drilling process, and dilled muck is forcibly discharged out through a spiral drill rod in a rotation mode and is completely removed by utilizing strong wind. The down-hole hammer drilling hole bottom is cleaned through air pressure for 2-3minutes and sediments are removed with lifting of the spiral drill rod after the depth of a drill hole reaches to the designed depth, and operation is stopped after detection shows that the hole depth and the sediment thickness are smaller than or equal to 50mm and meet the design requirements. When the sediment thickness is larger than 50mm, a down-hole hammer is put into the hole again to perform secondary hole cleaning till the actual requirement is met. The pipe pile leading-hole construction method under the boulder cluster geological condition is short in construction period, the construction cost can be saved by more than 10% under the same operating conditions, a stratum application range is wide, and the pipe pile leading-hole construction method is especially suitable for construction of landslide, instability and other complicated stratums. The pipe pile leading-hole construction method is strong in machine tool selectivity and low in field requirement and is especially suitable for mountains and other narrow and small fields.

Owner:二十二冶集团天津建设有限公司

Diamond compact

InactiveCN106089090AImprove crushing drilling performanceReduce drilling and cutting resistanceDrill bitsPenetration rateDrill bit

The invention relates to a diamond compact which comprises a hard alloy matric and a diamond composite layer. The diamond compact is characterized in that the end face of the diamond composite layer is provided with at least two upward-protruding strip-shaped flanges, and each strip-shaped flange is inclined upwards from the edge of the composite layer and extends and intersects at the middle of the end face. Due to the fact that the multiple strip-shaped flanges are arranged, cutting faces have the strong ploughing effect, the breaking and drilling performance of the compact is improved, the drilling cutting resistance is decreased, and then the mechanical penetration rate of a diamond drill bit is increased; meanwhile, the cutting faces composed of the strip-shaped flanges and the lateral inclined faces also have the impact resistance, the effect of guiding rock debris at the bottom of a well to be discharged can be achieved, and further the mechanical drilling speed of the diamond drill bit is increased; the impact resistance of the compact is further enhanced. The cutting faces of the compact are larger, the abrasion resistance of the compact can be further improved, and therefore the service life of the diamond drill bit can be prolonged.

Owner:KINGDREAM PLC CO +1

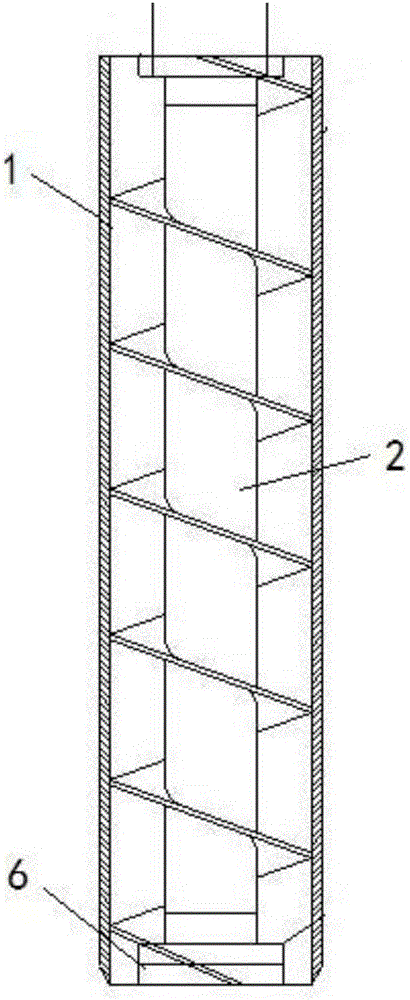

Steel sleeve for full sleeve working method for actively transporting waste and construction method thereof

InactiveCN106761474AOvercoming various difficulties in constructionPrevent collapseDrill bitsDrilling rodsSocial benefitsSlag

The invention discloses a steel sleeve for full sleeve working method for actively transporting waste, comprising several steel sleeve pipes, spiral drill stems and a drill bit for soil excavation; several spiral drill stems are axially connected from bottom to top, and axially penetrated through the inner parts of the steel sleeve pipes axially connected from bottom to top; the uppermost steel sleeve pipe is provided with a slag hole, the bottom part of the drill bit is provided with a connecting opening of a high pressure water gun; the drill bit is installed at the bottommost spiral drill stem, the blades of the spiral drill stems are fixedly connected with the inner wall of the steel sleeve pipe; when the steel sleeve pipe drives the spiral drill stem to rotate, the spiral upwards blade can convey the waste soil excavated by the drill bit to the slag hole. The steel sleeve pipe can be reformed by the steel sleeve pipe structure for Benoto working method, and a technical scheme of fixing the steel sleeve pipe with the spiral drill stem is presented, thus the excavation while soil taking during the construction process is realized, the construction efficiency is improved, and the construction time and cost are saved; the steel sleeve generates significant economic and social benefits.

Owner:CHINA RAILWAY 24TH BUREAU GRP +1

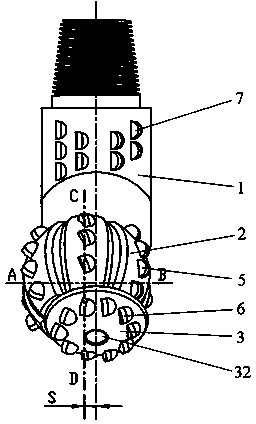

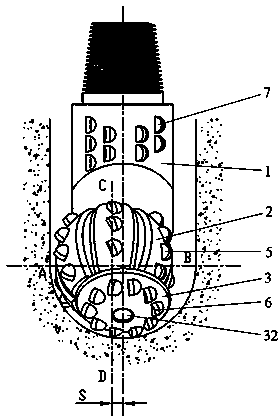

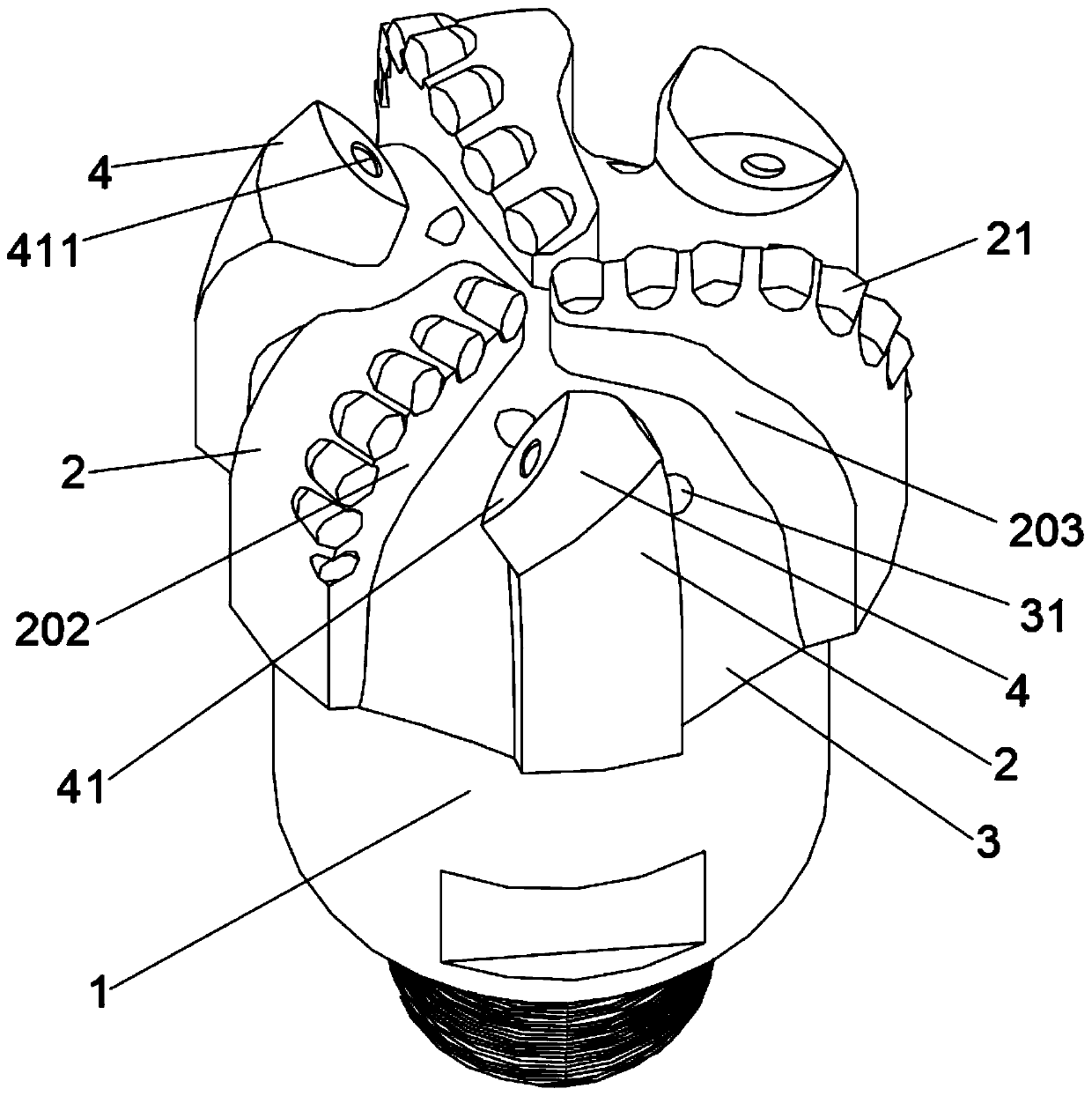

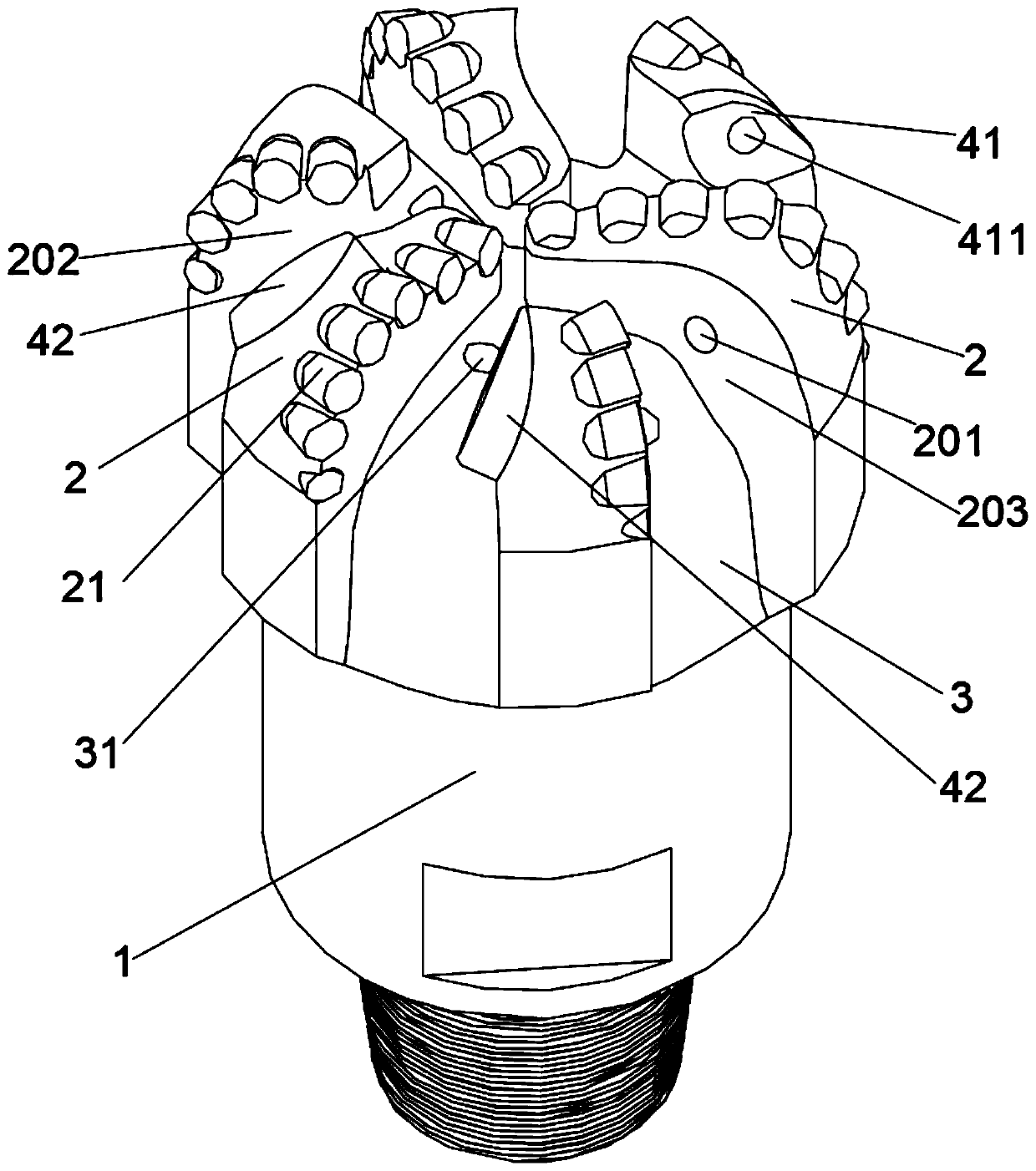

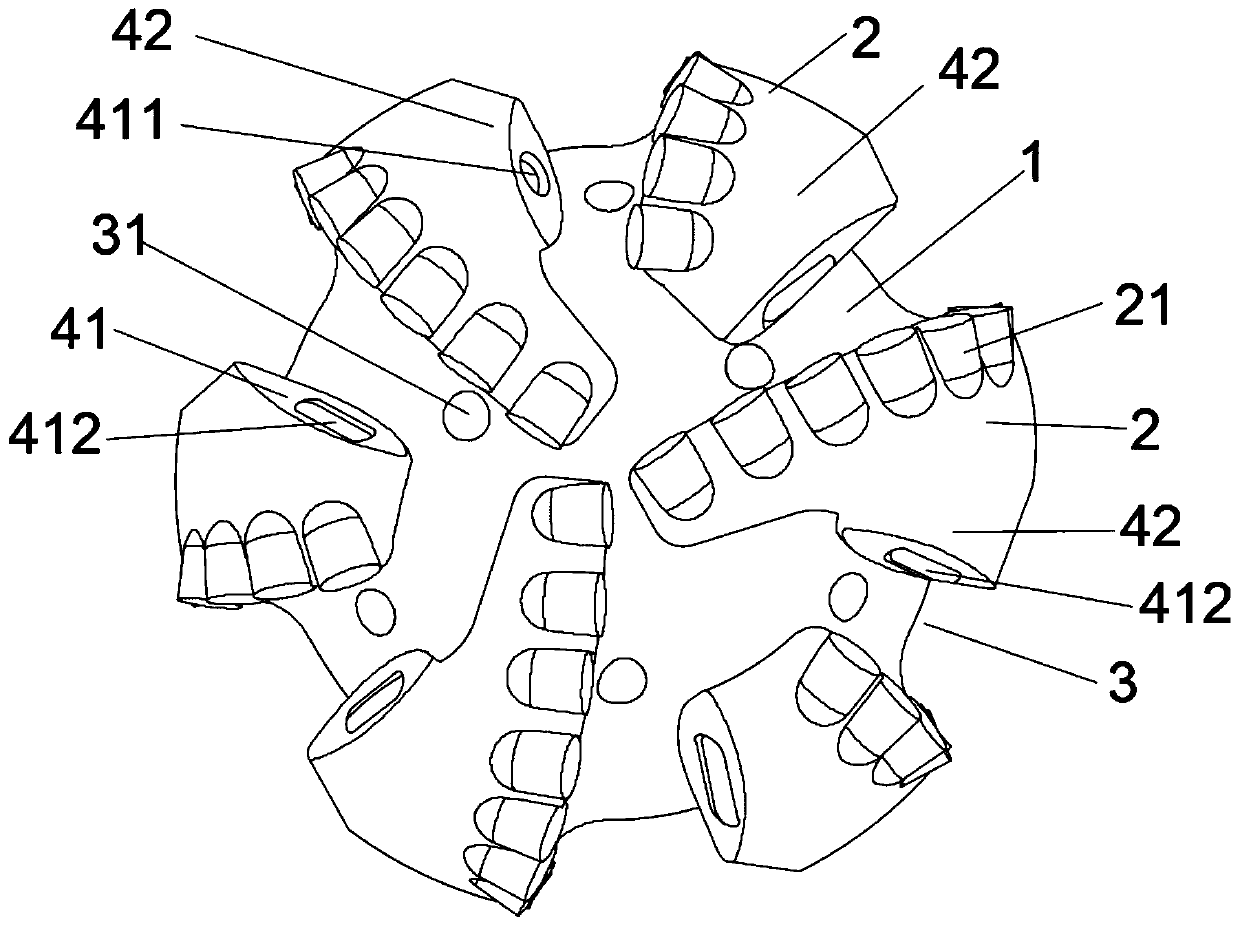

Composite type eccentric one-cone bit

ActiveCN103541660AImprove rock breaking efficiencyExtended service lifeDrill bitsHydrometryStructural engineering

The invention discloses a composite type eccentric one-cone bit and belongs to the technical field of drilling devices for oil and gas, mine engineering, building foundation engineering construction, geology, hydrology and the like. The composite type eccentric one-cone bit comprises a bit body, a roller, a cone and a cone front fixed cutting structure, wherein cone cutting teeth are distributed on the cone, fixed cutting teeth are distributed on the cone front fixed cutting structure, a shaft neck is arranged on the bit body, the cone is in rotary connection with the shaft neck, the cone front fixed cutting structure is fixedly connected with the front end of the shaft neck, the deviation S exists between the axis of the shaft neck and the axis of the bit, an absolute value is larger than zero and smaller than or equal to d / 3, and the d is the outer diameter of the bit. By adopting the composite type eccentric one-cone bit, the hydraulic power condition of the bit can be improved while the rock breaking efficiency of the bit is improved, and the service life of the bit is prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

Efficient high-strength composite drill bit

InactiveCN101812973AHigh strengthHigh drilling and grooving qualityConstructionsHigh intensityUltimate tensile strength

The invention relates to a high-strength composite drill bit, which comprises a drill pipe, a lower cutter body consisting of a lower cutter head and a lower cutter handle, an inner cutter body consisting of an inner cutter head and an inner cutter handle, blades, and an outer cutter body consisting of an outer cutter head and an outer cutter handle, wherein the lower cutter body is fixed at the lower end part of the drill pipe, the inner cutter body is fixed on the periphery surface at the lower part of the drill pipe, the number of the blades is 2-4, and the blades are uniformly fixed in a radiation form on the periphery surface at the lower part of the drill pipe and are positioned above the inner cutter body; the outer cutter body is fixed on the blades; the lower cutter head in the lower cutter body, the inner cutter head in the inner cutter body and the outer cutter head in the outer cutter body are respectively welded together with the lower cutter handle, the inner cutter handle and the outer cutter handle; the front ends of the lower cutter head, the inner cutter head and the outer cutter head are respectively provided with a lower cutting edge, an inner cutting edge and an outer cutting edge; and the installation directions of the lower cutter body, the inner cutter body and the outer cutter body are the rotation directions which make the lower cutter head, the inner cutter head and the outer cutter head arranged towards the drill pipe. The working efficiency of the drill bit is multiplied, the combination strength of the cutter head and the cutter handle is high, the wear of the cutter head and a rib is slowed down, and the construction quality is ensured.

Owner:上海工程机械厂有限公司

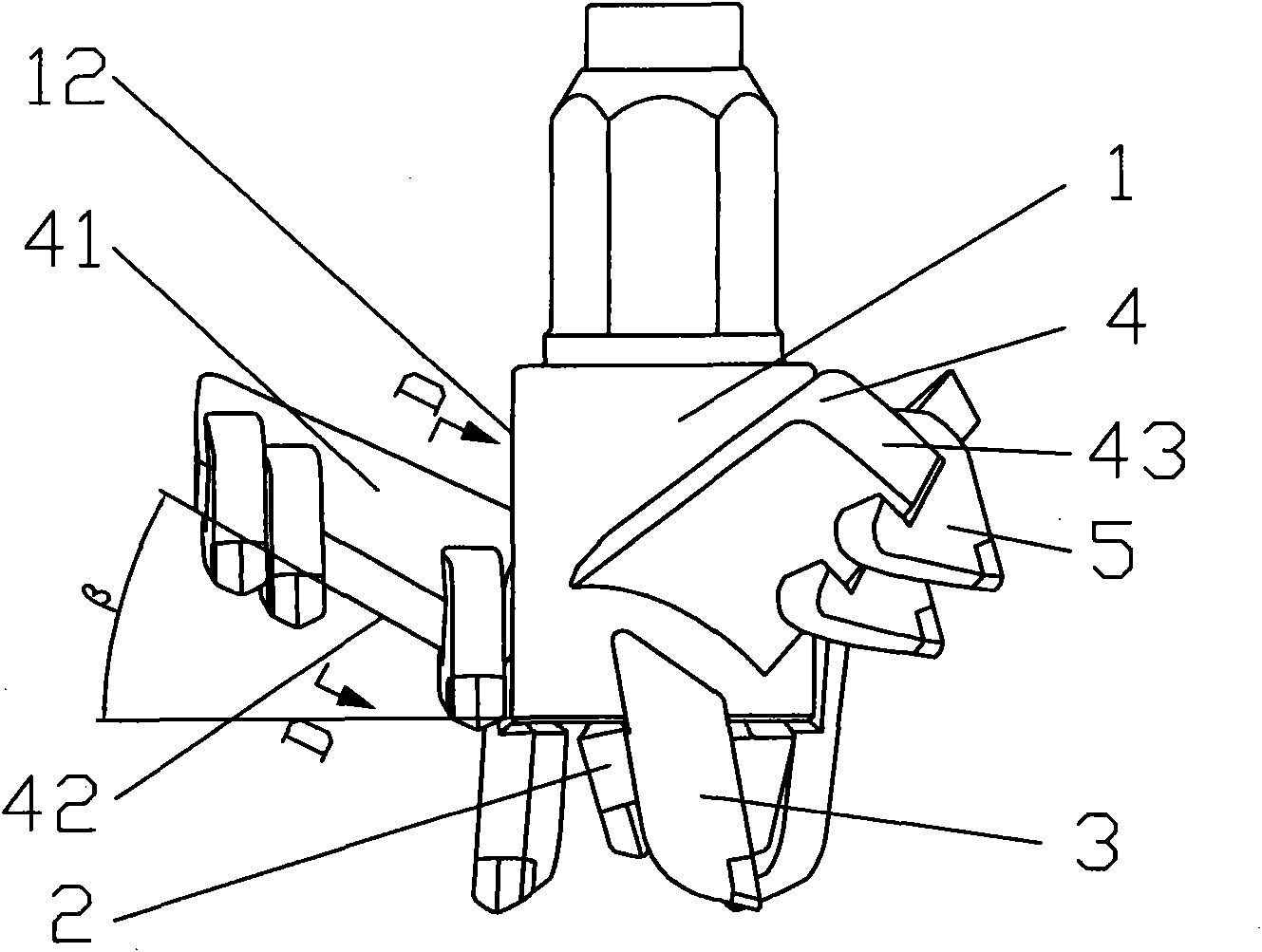

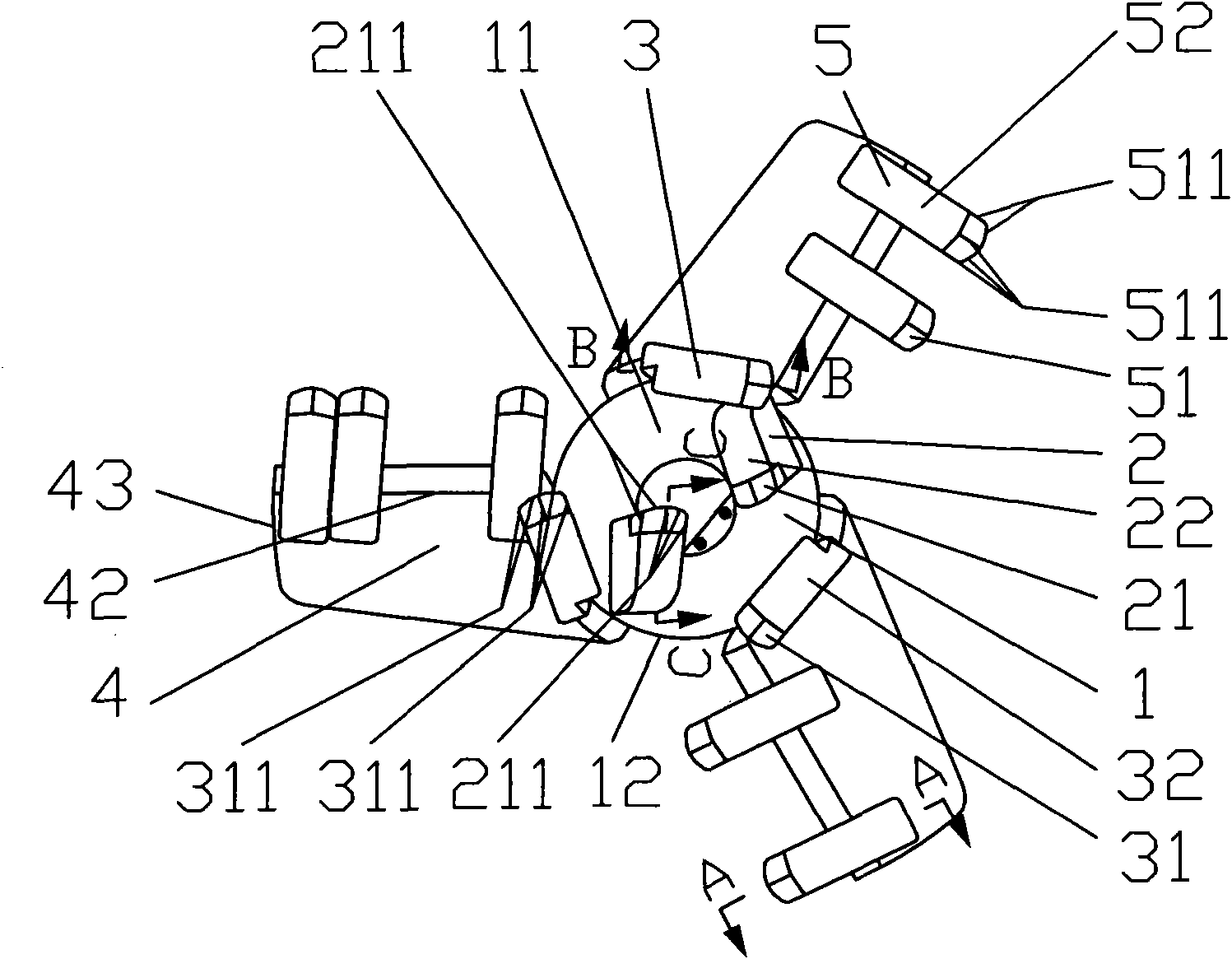

Drill bit suitable for hard sandy soil

ActiveCN103939024AImprove drilling abilityHigh strengthDrill bitsConstructionsEngineeringUltimate tensile strength

The invention discloses a drill bit suitable for hard sandy soil. The drill bit suitable for hard sandy soil comprises a drill bit center assembly, lower cutter bodies, inner cutter bodies, blades, outer cutter bodies, supporting plates and wear-resisting plates, wherein the lower cutter bodies and the inner cutter bodies are fixed to the outer circumferential surface of the lower end and the outer circumferential surface of the lower portion of a drill bit body respectively, the two to six blades are evenly fixed to the outer circumferential surface of the drill bit body in a radial and surrounding mode, the outer cutter bodies are fixed to the lower edges of the blades, two to eight outer cuter bodies are installed on each blade, for all the outer cutter bodies except the outer cutter bodies at the free ends of the blades, the outer cutter bodies on each blade and the outer cutter bodies on another blade are arranged in a cross mode in the rotation position, the blades and the drill bit bodies are fixed through the supporting plates, the wear-resisting plates are fixedly installed on the cambered surfaces of the free ends of the blades, the side faces of the outer cutter bodies at the outermost end and the side faces of the inner cutter bodies respectively, and the lower cutter bodies, the inner cutter bodies and the outer cutter bodies are installed in the directions enabling lower cutter heads, inner cutter heads and the outer cutter heads face the rotation direction of the drill bit body. The drill bit suitable for hard sandy soil has the advantages that the working efficiency can be improved effectively, the combining strength between the cutter heads and cutter handles is high, abrasion of the cutter bodies and the blades is reduced, and the construction quality is guaranteed.

Owner:上海工程机械厂有限公司

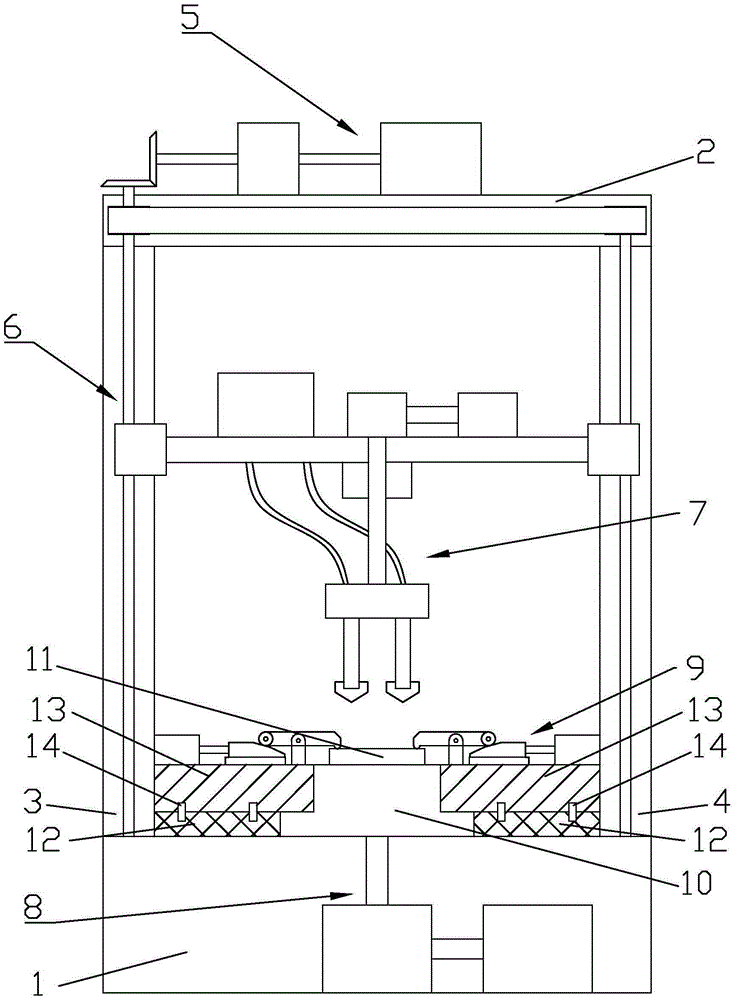

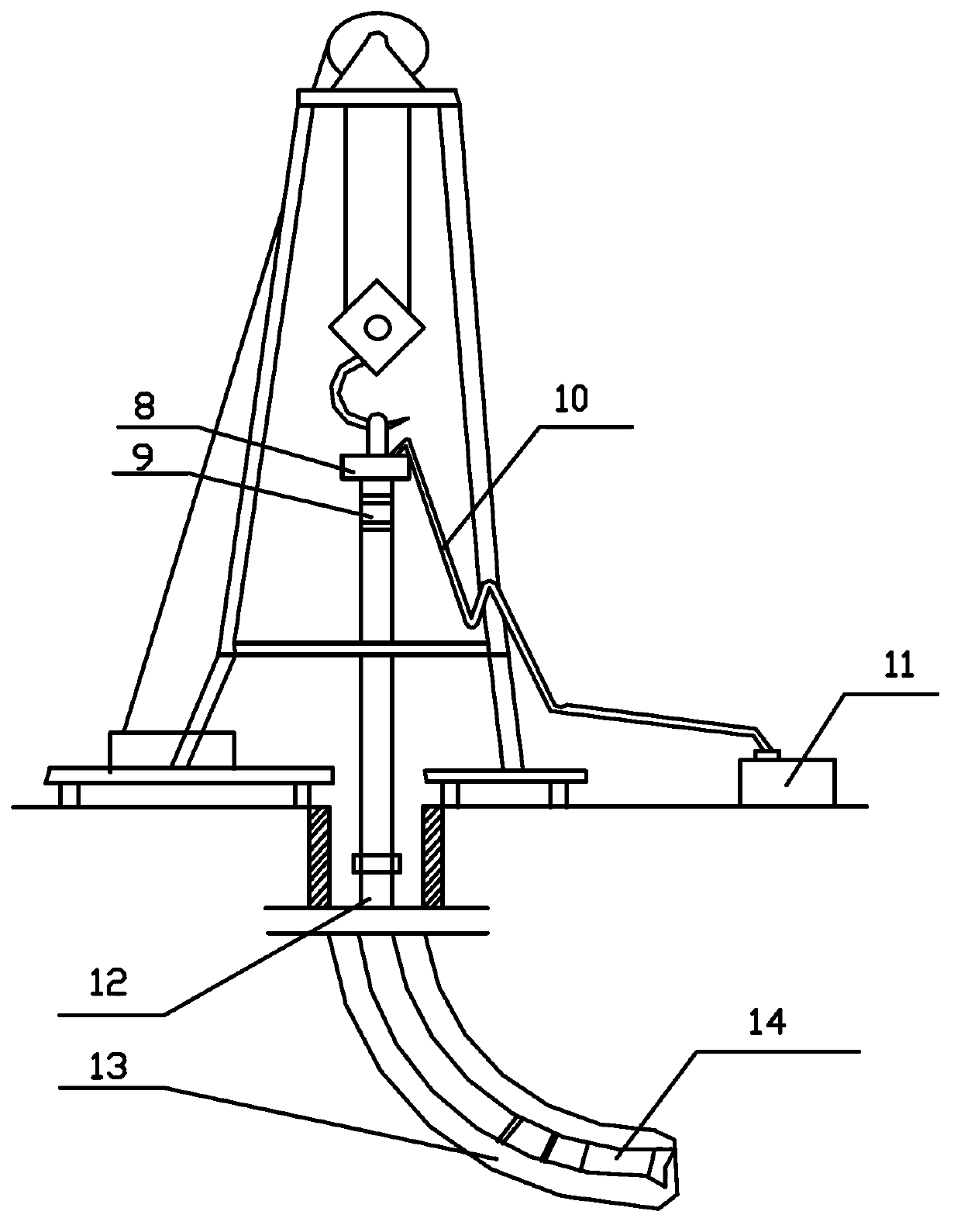

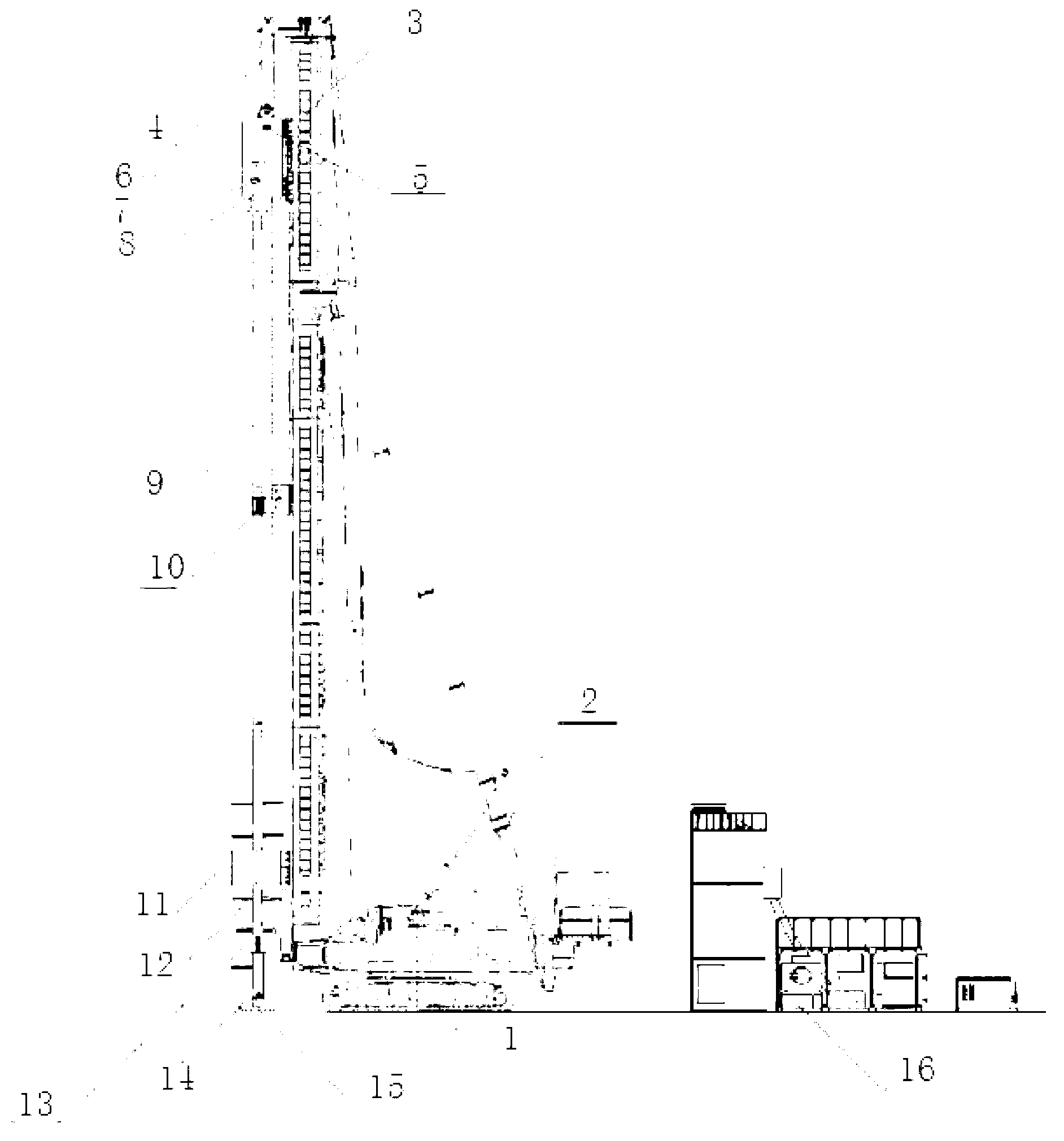

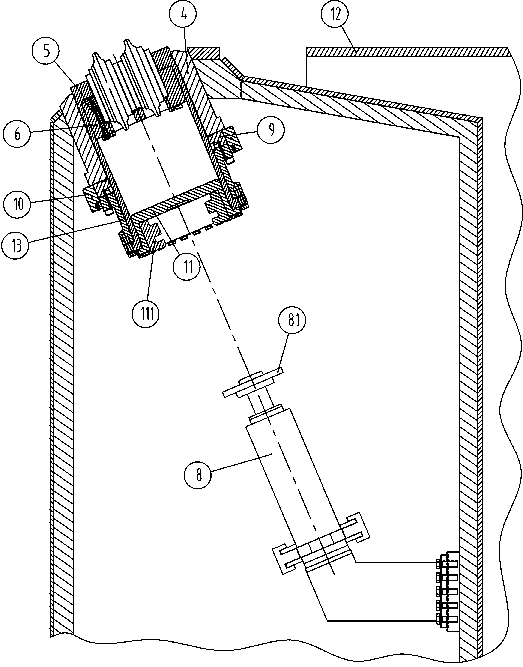

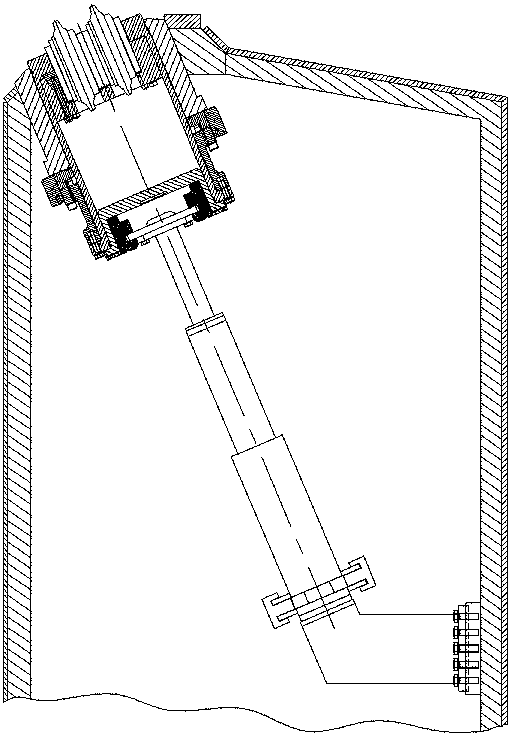

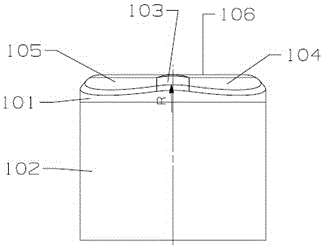

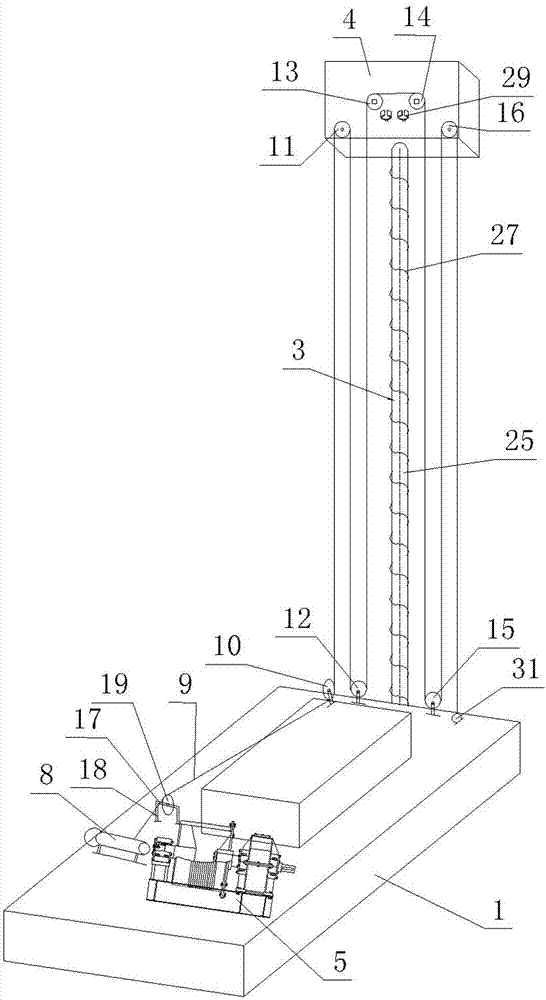

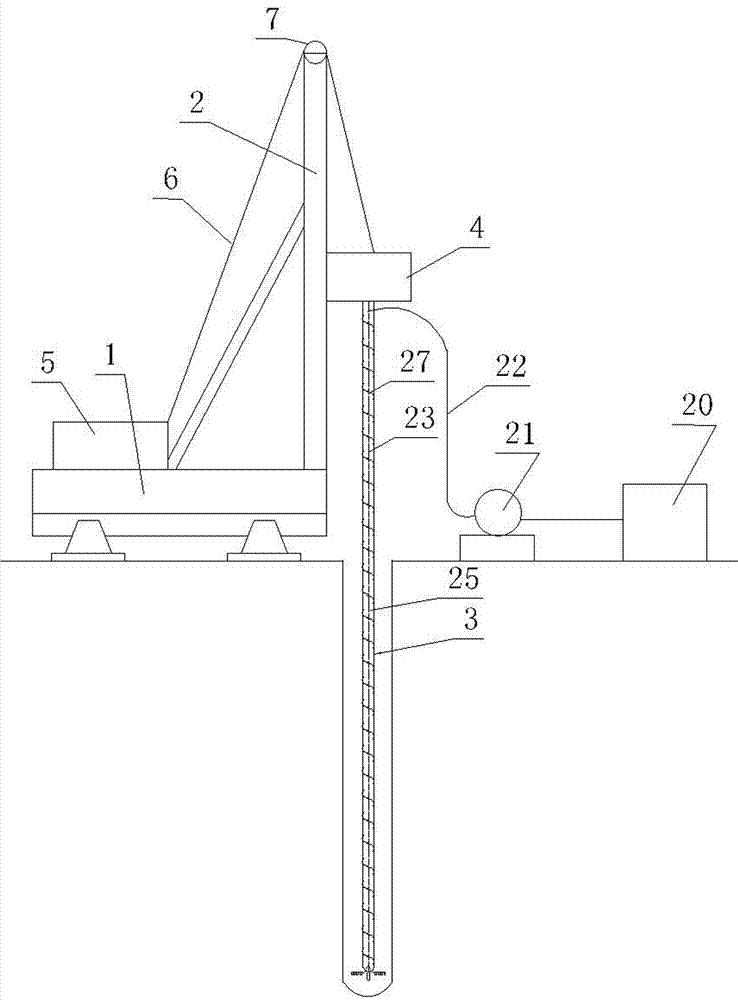

Pressurized type long bored pile machine and method for drilling by means of pile machine

ActiveCN103938629AOvercome limitations of limited abilityImprove drilling abilityRotary drillingRotary-drilling machinesEngineeringWinch

The invention discloses a pressurized type long bored pile machine and a method for drilling by means of the pile machine. The pile machine comprises a base plate (1), a main mast and a power head (4). The main mast is fixed to the base plate (1), the power head (4) is matched with the main mast, a pressurization winch (8) is fixed to the base plate (1), a pulley block is arranged between the base plate (1) and the power head (4) and the pulley block comprises a set of upper pulleys fixed to the power head (4), a set of lower pulleys fixed to the base plate (1), and steel wire ropes (9) connecting the two sets of the pulleys. The method includes the key steps of starting the pressurization winch (8), tensioning the steel wire ropes (9), increasing several times of traction of the pressurization winch (8) under the action of the pulley block and applying the traction to the power head (4) to drill up rocks. According to the pile machine and the method for drilling by means of the pile machine, drilling capacity can be improved greatly.

Owner:NINGBO HONGCHEN CONSTR

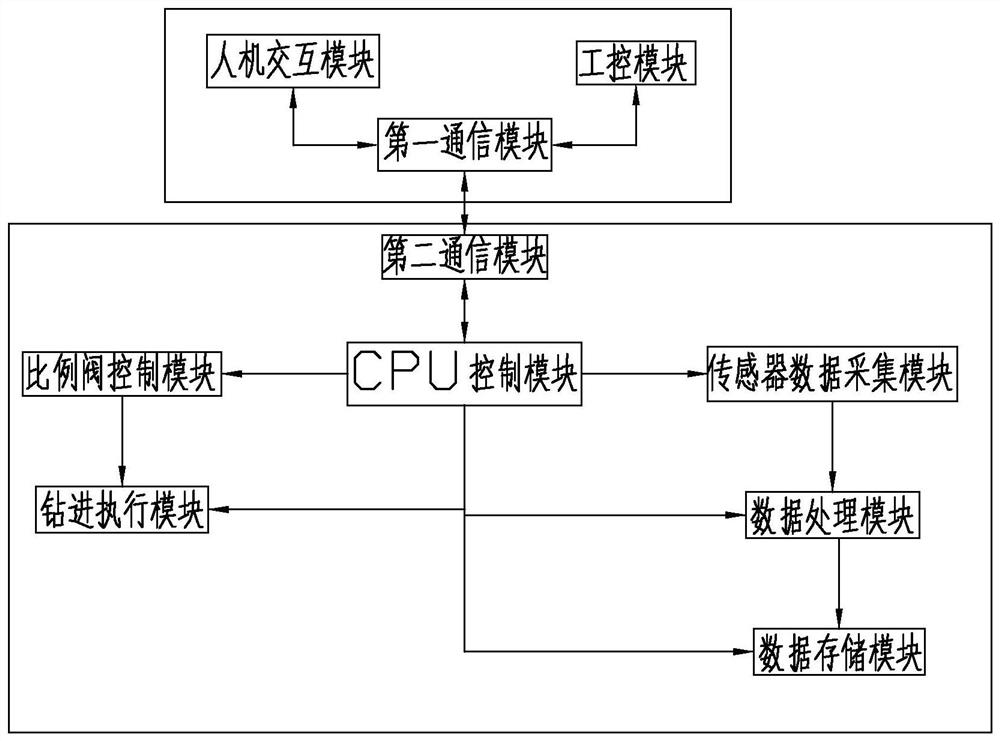

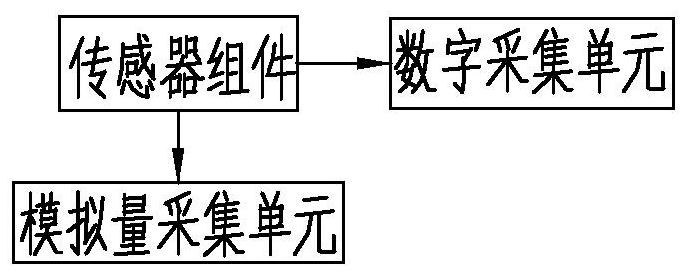

Self-adaptive drilling measurement and control system of deep sea core drill

PendingCN112554825AImprove drilling efficiencyImprove drilling abilitySurveyCore removalMachineHuman machine interaction

The invention discloses a self-adaptive drilling measurement and control system of a deep sea core drill. The self-adaptive drilling measurement and control system comprises an overwater control system and an underwater measurement and control system which are in communication connection; and the overwater control system comprises a first communication module, an industrial control module and a man-machine interaction module, the first communication module is in communication connection with the industrial control module and the underwater measurement and control system, and the man-machine interaction module is in communication connection with the industrial control module. According to the self-adaptive drilling measurement and control system, parameter feedback information such as the rotating speed and the bit pressure is added into a drilling execution module of the drill, a self-adaptive control algorithm is correspondingly fused into a proportional valve control module of the underwater measurement and control system, geological attributes of a drilling area block are recognized, the theoretical drilling speed under official big data in the geological environment is matchedin a self-adaptive mode, constant-rotating-speed cruise drilling is conducted, and the drilling efficiency and the drilling effect are effectively improved.

Owner:杭州瀚陆海洋科技有限公司

Diamond drill bit with high-efficiency water hole structure

PendingCN110107227AHigh rock breaking performanceShort spray distanceDrill bitsConstructionsWell drillingPetroleum

The invention relates to the technical fields of petroleum and natural gas, mine engineering, geothermal wells, building foundation engineering construction, geology and hydrological drilling, in particular to a diamond drill bit with a high-efficiency water hole structure. According to the diamond drill bit, a rear water spray hole seat extending to a drill bit body or connected to the drill bitbody is arranged in front of at least one of cutter wings, the rear water spray hole seat is provided with a rear water spray hole communicating with a flow channel in the drill bit, and the rear water spray hole can directly spray water onto cutting teeth on the cutter wings or rocks in front of the cutting teeth. According to the diamond drill bit with the high-efficiency water hole structure, the cutting teeth are fully cooled and cuttings are transported in time in high temperature well drilling, and the drilling performance of the drill bit is greatly improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

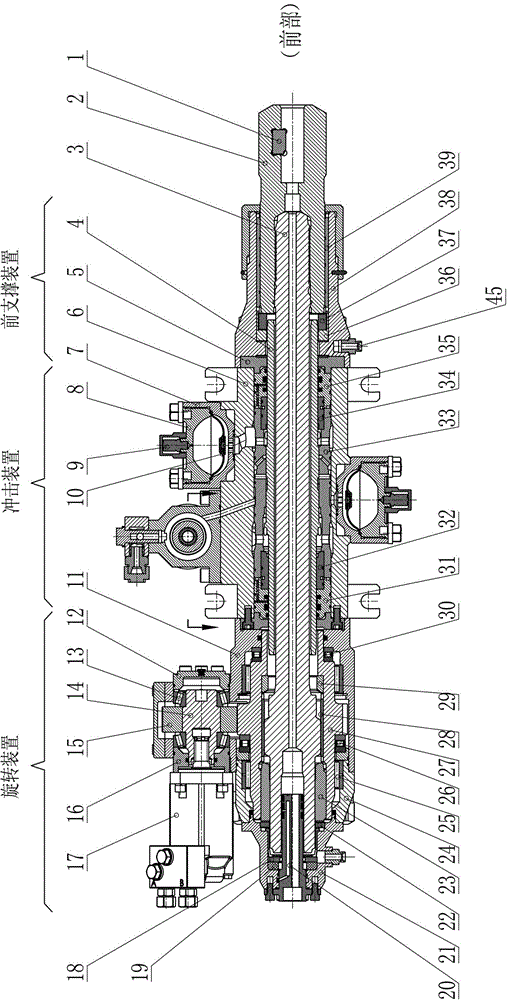

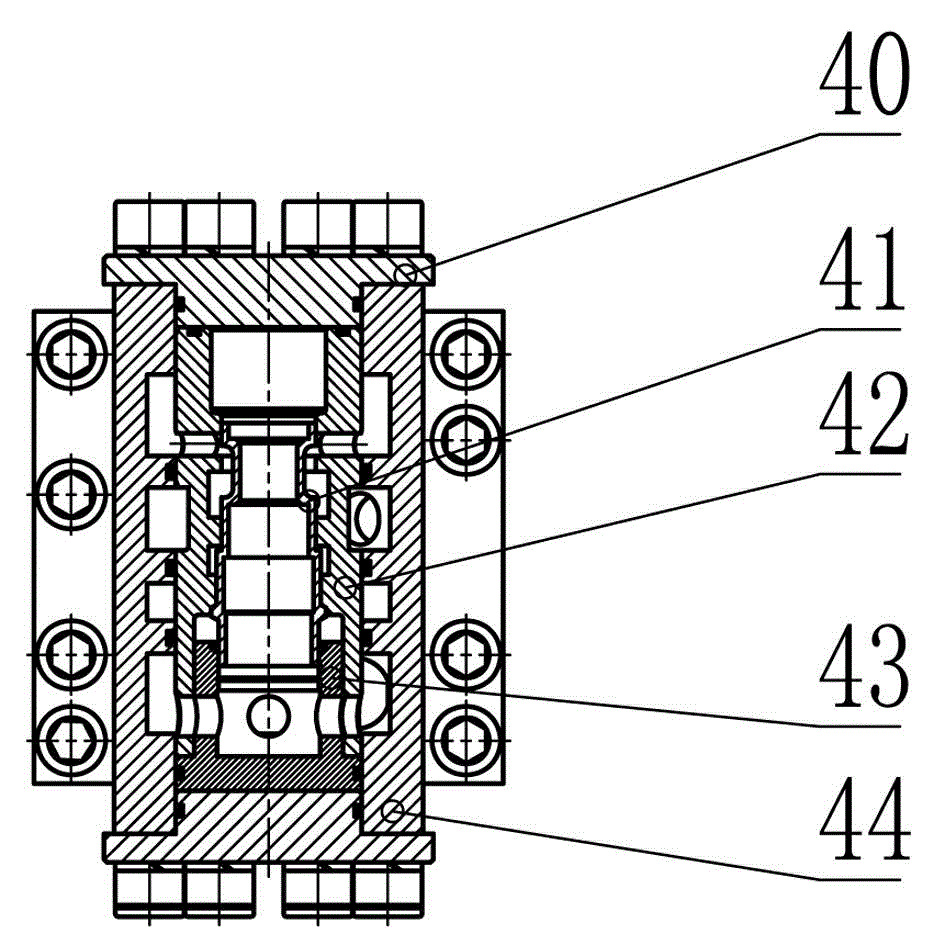

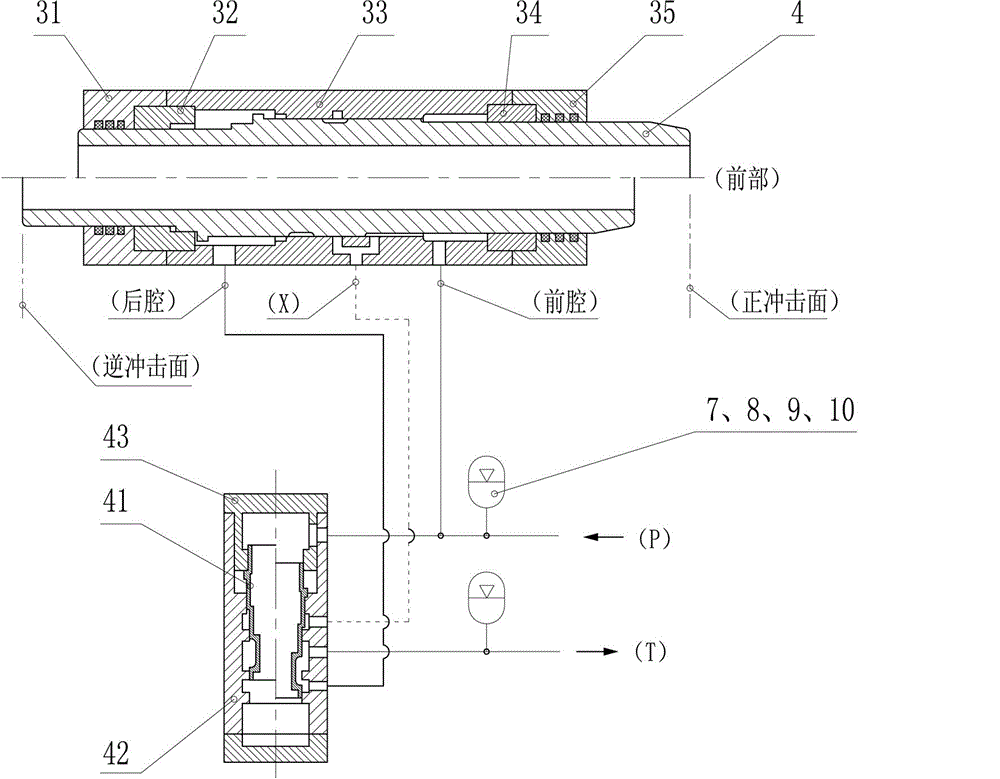

Double-impact integral hydraulic tapping machine

InactiveCN102912052AImproved power to weight ratioHigh impact frequencyBlast furnace componentsBlast furnace detailsControl functionEngineering

A double-impact integral hydraulic tapping machine comprises a borer assembly. A front support device, an impact device and a rotary device are sequentially arranged on the outer portion of the borer assembly from front to back, a backstop assembly is arranged at the rear end of the borer assembly, a rotary joint assembly is arranged at the outer end of the backstop assembly, the borer assembly comprises a rapping rod, a drill stem connecting sleeve is connected to the front end of the rapping rod, and the impact device comprises an impact functional module and a reversing control functional module. The double-impact integral hydraulic tapping machine has the advantages that the double-impact integral hydraulic tapping machine is adaptable to hard iron notches, is high in reverse impact output power and prevents the problem of stem withdrawal; a forward impact device and a reverse impact device are integrated, reverse impact operation can be carried out by retreating a trolley when the drill stem is required to be withdrawn, the stem withdrawal time is shortened, and misoperation is avoided; the double-impact integral hydraulic tapping machine is in a modular design, and is high in maintainability and low in failure rate; and the double-impact integral hydraulic tapping machine is high in protection performance, and the service life of equipment is long.

Owner:YICHANG YANSHI TECH DEV

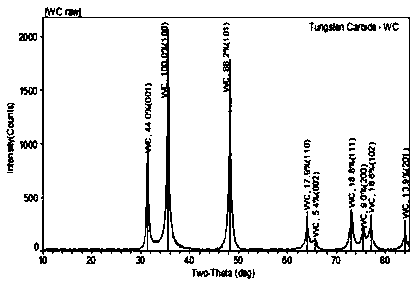

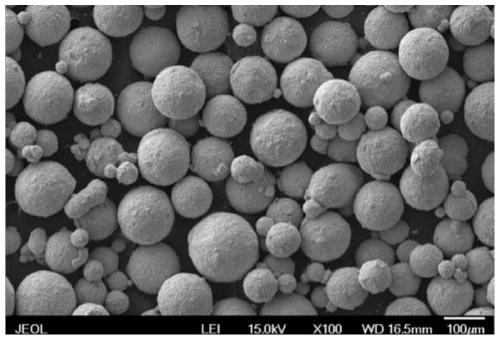

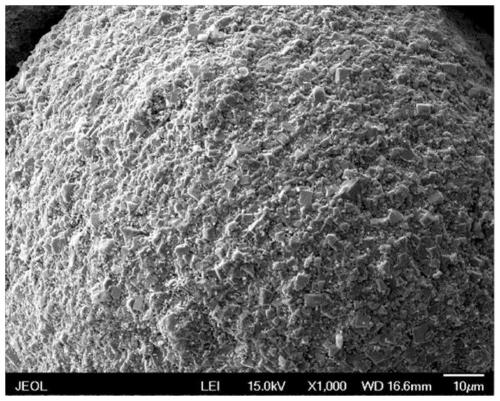

Powder material for 3D printing

ActiveCN110385430AHigh hardnessHigh strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantAlloy

The invention provides a powder material for 3D printing. The powder comprises a wear-resistant phase and a binding phase, wherein a mixture of sintered WC-Co hard alloy spherical particles and tungsten carbide particles serves as the wear-resistant phase, and Co-based alloy serves as the bonding phase. The weight percentage of the wear-resisting phase is 20-60%, the weight percentage of the bonding phase is 40-80%, the weight percentage of the sintered WC-Co hard alloy spherical particles is 5-15%, and the weight percentage of the coarse-grained or monocrystalline tungsten carbide particles is 15-45%. The failure period can be effectively avoided or delayed, and the wear resistance and working efficiency of the material are improved.

Owner:SEED TECH CORP LTD

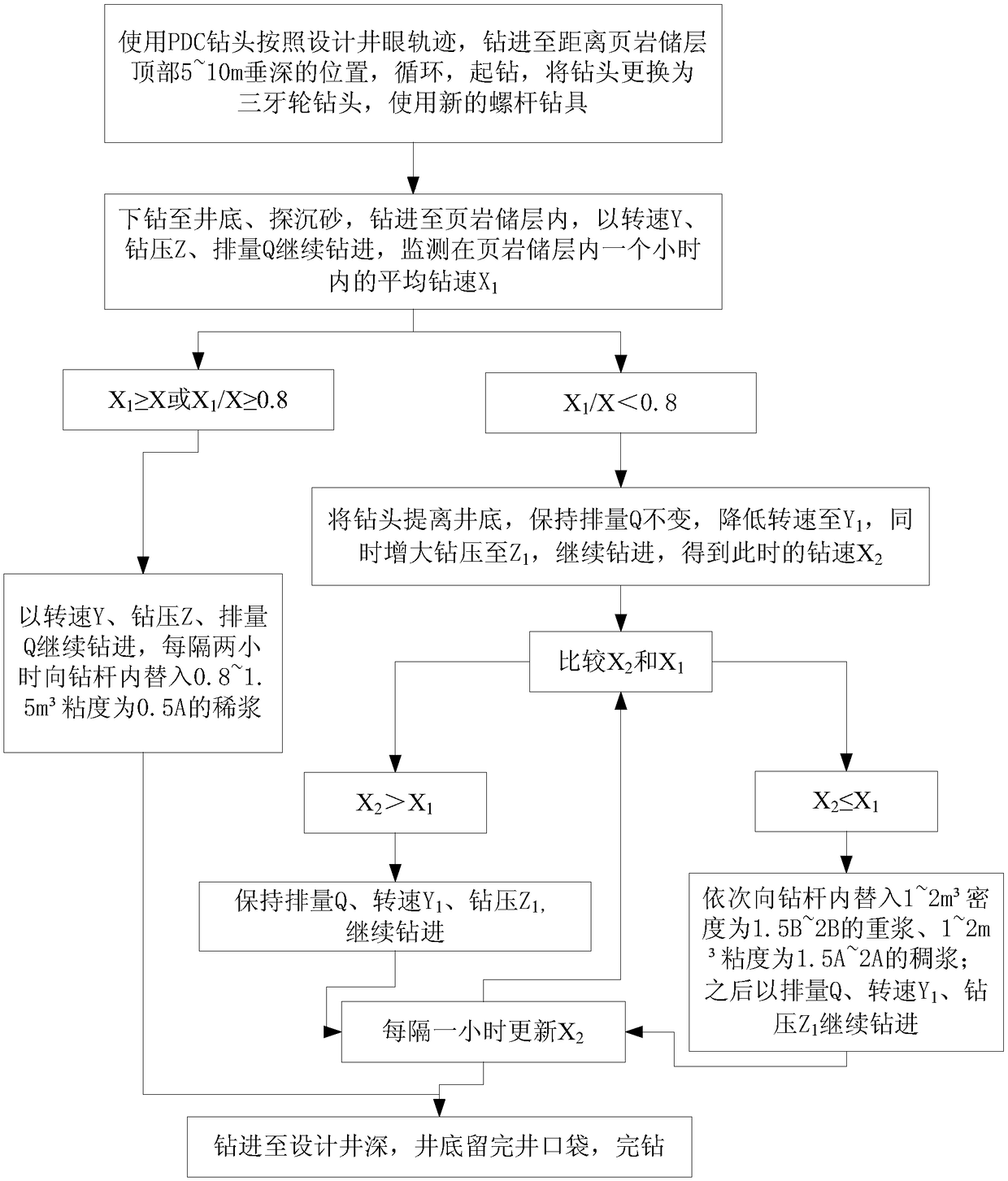

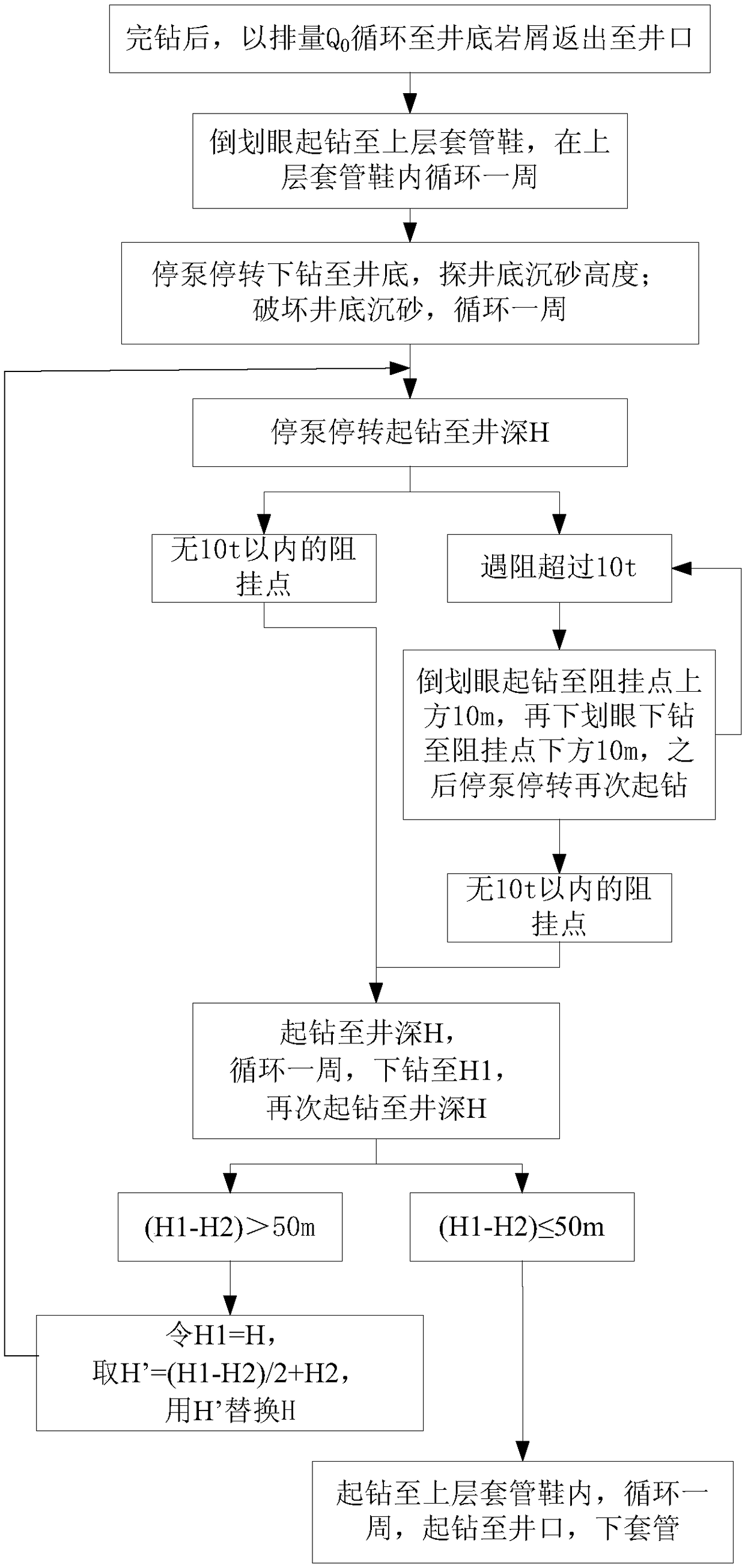

Drilling and drilling completion method for interior of shale reservoir in drilling engineering

ActiveCN109488212AIncrease drilling speedImprove drilling effectDrill bitsFlushingWell drillingViscosity

The invention discloses a drilling and drilling completion method for the interior of a shale reservoir in drilling engineering. The method is characterized in that a low-viscosity drilling fluid is periodically fed in for a well in which the drilling speed is not obviously reduced after drilling is carried out in the shale reservoir, the occurrence possibility of a bit balling phenomenon is greatly decreased, and it is further ensured that the drilling pressure is effectively applied to a stratum; for a well in which the drilling speed is obviously reduced after drilling is carried out in theshale reservoir, the cleanness degree of the interior of a well shaft is greatly improved so that the increased drilling pressure can effectively act on the bottom of the well through a drill bit. According to the method, a high-cost drilling fluid system is not needed, and open-hole well sections of a shale bed section are fully trimmed and standardized only from the engineering aspect. The method solves the problems in the prior art that drilling is slowly conducted in the shale reservoir, the drilling speed is low, drill bits are difficult to pull out of or put into drilling holes after drilling, and the risk coefficients of lower casing pipes are high. The purposes of increasing the drilling speed in the shale reservoir, improving the engineering efficiency, reducing operation risks and increasing the safety coefficient of the lower casing pipes are achieved.

Owner:滦平县伟源矿业有限责任公司

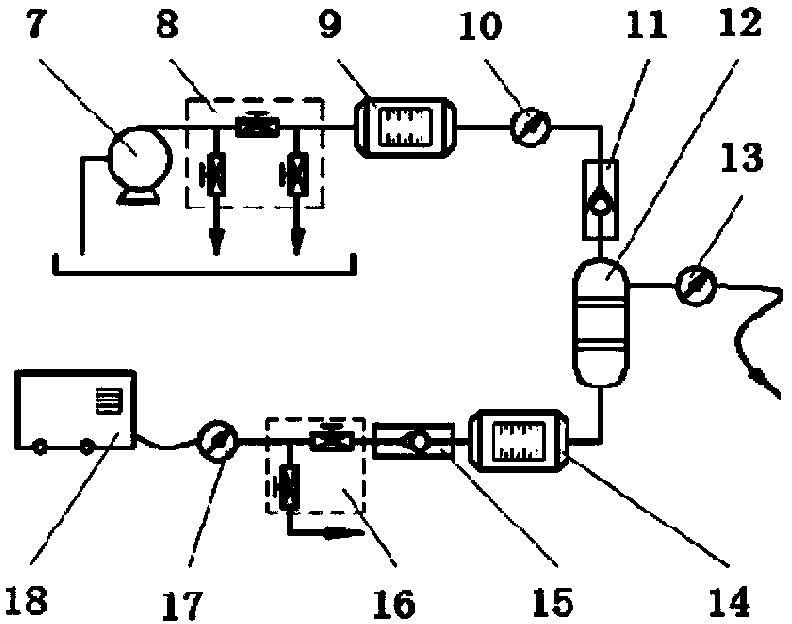

Method and device for constructing bedding gas extraction long drilled holes of soft coal seams

ActiveCN103452508ASafe and fast drillingOvercoming the Insufficiency of the Drilling TechnologyFlushingCooling effectEngineering

The invention discloses a method and a device for constricting bedding gas extraction long drilled holes of soft coal seams. The method and the device are applied to drilling the bedding gas extraction long drilled holes of the soft coal seams, and are characterized in that two types of gas-based fluid including compressed air and stable foams are used as drilled hole washing media, are alternately injected into a drilled hole, reach the bottom of the hole, then flow into annular clearance via flow channels in a drill bit, cool the drill bit and carry coal cinder dust which is generated along with drilling actions of the drill bit at the bottom of the hole, then the drilled hole washing media and the coal cinder dust return the outside of the hole, stable foam flow carries the coal cinder dust, and cools and lubricates drilling tools, and compressed air flow washes the bottom of the hole and pushes stable foam slug to flow. The method and the device have the advantages that the cinder discharge capacity is high, a drilling tool cooling effect is good, orifices are free of dust pollution, the rotation pressure of a drilling machine can be obviously reduced while the drilling capacity of the drilling machine is improved, and the drilling machine can normally drill holes in water-containing coal seams; the flow rates of gas and liquid are regulated under the control of special valve blocks by the aid of the method and the device, the device can be operated easily and conveniently, is small in size and is light, the method and the device are applicable to underground drilling construction operation environments of coal mines, and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

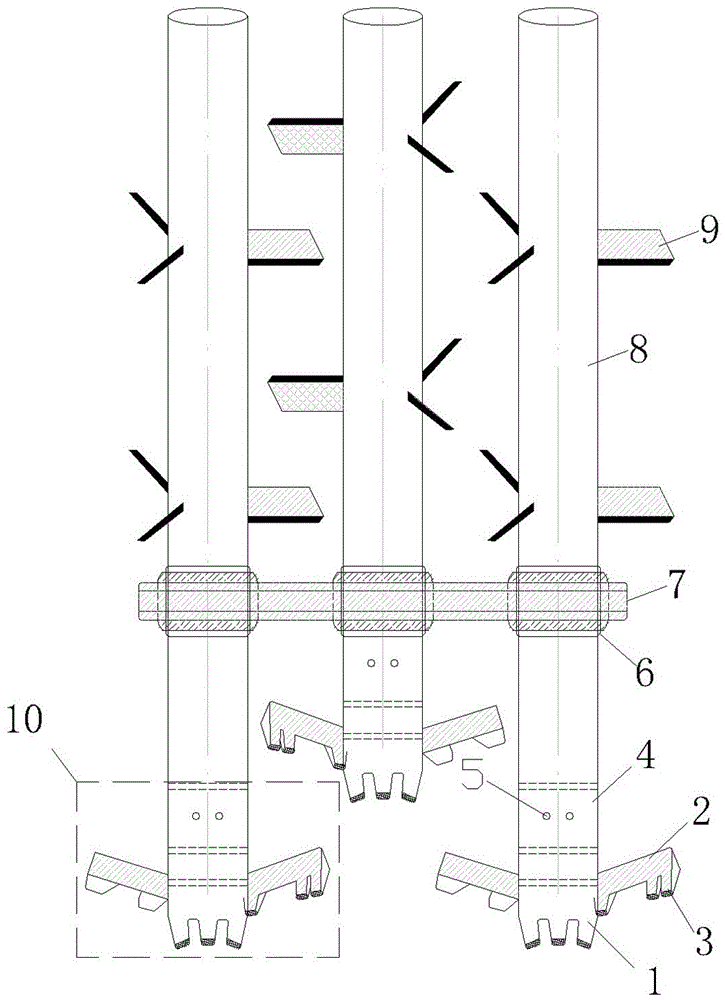

Cobble stratum super three-axis agitation stake and stirring method thereof

The invention belongs to the field of building pile foundation engineering construction, and particularly relates to a cobble stratum super three-axis agitation stake. The cobble stratum super three-axis agitation stake comprises three drill rods, a drill bit component fixed to the bottom of the drill rods, and a blade component connected to the drill rods, wherein the drill bit component is connected with a stepless speed change power head through the drill rods, and the drill rods are connected to a pile frame through a supporting frame; the drill bit component comprises a drill collar connected to the drill rods, a drilling rig connected to the drill collar, and a hollow drill bit, and three to four alloy tool bits are fixed to the drilling rig; the blade component comprises multiple sets of blades connected to the drill rods, and the blades are cutter type blades. The drilling bit component transmits the rotation moment of the power head through the drill rods and conducts drilling into soil mass, drilling capacity is high, abrasion of the drilling rig is small, and efficient construction of the three-axis agitation stake in hard stratums including cobble stratum is achieved; furthermore, pollution can not be caused during construction, construction site is clean and tidy, noise is low, mud recovery and treatment are not needed, and an environment-friendly construction technology is realized.

Owner:ZHEJIANG GEOFORE GEOTECHN TECH

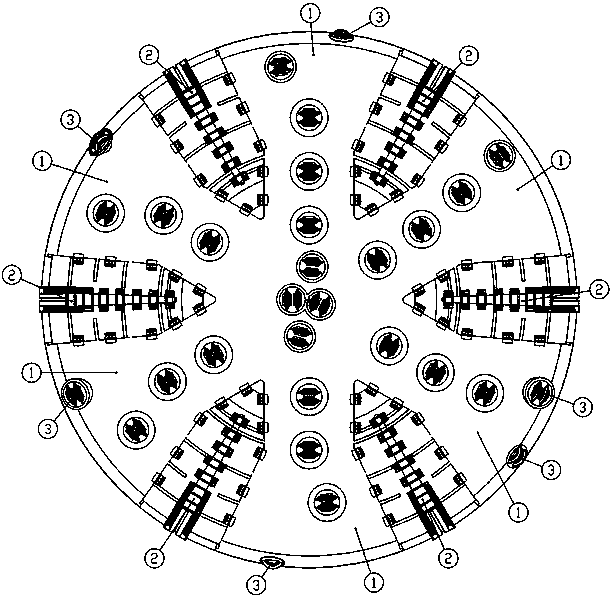

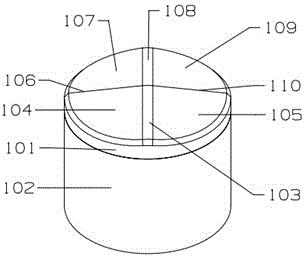

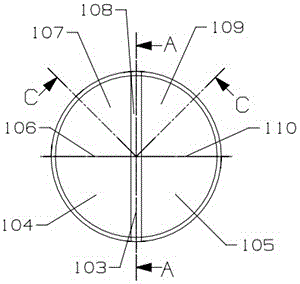

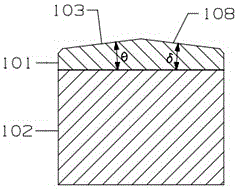

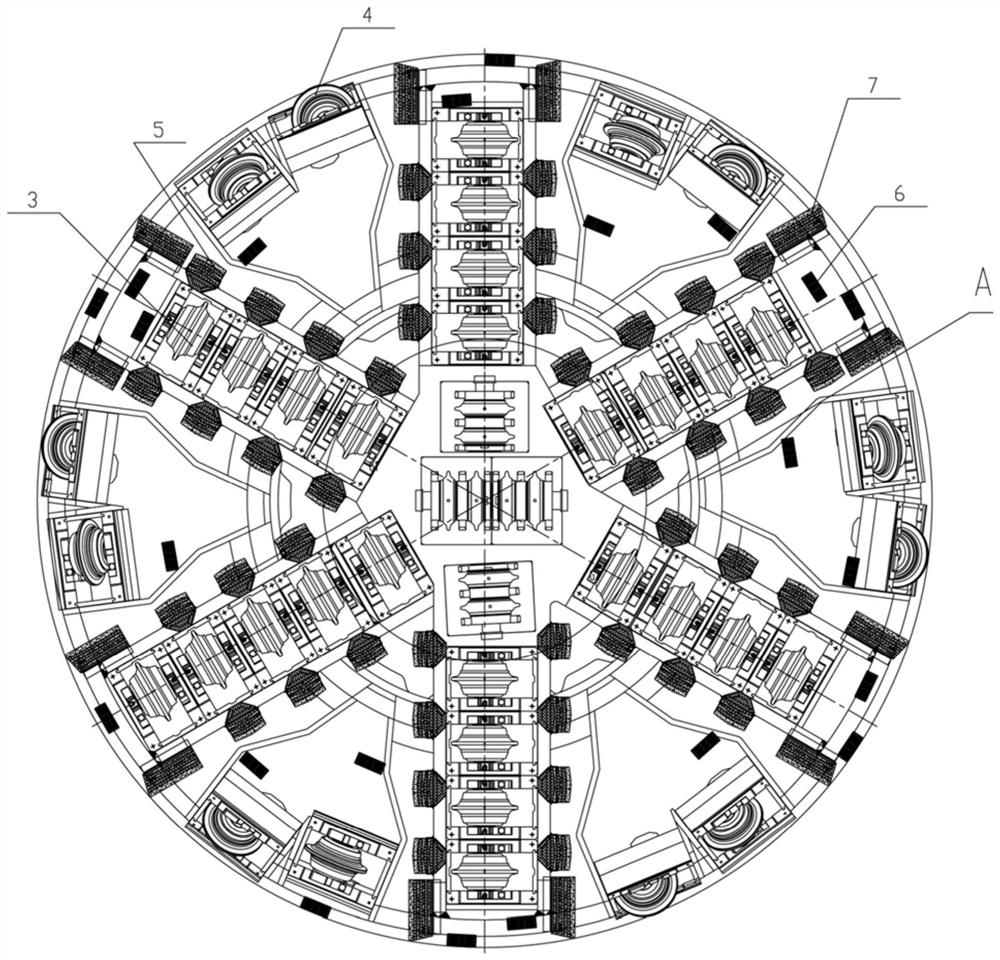

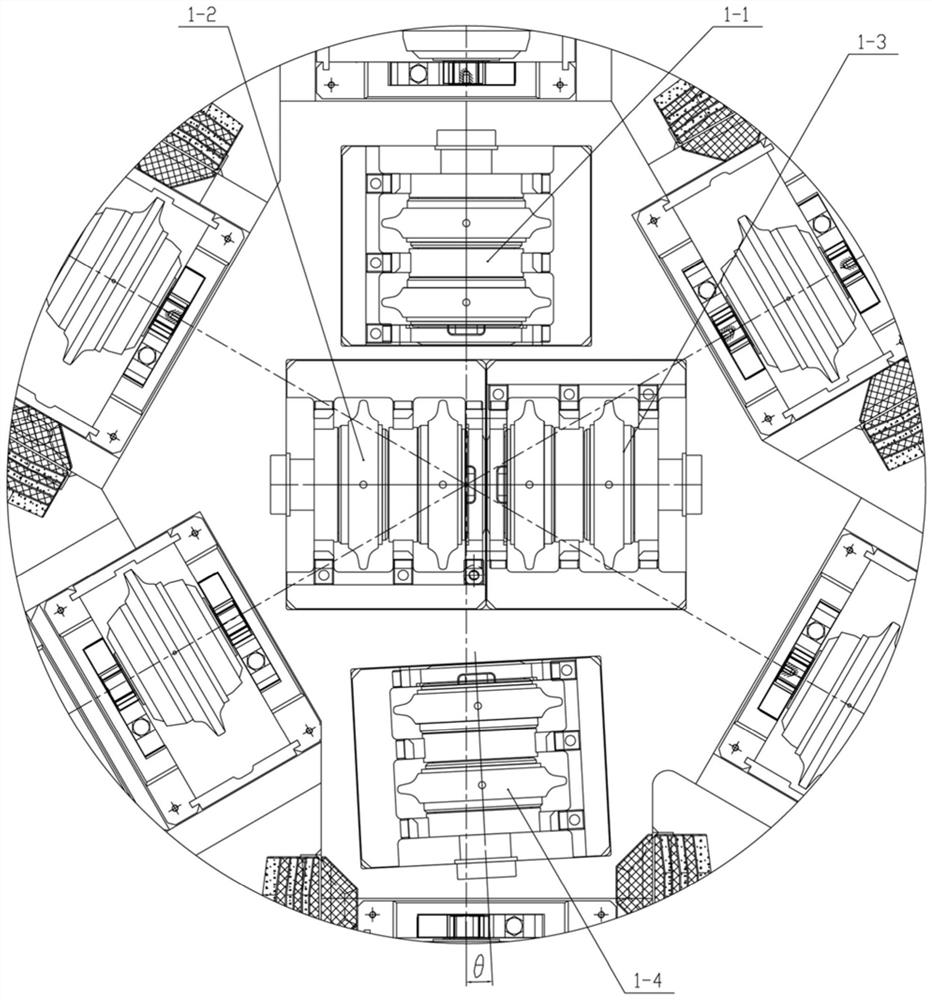

Six-main-beam cutterhead center hob mounting structure and six-main-beam cutterhead

PendingCN111663949AImprove tunneling efficiencyImprove drilling abilityTunnelsEngineeringStructural engineering

The invention relates to the technical field of engineering equipment special for tunnels, in particular to a six-main-beam cutterhead center hob mounting structure. The six-main-beam cutterhead center hob mounting structure comprises a cutterhead, a center hob set is arranged in the center of the front end face of the cutterhead, the center hob set comprises a first hob module, a second hob module, a third hob module and a fourth hob module, the four hob modules are in a cross shape, the hob axis of the fourth hob module deflects towards one side by an angle theta to provide arrangement spacefor a front face hob set, the arrangement number of front face hobs is increased, the hob size of the front hob set is larger than the hob size of the center hob set; and a six-main-beam cutterhead comprises the six-main-beam cutterhead center hob mounting structure. According to the six-main-beam cutterhead center hob mounting structure, the arrangement number of the front face hobs can be increased, and due to the fact that the front face hobs are larger in size and higher in bearing capacity and rock breaking capacity, the rock breaking capacity and the bearing capacity of a center area ofthe cutterhead are enhanced, and then the tunneling efficiency and the tunneling capacity of the cutterhead are improved.

Owner:中铁工程装备集团盾构制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com