Drill bit suitable for hard sandy soil

A drill bit and soil texture technology, applied in drill bits, earthwork drilling, drilling equipment, etc., can solve problems affecting the construction quality, wear, warping and deformation of underground diaphragm walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

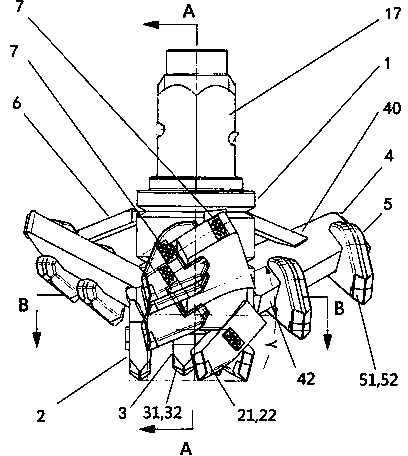

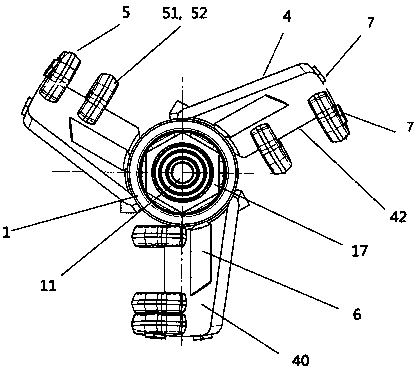

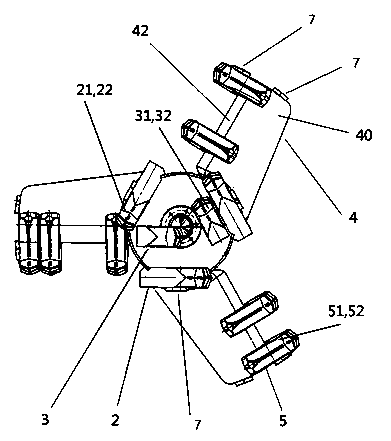

[0035] like Figure 1-7 As shown, a hard sandy soil drill bit includes: a drill bit center assembly, including a drill bit body 1, a grouting pipe 11 arranged in the drill bit body 1 or on the drill bit body 1, a screw plug 12, a stopper 14 and a joint 17; Lower cutter body 2 includes lower cutter head 21 and lower cutter handle 22; inner cutter body (3) includes inner cutter head 31 and inner cutter handle 32; outer cutter body 5 includes outer cutter head 51 and outer cutter handle 52; blade 4, Including blade surface 40 and lower edge 42; several support plates 6 and a plurality of wear plates 7; wherein: the lower part of the grouting pipe 11 in the drill bit body 1 is provided with uniformly distributed or symmetrically arranged circumferentially along its radial direction and The horizontal pipe 112 connected with the grouting pipe (11) has a screw plug 12 installed at its end; the stopper 14 is installed in the sinkhole of the grouting pipe 11 on the lower end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com