Drilling and drilling completion method for interior of shale reservoir in drilling engineering

A technology for shale reservoirs and drilling engineering, which is applied to drilling equipment and methods, drilling equipment, drill bits, etc., and can solve the problems of slow drilling time, high risk of casing running, and difficulty in tripping and running after drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

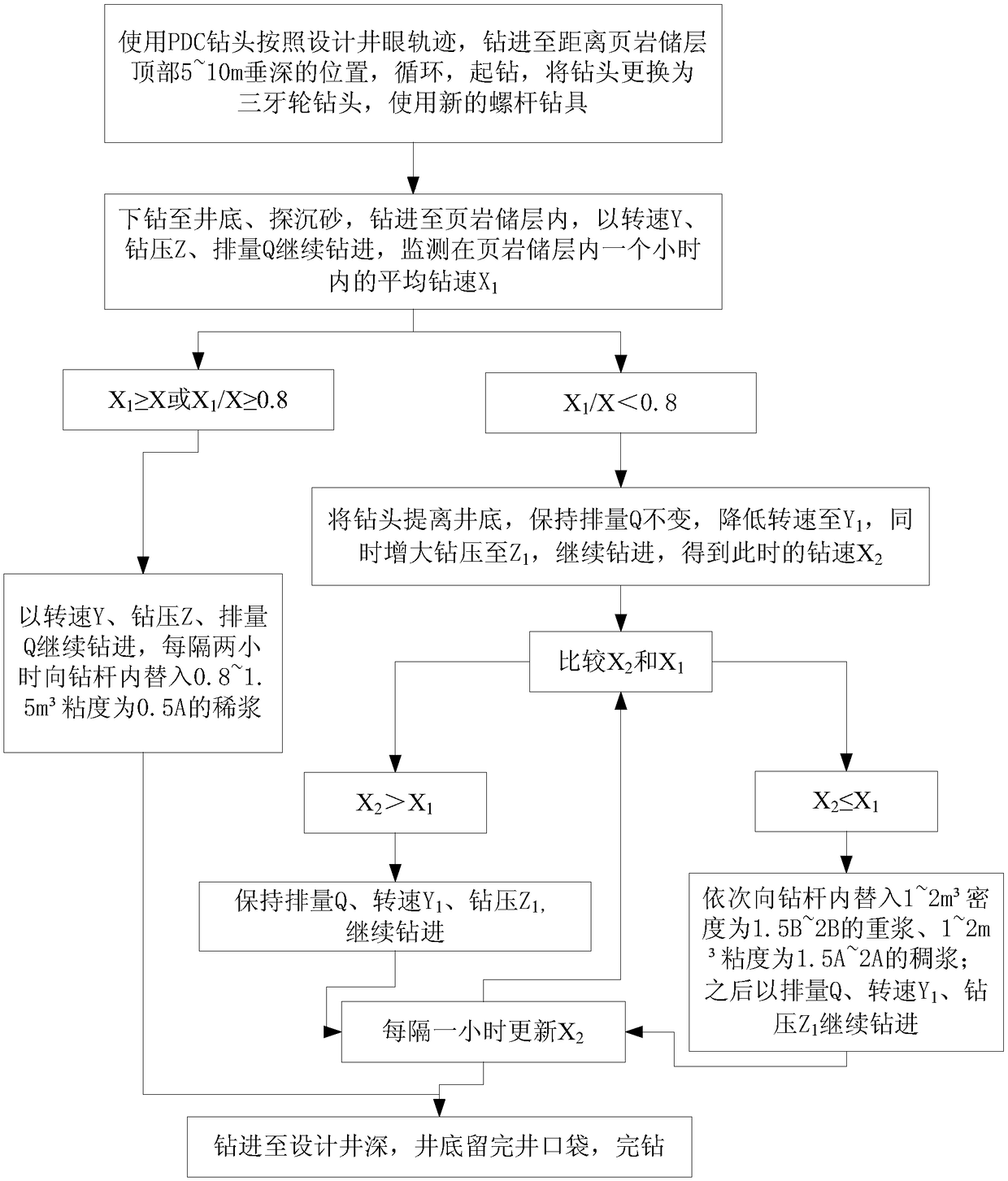

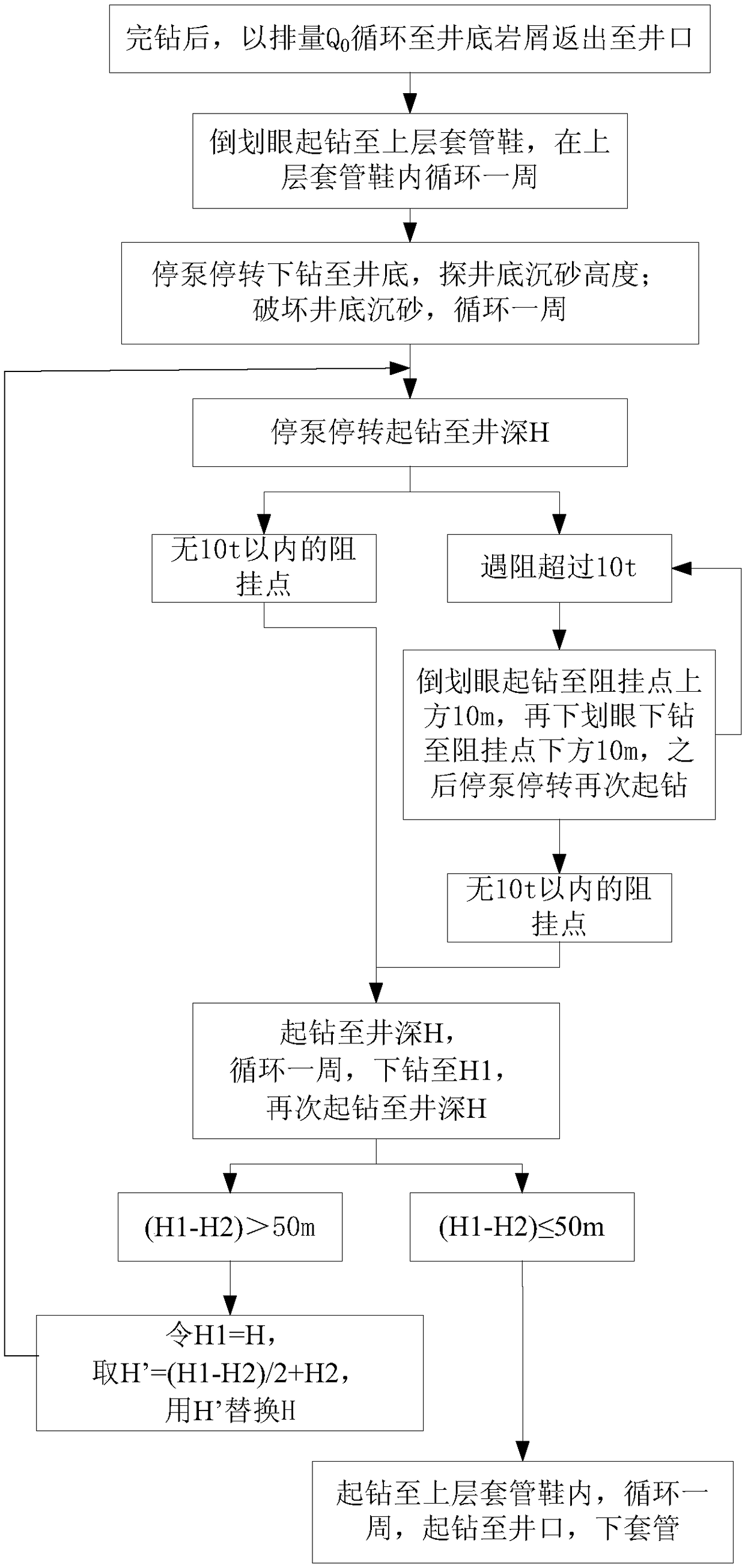

[0044] Such as figure 1 and figure 2 The drilling and completion methods in the shale reservoir in the shown drilling engineering, including the drilling process and the drilling completion process;

[0045] The drilling process includes:

[0046] (a) Use the PDC bit to drill to a vertical depth of 5-10m from the top of the shale reservoir according to the designed wellbore trajectory. During the drilling process, the viscosity of the drilling fluid is A, in centipoise; the density is B, in g / cm 3 ;Statistics The average drilling speed in the last 24 hours during the drilling process is X, the unit is m / h; the average speed of the drill pipe is Y, the unit is rpm; the average drilling pressure is Z, the unit is ton; the average displacement is Q, the unit is L / min Circulation, tripping out, changing the drill bit into a tricone bit equal to the PDC drill bit, and using a new screw drilling tool in the bottom hole assembly; (b) going down to the bottom of the well, explori...

Embodiment 2

[0052] Such as figure 1 and figure 2 The drilling and completion method in the shale reservoir in the shown drilling engineering, on the basis of Example 1, the displacement when replacing the heavy slurry and thick slurry in step (d) is Q', and the Q ' / Q=0.6~0.7; after the thick slurry is completely returned from the wellhead, increase the displacement to Q again. The displacement when replacing the slurry in step (b) is Q", said Q" / Q=1.2~1.4; after the slurry is completely returned from the wellhead, reduce the displacement to Q again. The slurry returns from the wellhead, and after the cuttings are screened out by the vibrating screen, it no longer enters the drilling fluid circulation pool. In step (b), when judging from the number of pump strokes that the slurry is coming out of the drill bit, the rotation speed of the drilling tool is increased; after the slurry returns from the wellhead, the rotation speed is adjusted to Y. Displacement Q 0 The annulus return veloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com