Method and device for constructing bedding gas extraction long drilled holes of soft coal seams

A technology for gas drainage and soft coal seams, which is applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the hidden danger of gas explosion in holes with poor cooling capacity of pure air, which is not conducive to the stability of soft coal seam hole walls, The problem of high velocity of the surrounding air flow can avoid the dust pollution of the orifice, improve the working environment of the underground construction, and reduce the construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

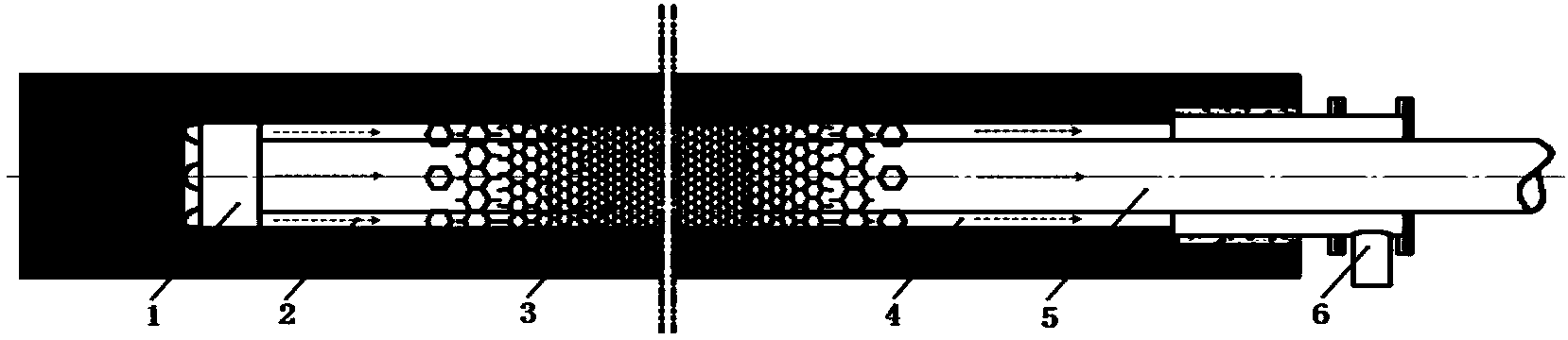

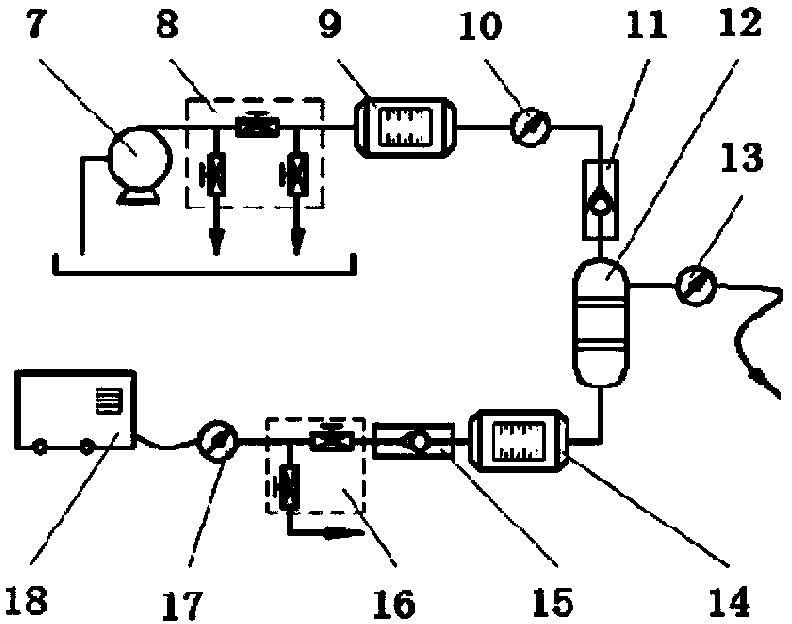

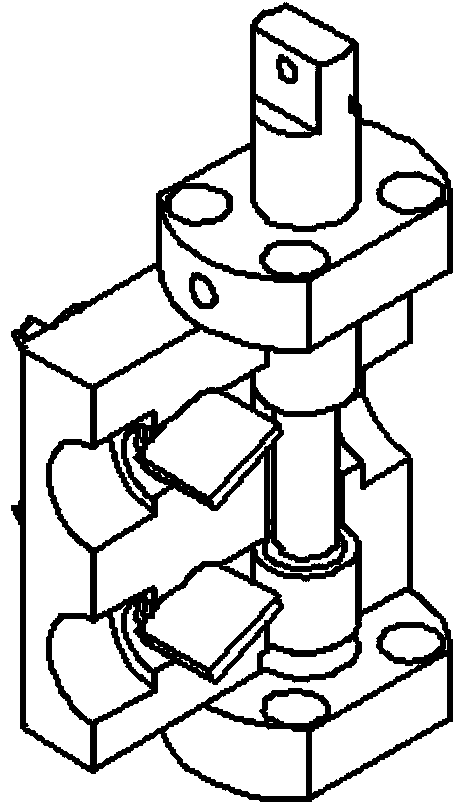

[0040] see figure 1, shows a schematic diagram of the application of the long borehole construction method for bedding gas drainage in soft coal seams of the present invention, which is applied to long borehole drilling equipment for bedding gas drainage in soft coal seams, and the drilling equipment includes a drill bit 1, a drill The rod string 5 is provided with a hole sealer 6 on the drill rod string 5, and the hole sealer 6 seals the hole when drilling.

[0041] The inventors of the present invention have found that the use of foam flow can better cool the drill bit 1, and has less damage to the soft coal seam, ensuring the safety of the drilling process. To drive the effect, avoid cinders to block the drill hole; and in order to ensure the advantages of compressed air in the drill hole at the same time, the inventor of the present invention creatively proposed the following construction method:

[0042] When drilling, the construction method of the present invention use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com