Pressure response type consolidation plugging agent as well as preparation method and application thereof

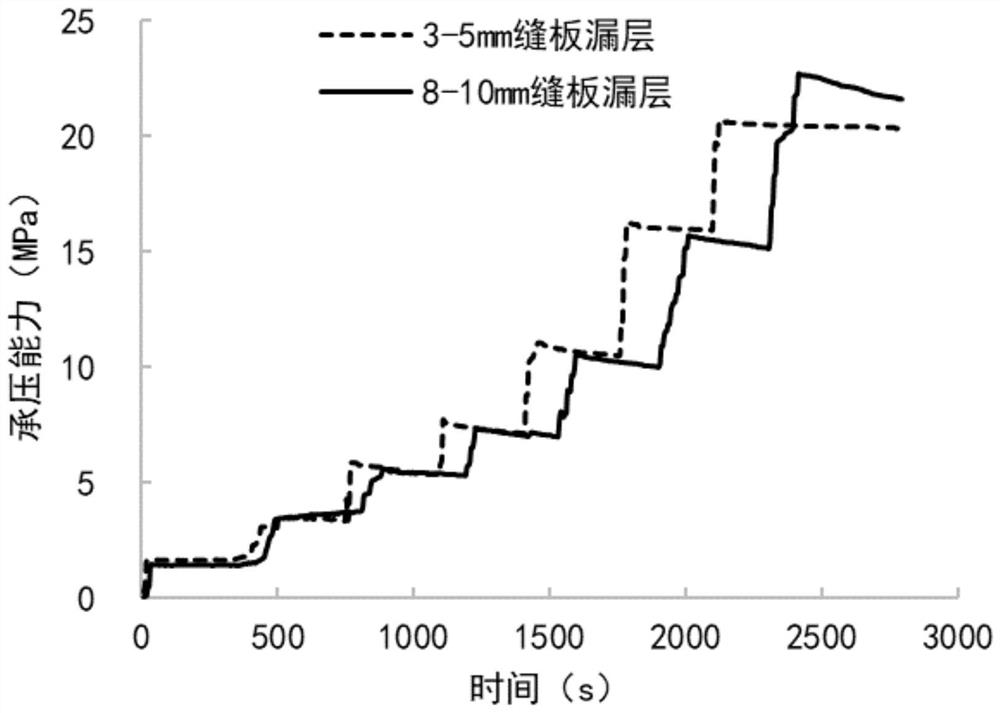

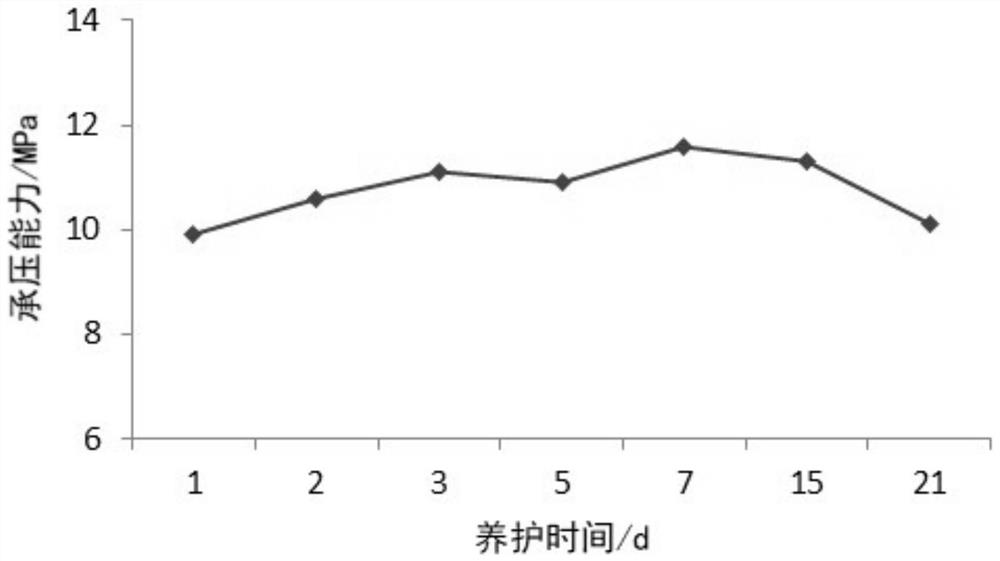

A kind of lost circulation agent and pressure technology, applied in the field of lost circulation agent, can solve the problems of insufficient adaptability of fractured leakage layers, low pressure bearing capacity, low leakage blocking success rate, etc., to achieve rapid response to environmental pressure changes, reduce drilling Cost, effect of safe and fast drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

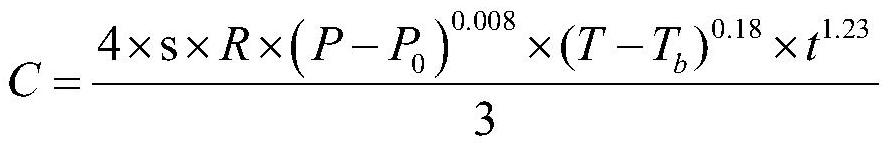

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a leakage blocking agent, and the preparation method of the leakage blocking agent is as follows:

[0044] 1. Add 130g / L of anhydrous calcium sulfoaluminate to the calcium sulfate aqueous solution with a mass concentration of 3% and then add 30ml / L of 99.5% absolute ethanol, react in a constant temperature water bath at 60°C for 30 minutes to obtain pretreatment Anhydrous calcium sulfoaluminate;

[0045] 2. Preprocess the dicalcium silicate according to the method and parameters of step 1 to obtain pretreated dicalcium silicate;

[0046] 3. In parts by weight, combine 15 parts of pretreated anhydrous calcium sulfoaluminate (200 mesh), 15 parts of pretreated dicalcium silicate, 30 parts of diatomaceous earth, 30 parts of ceramic fibers, 4 parts of polymer Acrylamide, 1 part of polyvinyl butyral, and 3 parts of sodium pyrophosphate are mixed in a mixer, then add water and stir evenly, then add 0.1 part of ferric chloride, and stir and reac...

Embodiment 2

[0048] The present embodiment provides a leakage blocking agent, and the preparation method of the leakage blocking agent is as follows:

[0049] 1, calcium sulfoaluminate and nano calcium carbonate are respectively pretreated according to the method of step 1 in embodiment 1;

[0050] 2. In parts by weight, 10 parts of pretreated anhydrous calcium sulfoaluminate (200 mesh), 20 parts of pretreated nano calcium carbonate, 40 parts of ultrafine perlite (particle size less than 100 μm), 40 parts of Ceramic fiber, 2 parts of magnesium aluminum silicate, 1.2 parts of polyvinyl butyral, and 3 parts of sodium pyrophosphate are mixed in a mixer, then add water and stir evenly, then add 0.18 parts of ferric chloride, and stir at room temperature for 1 hour. Formulated to obtain a density of 1.60g / cm 3 The leakage plugging slurry is in the form of an aqueous solution of a leakage plugging agent.

Embodiment 3

[0052] The present embodiment provides a leakage blocking agent, and the preparation method of the leakage blocking agent is as follows:

[0053] 1. Calcium sulfoaluminate and dicalcium silicate are respectively pretreated according to the method of step 1 in Example 1;

[0054] 2. In parts by weight, combine 10 parts of pretreated anhydrous calcium sulfoaluminate (200 mesh), 20 parts of pretreated dicalcium silicate, 40 parts of diatomaceous earth, 30 parts of ceramic fibers, 3 parts of polymer Acrylamide, 1.8 parts of polyvinyl butyral, and 5 parts of boric acid are mixed in a mixer, then add water and stir evenly, then add 0.3 parts of ferric chloride, and stir and react at room temperature for 1 hour to obtain a density of 1.85g / cm 3 The leakage plugging slurry is in the form of an aqueous solution of a leakage plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com