Carbon fiber bicycle frame pull cap drilling equipment

A bicycle frame and drilling equipment technology, applied in drilling/drilling equipment, boring/drilling, metal processing equipment and other directions, can solve problems such as inconvenience, improve production efficiency, reasonable design, and safe drilling quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

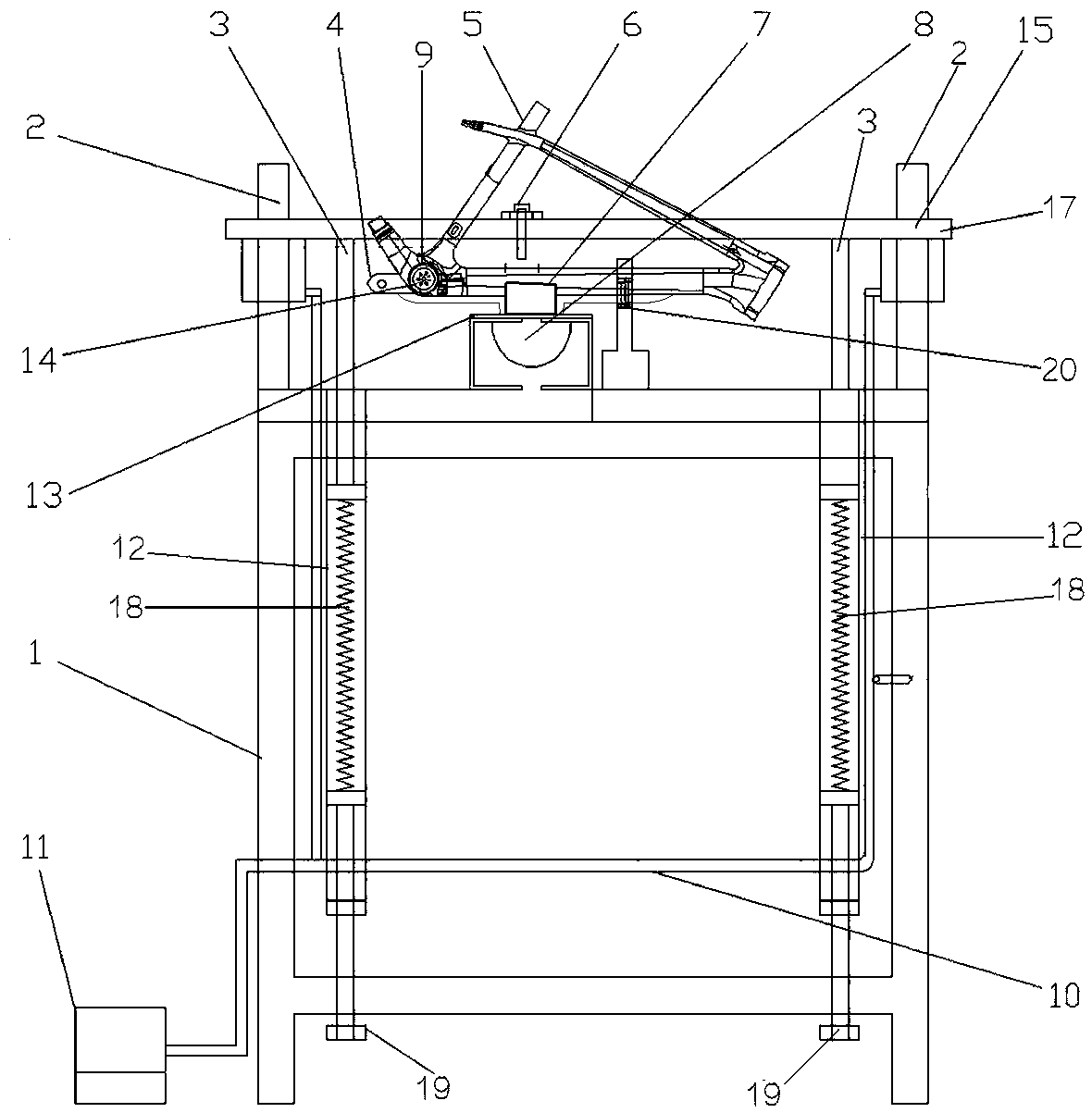

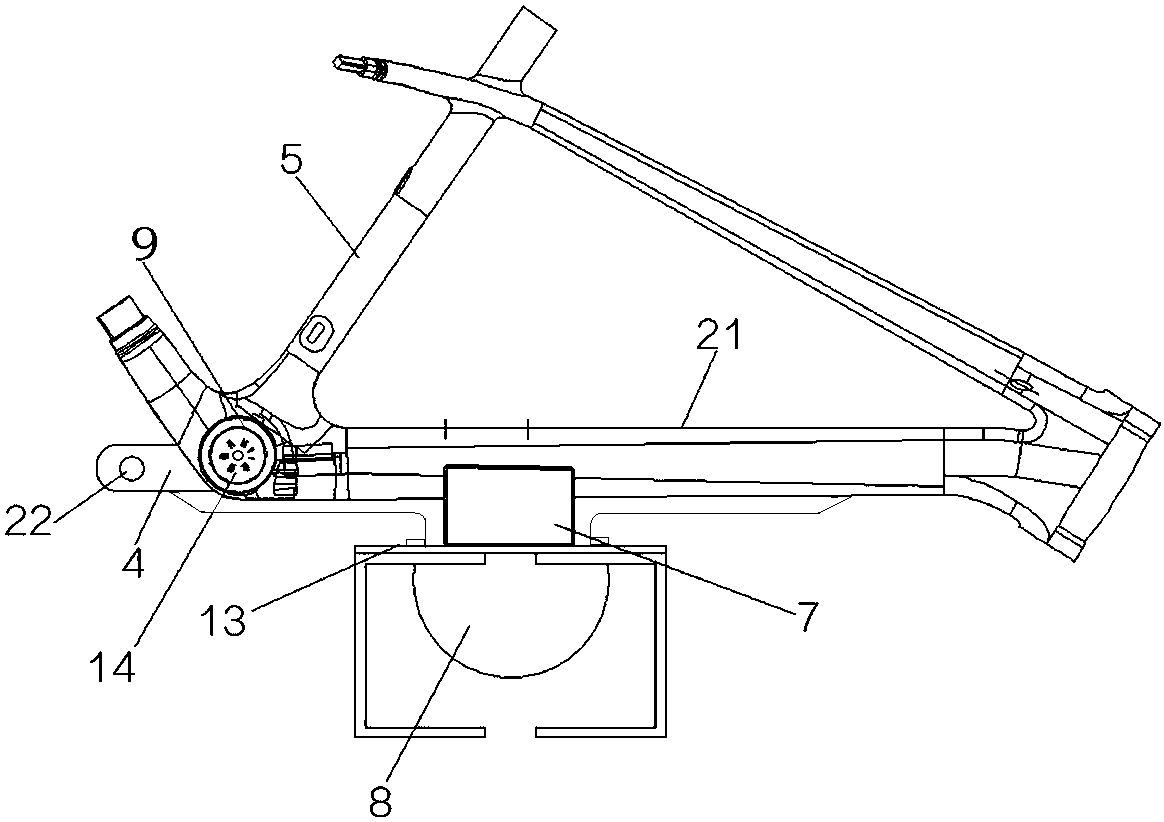

[0025] Refer to attached figure 1 , 2 , carbon fiber bicycle frame pull cap drilling equipment includes pull cap drilling chassis 1, workbench 17, pneumatic drill (pneumatic drill) 6, air pipe 10, pedal control air valve 11, drilling fixture 7, drilling fixture mounting plate 13. Drill and pull cap hole positioning crossbar 4, frame bottom bracket positioning pin 14, air pressure rod 2, drilling buffer device and air drill fixing rod 15.

[0026] Pull cap drilling cabinet 1 top is provided with workbench 17, is equipped with drilling fixture mounting plate 13 on the workbench 17, and drilling fixture 7 is installed on the drilling fixture mounting plate 13, is fastened by screw. The drilling jig 7 is provided with a circular arc slot for clamping the down tube 21 of the frame 5 .

[0027] Drill and pull the cap hole positioning crossbar 4 to be locked on the drilling jig fixing plate 13 by screws. Drill and pull the cap hole positioning cross bar 4 and be provided with vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com