Patents

Literature

65results about How to "Improve the quality of the wall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

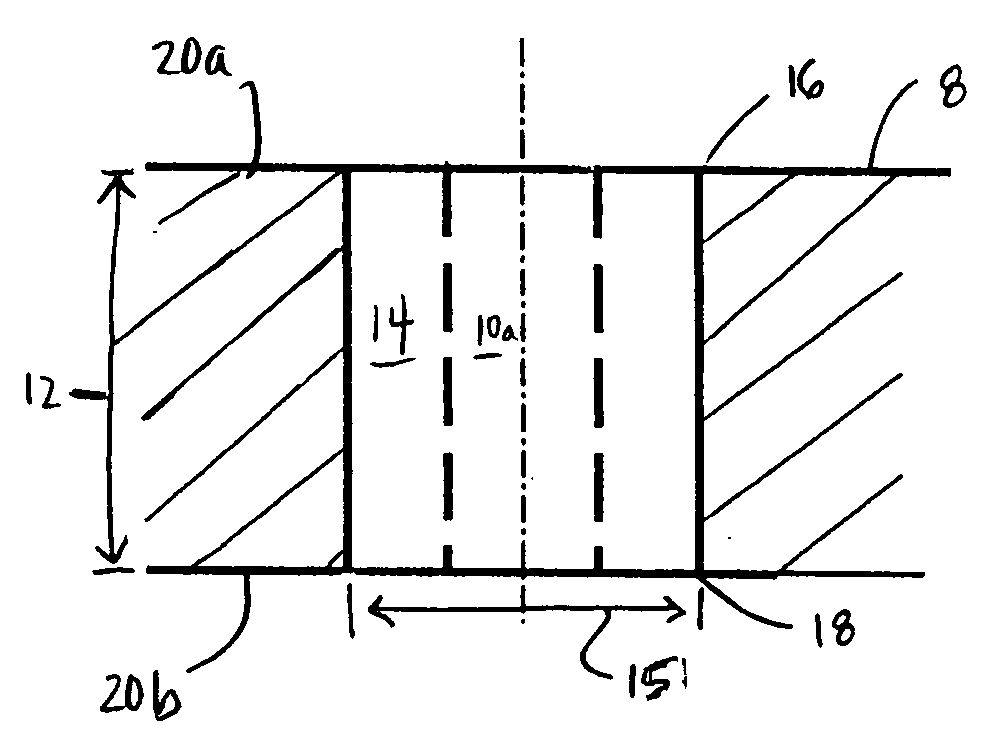

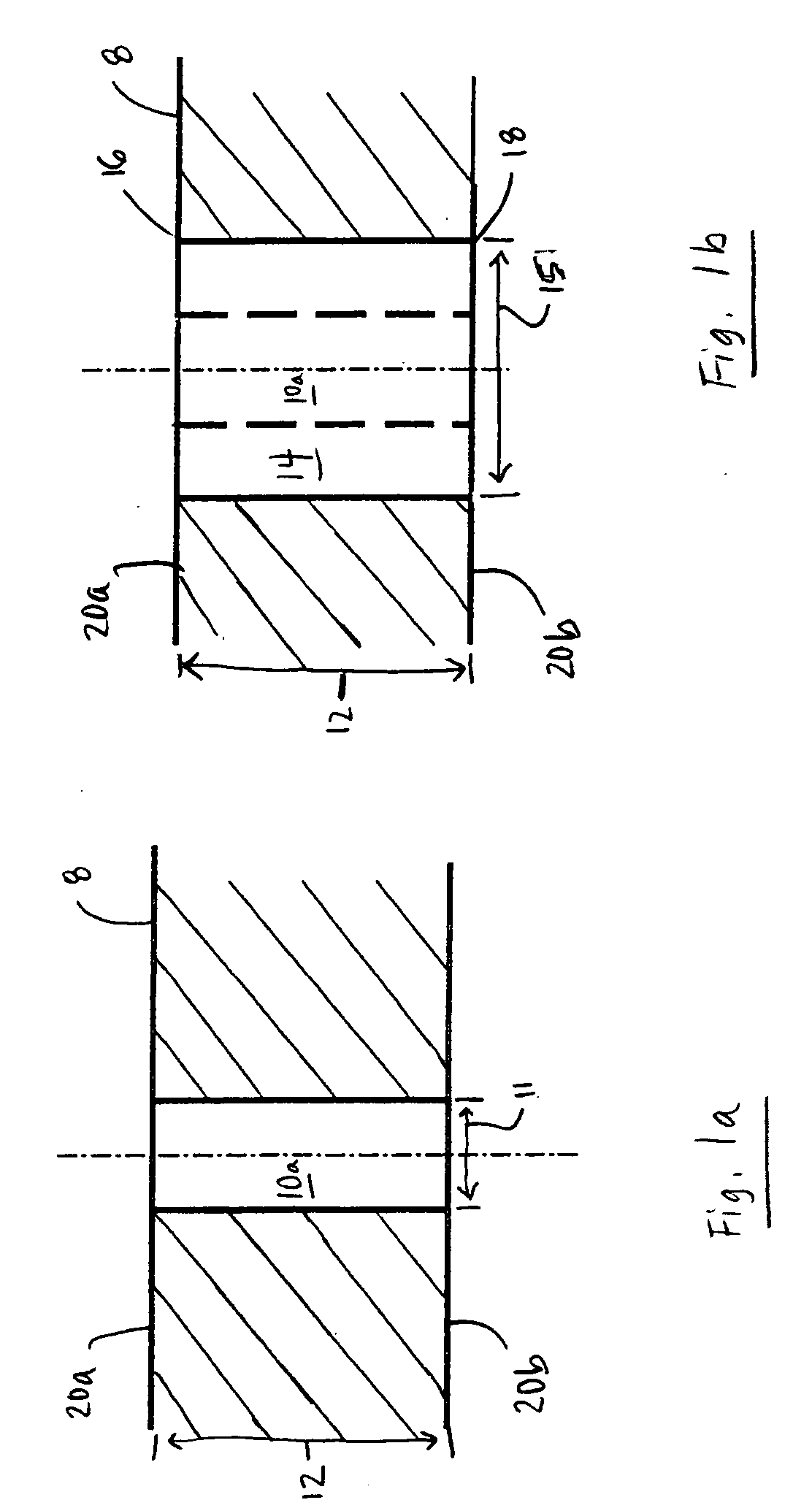

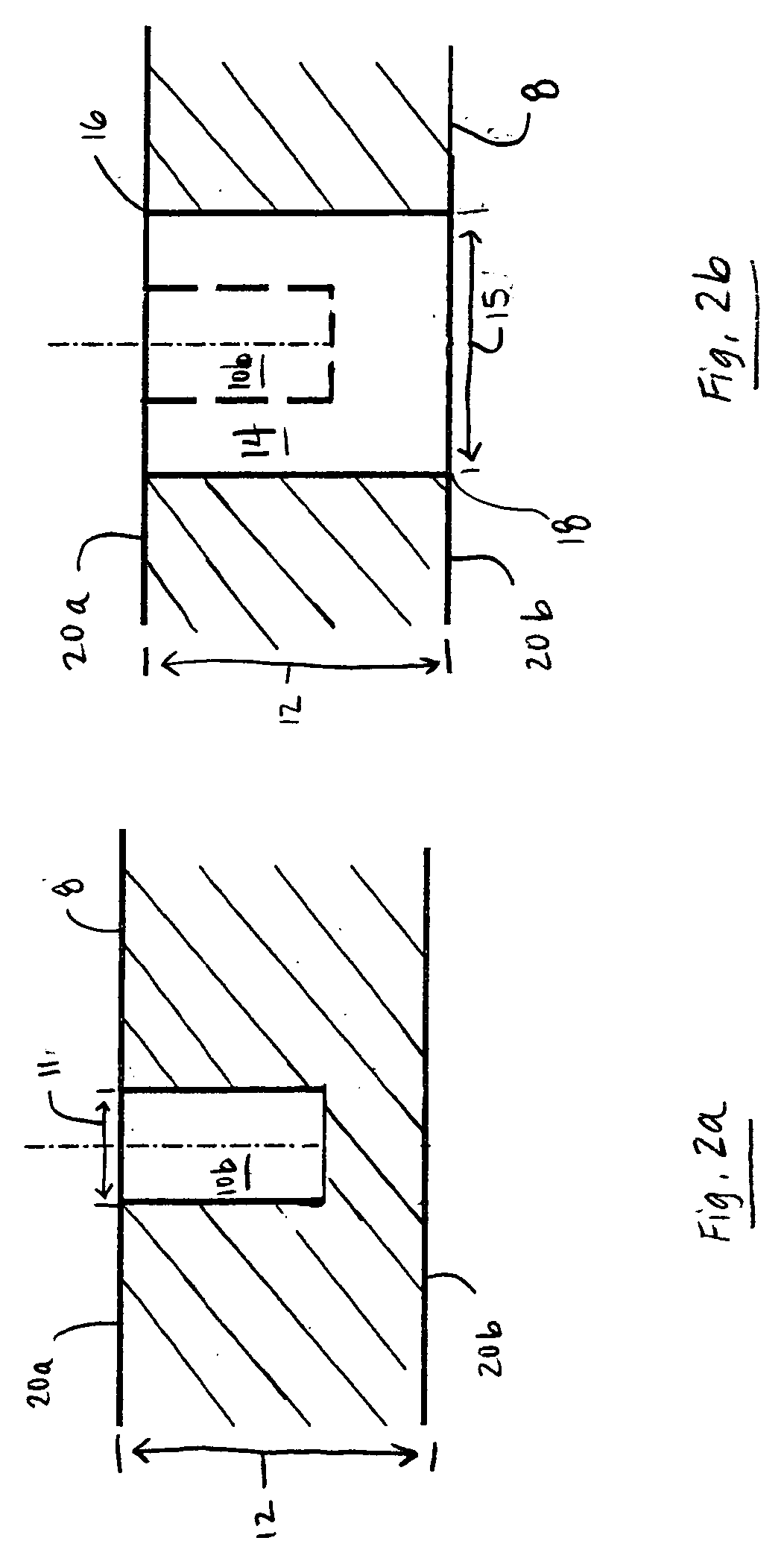

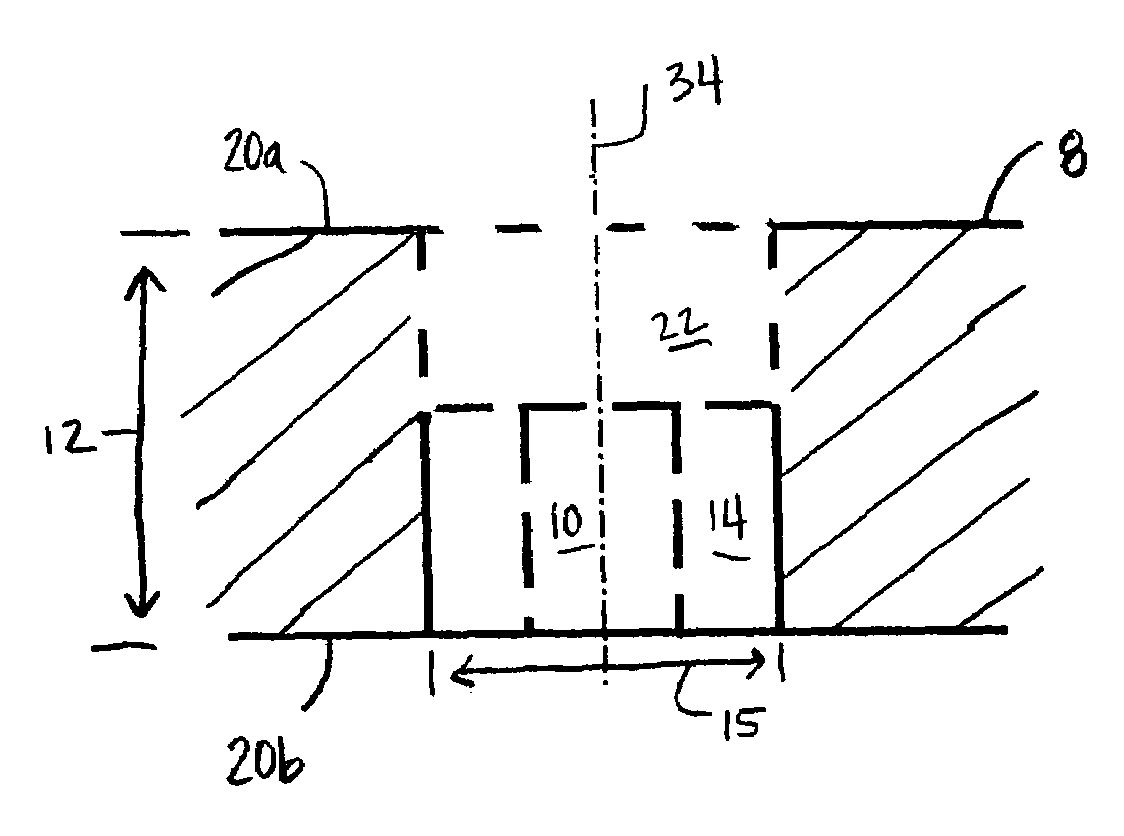

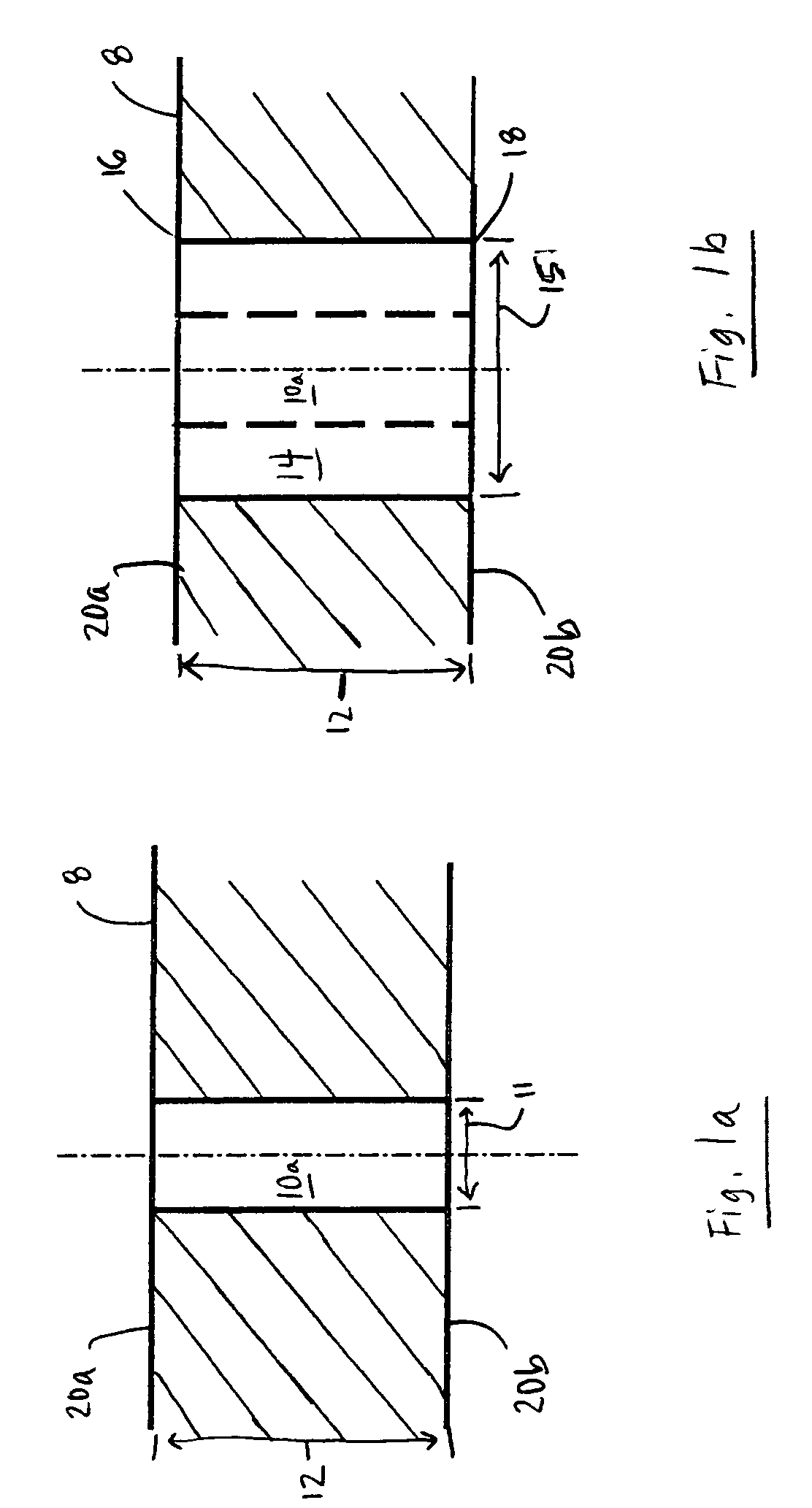

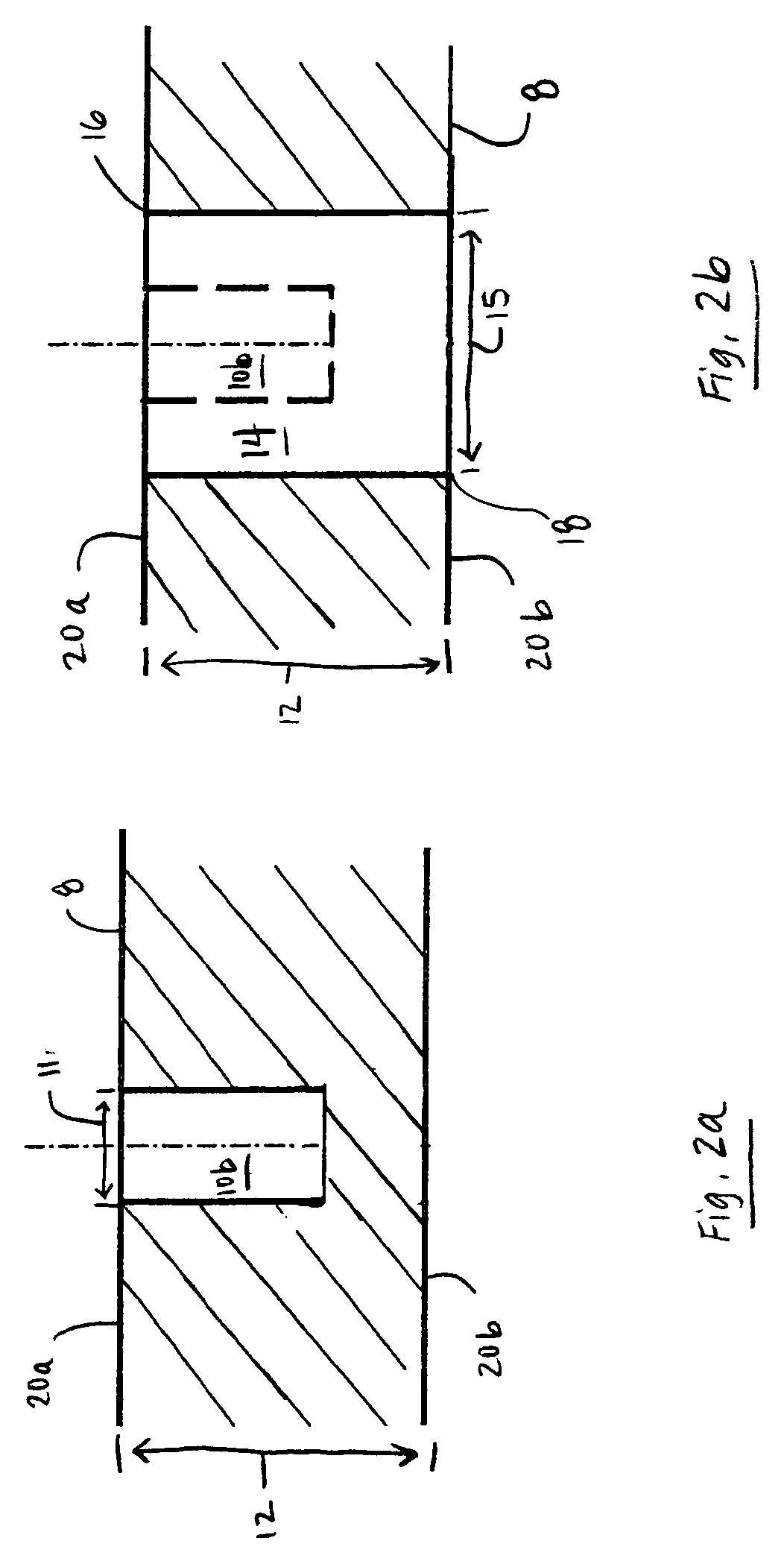

Methods of drilling through-holes in homogenous and non-homogeneous substrates

InactiveUS20050230365A1Minimum thermal damageImprove performanceSemiconductor/solid-state device detailsSolid-state devicesThermal energyPilot hole

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

Methods of drilling through-holes in homogenous and non-homogenous substrates

InactiveUS7057133B2Efficient and economicalMinimal damageSemiconductor/solid-state device detailsSolid-state devicesThermal energyHeat-affected zone

A differential diameter hole drilling method by which through-holes having improved major surface quality are formed in a target material involves drilling a pilot hole having a diameter that is less than the desired diameter of the through-hole and then drilling a through-hole having the desired diameter. The pilot hole forms a channel from which thermal energy produced during laser drilling can diffuse into the environment, thereby reducing the amount of thermal energy diffusing into the surrounding target material matrix and the degree of thermal damage to the heat affected zone of the target material matrix. The pilot hole also forms a channel through which ablated target material may be removed, thereby increasing overall through-hole throughput. Pilot hole formation reduces the thermal energy required to form the remaining portion of the through-hole and thereby results in less thermal damage to the surrounding target material matrix.

Owner:ELECTRO SCI IND INC

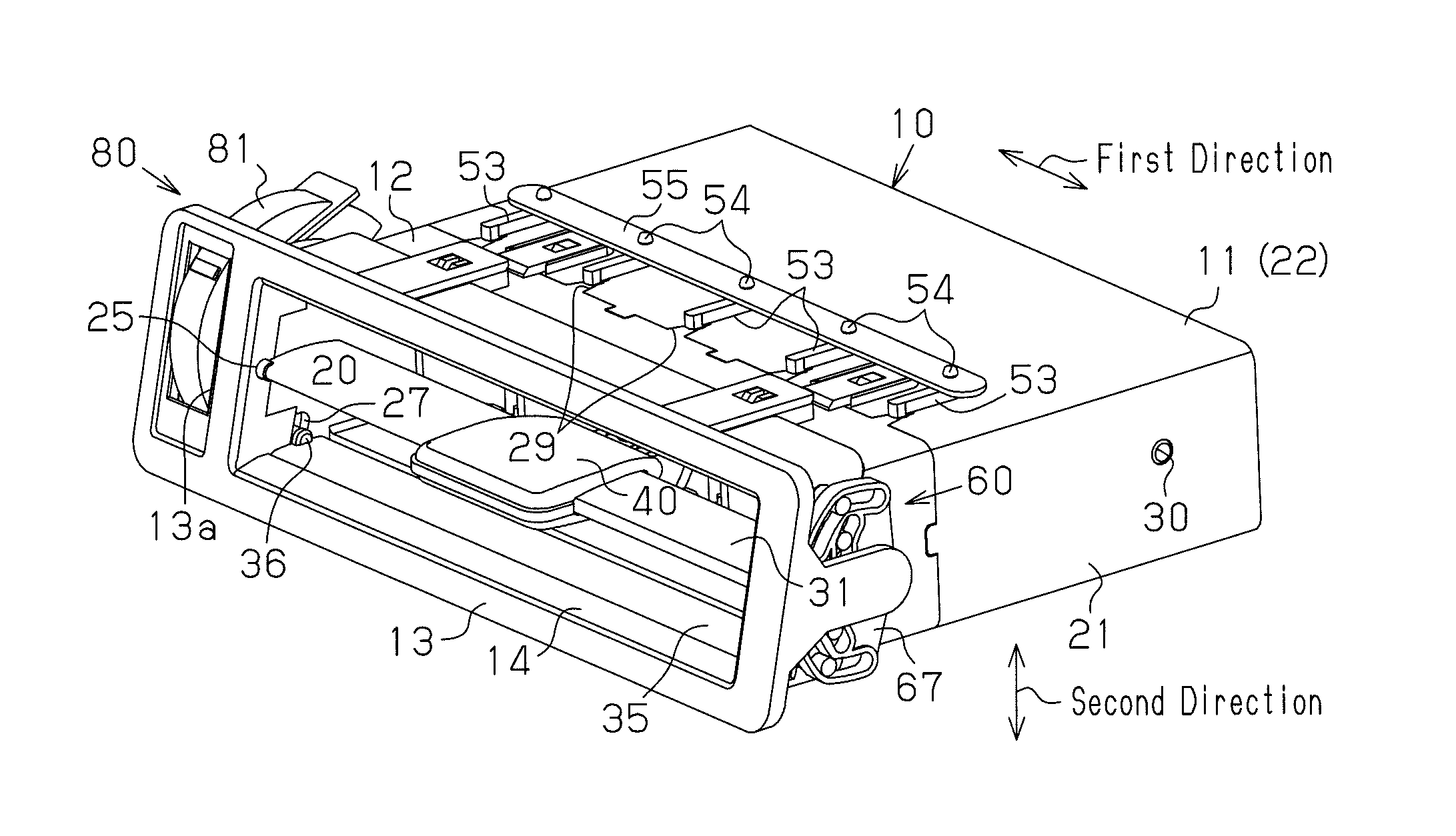

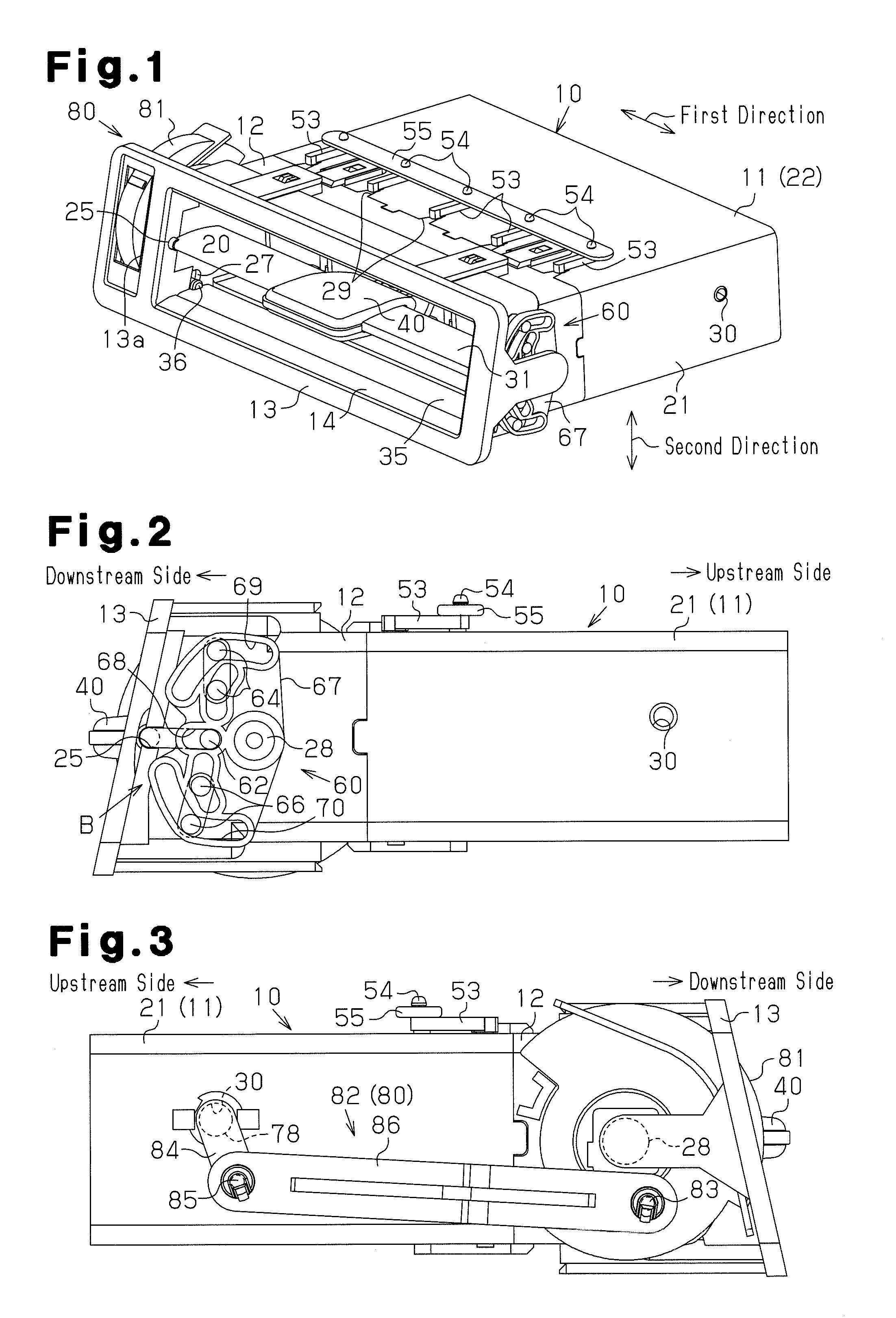

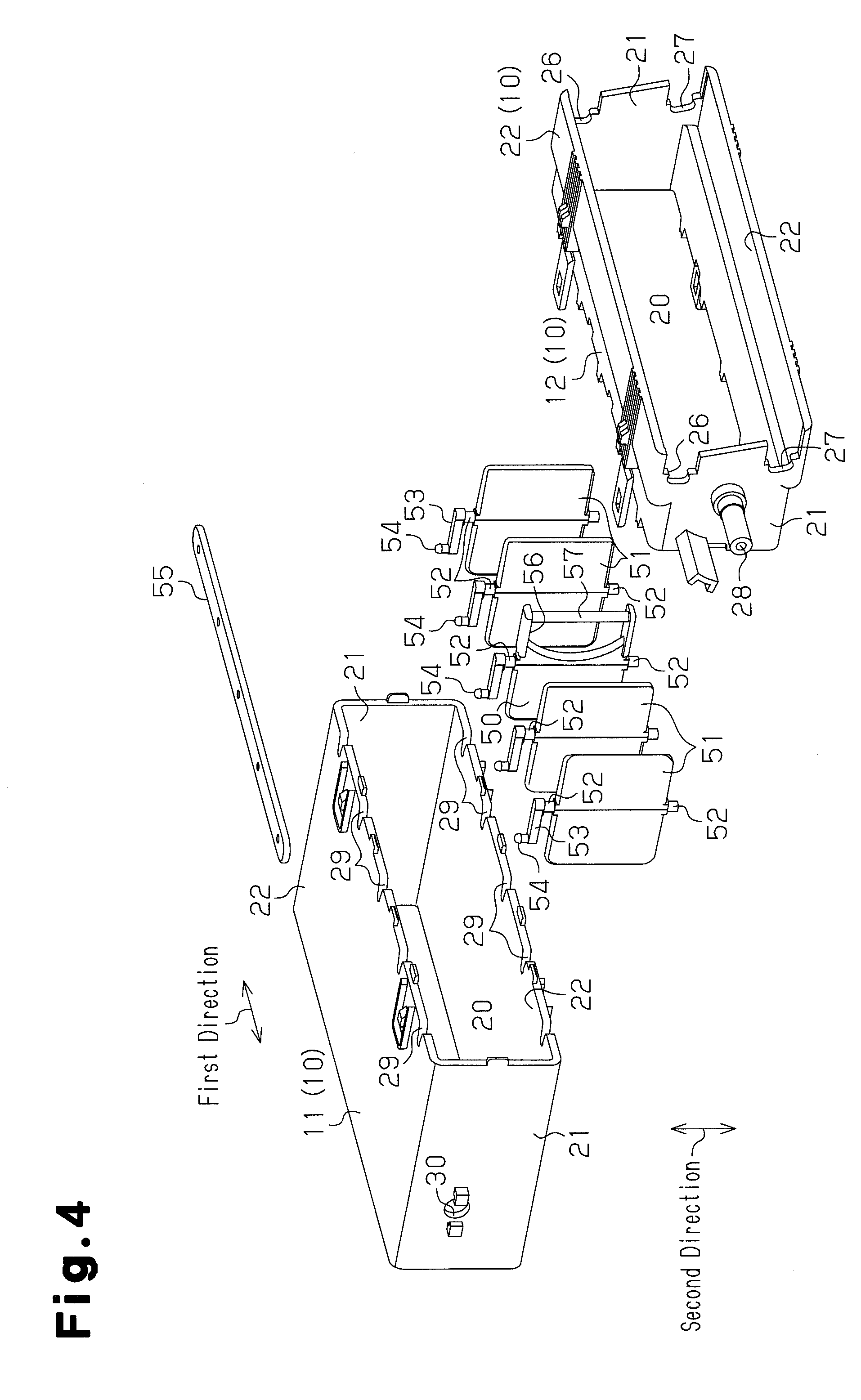

Register for air conditioning

ActiveUS9555692B2Suppress interferenceImprove the quality of the wallAir-treating devicesVehicle heating/cooling devicesDrive shaftEngineering

Owner:TOYODA GOSEI CO LTD

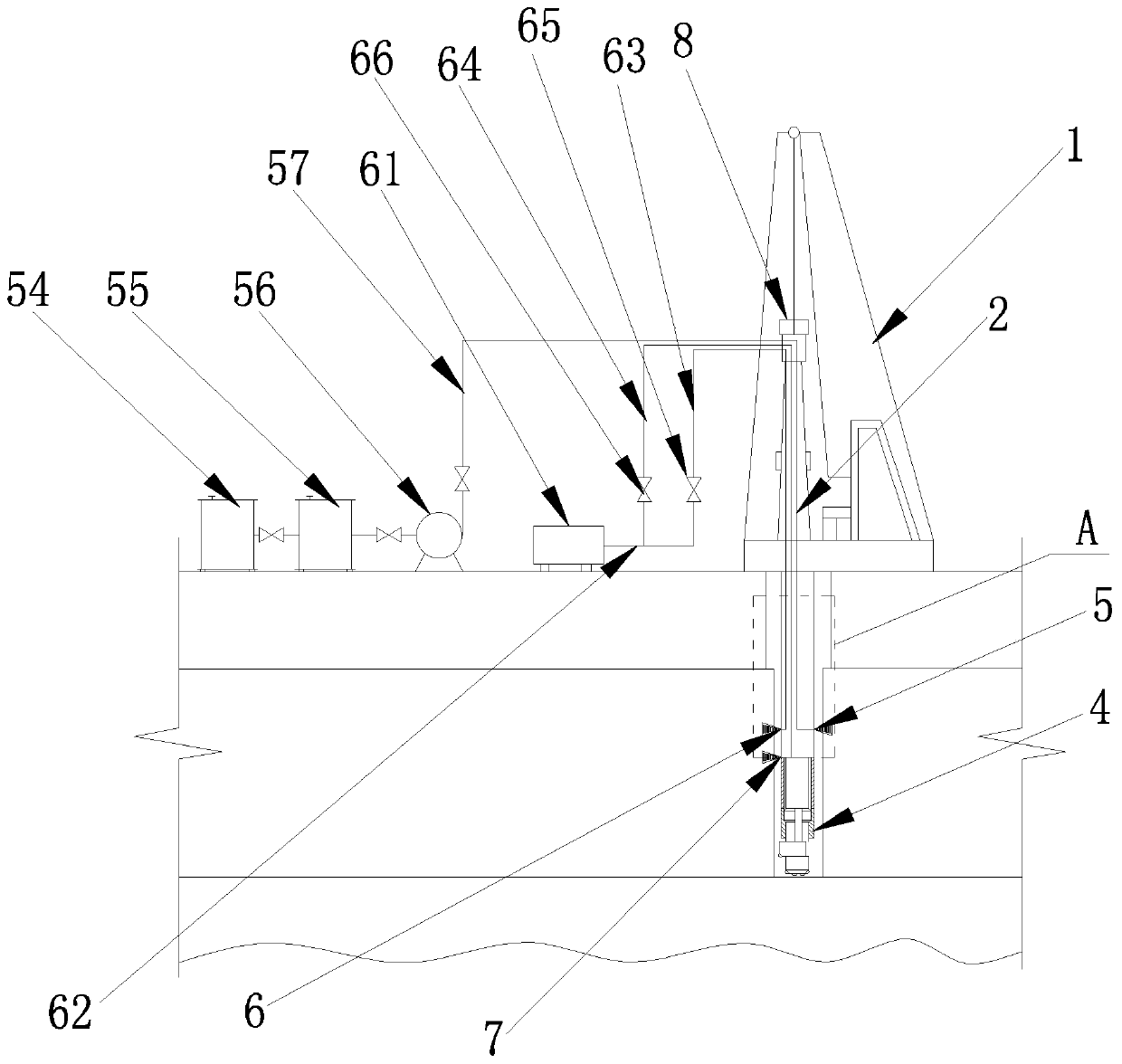

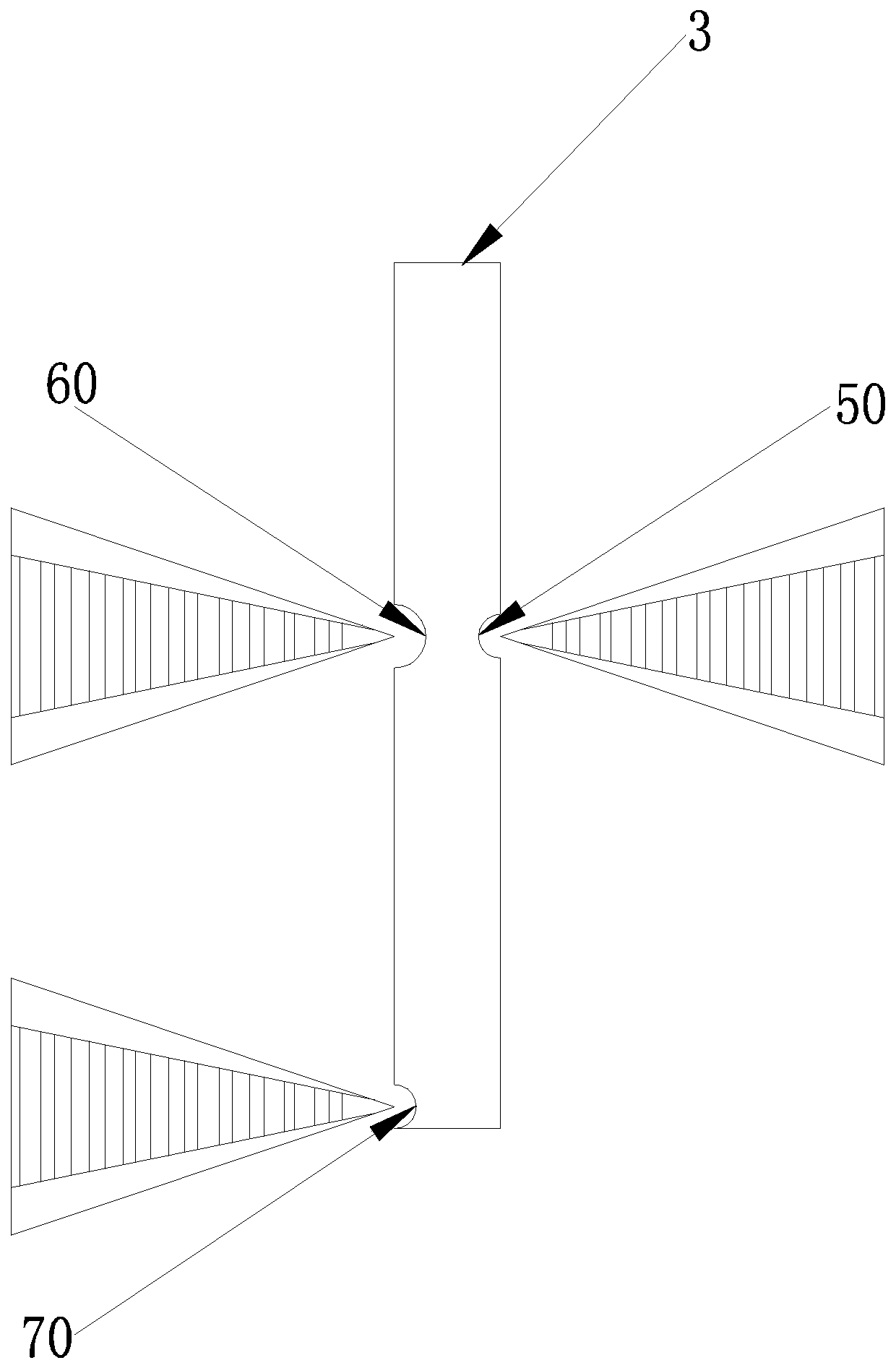

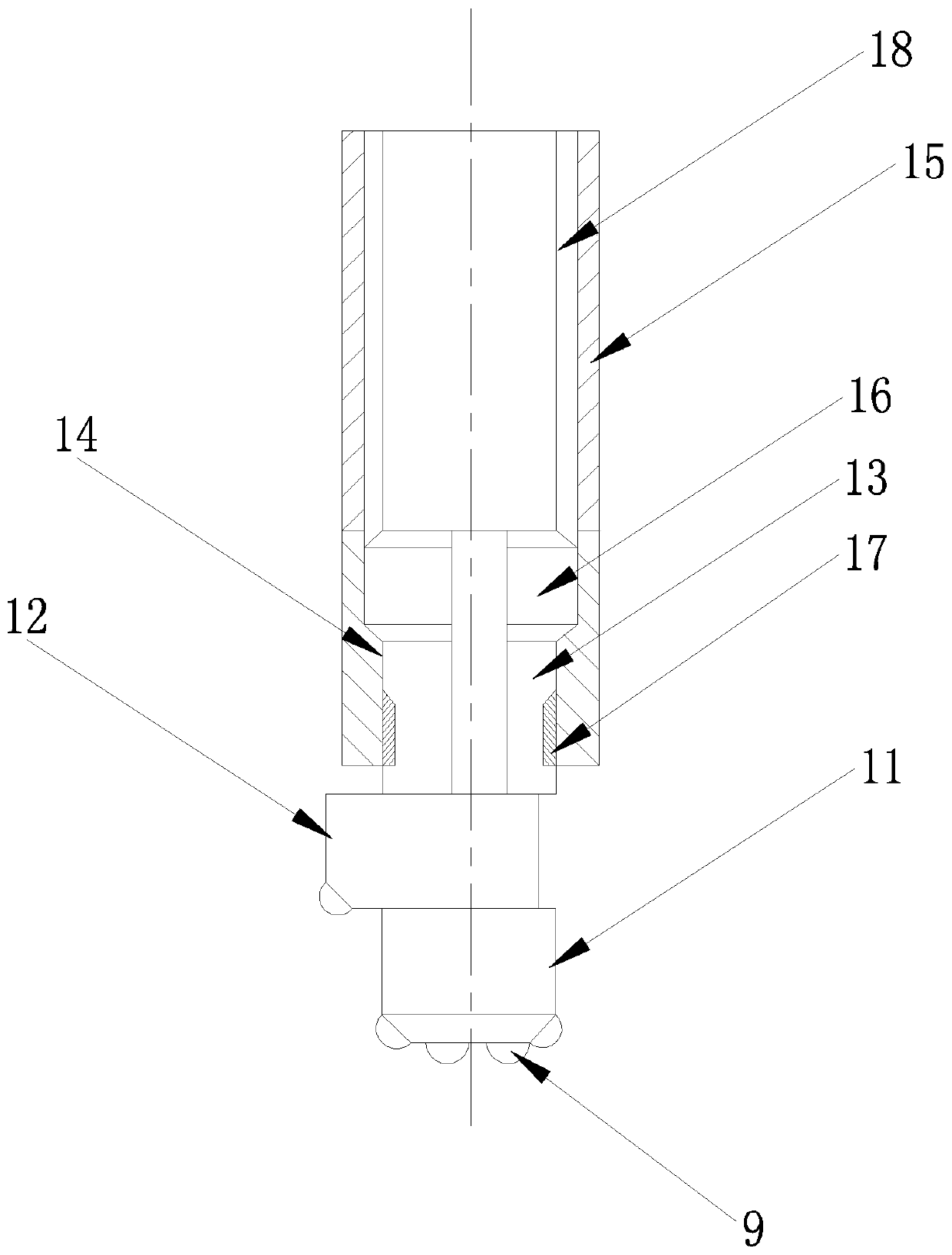

High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

PendingCN111577136ASimple structureHigh pile strengthDirectional drillingBorehole drivesPipeUltimate tensile strength

The invention relates to a high-pressure jet grouting pile hole leading construction integrated device and a construction method thereof. The high-pressure jet grouting pile hole leading constructionintegrated device comprises a jet grouting drilling machine, a high-pressure jet grouting drill rod and a triple pipe, wherein the triple pipe is fixedly arranged at the bottom of the high-pressure jet grouting drill rod, and a down-the-hole hammer is fixedly arranged at the bottom of the triple pipe; and the triple pipe comprises a grout outlet ejector, an inner air outlet ejector and an outer air outlet ejector which are sequentially arranged from inside to outside. The high-pressure jet grouting pile hole leading construction integrated device is simple in structure, convenient to use and practical, the construction technology of combining the triple pipe and the down-the-hole hammer is adopted for the environment of a complex geological layer, and by optimizing construction technical parameters, an obtained pile body is high in strength and good in construction quality. Compared with a traditional high-pressure jet grouting pile construction method, the input mechanical materials are few, the cost is low, construction is safe, and construction is rapid.

Owner:浙江岩科建设有限公司

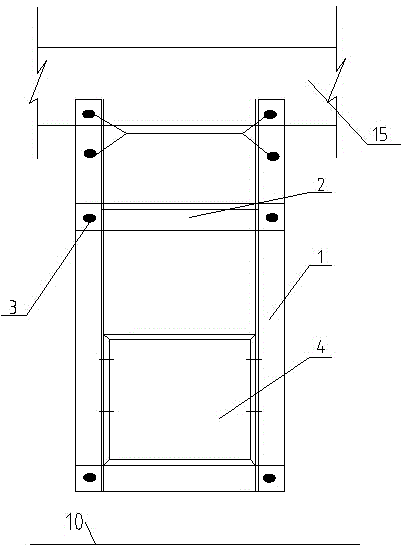

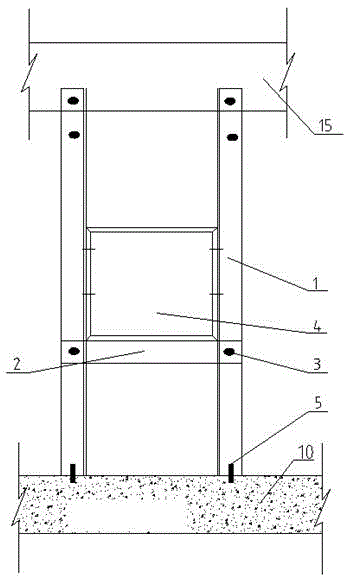

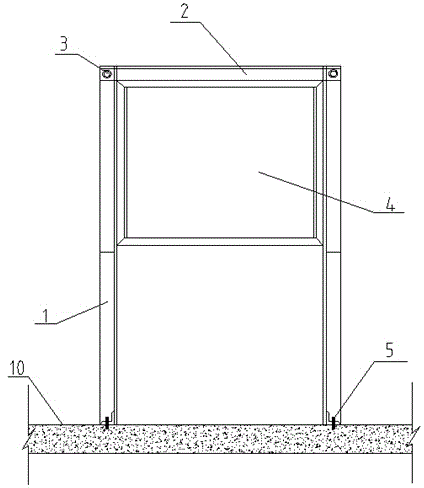

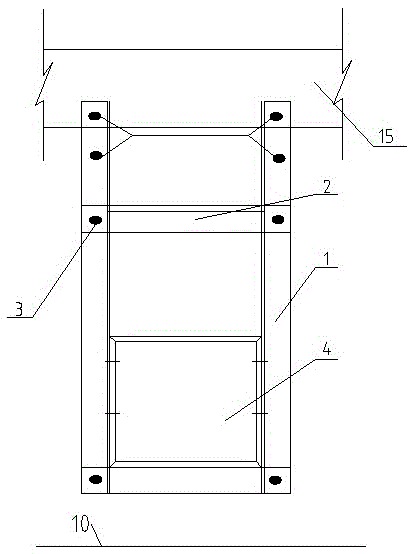

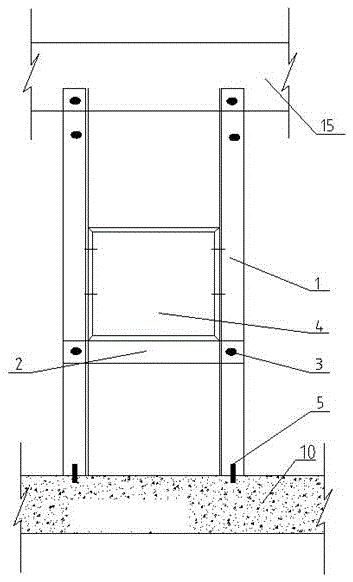

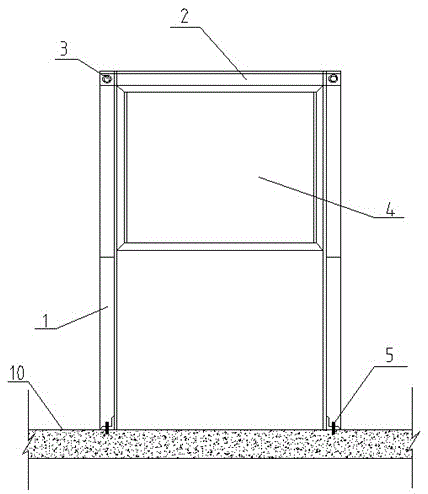

Earlier direct mounting method for concealed distribution box of filler wall

ActiveCN104405128AEasy to installFlexible adjustmentElectrical apparatusWallsSocial benefitsEngineering

The invention provides an earlier direct mounting method for a concealed distribution box of a filler wall. According to the technical scheme, the method comprises the following steps: preparing for construction; selecting a section bar bracket; making and mounting the section bar bracket; mounting the box; mounting inlet / outlet pipes of the box; building the filler wall; forming the wall masonry; after achieving design strength, removing the section bar bracket. According to the earlier direct mounting method for the concealed distribution box of the filler wall provided by the invention, the mounting is convenient, the adjusting is flexible, a large quantity of engineering practices prove that the mounting quality is greatly increased by the technique, and meanwhile, the quality of the filler wall and plastering is effectively increased, the construction is safe and environment-friendly, the construction period is effectively shortened, the cost is reduced, the excellent economic, technical and social benefits are achieved, and the method has positive popularization and application values.

Owner:CHINA MCC17 GRP

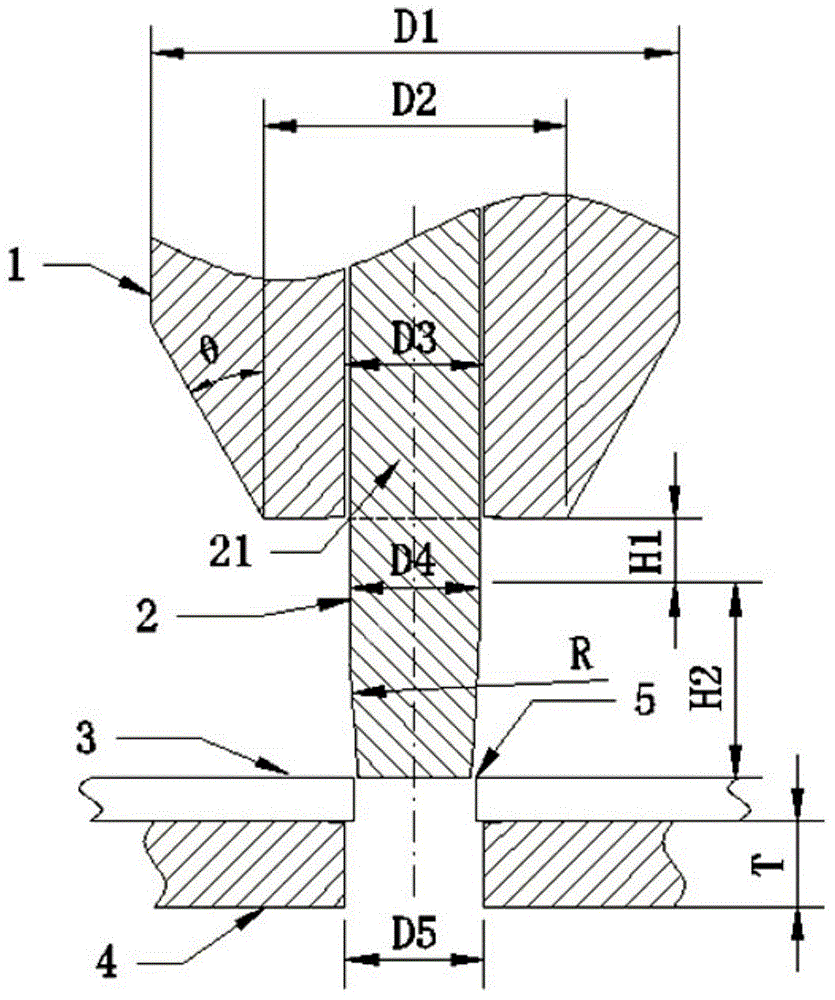

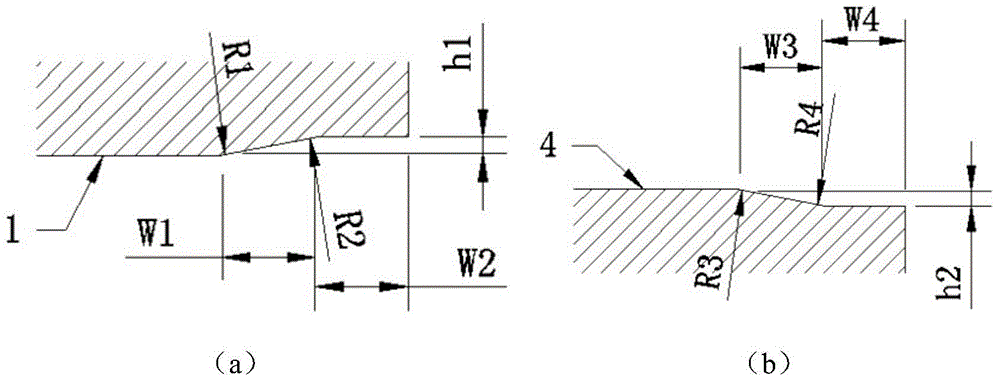

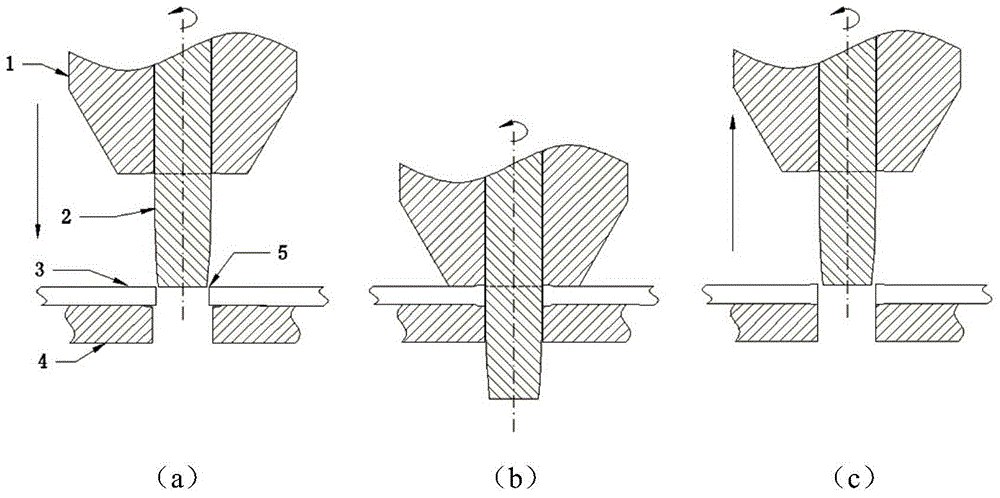

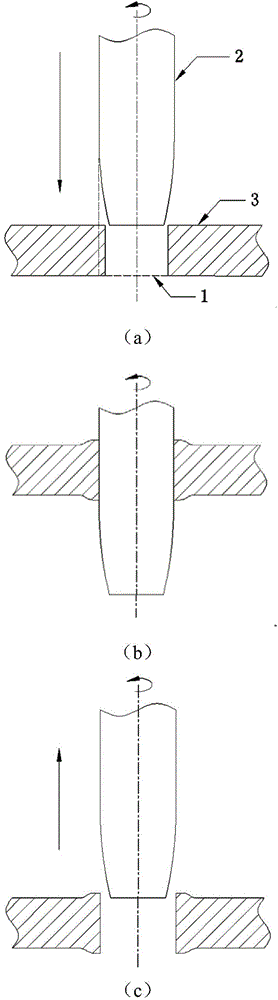

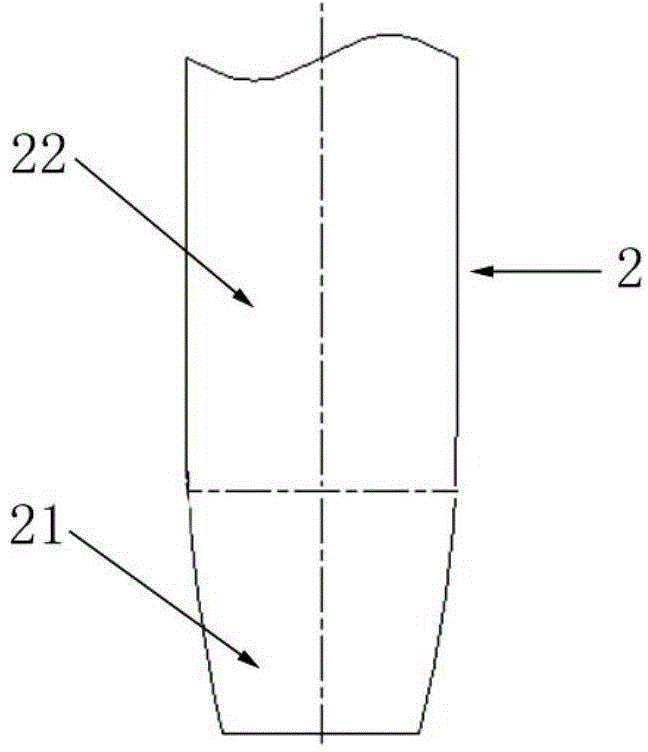

Tool and method for strengthening friction extrusion of structural member connecting hole

The invention discloses a tool and a method for strengthening friction extrusion of structural member connecting holes, and belongs to the technical field of machining. The friction extrusion strengthening tool comprises three parts of a friction extrusion head, a necking, and a base plate. When the tool is used to strengthen a structural member connecting hole, under the condition of maintaining 0.02-1 mm extruding magnitude of interference between the friction extrusion head and the connecting hole, the friction extrusion head is rotated and is inserted into the connecting hole in uniform speed. After stopping rotation for 2-5 s, the friction extrusion head is pulled out. The rotation speed of the friction extrusion head is 100-1000 rpm, the insertion speed is 0.1-2 mm / s, and pulling-out speed is 0.3-2 mm / s. In the above process, residual compressive stress is formed near the wall surface of the hole, and plastic flow occurs to the material near the wall surface of the hole, and the material has lattice distortion, and dislocation density is increased, so as to realize friction extrusion strengthening on the connecting hole. The tool and the method are mainly used in strengthening of important structural member connecting holes in aviation, aerospace, trains, and ships, and other industries.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Special backing board for hole drilling of printed circuit board and manufacturing method of special backing board

ActiveCN104191457AReduce internal stressReduce the problem of low hole position accuracyMetal working apparatusMetal layered productsElectrical resistance and conductanceAdhesive

The invention discloses a special backing board for hole drilling of a printed circuit board and a manufacturing method of the special backing board. The special backing board for hole drilling of the printed circuit board is formed by combining a metal sheet or a glue-impregnated cured sheet with a metal core material in a bonding mode through adhesives or is formed by bonding the metal core material and an adhesive layer which is formed by coating the surface of the metal core material with a mixture in a bonding and combining mode, wherein the mixture is formed by mixing the adhesives and inorganic powder. The special backing board for hole drilling of the printed circuit board has good flatness and hardness; when the special backing board for hole drilling of the printed circuit board is stored and used, the phenomenon that resistance is increased due to buckling deformation and flashing is avoided; meanwhile, the service life of a drill pin can be prolonged, and the quality of the wall of a hole can be improved.

Owner:SHENZHEN NEWCCESS IND

Drill bit suitable for hard sandy soil

ActiveCN103939024AImprove drilling abilityHigh strengthDrill bitsConstructionsEngineeringUltimate tensile strength

The invention discloses a drill bit suitable for hard sandy soil. The drill bit suitable for hard sandy soil comprises a drill bit center assembly, lower cutter bodies, inner cutter bodies, blades, outer cutter bodies, supporting plates and wear-resisting plates, wherein the lower cutter bodies and the inner cutter bodies are fixed to the outer circumferential surface of the lower end and the outer circumferential surface of the lower portion of a drill bit body respectively, the two to six blades are evenly fixed to the outer circumferential surface of the drill bit body in a radial and surrounding mode, the outer cutter bodies are fixed to the lower edges of the blades, two to eight outer cuter bodies are installed on each blade, for all the outer cutter bodies except the outer cutter bodies at the free ends of the blades, the outer cutter bodies on each blade and the outer cutter bodies on another blade are arranged in a cross mode in the rotation position, the blades and the drill bit bodies are fixed through the supporting plates, the wear-resisting plates are fixedly installed on the cambered surfaces of the free ends of the blades, the side faces of the outer cutter bodies at the outermost end and the side faces of the inner cutter bodies respectively, and the lower cutter bodies, the inner cutter bodies and the outer cutter bodies are installed in the directions enabling lower cutter heads, inner cutter heads and the outer cutter heads face the rotation direction of the drill bit body. The drill bit suitable for hard sandy soil has the advantages that the working efficiency can be improved effectively, the combining strength between the cutter heads and cutter handles is high, abrasion of the cutter bodies and the blades is reduced, and the construction quality is guaranteed.

Owner:上海工程机械厂有限公司

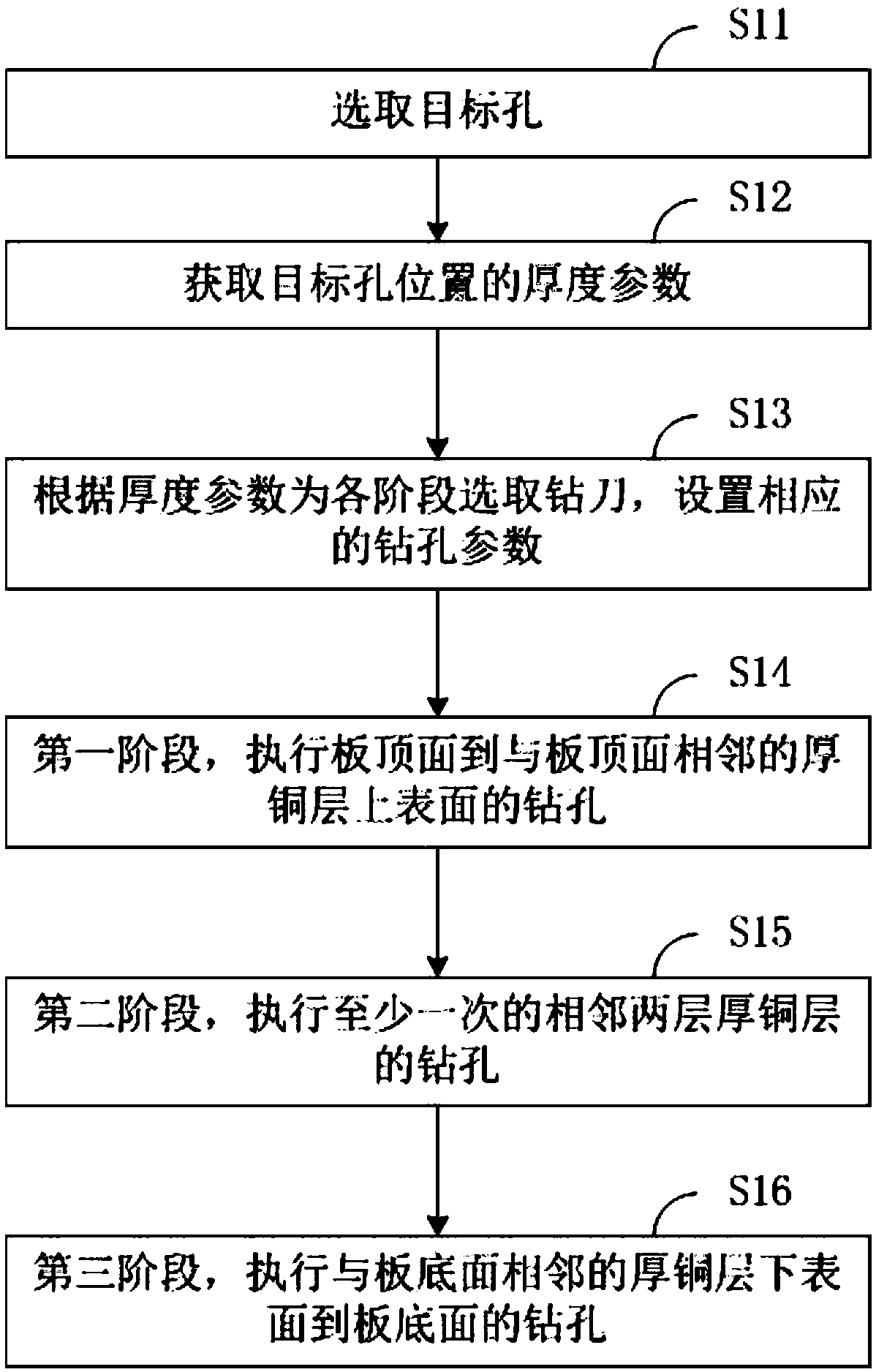

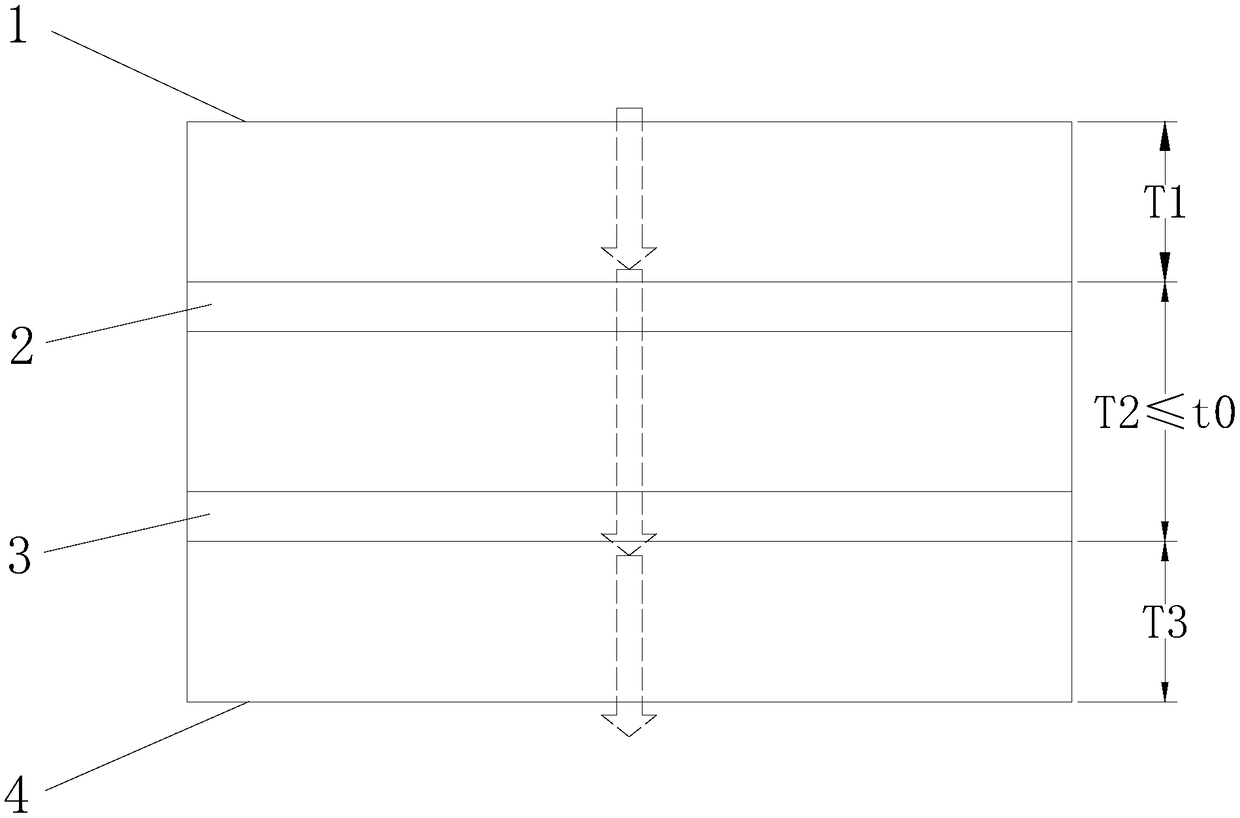

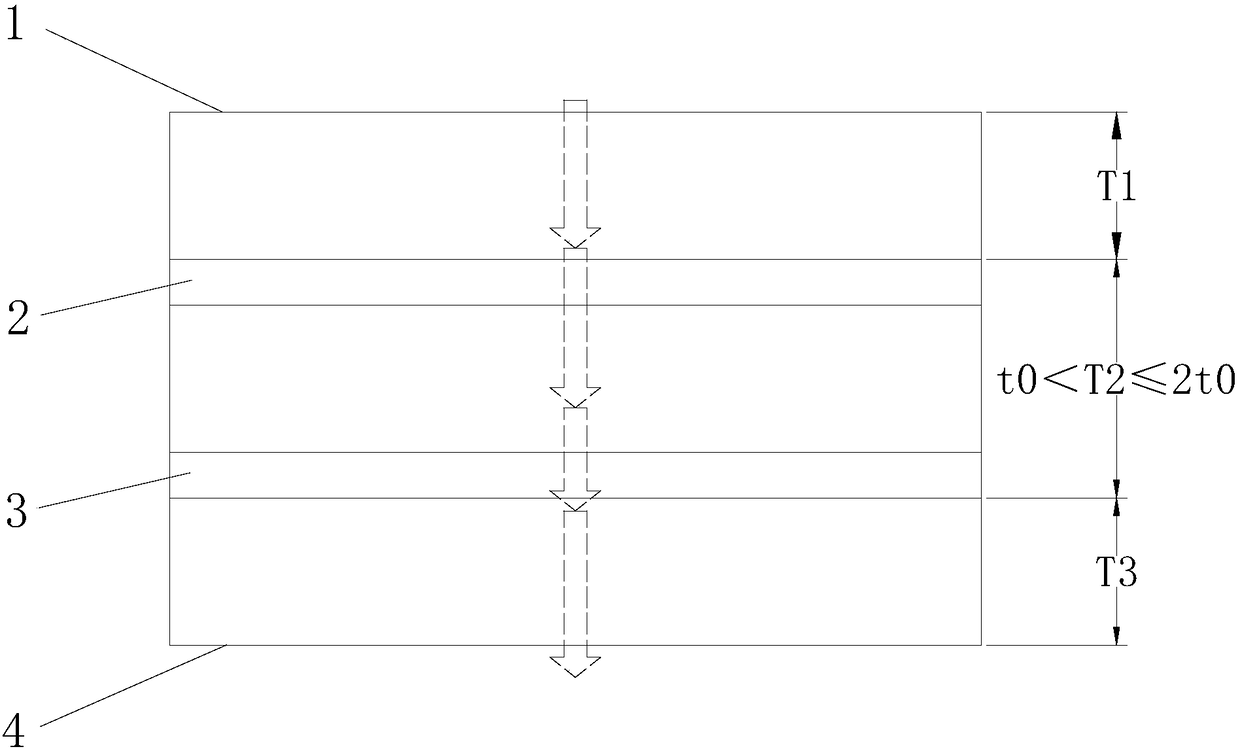

Method of drilling hole in PCB

ActiveCN108541145AImprove the quality of the wallEasy to chooseConductive material mechanical removalCircuit metal processingManufacturing technologyCopper

The invention discloses a method of drilling a hole in a PCB, and relates to a production technology of the PCB. The method comprises the following steps of acquiring the thickness parameter at the position of a target hole and completing drilling in each stage according to the thickness parameter, and comprises the following specific steps: in a first stage, drilling from the top surface of the board to the upper surface of a thick copper layer adjacent to the top surface of the board; in a second stage, drilling two adjacent thick copper layers at least once; in a third stage, drilling fromthe lower surface of a thick copper layer adjacent to the bottom surface of the board to the bottom surface of the board, wherein the thick copper layer is a copper layer with the copper thickness being greater than or equal to 2OZ. By the method, according to the condition of the copper layers at the drilled position, the drilling stages are divided by using the thick copper layers as boundary points so as to complete drilling of a through hole step by step, so that selection of drilling tools and setting of drilling parameters according to the thicknesses of the copper layers in different drilling stages are facilitated so as to reduce wear on the drilling tools, and the through hole having good hole wall quality can be obtained and the reliability of a product is improved.

Owner:DONGGUAN SHENGYI ELECTRONICS +1

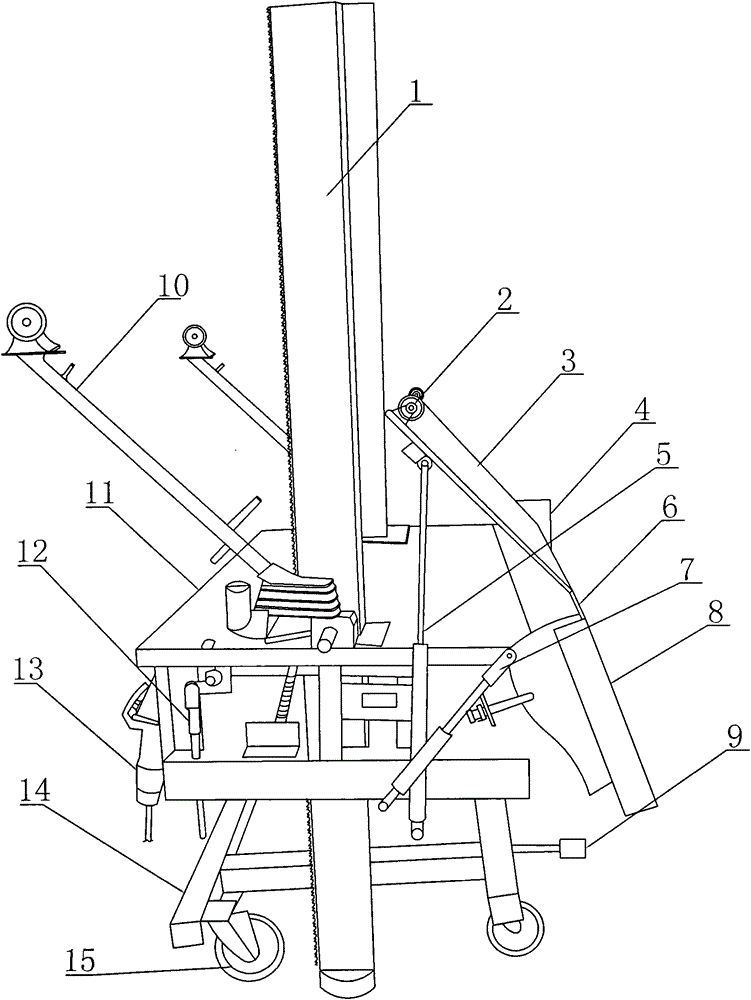

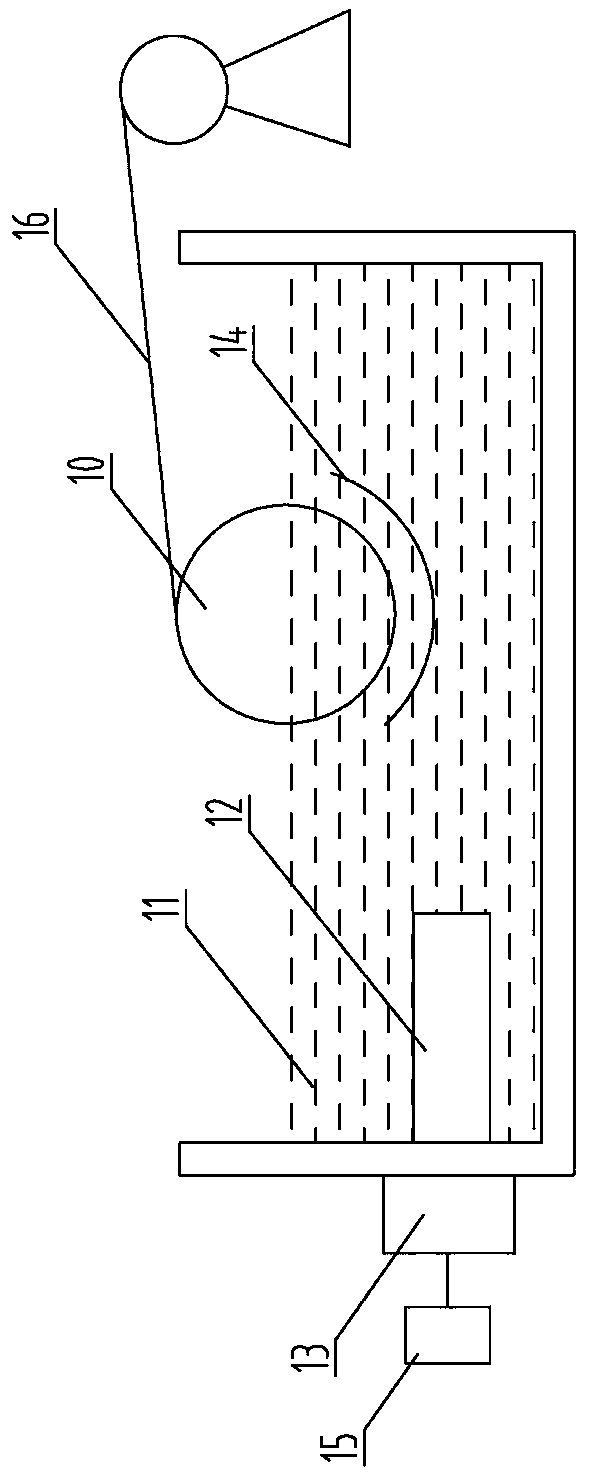

Novel automatic wall painting machine

ActiveCN103982035ARise at a constant speedUniform descentBuilding constructionsEngineeringGear tooth

The invention provides a novel automatic wall painting machine and belongs to the construction machinery technical field. The novel automatic wall painting machine is formed by a base, a plaster pasting main machine, a directional rod, a plaster blocking plate and a plaster pasting plate; universal wheels are arranged under the base; the plaster pasting main machine is arranged above the base; the directional rod vertically penetrates the plaster pasting main machine and the base; the plaster pasting main machine is provided with the plaster pasting plate and the plaster blocking plate which are close to a wall surface; the directional rod is provided with gear teeth and snapped to gears of the plaster pasting main machine and the base through the gear teeth; the directional rod is formed by segmentation and combination; a joint of the base and the directional rod is provided with a fine adjustment device; the directional rod can be adjusted to ascend and descend within a small distance through the fine adjustment device; a manipulation device, a transmission device and a power device are arranged in the plaster pasting main machine. According to the novel automatic wall painting machine, the structure is simple, the operation is easy, automatic treatment is performed at the wall top and the position of a joint, manual post-treatment is not required, the quality effect of the painted wall surface is good, and the plaster pasting main machine can ascend and descend at a constant speed due to the fact that ascending and descending of the plaster pasting main machine are achieved through the gears.

Owner:陈广杰

Preparation method of micropore copper foil used for negative electrode current collector of lithium ion battery

ActiveCN108649183AImprove corrosion resistanceHigh purityElectrode manufacturing processesElectrode carriers/collectorsWater basedPorosity

The invention discloses a preparation method of a micropore copper foil used for a negative electrode current collector of a lithium ion battery, and belongs to the technical field of an apparatus fordirectly converting chemical energy into electric energy. The preparation method comprises the steps of (1) processing a titanium alloy roller; (2) preparing a second working solution, comprising 40-70 parts of copper sulfate, 90-100 parts of sulfuric acid, 80-100 parts of polyethylene glycol, 20-30 parts of sodium bromide and 1,000 parts of water based on parts by mass; and (3) preparing the micropore copper foil. According to the method, the processed titanium alloy roller is adopted, so that corrosion resistance is improved and the purity of the copper foil is improved, thereby maintaininghigh conductivity of copper; in addition, the surface evenness of the titanium alloy roller is also improved, and distribution uniformity and dimensional uniformity of hydrogen bubbles on the rollerwall are also facilitated, so that micro pores with uniform hole diameters are prepared; and by virtue of a synergistic effect of bromide ions and polyethylene glycol additive in the second working liquid, the hole diameters can be more uniform, the hole wall quality can be higher, the porosity is lowered, and the conductive performance and mechanical performance of the micropore copper foil are improved.

Owner:SHANDONG JINBAO ELECTRONICS +1

Friction extrusion strengthening method of structural member connecting hole

InactiveCN105855791AImprove stress environmentEnhanced ability to sprout and expandDislocationEngineering

The invention discloses a friction extrusion strengthening method of a structural member connecting hole, and belongs to the technical field of machining. The method comprises: using a friction extrusion head as a friction extrusion strengthening tool, under the condition of maintaining 0.02-1 mm extruding magnitude of interference between the friction extrusion head and a connecting hole, rotating the friction extrusion head and inserting into the connecting hole on a structural member in uniform speed, and stopping rotation for 2-5 s, and then pulling the friction extrusion head out; the rotation speed of the friction extrusion head being 100-1000 rpm, insertion speed being 0.1-2 mm / s, and pulling-out speed being 0.3-2 mm / s. In the above process, residual compressive stress is formed on neighborhood of the wall surface of the hole, and plastic flow occurs to the material near the wall surface of the hole, and the material has lattice distortion, and dislocation density is increased, so as to realize friction extrusion strengthening on the structural member connecting hole. The method is mainly used in strengthening of important structural member connecting holes in aviation, aerospace, trains, and ships, and other industries.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

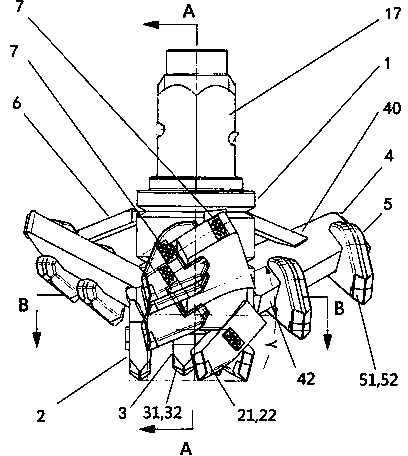

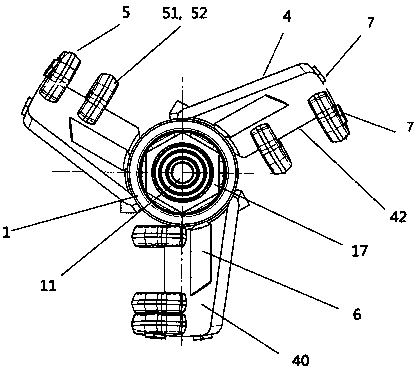

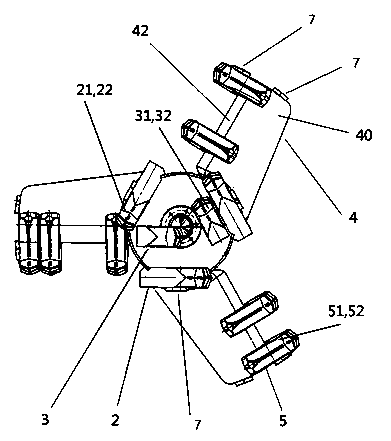

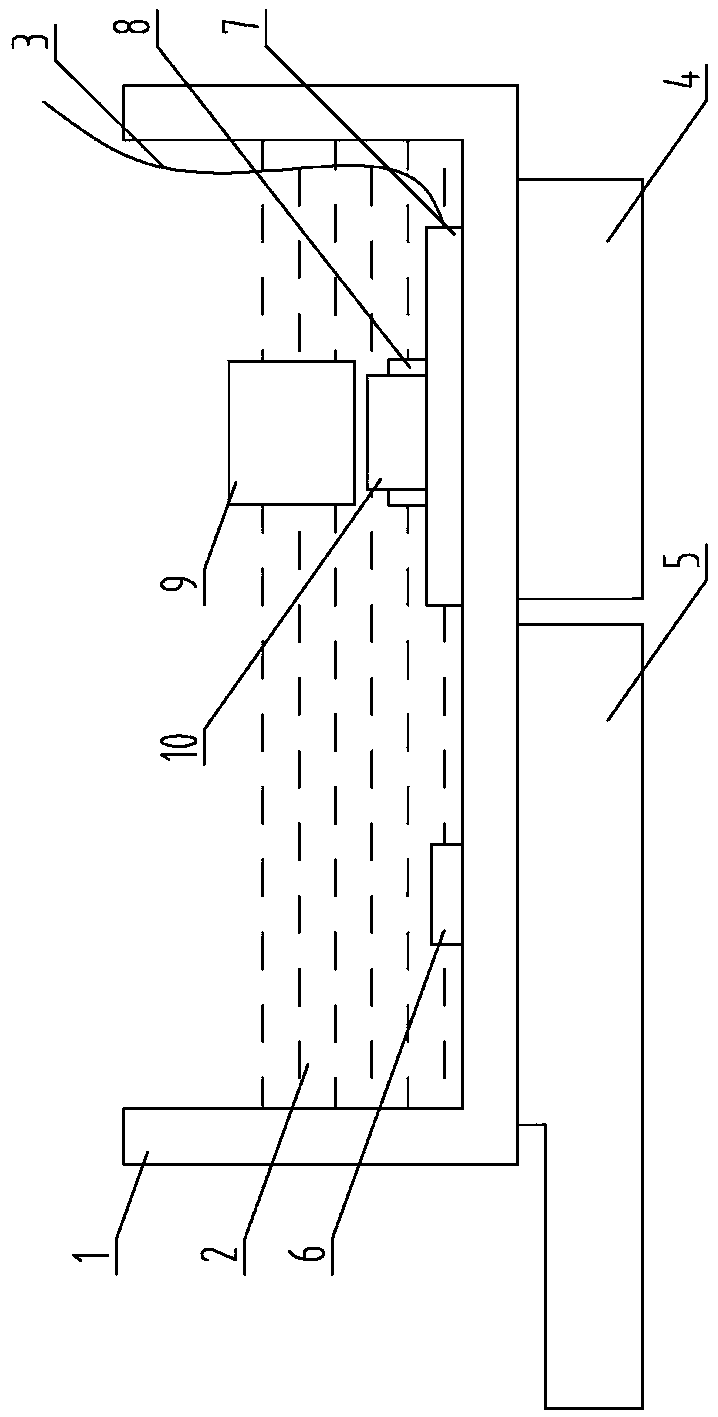

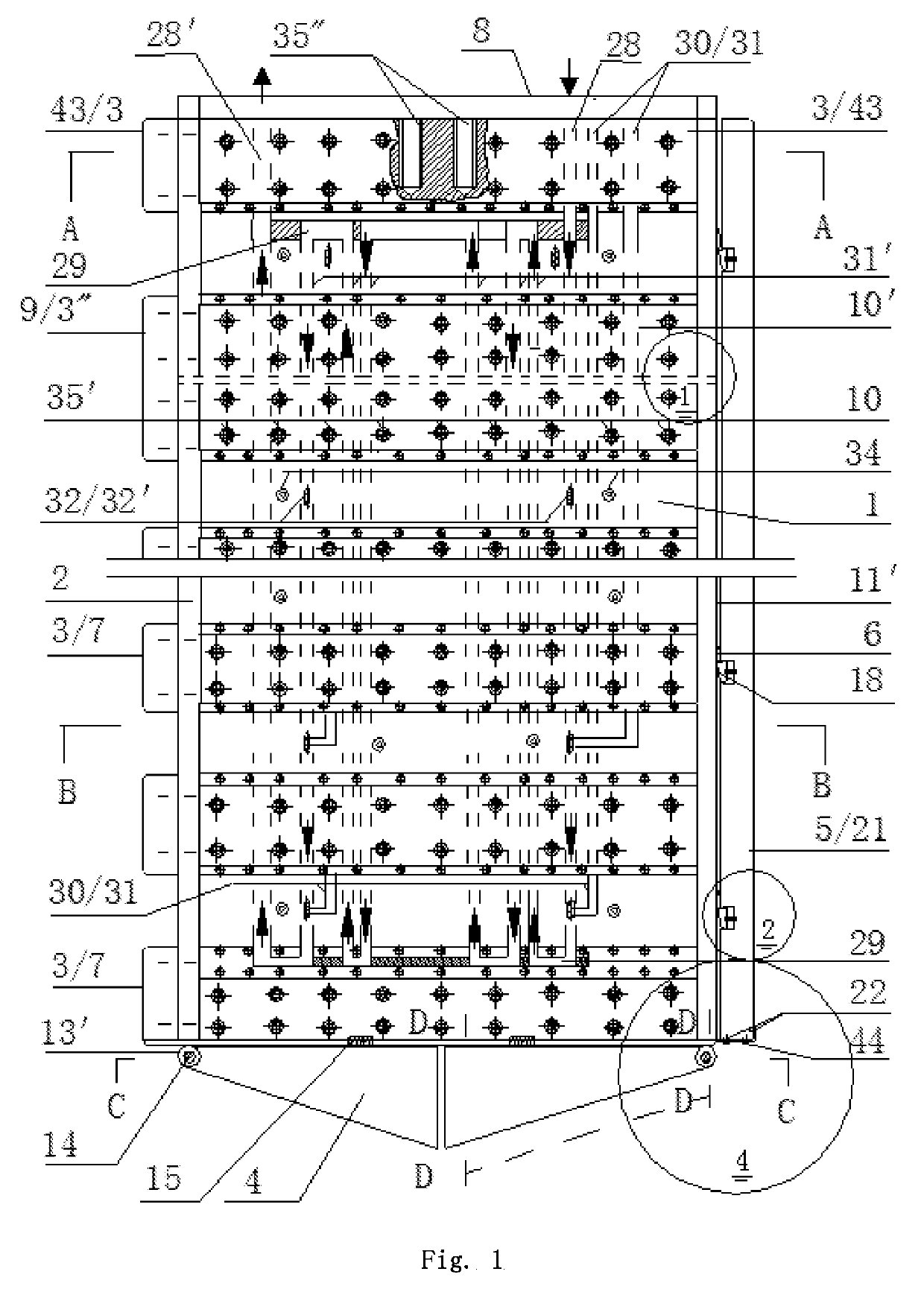

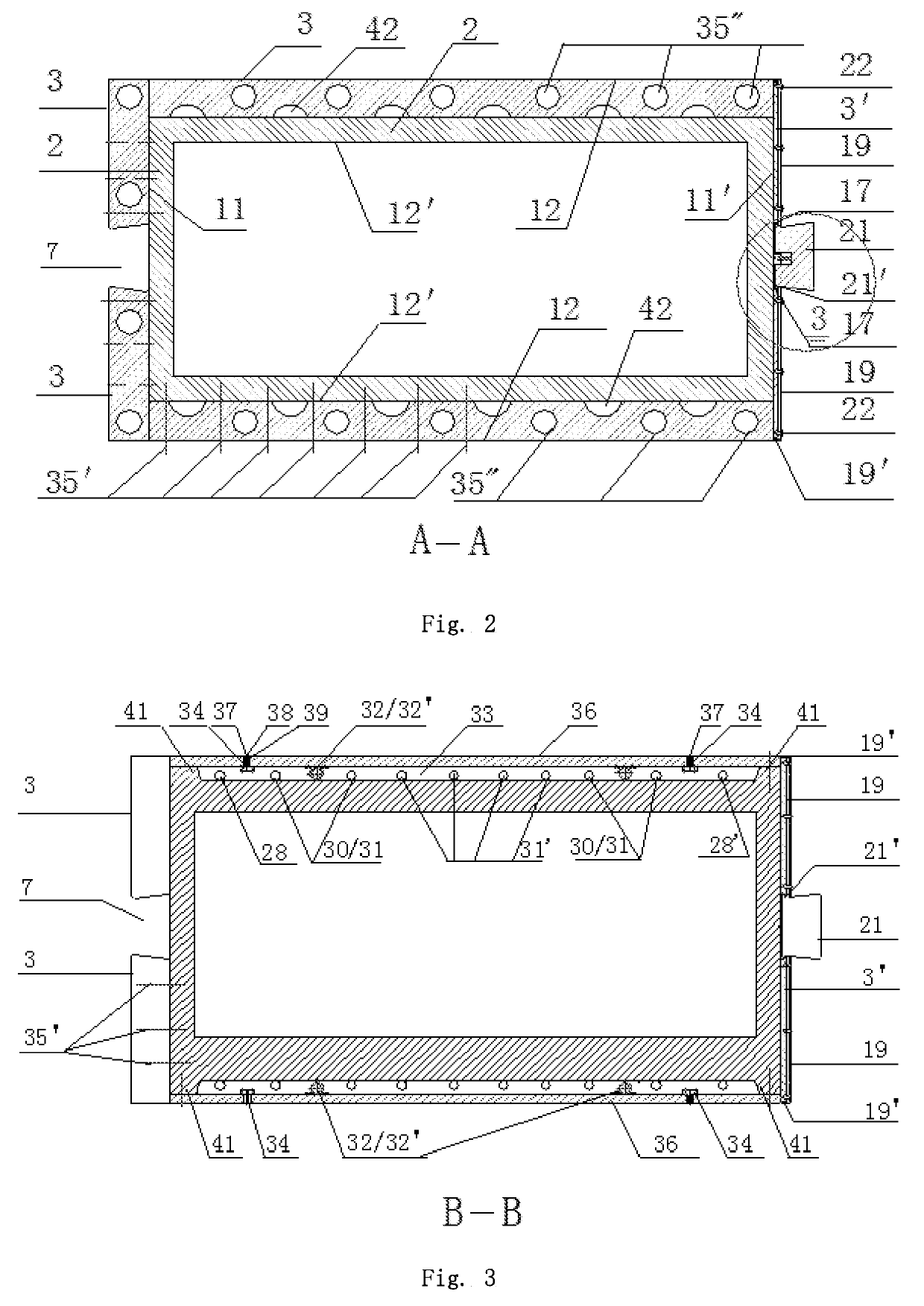

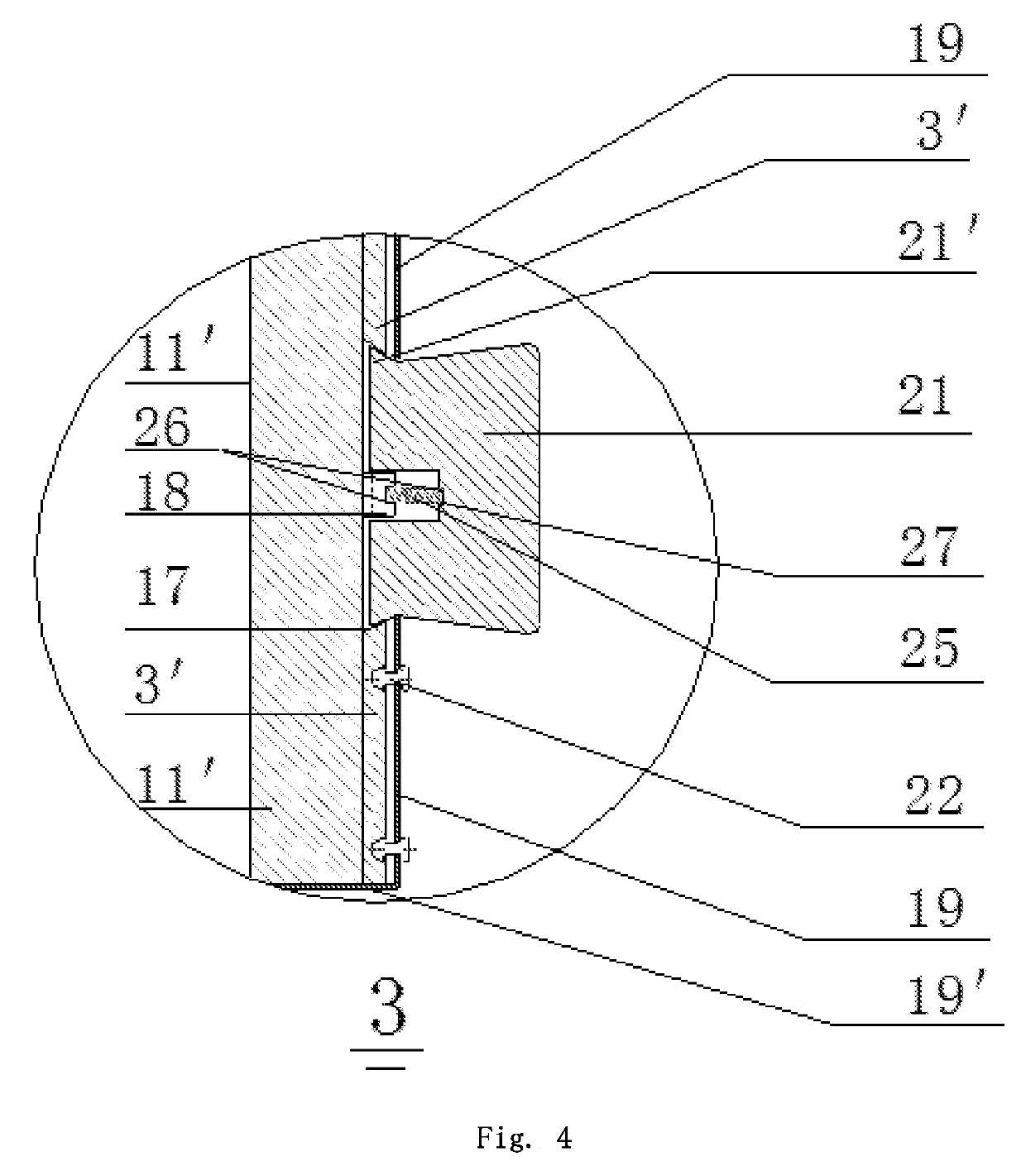

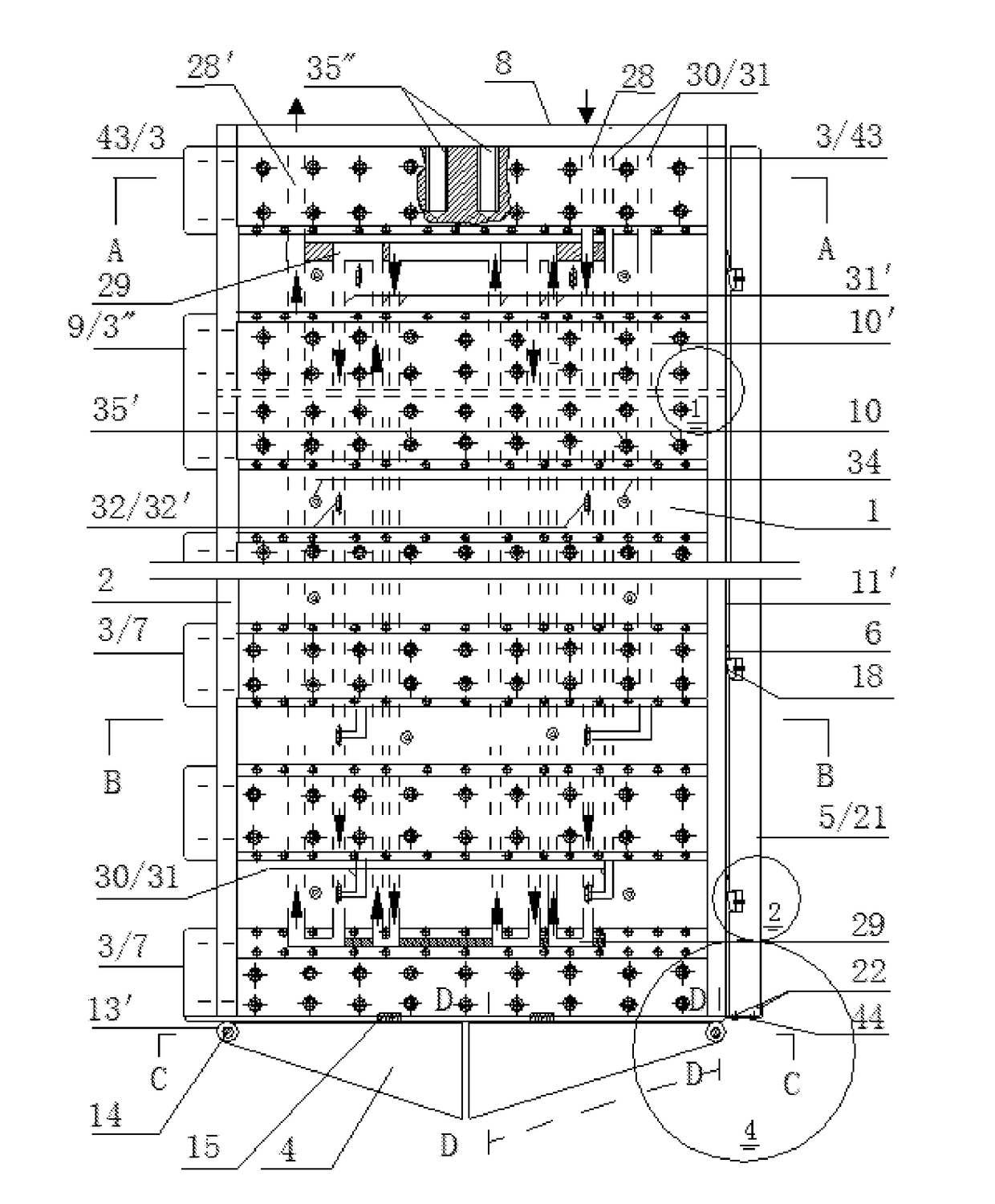

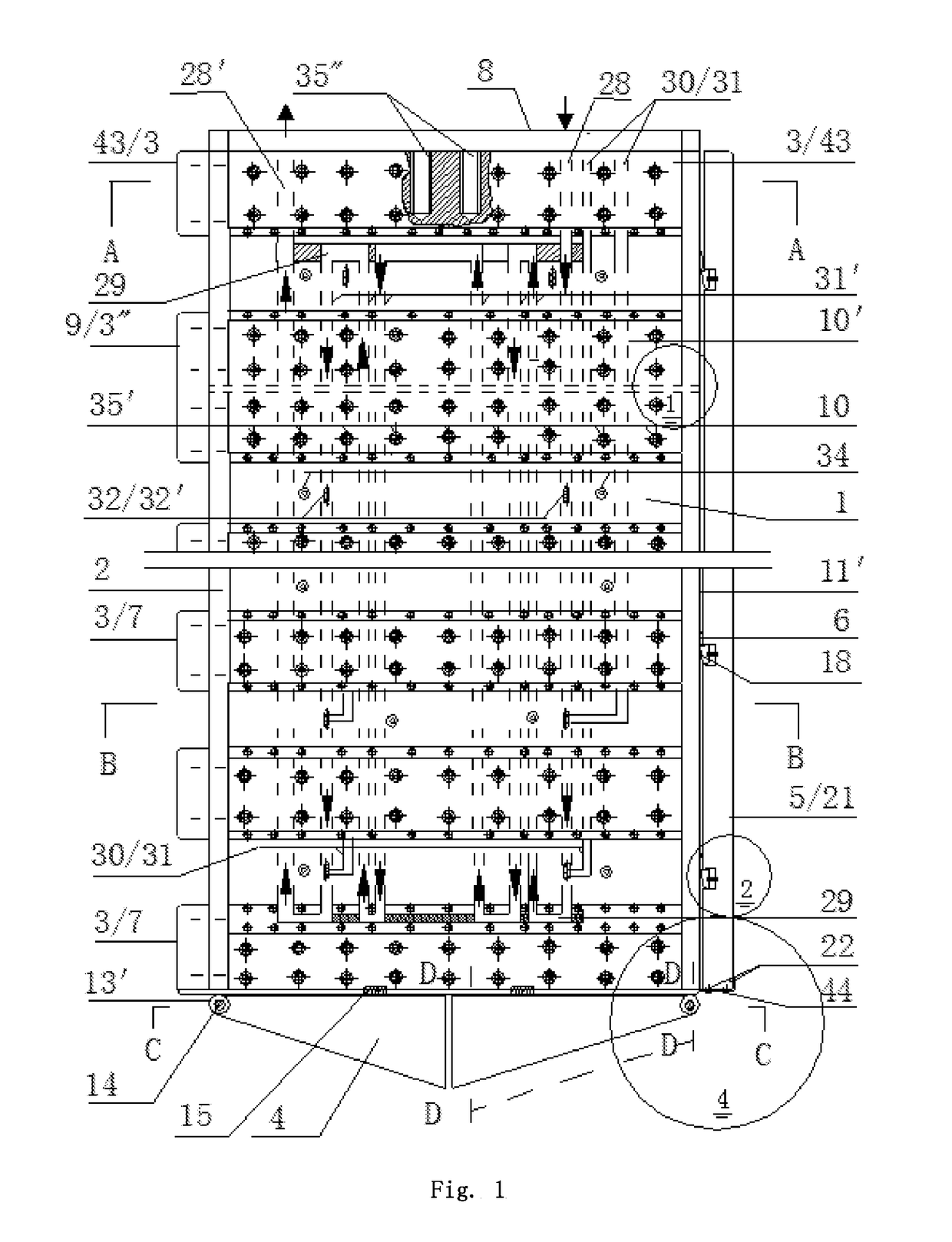

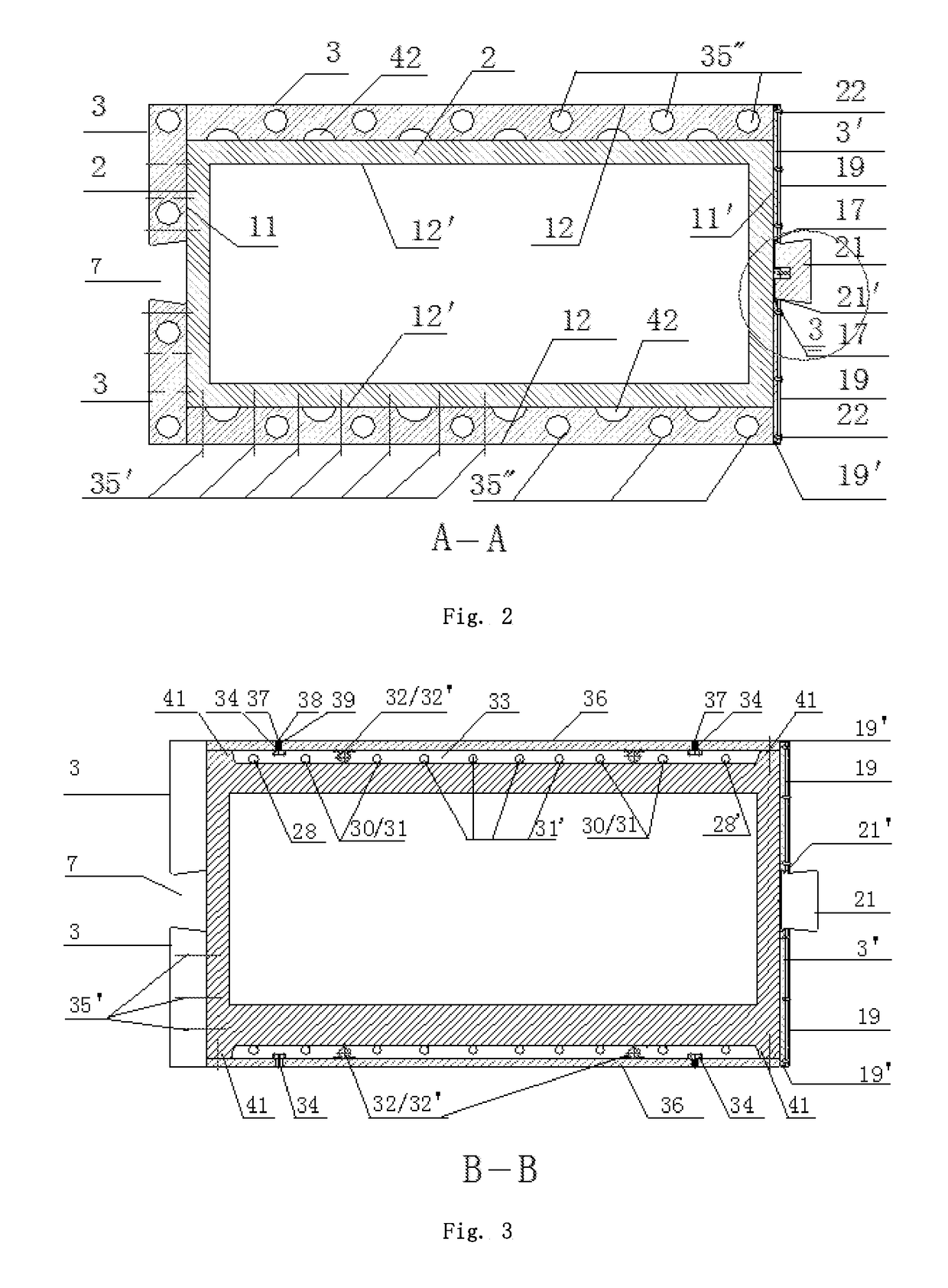

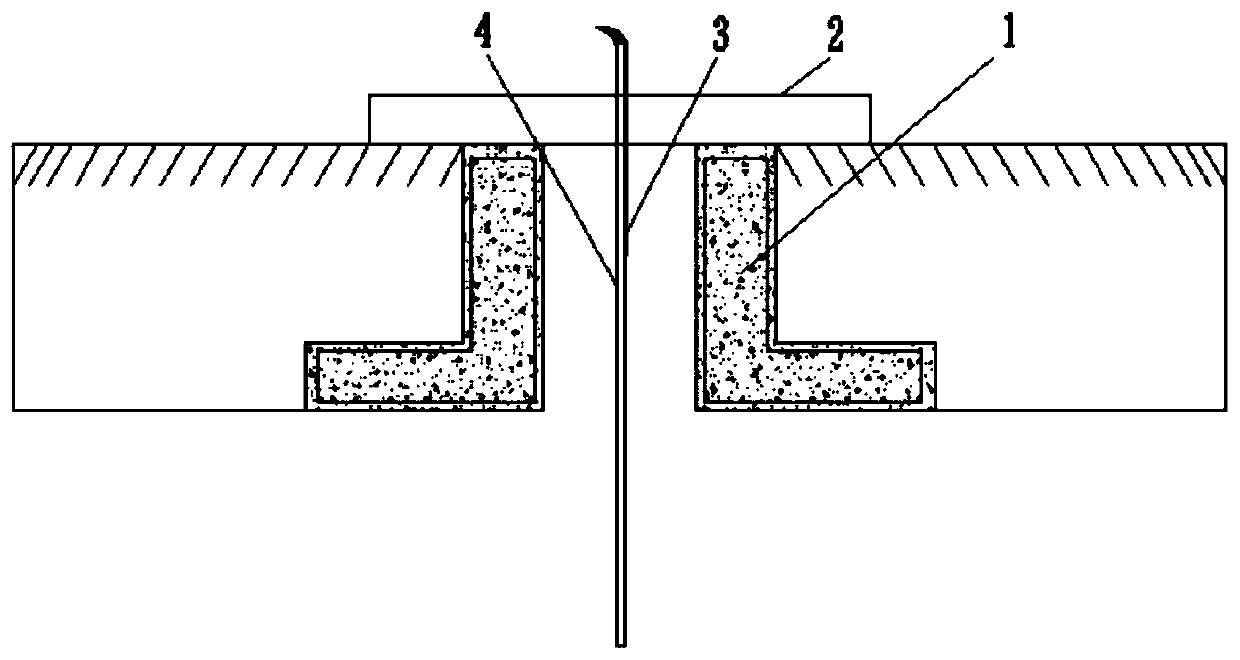

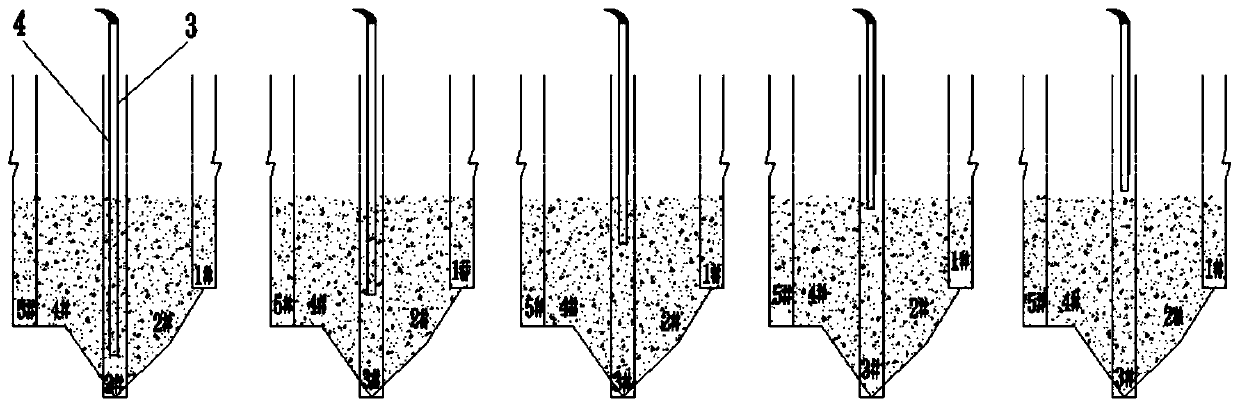

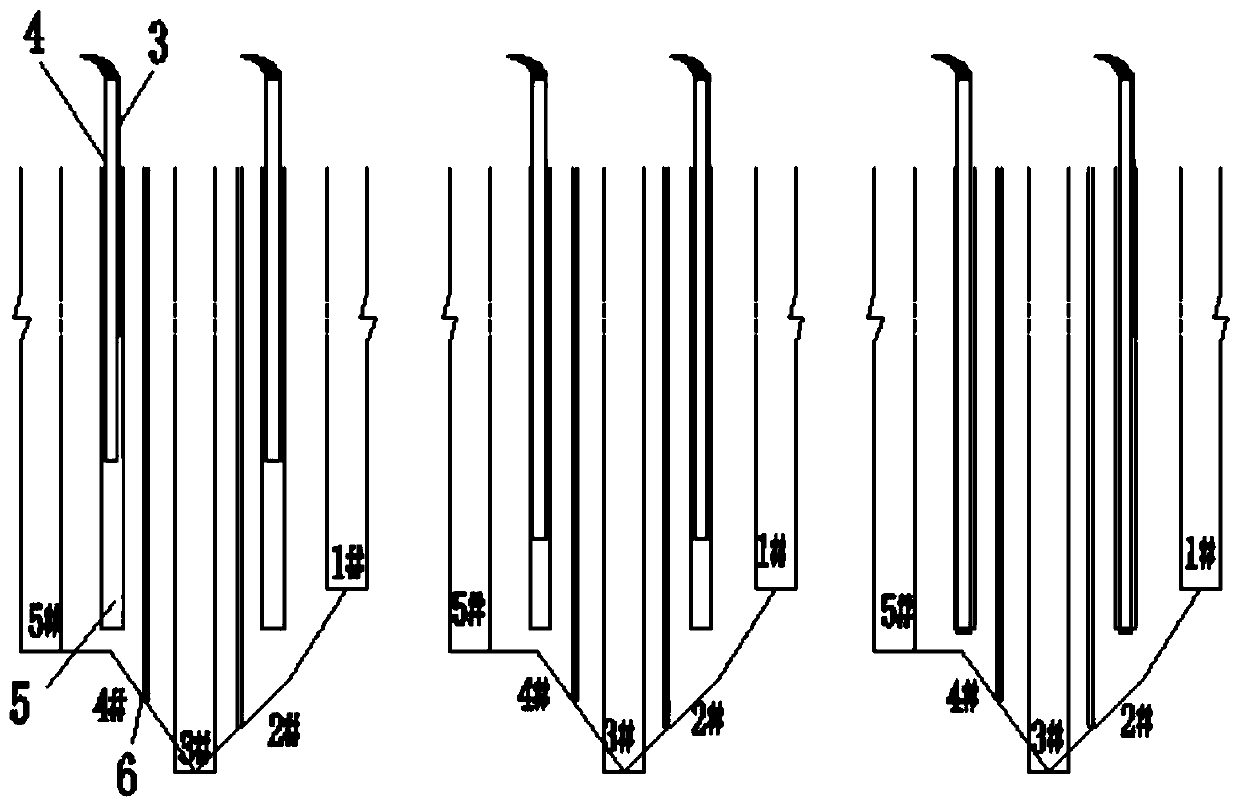

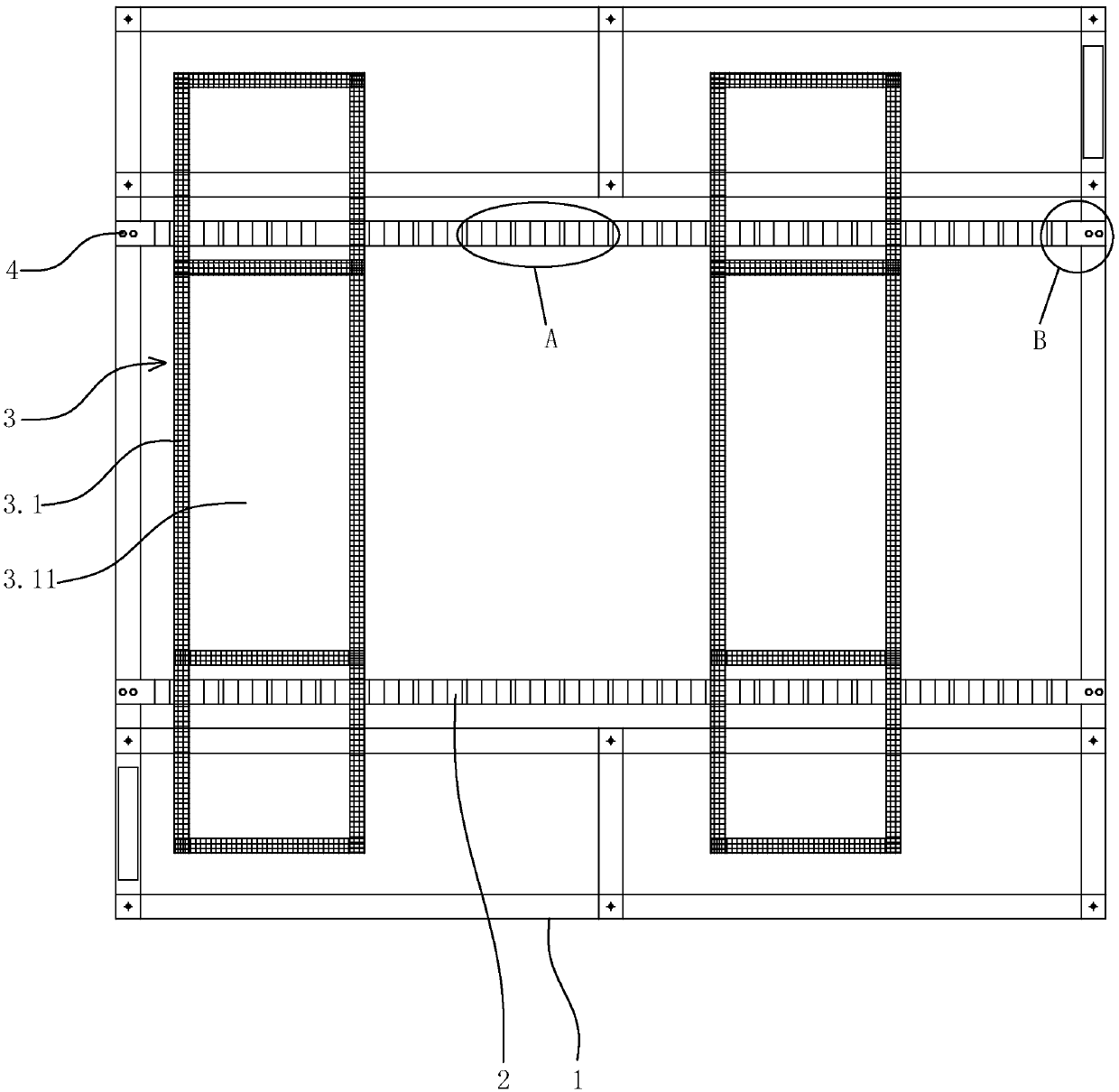

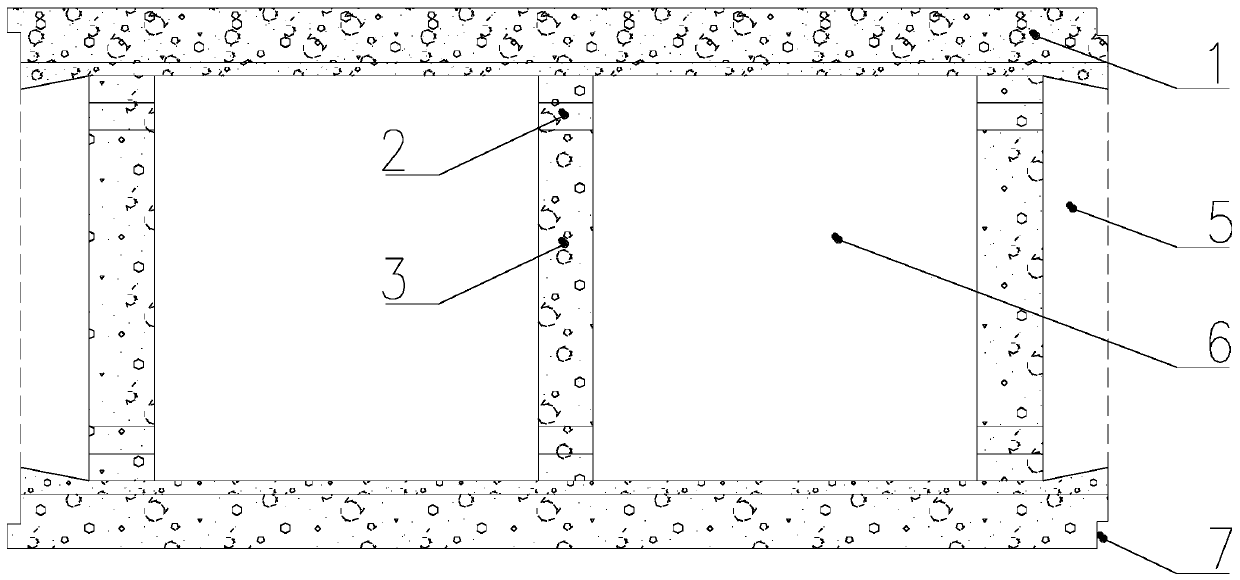

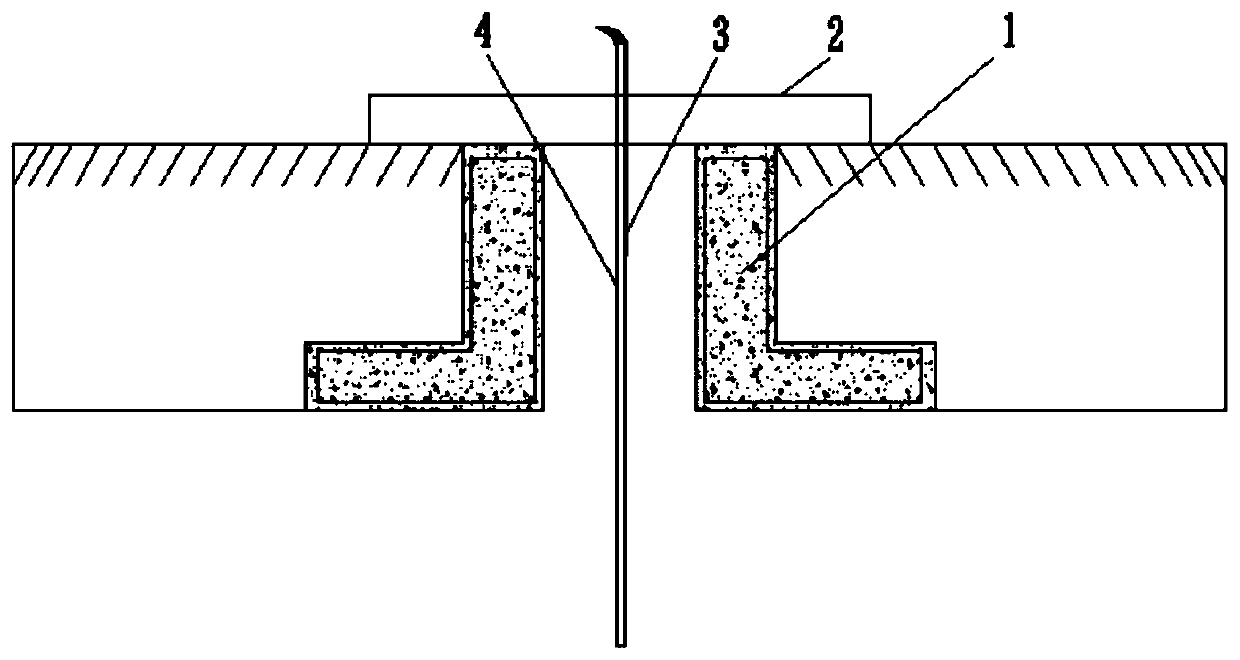

End point closing wall forming device of extrusion type underground diaphragm wall and method for operating same

InactiveUS10407858B2Improve the quality of the wallSave resourcesArtificial islandsUnderwater structuresSlurry wallWater spray

An end point closing wall forming device of an extrusion type underground diaphragm wall comprises a main body (1) and a vibration water spraying device. The vibration water spraying device is fixedly disposed inside the main body (1). The end point closing wall forming device of an extrusion type underground diaphragm wall further comprises a separation device. The separation device is movably sheathed on the outer side of a short edge (11′) of the main body (1). Also provided is a method for operating an end point closing wall forming device of an extrusion type underground diaphragm wall.

Owner:QINGDAO JINGLI ENG

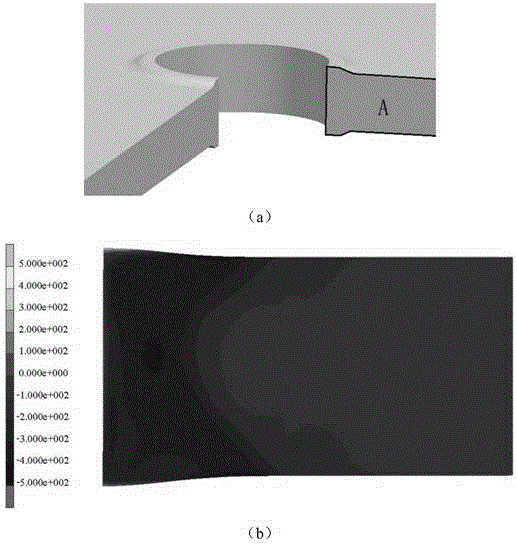

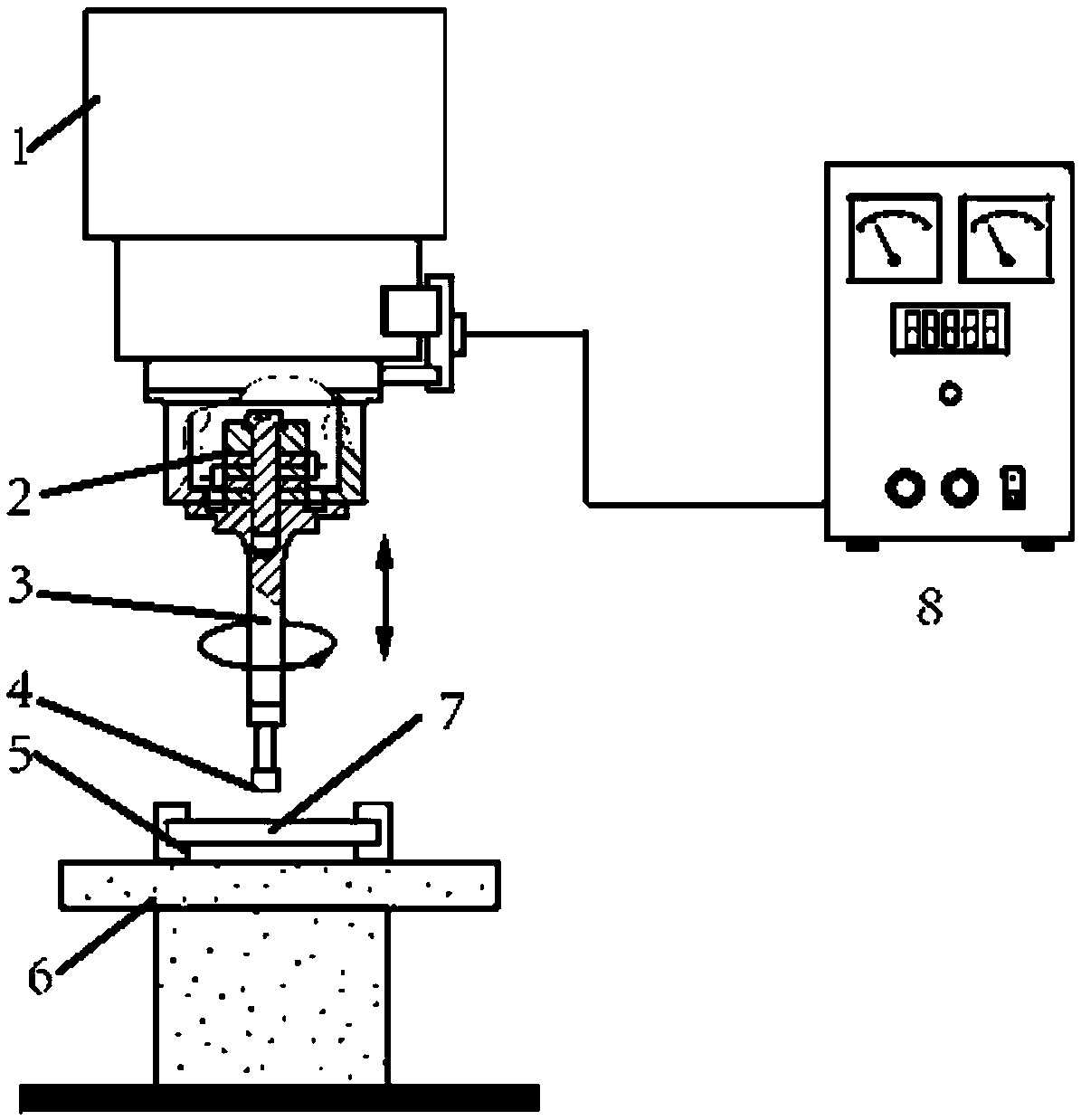

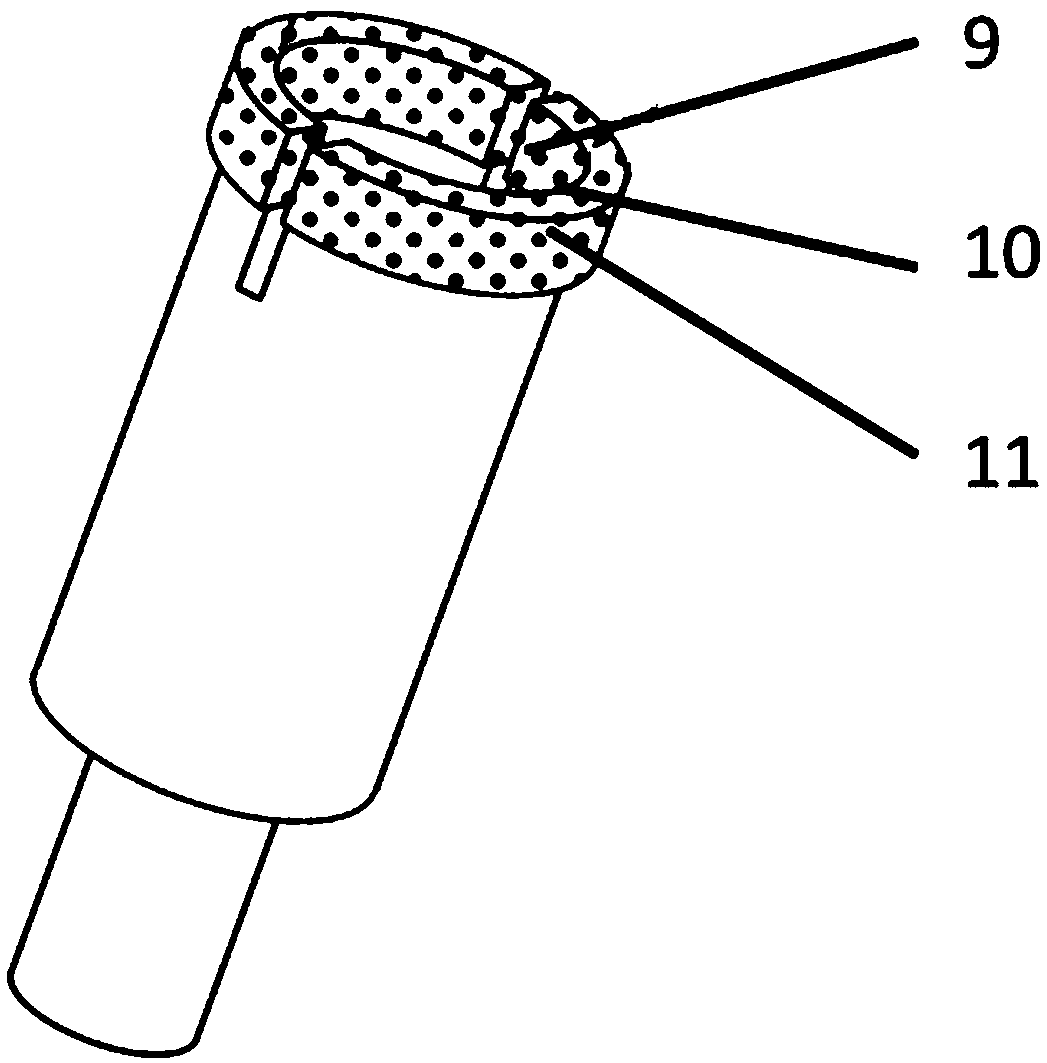

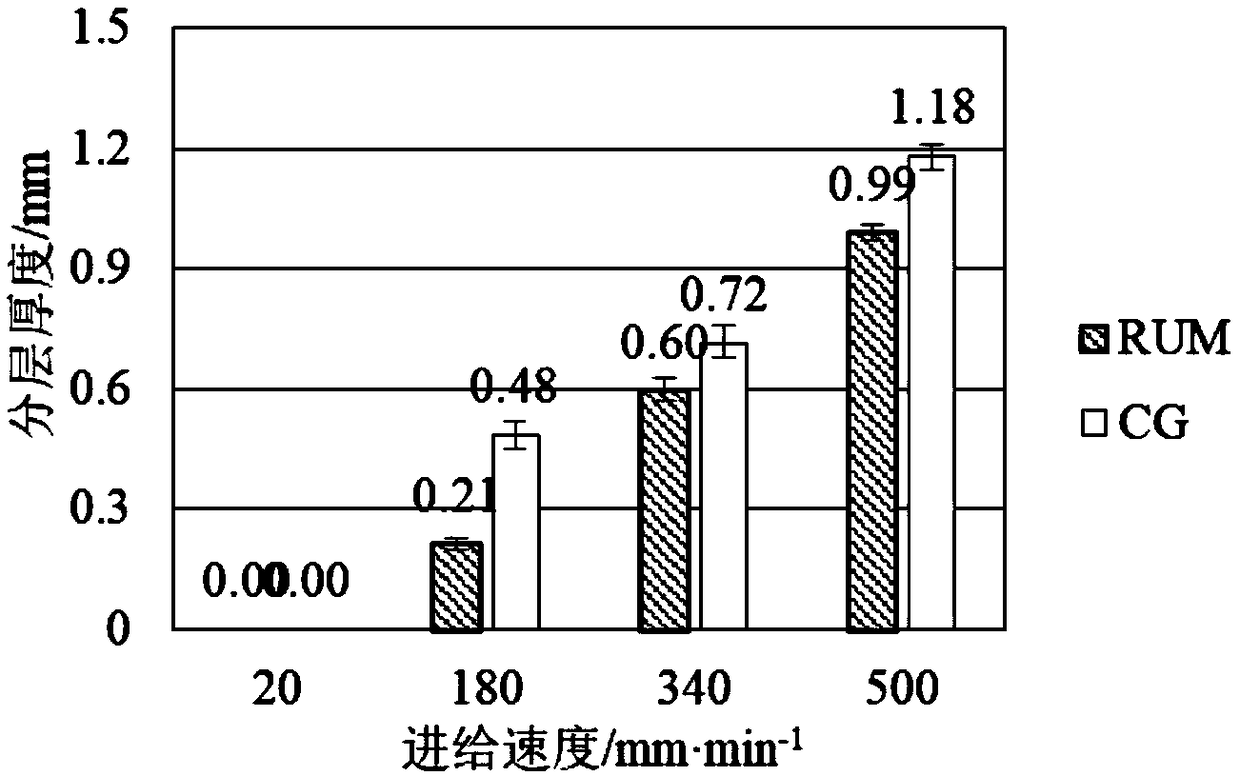

Layering control method in carbon fiber machining process

InactiveCN109048510AHigh removal rateImprove the quality of the wallBonded abrasive wheelsGrinding machinesFiberCarbon fibers

The invention provides a layering control method in a carbon fiber machining process. The layering control method in the carbon fiber machining process is characterized in that an ultrasonic machine tool is used for machining carbon fibers, and an electroplated diamond tool is adopted in a machining tool of the ultrasonic machine tool; and in the carbon fiber material machining process, reasonablemain-shaft speed value, feeding speed value, material treatment mode and an machined on a carbon fiber material, different feeding speeds are adopted for machining at different machining stages separately. According to the layering control method in the carbon fiber machining process, by adopting the electroplated diamond tool, the material removal rate during carbon fiber machining is improved,and the hole wall quality of the machined carbon fiber is improved; rotary ultrasonic machining technology is used for reducing the cutting force during carbon fiber machining and achieving a good layering control effect. A variable process machining method of the carbon fiber is proposed, the machining efficiency and machining quality are taken into account. The layering control method adopting support adding on the outlet side is adopted to effectively avoid or reduce the phenomenon of layering in machining.

Owner:WUHAN UNIV OF TECH

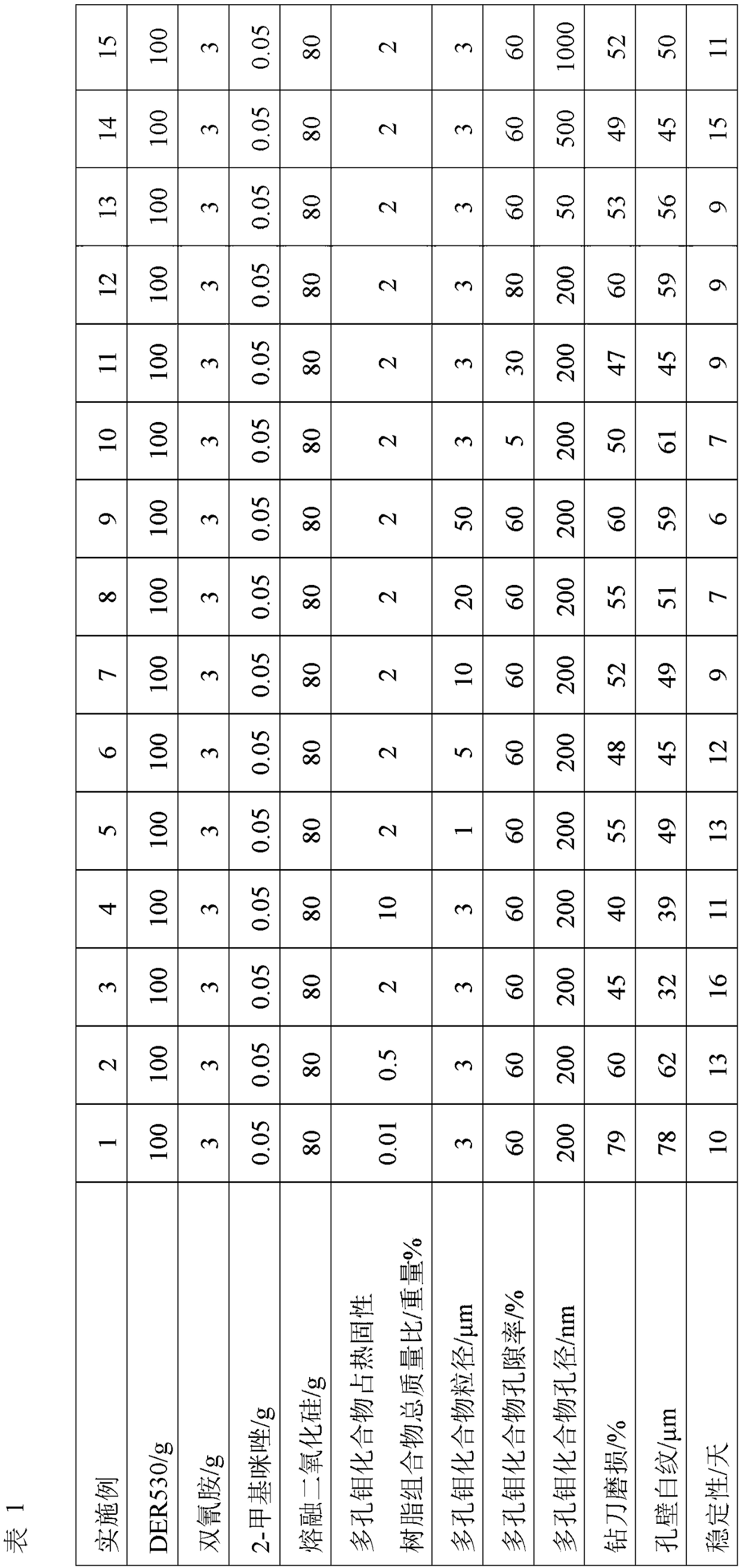

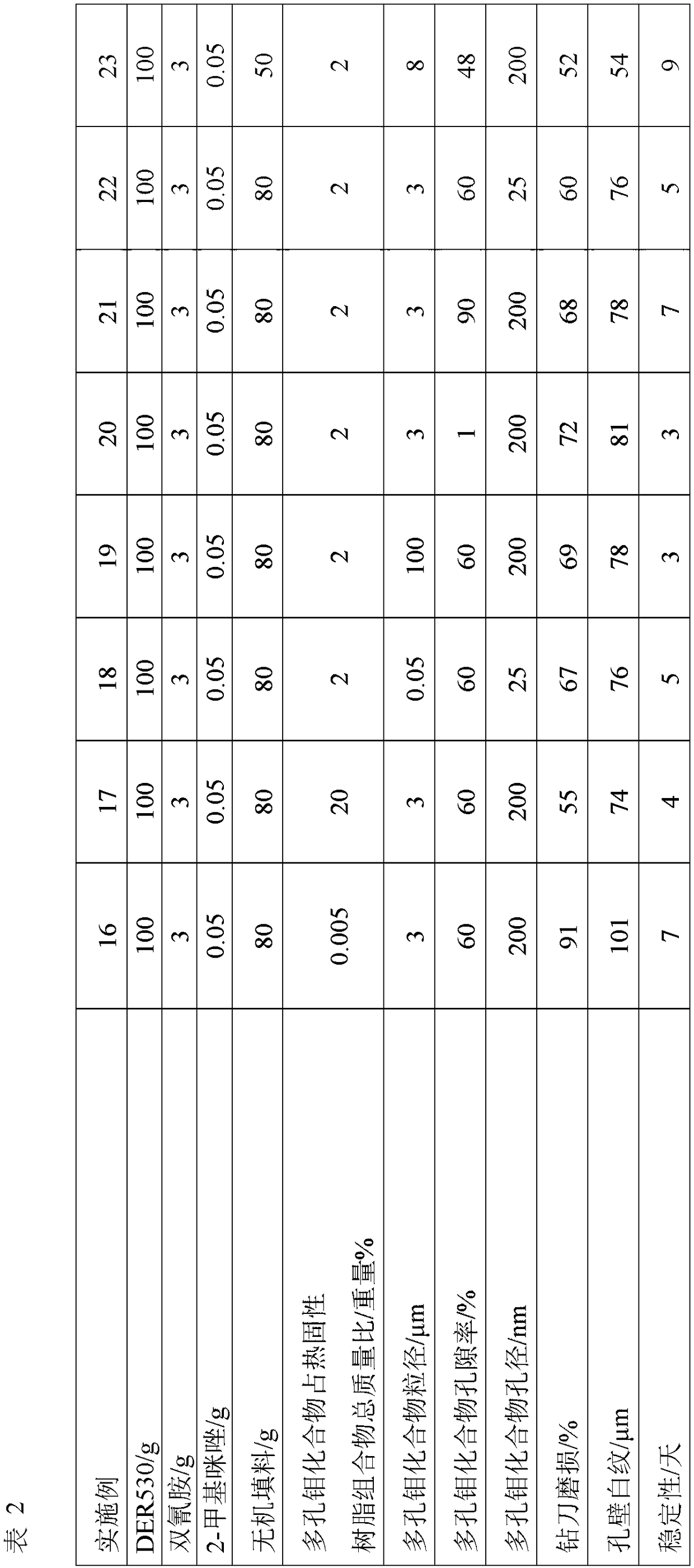

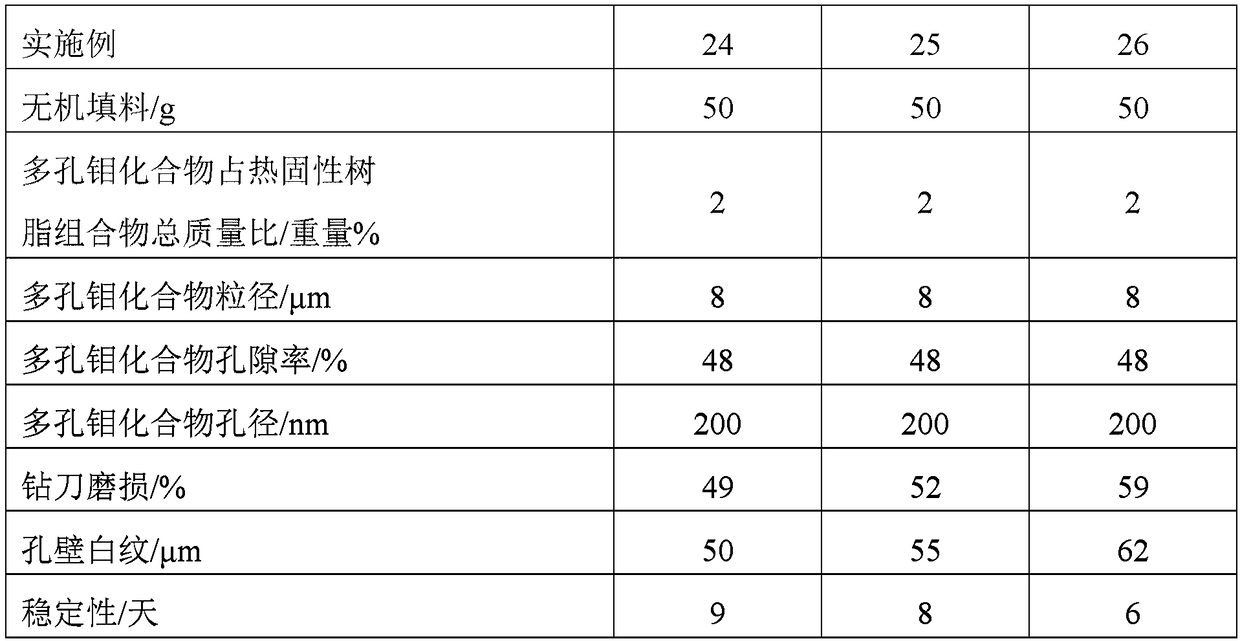

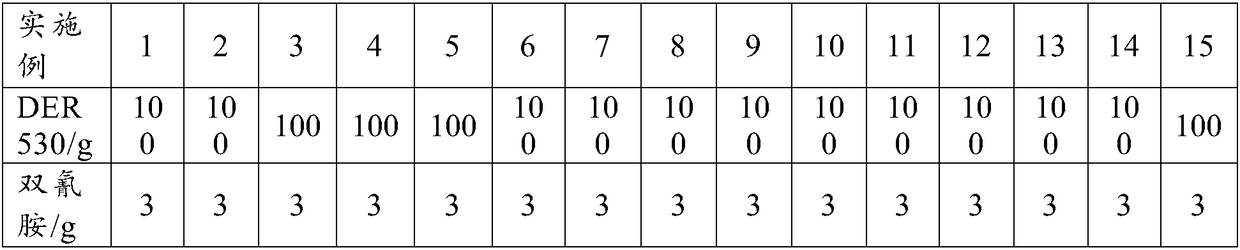

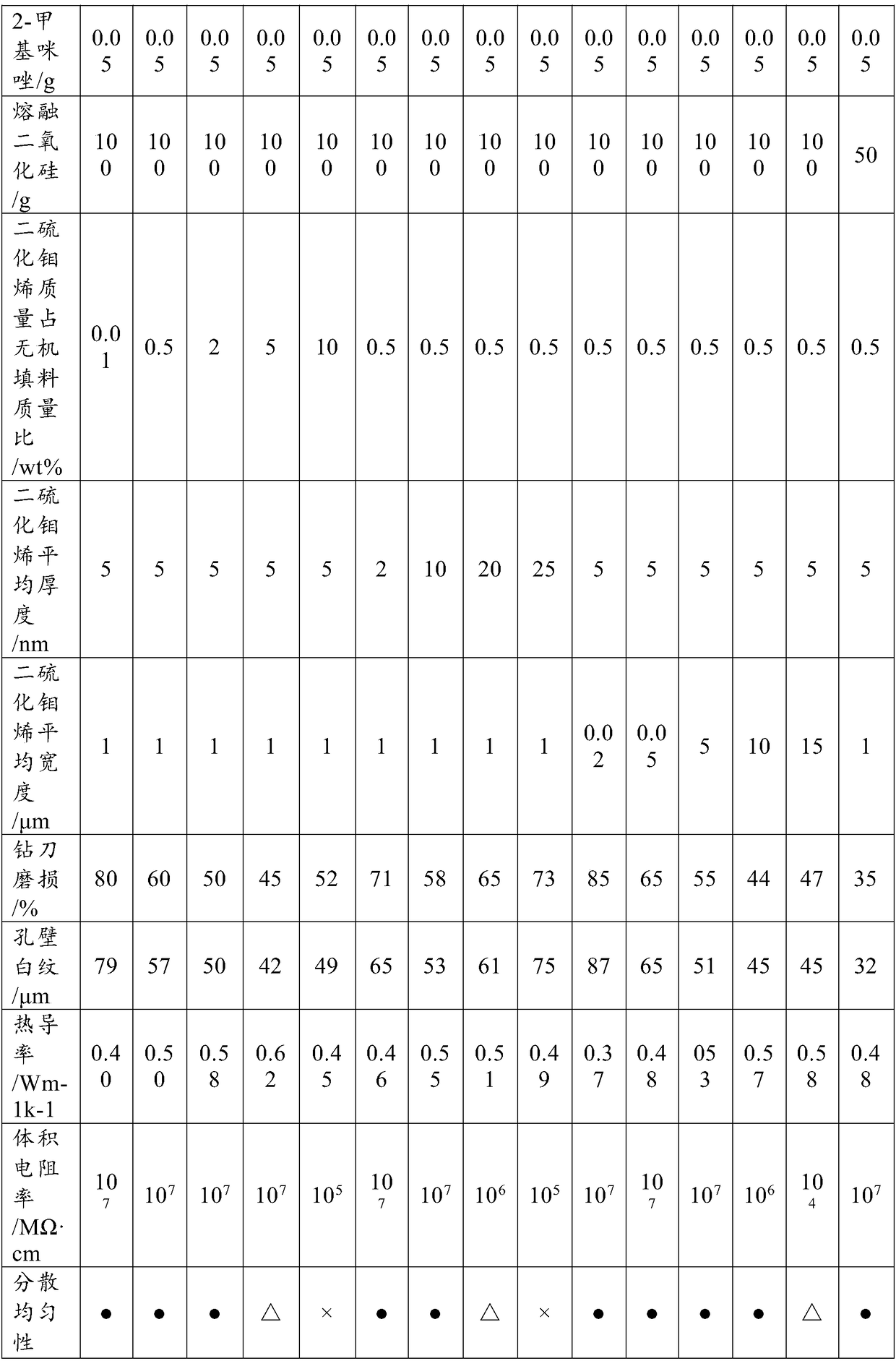

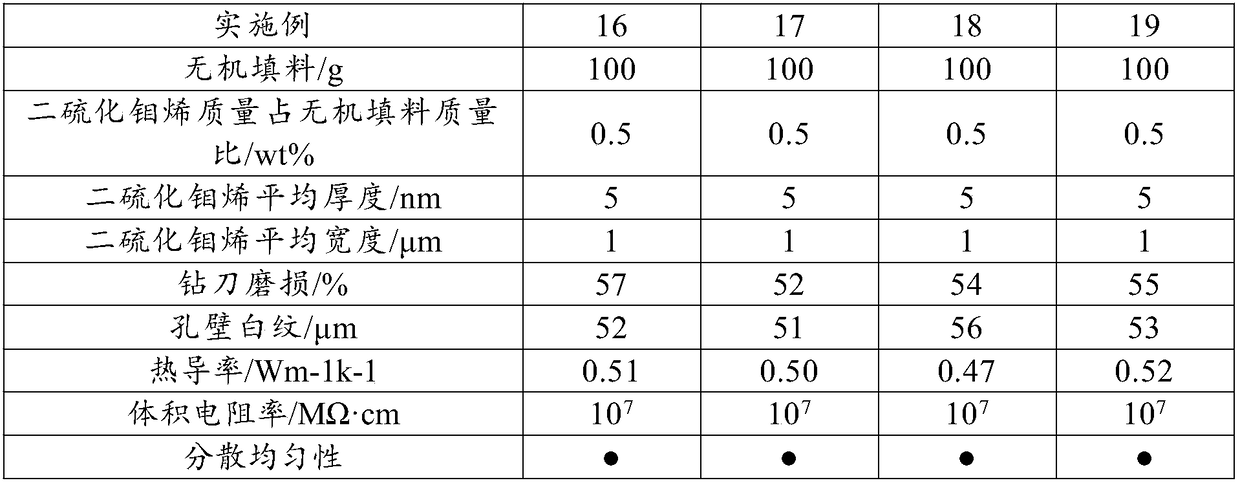

Thermosetting resin composition, prepreg, laminated board and printed circuit board

ActiveCN108148352AImprove thermal conductivitySolving Dispersion ProblemsSynthetic resin layered productsElectrical equipmentPrinted circuit boardLubricant

The invention provides a thermosetting resin composition, prepreg, a laminated board and a printed circuit board. The thermosetting resin composition is prepared from thermosetting resin, an inorganicfiller and a porous molybdenum compound. The thermosetting resin composition, the prepreg, the laminated board and the printed circuit board provided by the invention have the beneficial effects thatby use of the porous molybdenum compound as a solid lubricant, the problem of dispersion and sedimentation of the molybdenum compound can be effectively solved, and the molybdenum compound can be uniformly distributed in the prepreg; due to better heat conductivity of the porous molybdenum compound, the heat can be better conducted in drilling, the resin can be prevented from sticking on a drilling cutter after being molten, simultaneously the conditions such as hole cracking also can be reduced and the hole-wall quality after drilling can be obviously improved.

Owner:GUANGDONG SHENGYI SCI TECH

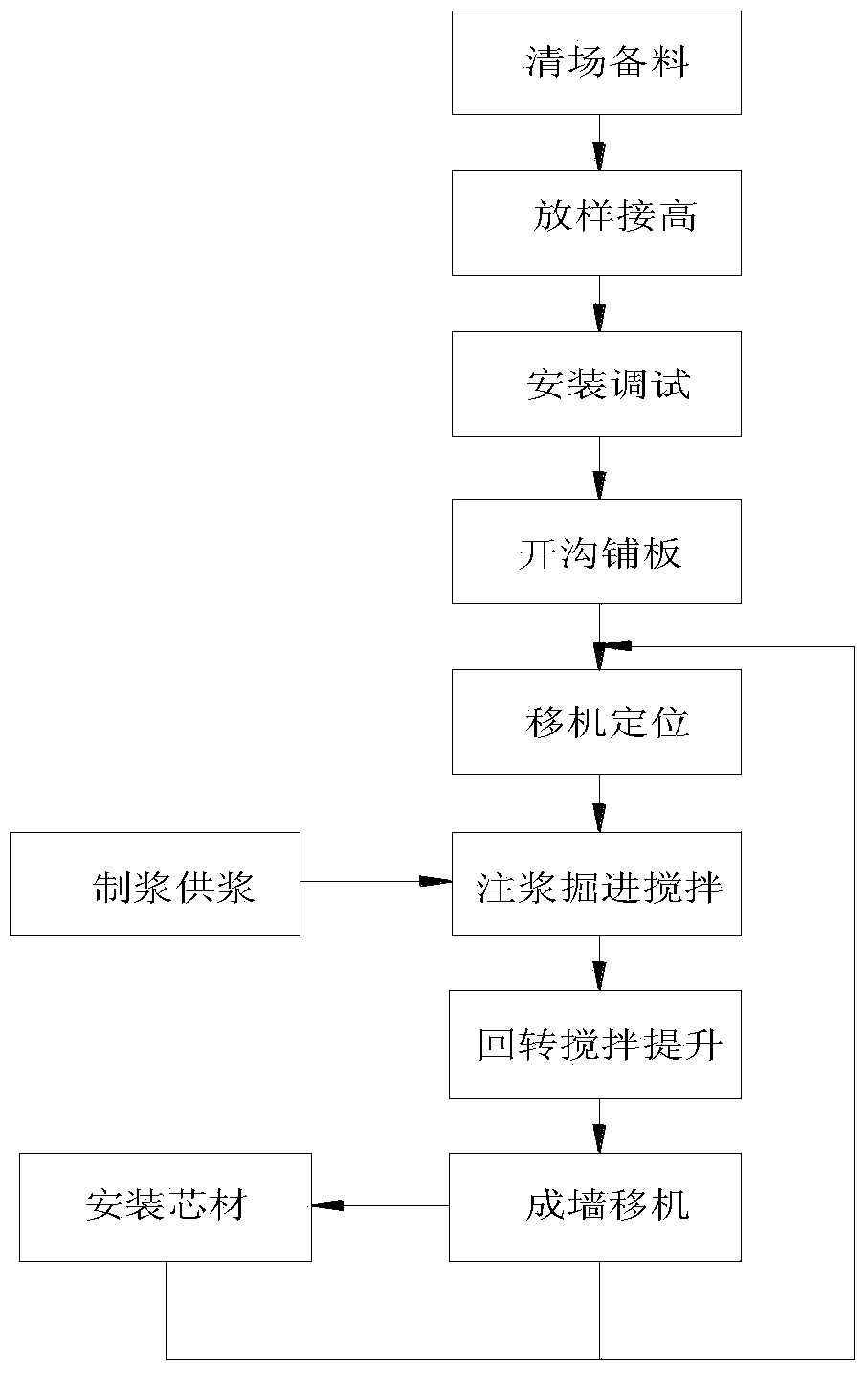

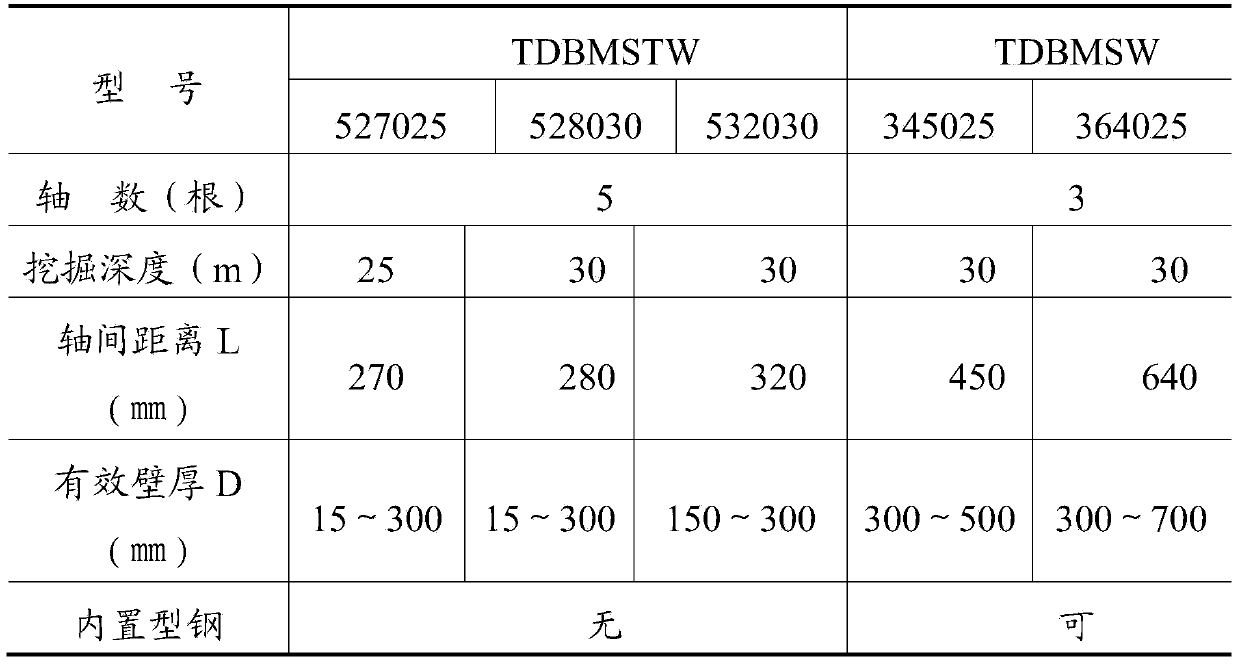

Method of constructing underground diaphragm wall by cement deep mixing

InactiveCN103741713AAdvanced methodGood impermeabilityArtificial islandsUnderwater structuresDrill pipeEnvironment effect

The invention discloses a method of constructing an underground diaphragm wall by cement deep mixing. The method includes: clearing a site and preparing materials; setting out and performing high jointing; mounting and regulating; trenching and laying plates; moving a machine and positioning; grouting, advancing and mixing; performing rotation mixing and lifting; forming a wall and removing the machine. The method has the advantages that the method is advanced; the wall has good continuity, integrity and impermeability; cement mixing volume in the depth direction meets the design requirements, mixing is even with compactness, and the wall is high in quality; the wall formed has high depth and small wall thickness; the use of split independent drive requires low energy consumption; stability is good and vertical accuracy is high; inner and outer drill pipes are good in concentricity and tightness; the structure is compact and fast and convenient to remove; strength is high and bearing capacity is high; work efficiency is high and manufacturing cost is low; the quality is good and environmental influence is low.

Owner:成张佳宁

End point closing wall forming device of extrusion type underground diaphragm wall and method for operating same

InactiveUS20180216304A1Improve the quality of the wallSave resourcesArtificial islandsUnderwater structuresSlurry wallWater spray

An end point closing wall forming device of an extrusion type underground diaphragm wall comprises a main body (1) and a vibration water spraying device. The vibration water spraying device is fixedly disposed inside the main body (1). The end point closing wall forming device of an extrusion type underground diaphragm wall further comprises a separation device. The separation device is movably sheathed on the outer side of a short edge (11′) of the main body (1). Also provided is a method for operating an end point closing wall forming device of an extrusion type underground diaphragm wall.

Owner:QINGDAO JINGLI ENG

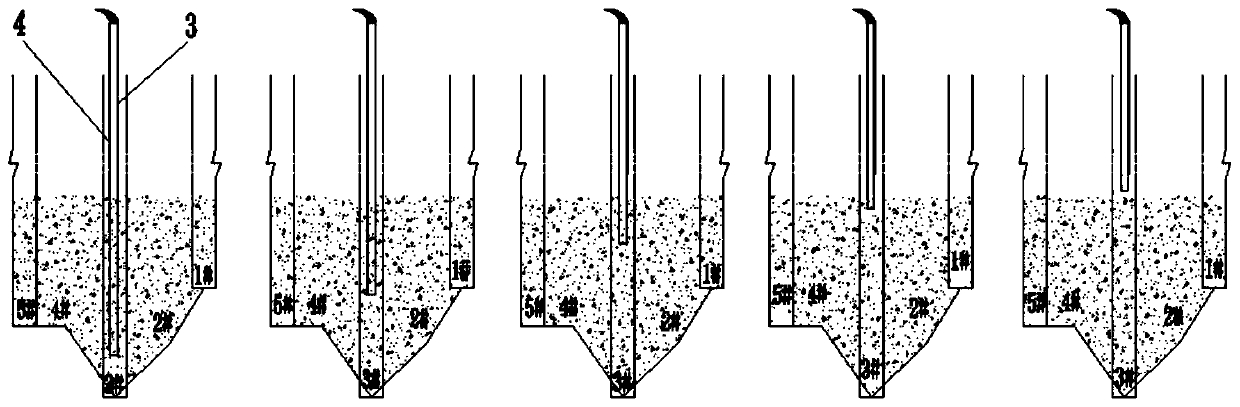

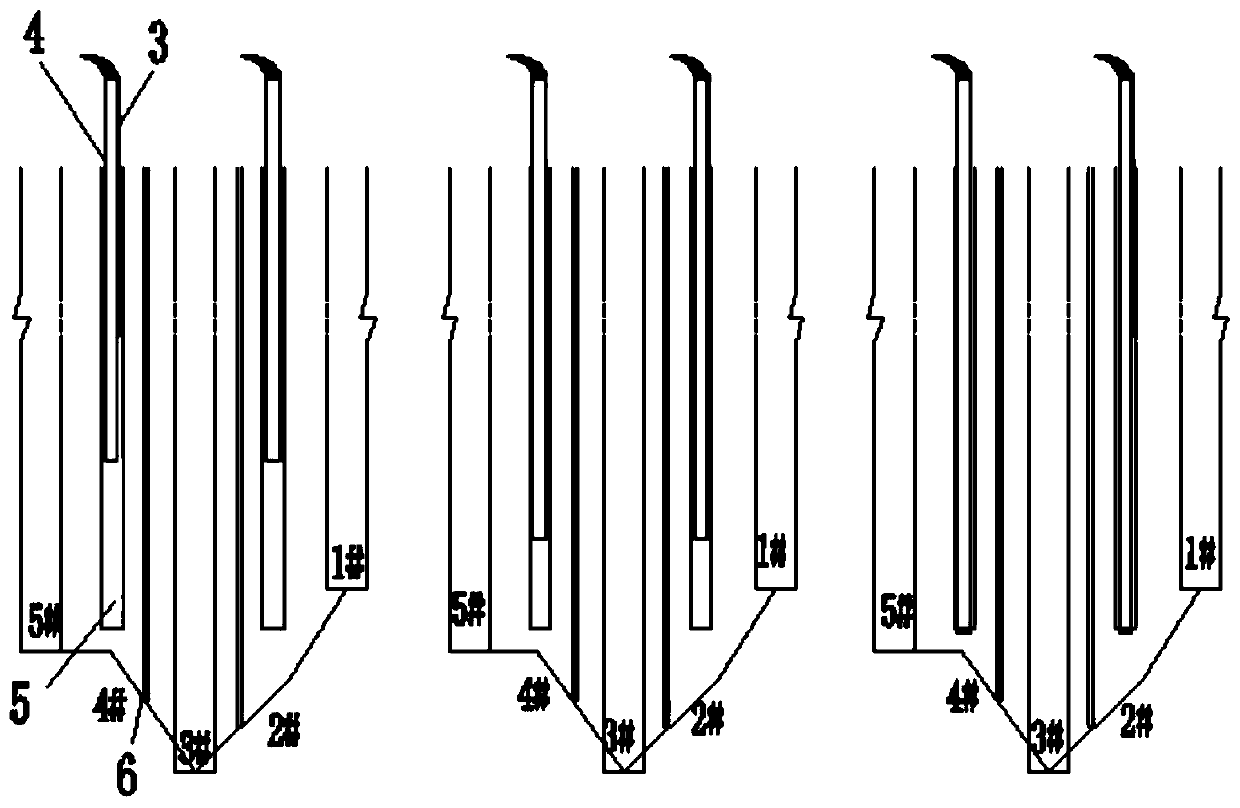

Dynamic hole cleaning method for ultra-deep impermeable wall

ActiveCN111042063ANo wall breakingGuaranteed cleaning effectMarine site engineeringBulkheads/pilesSlurryPipe

The invention discloses a dynamic hole cleaning method for an ultra-deep impermeable wall. The method includes the steps that after construction of a trench hole of the ultra-deep impermeable wall iscompleted, the trench hole is cleaned, and a plurality of embedded pipes, a joint pipe and a plurality of pouring conduits are lowered into the trench hole; air pipes for applying air force to the trench hole to be poured with concrete are lowered between the adjacent pouring conduits; and the concrete is poured into the trench hole through the pouring conduits, continuous lifting slurry discharging is carried out on the trench hole poured with the concrete by utilizing the air force applied by the air pipes to synchronously discharge slurry-mixed floccules formed by the upper layer of the concrete in the trench hole and slurry, and then the vertically continuous ultra-deep impermeable wall is formed by the continuously poured concrete. By means of the method, impermeable wall constructioncan be carried out on a river dike with the largest depth exceeding 180 meters, the slurry-mixed floccules and waste residues at the hole bottom are thoroughly removed during impermeable wall construction, the hole cleaning effect is guaranteed, the situation of pipe blockage is avoided, concrete pouring can be continuously carried out, and the phenomenon that the impermeable wall breaks due to cementation and hardening of the slurry-mixed floccules will not occur.

Owner:SINOHYDRO FOUND ENG

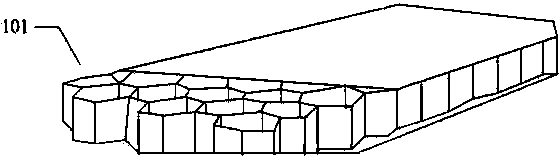

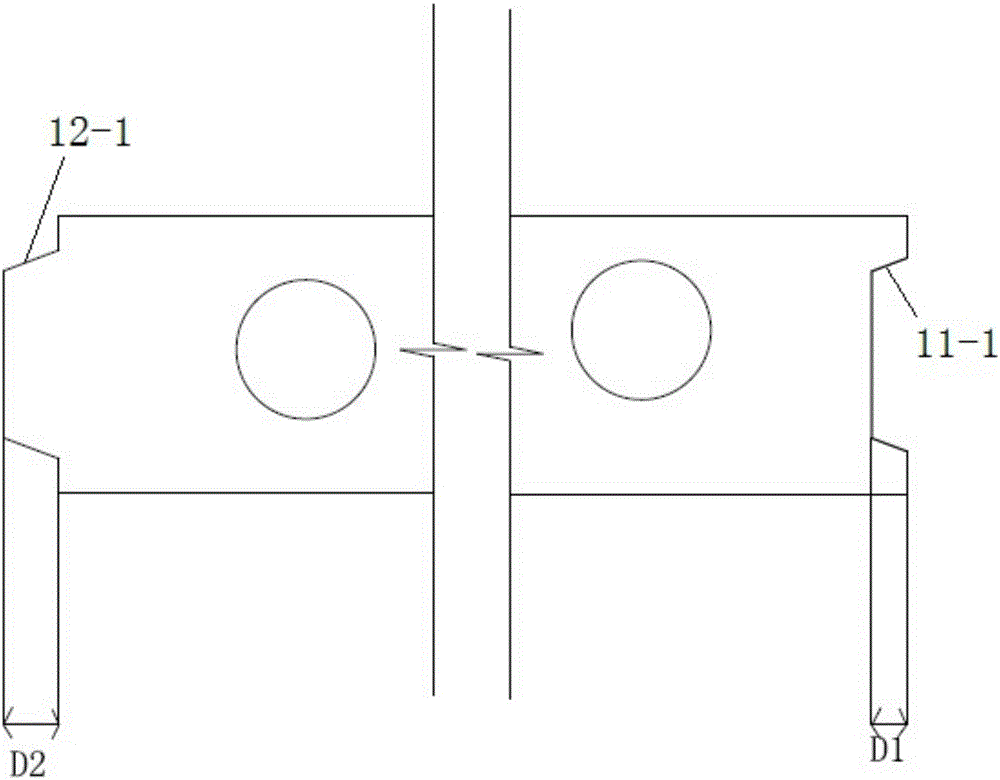

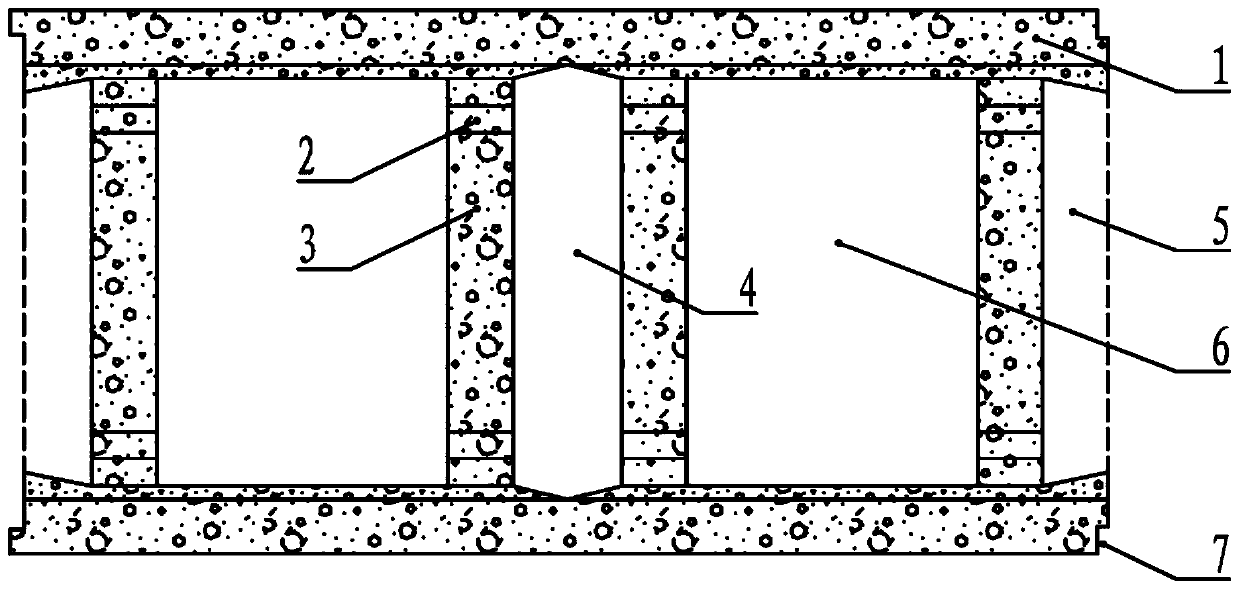

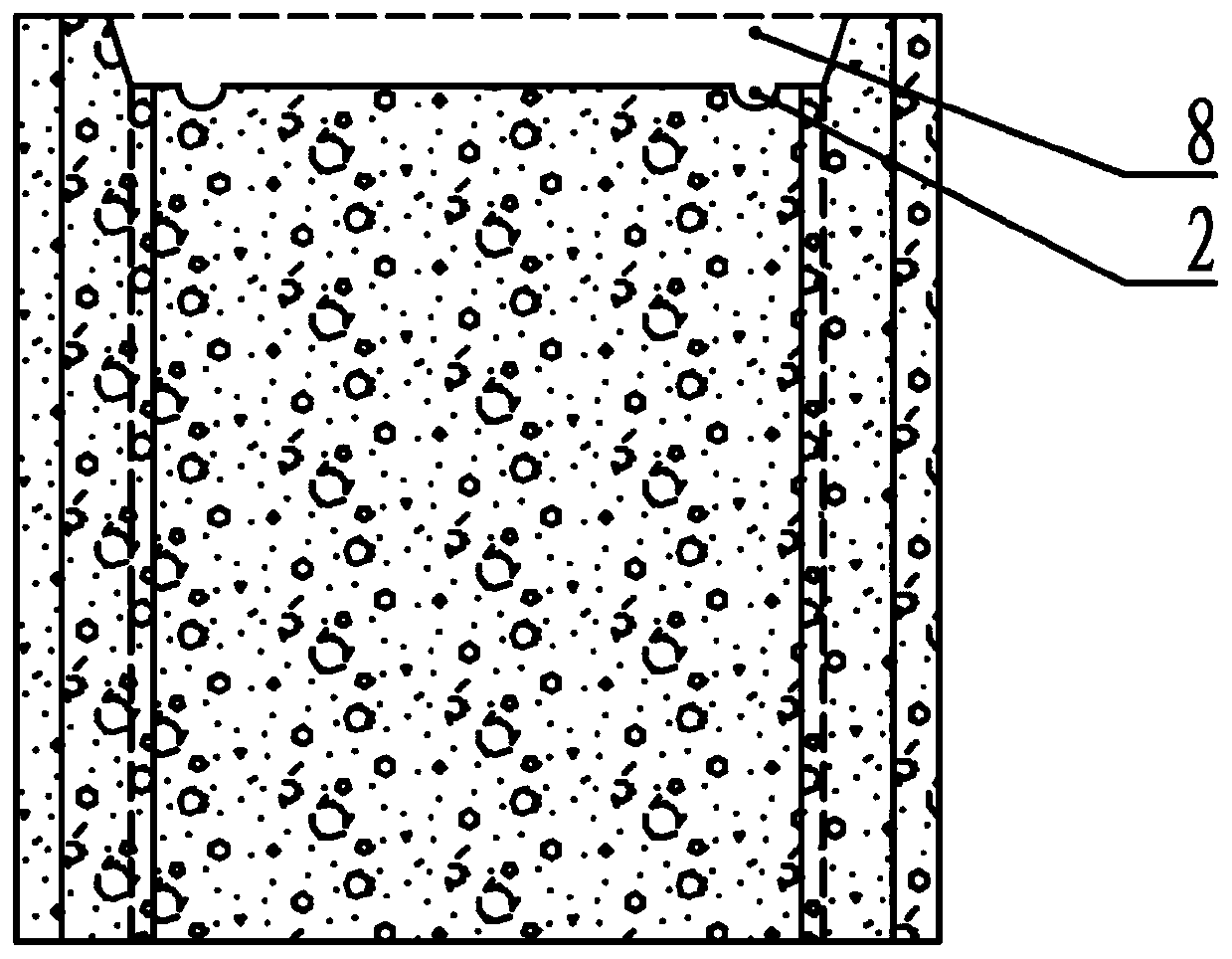

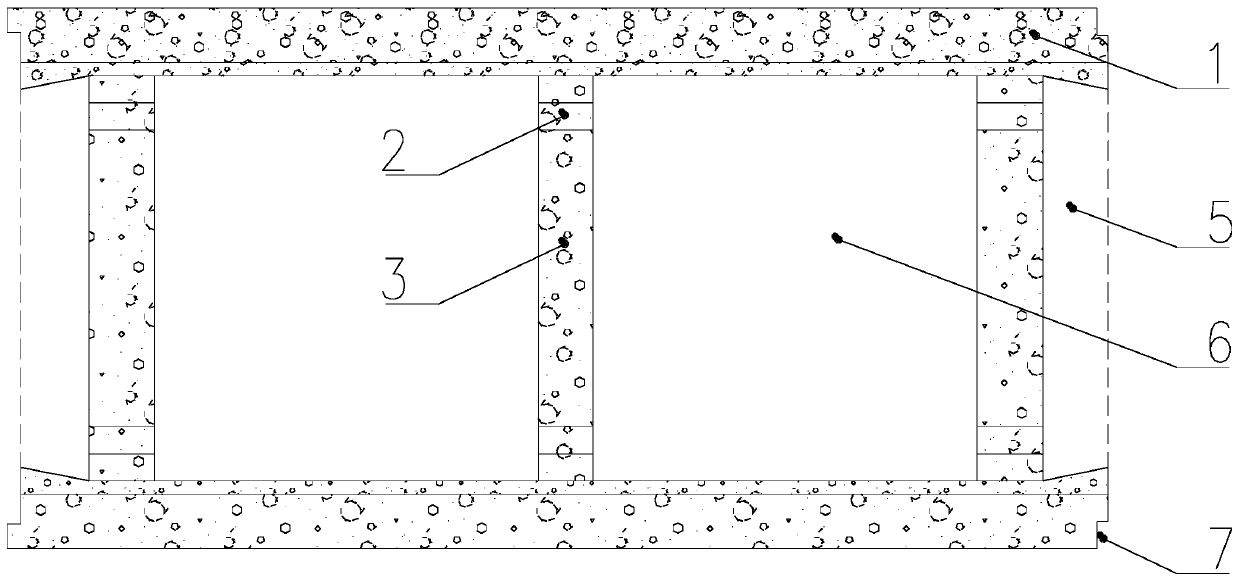

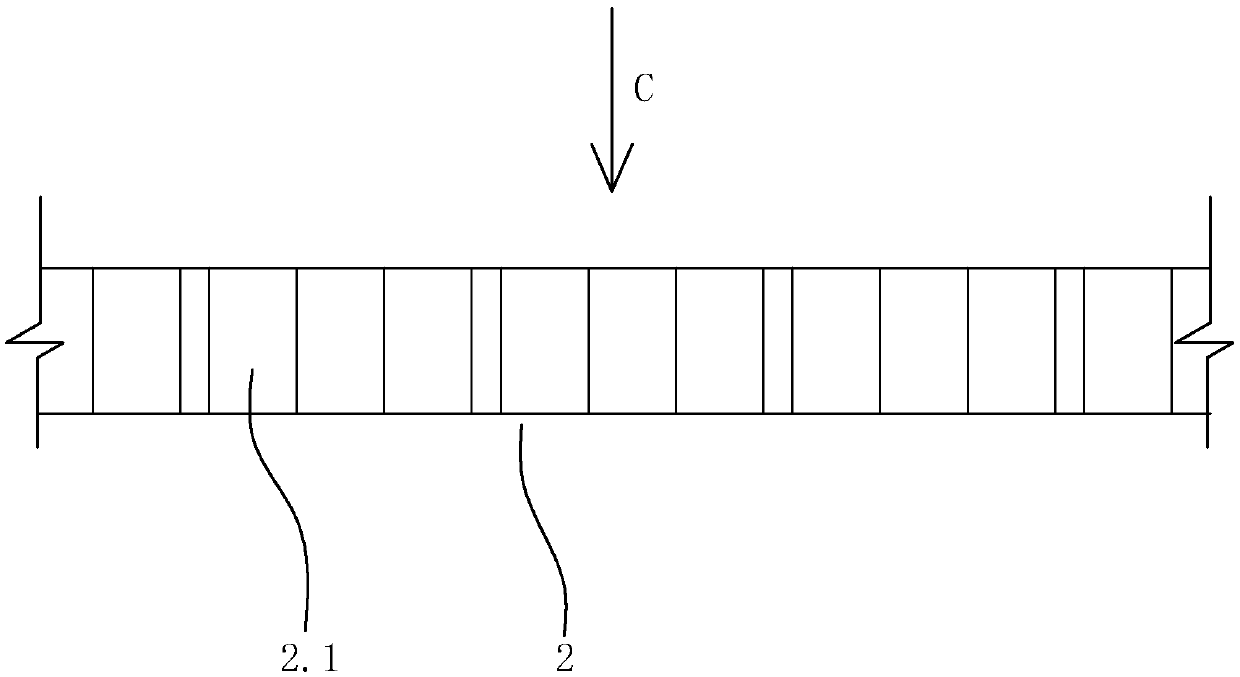

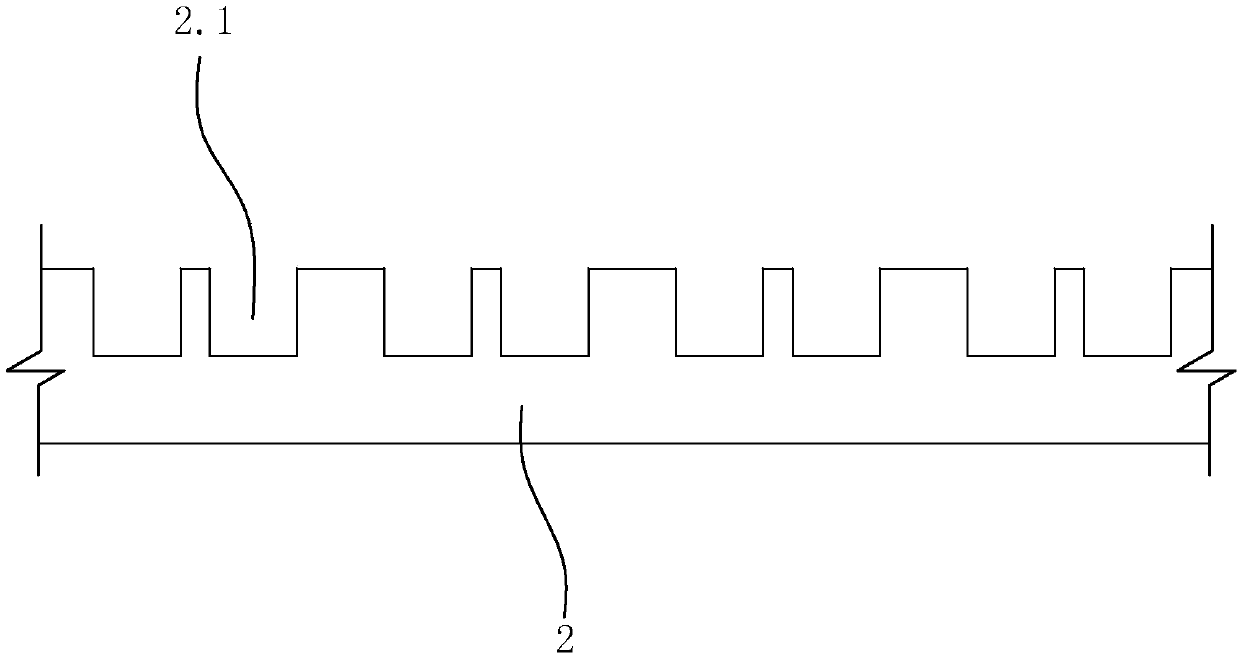

Light interior partition wall board and walling method for wall body

The invention discloses a light interior partition wall board and a walling method for the wall body. The wall board comprises a wall board body, wherein a groove and a protruding block are arranged on two longitudinal side faces of the wall board body respectively, and the widths of the groove and the protruding block are matched with each other; and the length D2 of the protruding block is 5-10 mm larger than the depth of the groove. According to the light interior partition wall board, the length of the protruding block is larger than the depth of the groove, so that not only splicing and fixing can be carried out, but also a gap can be formed, and during walling, two steps can be performed as follows: first, only the wall body is spliced, and second, grouting is carried out; and not only construction is facilitated, but also the fastness of the wall body is improved.

Owner:华夏 +1

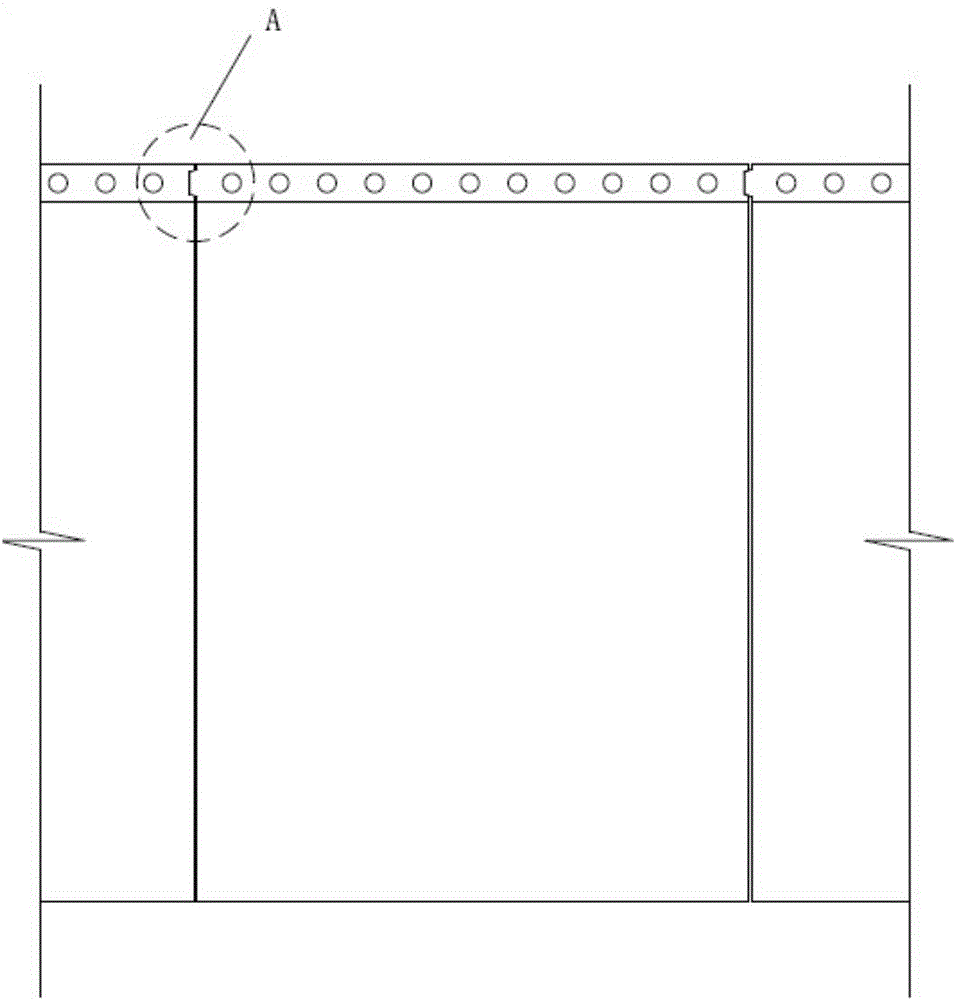

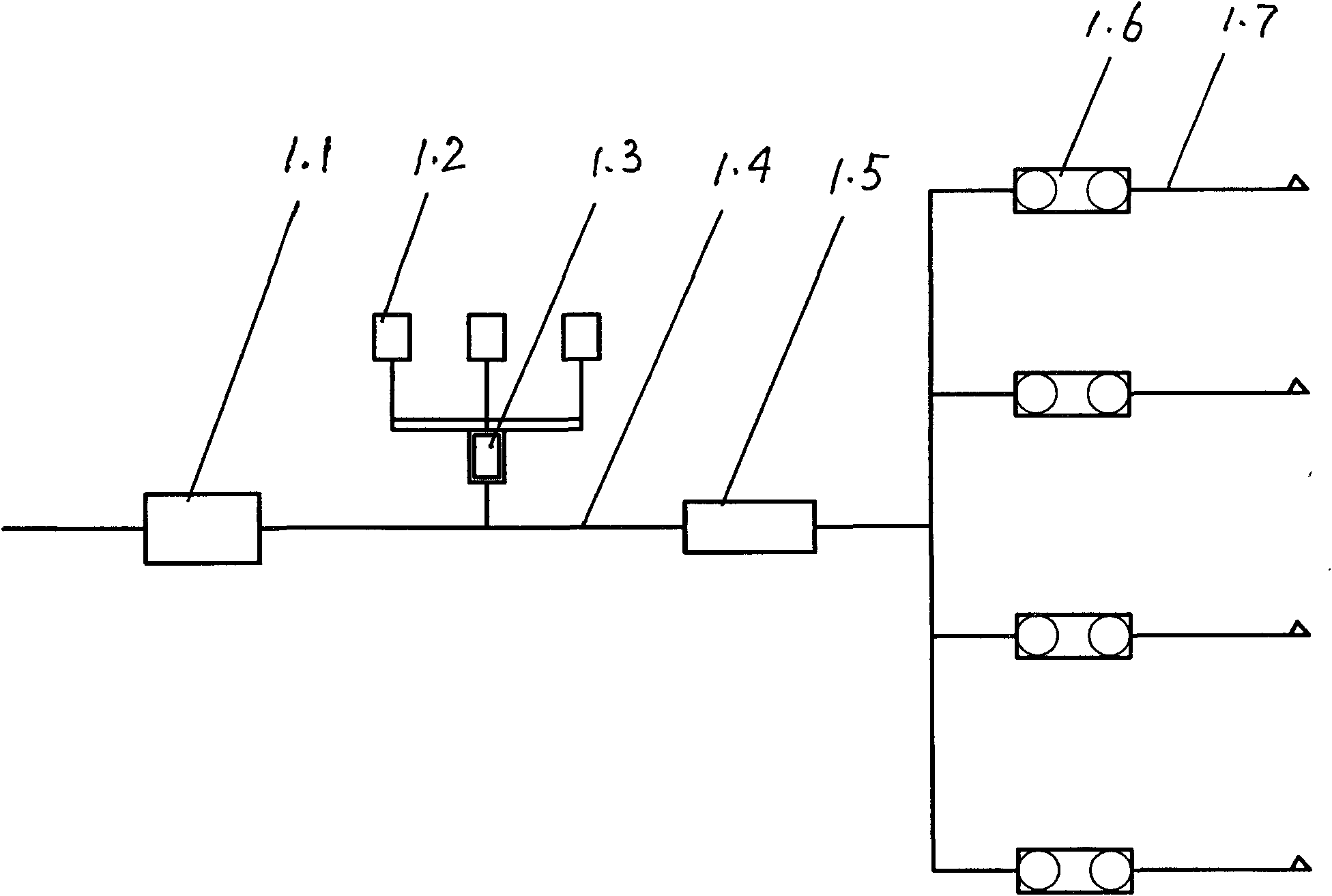

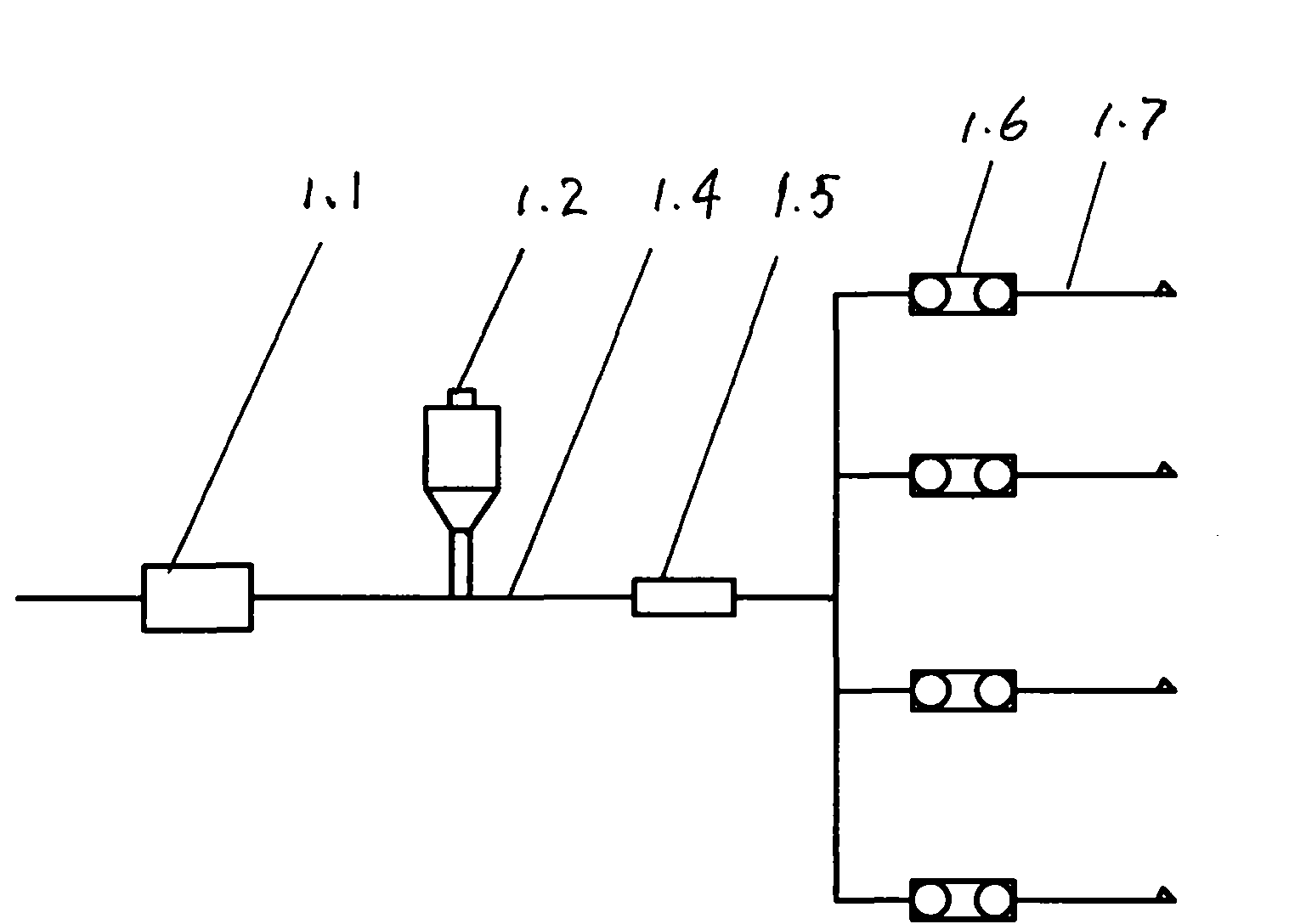

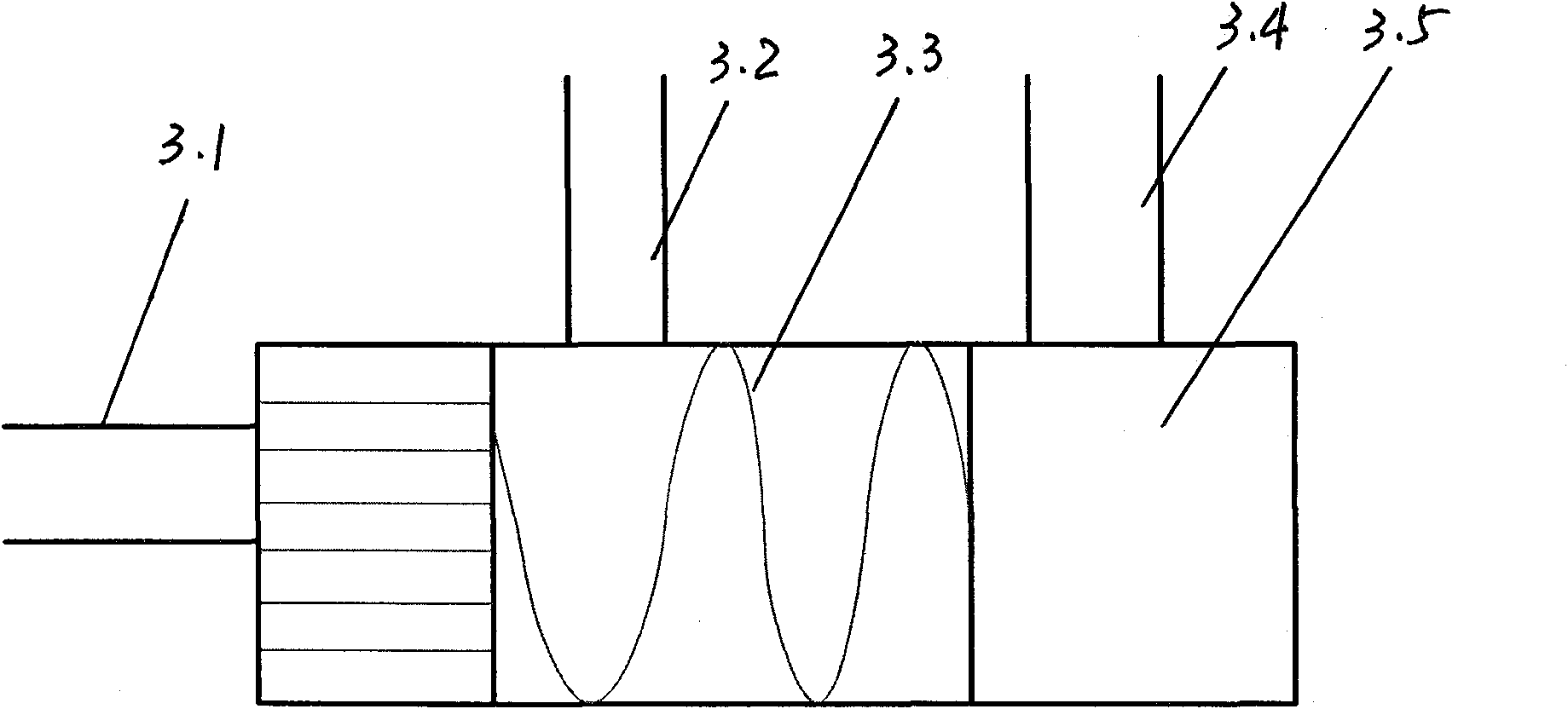

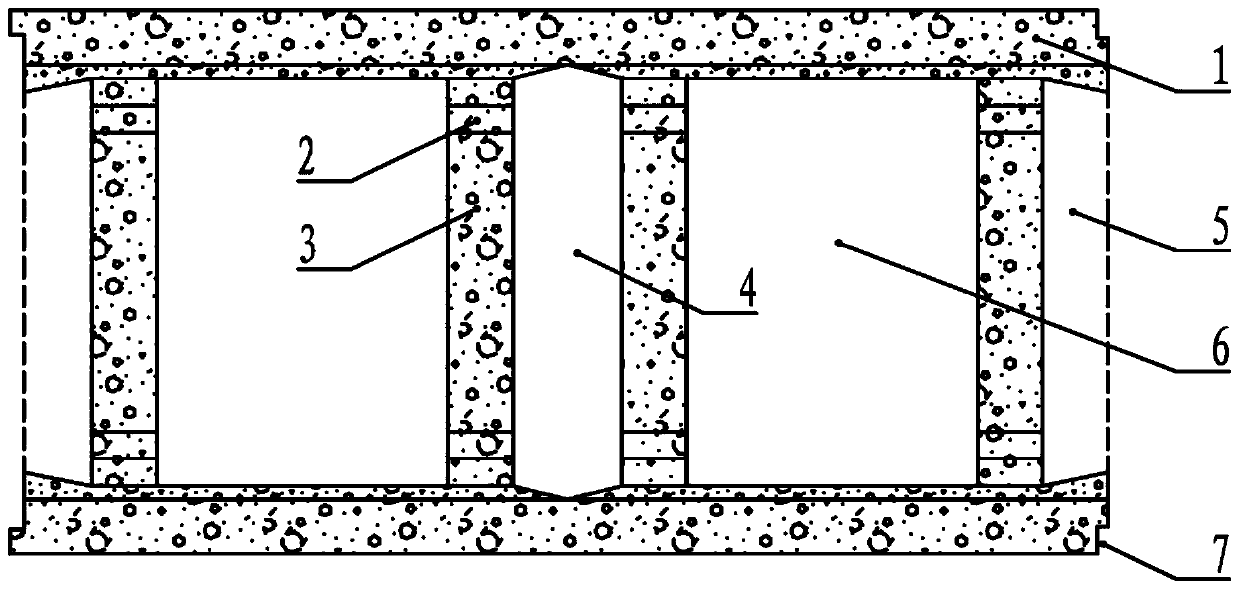

Gypsum wall in-situ concreting equipment system and construction method thereof

InactiveCN101914991AReduce labor intensityReduce wear and tearForms/shuttering/falseworksBuilding material handlingAdditive ingredientElectrical control

The invention provides a gypsum wall in-situ concreting equipment system and a construction method thereof. The invention is characterized in that gypsum and ingredients are conveyed to each operation point through pneumatic conveying; gypsum and ingredients are mixed with water at each operation point; the equipment system of the invention comprises a fan, a feeder, a conveying pipe, a shunt valve, a template group, a duct-type spiral mixing-delivering pump assembly and an electrical control part; and material is fed from one point and discharged from multiple points, or material is fed from multiple points and discharged from multiple points. The moulding method of the wall adopts the staged and layered construction method. The equipment system and method of the invention are characterized by high degree of automation, small dosage of material and high work efficiency.

Owner:曾周亮

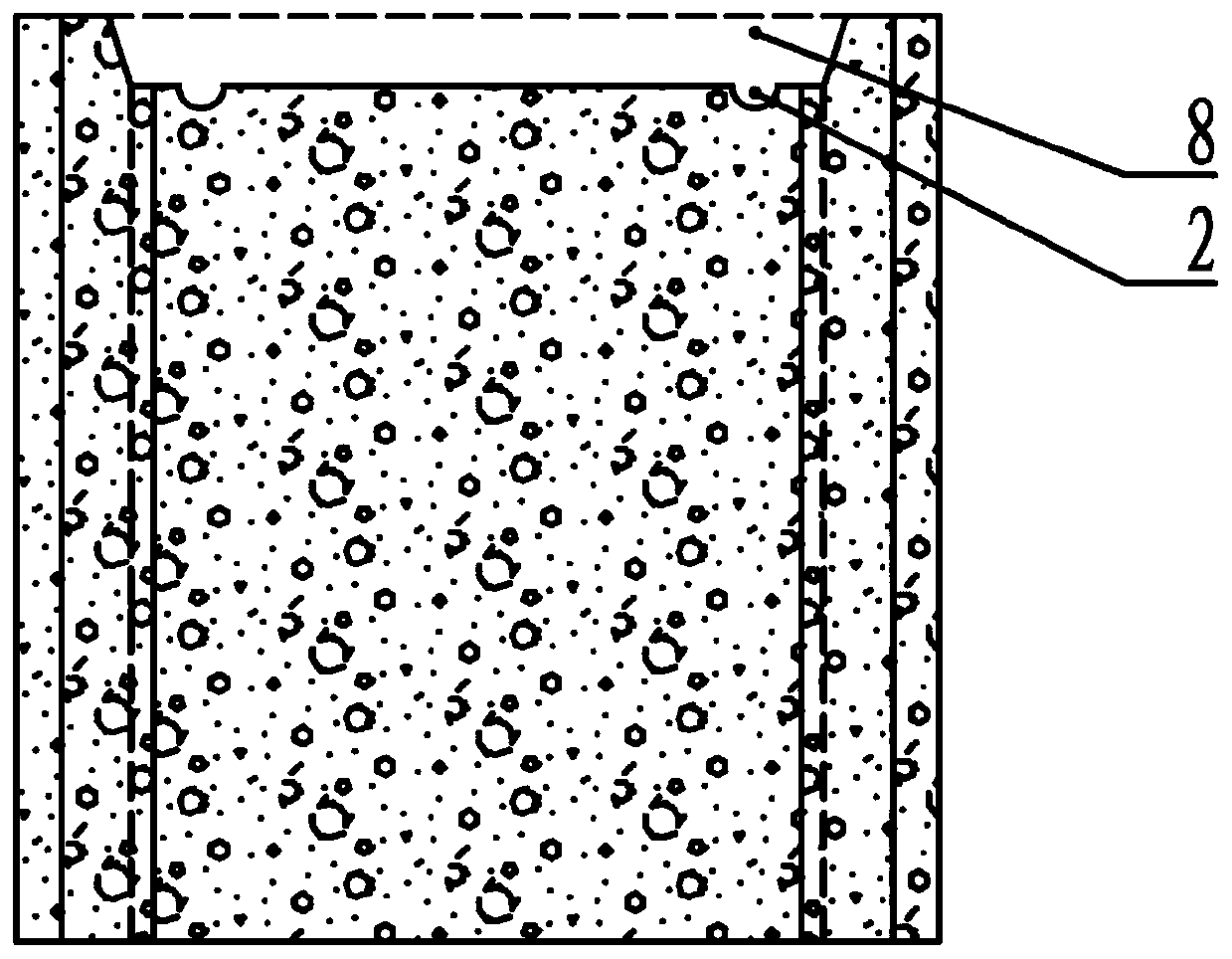

Construction technology for grouting type building blocks with aligned seams and assembled vertical holes

The invention relates to a construction technology for grouting type building blocks with aligned seams and assembled vertical holes. Building-block upper grooves are formed in the upper end faces ofthe building blocks, end grooves are formed in the left ends and the right ends of the building blocks, reserved steel bar grooves are formed in the groove bottoms of the building-block upper groovesin the length direction of the building blocks, holes are vertically formed in the middles of the building blocks in a penetrating mode, the end grooves are closing-in grooves with small openings andlarge bottoms, and grouting is carried out in the end grooves. The construction technology comprises the following steps that 1, the building blocks are stacked, wherein the lower-layer building blocks are stacked firstly, steel bars are pre-buried along the reserved steel bar grooves (2) after the lower-layer building blocks are stacked, then the upper-layer building blocks are stacked, the end grooves of the building blocks on each layer are tightly attached to one another, and the stacked building blocks on each column are arranged in an up-down aligned mode to form the aligned seams; 2, abonding material is poured into the end grooves of the building blocks stacked on the uppermost layer in the step 1; and 3, the bonding material forms bonding core columns.

Owner:宫莉

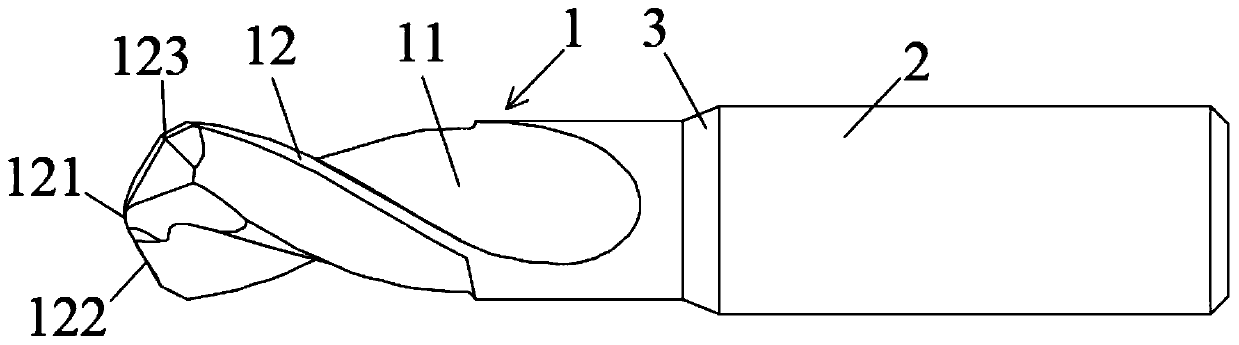

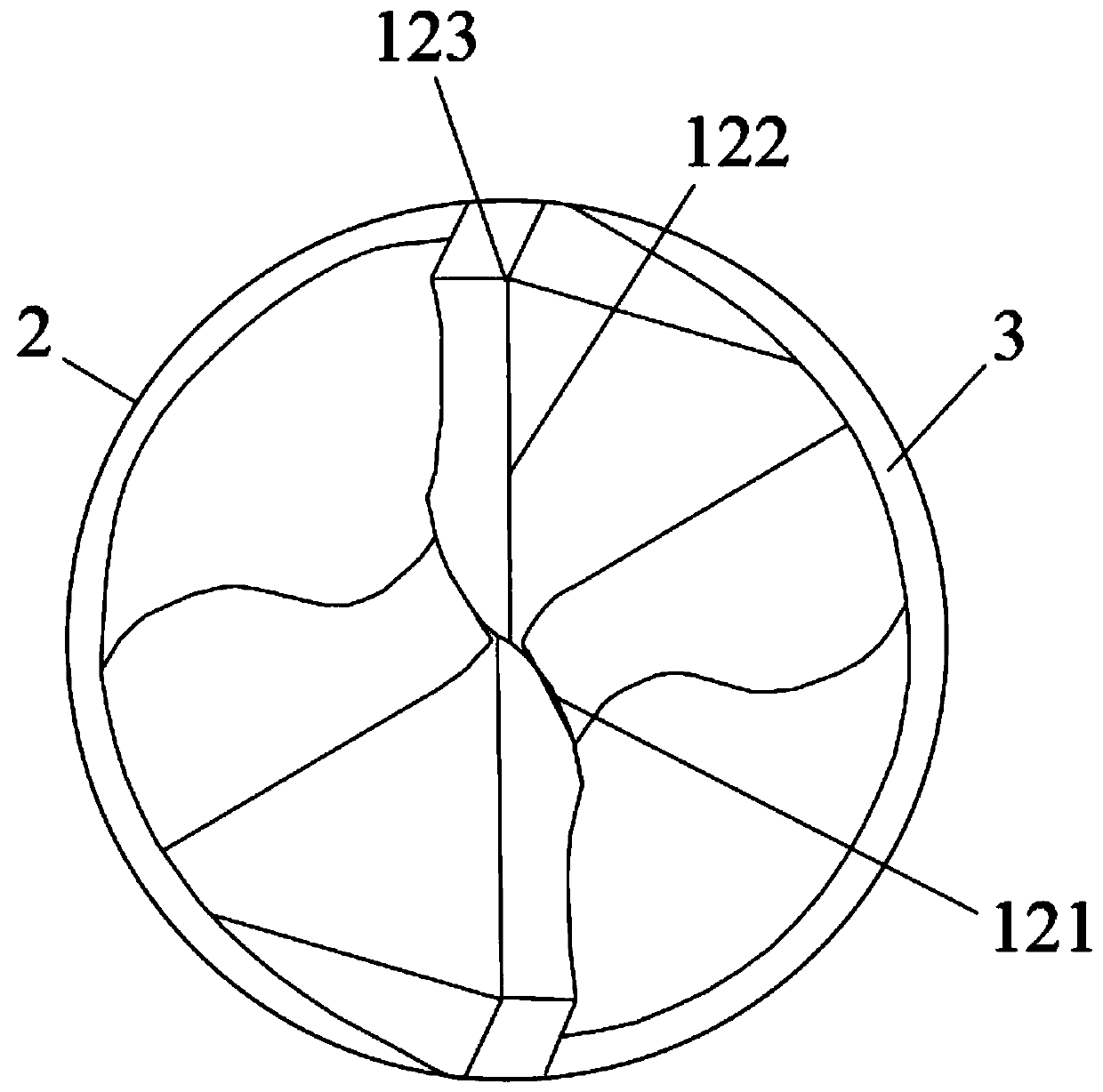

Drill bit for high-TG plate targeting hole machining

The invention belongs to the technical field of machining equipment, and particularly relates to a drill bit for high-TG plate targeting hole machining. The drill bit comprises a drill bit body and alengthened cutter handle; the drill bit body is connected with the lengthened cutter handle through a transition cone; the drill bit body is provided with a cutter groove and a cutting edge, wherein the cutter groove is arranged adjacent to the cutting edge; and the end part of the cutting edge is provided with a transverse edge, a low-edge drill point and a nose protection structure, and the transverse edge, the low-edge drill tip and the nose protection structure are sequentially connected. The drill point contains a grinding transverse edge, which is sharp in cutting, and a plate is not prone to deform; due to the fact that the nose protection is adopted at the sharp points on the two sides of a vertex angle, a hole is not limited to a straight-line shape or an arc shape, and the nose is resistant to disintegration and abrasion; and a side edge adopts a mode of grinding a back angle or reserving a cylindrical blade, and the quality of machining a hole wall is high due to the fact that grinding the back angle of the side edge is adopted.

Owner:GUANGDONG DTECH TECH CO LTD

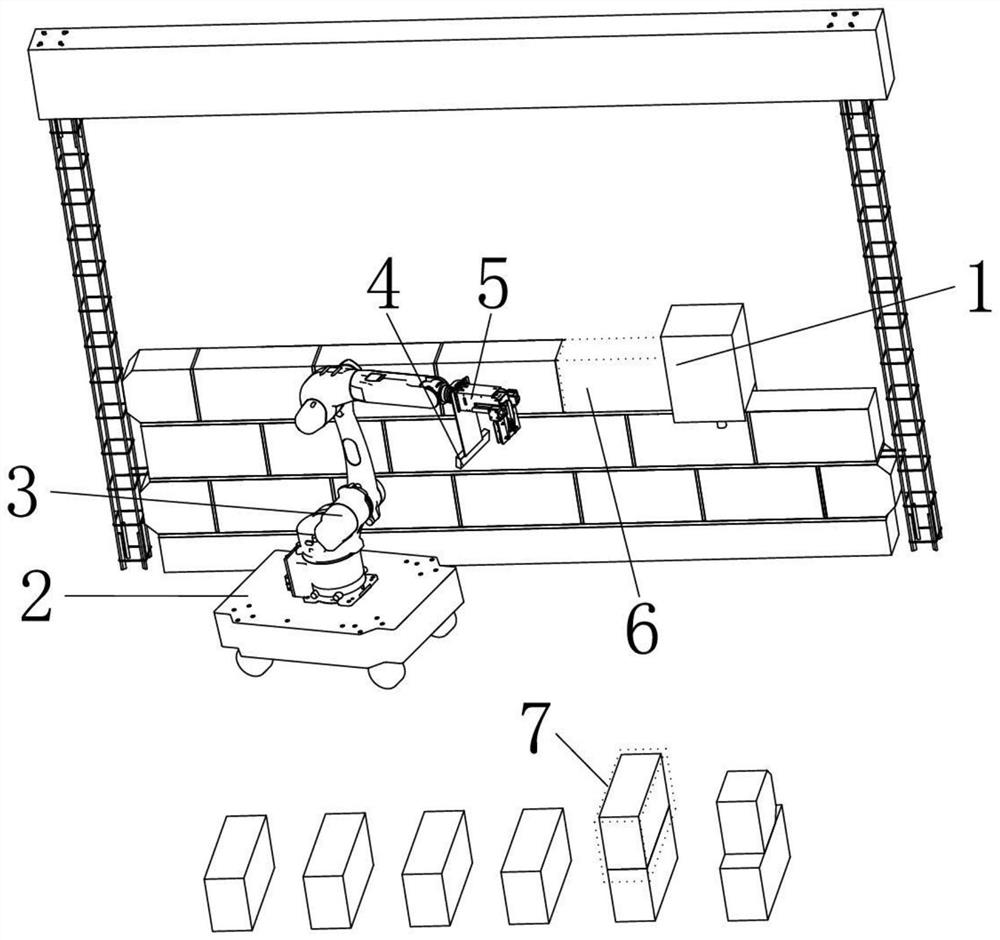

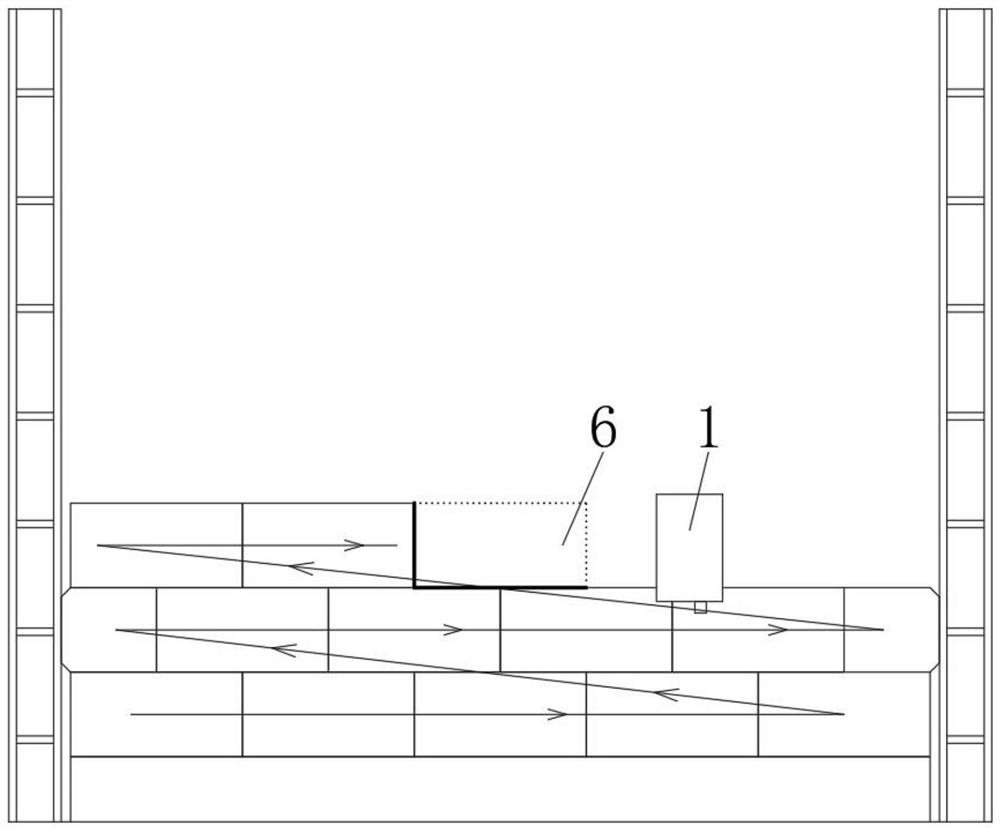

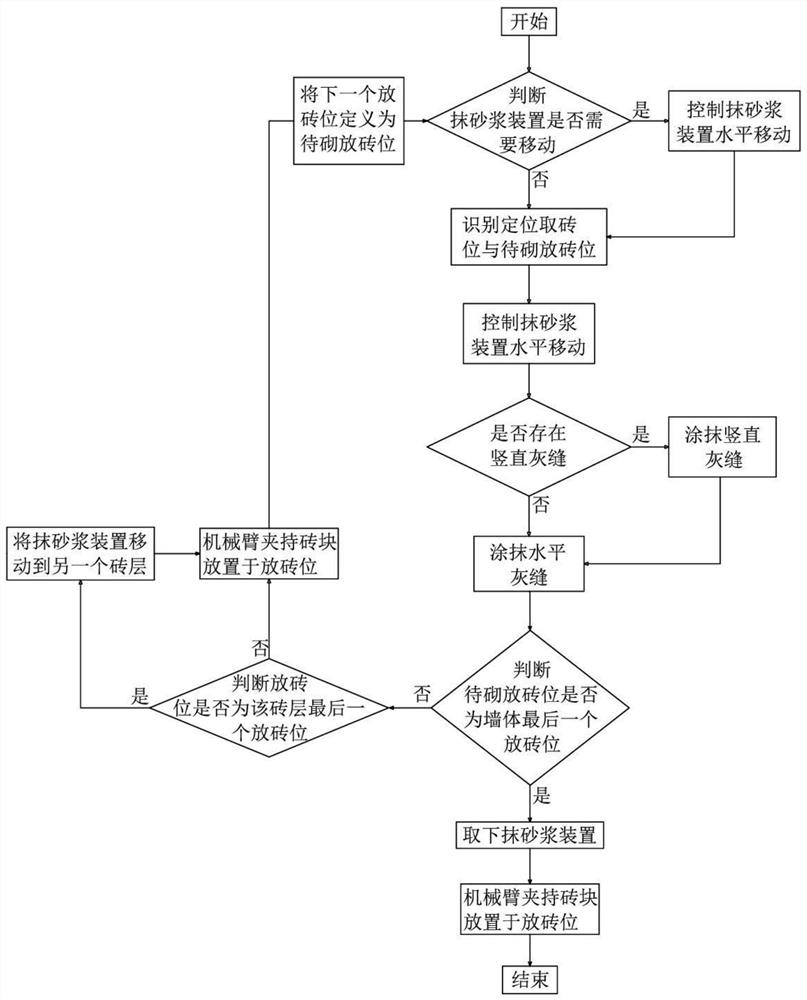

Wall building control method and system

InactiveCN112267696ALittle error in code placementImprove wall qualityProgramme-controlled manipulatorBuilding material handlingMortar jointStructural engineering

The invention discloses a wall building control method. A wall building robot and a mortar plastering device are included. The wall building control method is characterized by comprising the followingsteps that S1, whether the mortar plastering device is positioned on a wall body to be built or not is judged, and if yes, the next step is carried out; S2, whether the mortar plastering device is located at a to-be-built brick placing position or not is judged, and if yes, the mortar plastering device is controlled to move to expose the to-be-built brick placing position; and S3, a mechanical arm of the robot is controlled to move so as to carry an image acquisition device to shoot an image to acquire a brick taking position and the to-be-built brick placing position. According to the wall building control method, mortar plastering and brick stacking are separated, in the process that the mechanical arm controls a clamping device to clamp bricks, the mortar plastering device synchronously operates to plastering vertical mortar joints and horizontal mortar joints, so that the mechanical arm is directly placed into a brick placing position after clamping the bricks, brick stacking andmortar plastering synchronously operate, the wall building time is shortened, the mortar plastering device is separated from the mechanical arm, the mechanical arm only needs to execute brick stackingoperation, and the action process of the tail end of the mechanical arm is simplified.

Owner:中物智建(武汉)科技有限公司

Pre-installation method of concealed electrical box for filling wall

ActiveCN104405128BEasy to installFlexible adjustmentElectrical apparatusWallsSocial benefitsEngineering

The invention provides an earlier direct mounting method for a concealed distribution box of a filler wall. According to the technical scheme, the method comprises the following steps: preparing for construction; selecting a section bar bracket; making and mounting the section bar bracket; mounting the box; mounting inlet / outlet pipes of the box; building the filler wall; forming the wall masonry; after achieving design strength, removing the section bar bracket. According to the earlier direct mounting method for the concealed distribution box of the filler wall provided by the invention, the mounting is convenient, the adjusting is flexible, a large quantity of engineering practices prove that the mounting quality is greatly increased by the technique, and meanwhile, the quality of the filler wall and plastering is effectively increased, the construction is safe and environment-friendly, the construction period is effectively shortened, the cost is reduced, the excellent economic, technical and social benefits are achieved, and the method has positive popularization and application values.

Owner:CHINA MCC17 GRP

Thermosetting resin composition and application thereof

ActiveCN109486111AUniform and stable dispersionGood compatibilityGlass/slag layered productsCircuit susbtrate materialsAlkenePrinted circuit board

The invention discloses a thermosetting resin composition and application thereof. The thermosetting resin composition contains thermosetting resin and inorganic filler, and the inorganic filler is subjected to wrapping treatment by molybdenum alkene disulfide; and on the basis of the total mass of the thermosetting resin composition, the content of the inorganic filler is 10wt%-80wt%. According to the provided thermosetting resin composition, the molybdenum alkene disulfide wraps the inorganic filler, the compatibility of the inorganic filler and a resin system can be improved effectively, and the resin composition which is uniform and stable in dispersion can be obtained without complicated dispersing equipment. Provided prepreg is prepared by dipping the thermosetting resin compositionin a reinforcing material and then drying the thermosetting resin composition, problems about dispersion and settling of a molybdenum compound are solved effectively, and the molybdenum compound can be uniformly distributed in the prepreg. A provided laminated board contains at least one prepreg; and a provided printed circuit board contains at least one prepreg.

Owner:珠海三臻新材料科技有限公司

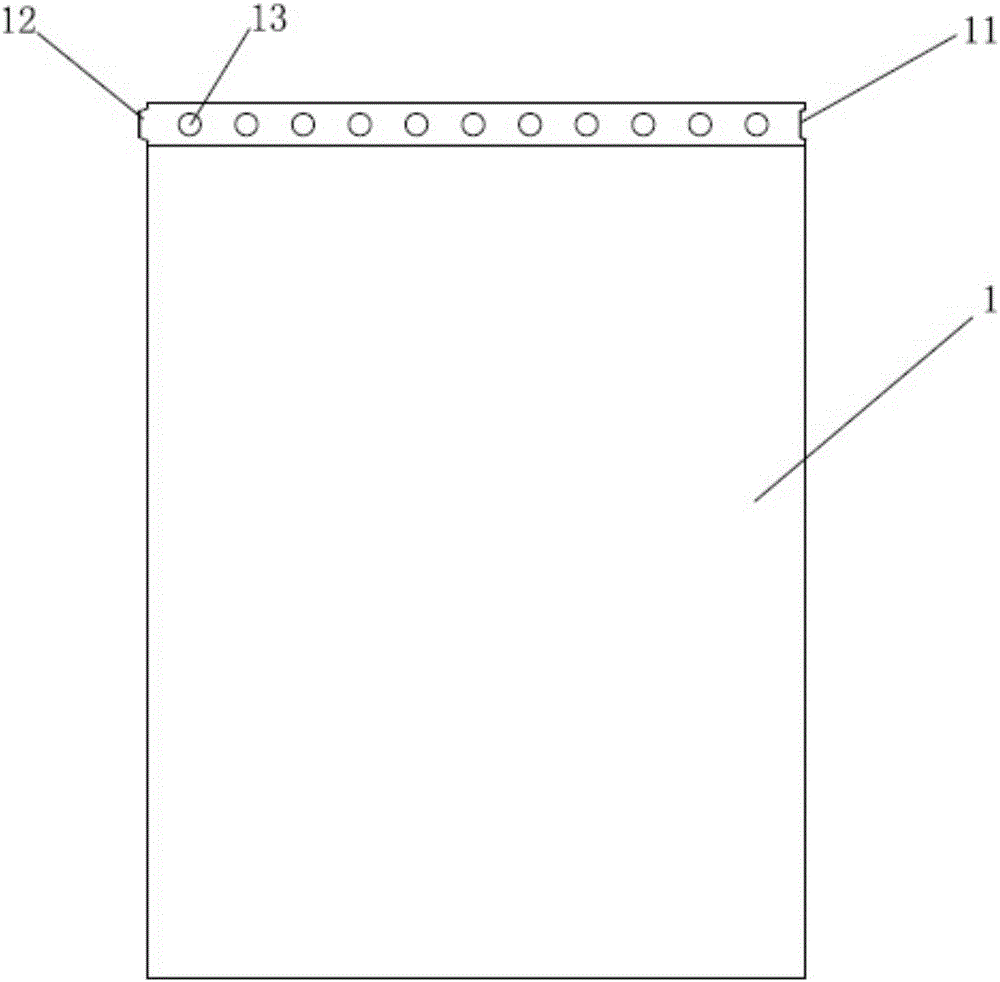

Positioner for profile steel fender pile construction and profile steel construction method

ActiveCN109537575AImprove the quality of the wallBulkheads/pilesMaterials scienceBuilding construction

The invention discloses a positioner for profile steel fender pile construction and a profile steel construction method, wherein profile steel can be inserted into a cement cob wall according to designed axis when the profile steel is inserted into the stirred cement cob wall by means of a TRD construction method or an SMW construction method, so that the profile steel in the cement cob wall is ina vertical state and the steel profile can be inserted into the stirred cement cob wall according to the separation distances required by the design. The positioner for profile steel fender pile construction comprises a supporting and positioning framework and at least two movable positioning frames, wherein two slot cross beams which are parallel to each other are arranged on the supporting andpositioning framework, and a plurality of positioning slots are formed in the slot cross beams; each movable positioning frame comprises a positioning top frame, a positioning bottom frame below the positioning top frame and a vertical connecting rod which connects the positioning top frame and the positioning bottom frame. The movable positioning frames are hung on the two slot cross beams through the positioning top frames, and the positioning top frames are positioned in the positioning slots of the slot cross beams.

Owner:DONGTONG ROCK SOIL SCI & TECH HANGZHOU

Selection and control method of punching pile protection wall structure material for special geological conditions

The invention discloses a selection and control method of a punching pile protection wall structure material for special geological conditions. During punching in strongly and moderately weathered rock, the protection wall material adopts clay slurry making; during punching in powder sand layers and gravel geological structure layers, the slurry making material is formed by mixing expansive soil with cement, and parameters such as the viscosity and the like of the mixed slurry are controlled strictly; during punching under moderately and weakly weathered geological conditions and in sections having relatively flat pile construction positions, clay, cement and calcined gypsum are mixed to form slurry, and parameters such as the viscosity and the like of the mixed slurry are controlled strictly; the protection wall quality under the different geological conditions is improved, and the construction progress is accelerated.

Owner:云南建投第十一建设有限公司

Vertical hole grouting type building block its construction process thereof

PendingCN111411731AReduce manufacturing costImprove stabilityWallsEarthquake resistanceArchitectural engineering

The invention relates to a vertical hole grouting type building block and a construction process thereof. End grooves are formed in the two ends of building blocks, holes are reserved in the middles of the building blocks, after the building blocks are stacked, bonding mortar or concrete are poured into the end grooves to form a mortar or concrete core column, and through the core column, the leftparts and the right parts of the building blocks are bound in a connected mode and the upper parts and the lower parts of the building blocks are bound in serious; the construction effect is high, the connection strength between the building blocks and the flatness, stability and seismic resistance of an entire building block wall surface are high, the efficiency is improved, and the cost is saved; and a wall body is not hollow or not cracking, the vertical hole grouting type building block and the construction process thereof are suitable for neat joint masonry, furthermore, grouting holes are formed on the basis of forming the end grooves in the two ends of the building blocks, and the vertical hole grouting type building block and the construction process thereof are suitable for bothneat joint masonry and staggered joint masonry.

Owner:宫莉

The way to form ultra -deep anti -seepage walls

ActiveCN111042063BNo wall breakingGuaranteed cleaning effectMarine site engineeringBulkheads/pilesSlurryPipe

The invention discloses a dynamic hole cleaning method for an ultra-deep impermeable wall. The method includes the steps that after construction of a trench hole of the ultra-deep impermeable wall iscompleted, the trench hole is cleaned, and a plurality of embedded pipes, a joint pipe and a plurality of pouring conduits are lowered into the trench hole; air pipes for applying air force to the trench hole to be poured with concrete are lowered between the adjacent pouring conduits; and the concrete is poured into the trench hole through the pouring conduits, continuous lifting slurry discharging is carried out on the trench hole poured with the concrete by utilizing the air force applied by the air pipes to synchronously discharge slurry-mixed floccules formed by the upper layer of the concrete in the trench hole and slurry, and then the vertically continuous ultra-deep impermeable wall is formed by the continuously poured concrete. By means of the method, impermeable wall constructioncan be carried out on a river dike with the largest depth exceeding 180 meters, the slurry-mixed floccules and waste residues at the hole bottom are thoroughly removed during impermeable wall construction, the hole cleaning effect is guaranteed, the situation of pipe blockage is avoided, concrete pouring can be continuously carried out, and the phenomenon that the impermeable wall breaks due to cementation and hardening of the slurry-mixed floccules will not occur.

Owner:SINOHYDRO FOUND ENG

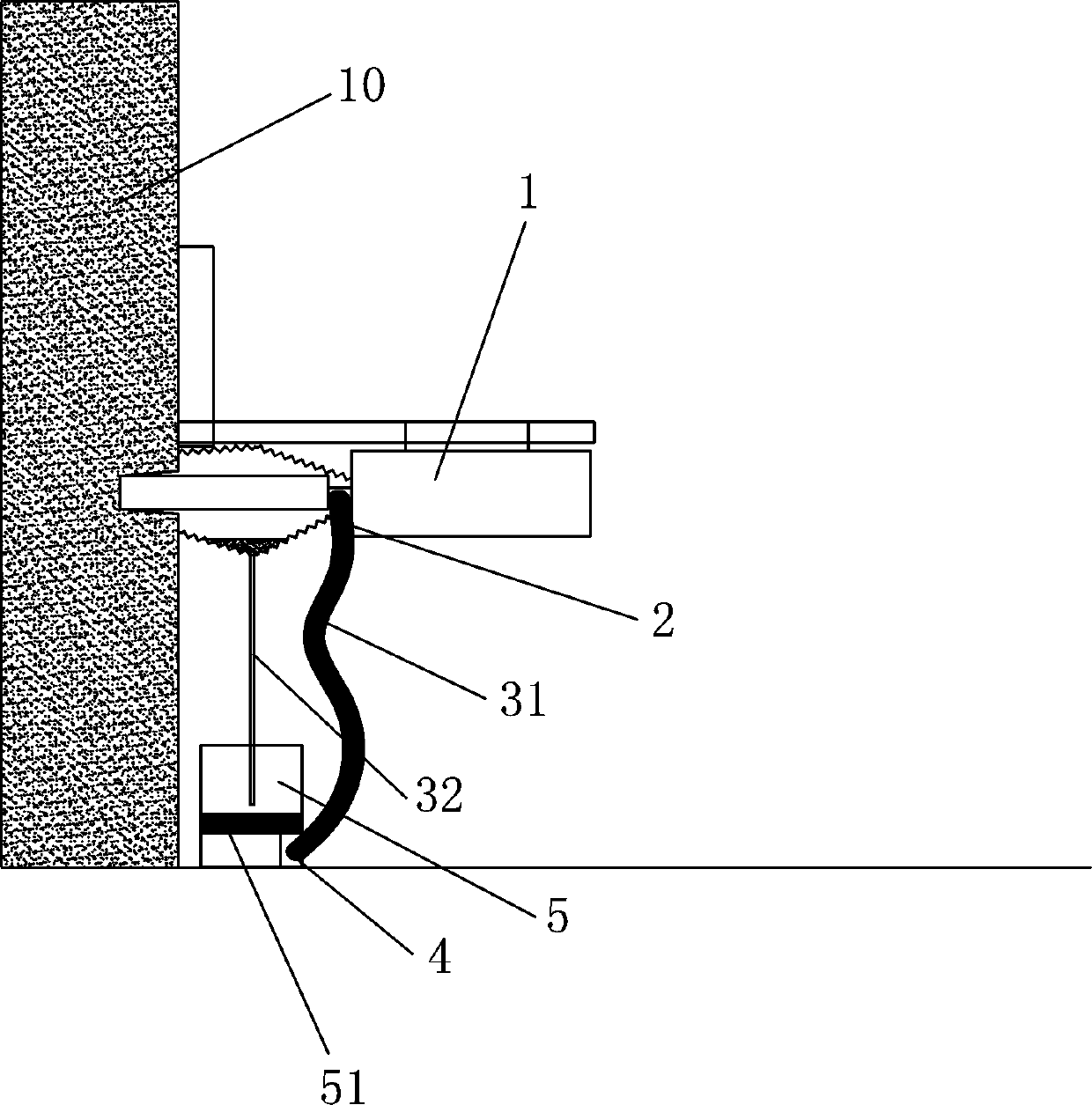

Wall face drilling device achieving circulating water utilization and application method of wall face drilling device

InactiveCN109849193ASolve pollutionEmission reductionWorking accessoriesStone-like material working toolsHand heldEngineering

The invention relates to the field of handheld or similar portable drilling machines, in particular to a wall face drilling device achieving circulating water utilization and an application method ofthe wall face drilling device. The wall face drilling device achieving circulating water utilization comprises a water drill (1), and is characterized in that the wall face drilling device further comprises a water collection cover (2), a water inlet pipe (31), a water outlet pipe (32), a water pump (4), a water collection box (5) and a filter screen (51); a shell of the water drill (1) is fixed to a wall face (10) through an expansion bolt; the water collection cover (2) is arranged outside the water drill (1) in a sleeving manner; the water inlet pipe (31) is connected with the water pump (4) and the water drill (1); and the water outlet pipe (32) is connected with the water collection cover (2) and the water collection box (5). The application method of the wall face drilling device achieving circulating water utilization is characterized by comprising the following steps of a, pre-drilling, b, device fixing and c, drilling in sequence. By means of the wall face drilling device andthe application method, water consumption is reduced, mud discharging is reduced, the wall face quality is high, and the environment is protected.

Owner:CHINA MCC20 GRP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com