Earlier direct mounting method for concealed distribution box of filler wall

An installation method and technology for filling walls, applied in the direction of walls, electrical components, building components, etc., can solve the problems of many cross-operations, difficult protection of finished products, confusion of processes, etc., so as to improve the quality of installation, improve the quality of plastering and shorten the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

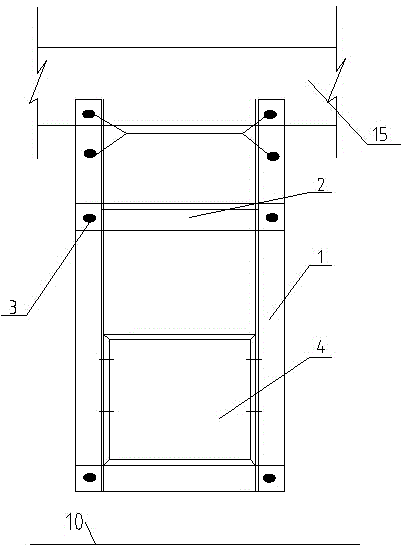

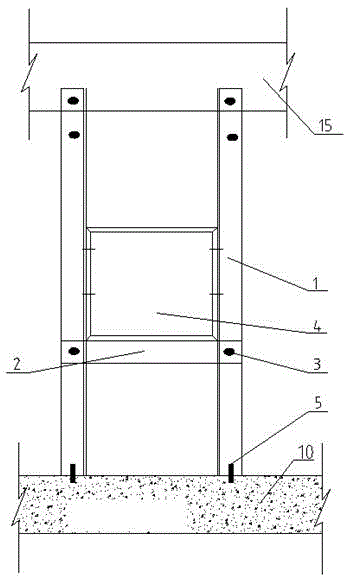

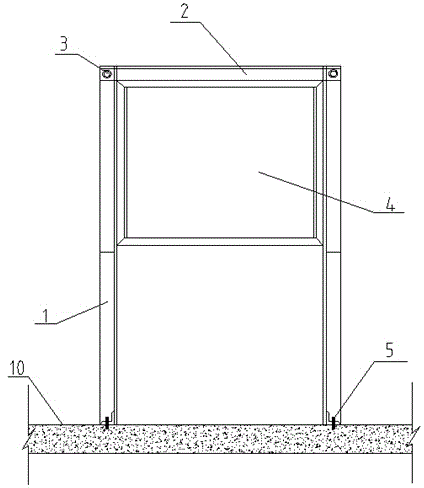

[0022] Referring to the accompanying drawings, the direct installation method of the concealed electrical box in the filling wall in advance, the specific technical scheme is as follows:

[0023] 2. Construction preparation: count the specifications and models of the box body 4 and classify them, determine the installation position of the box body, determine the positional relationship between the wall surface of the box body and the side of the top beam of the same side wall, and determine the flow construction section and the reasonable construction period of each section ;

[0024] 2. Select the steel bracket: According to the height of the building and the installation height of the box, the steel fixed bracket is divided into three types: floor type, suspension type, and upper and lower fixed type: when the installation position of the box is 10 meters from the floor of the building, the height is less than or equal to 1m. , using a floor-standing steel bracket, the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com