Patents

Literature

49results about How to "Improve plaster quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

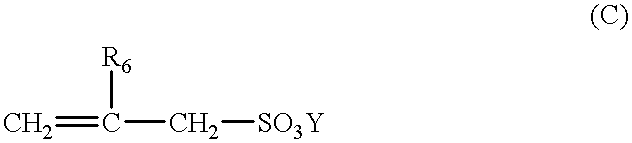

Dispersant for plaster

InactiveUS6264739B1PowerfulSolve the real problemTransportation and packagingMixingCarboxylic acidGypsum

An dispersant for plaster comprising a copolymer prepared by copolymerizing (a) a polyalkylene glycol monoester monomer having 2 to 300 mols of an oxyalkylene group(s) each having 2 to 3 carbon atoms, with (b) at least one monomer selected from among acrylic monomers, unsaturated dicarboxylic monomers and allylsulfonic monomers. When the dispersant of the present invention is used in preparing a plaster board, the foam stability is maintained so that the quality of the plaster board composition can be easily controlled.

Owner:KAO CORP

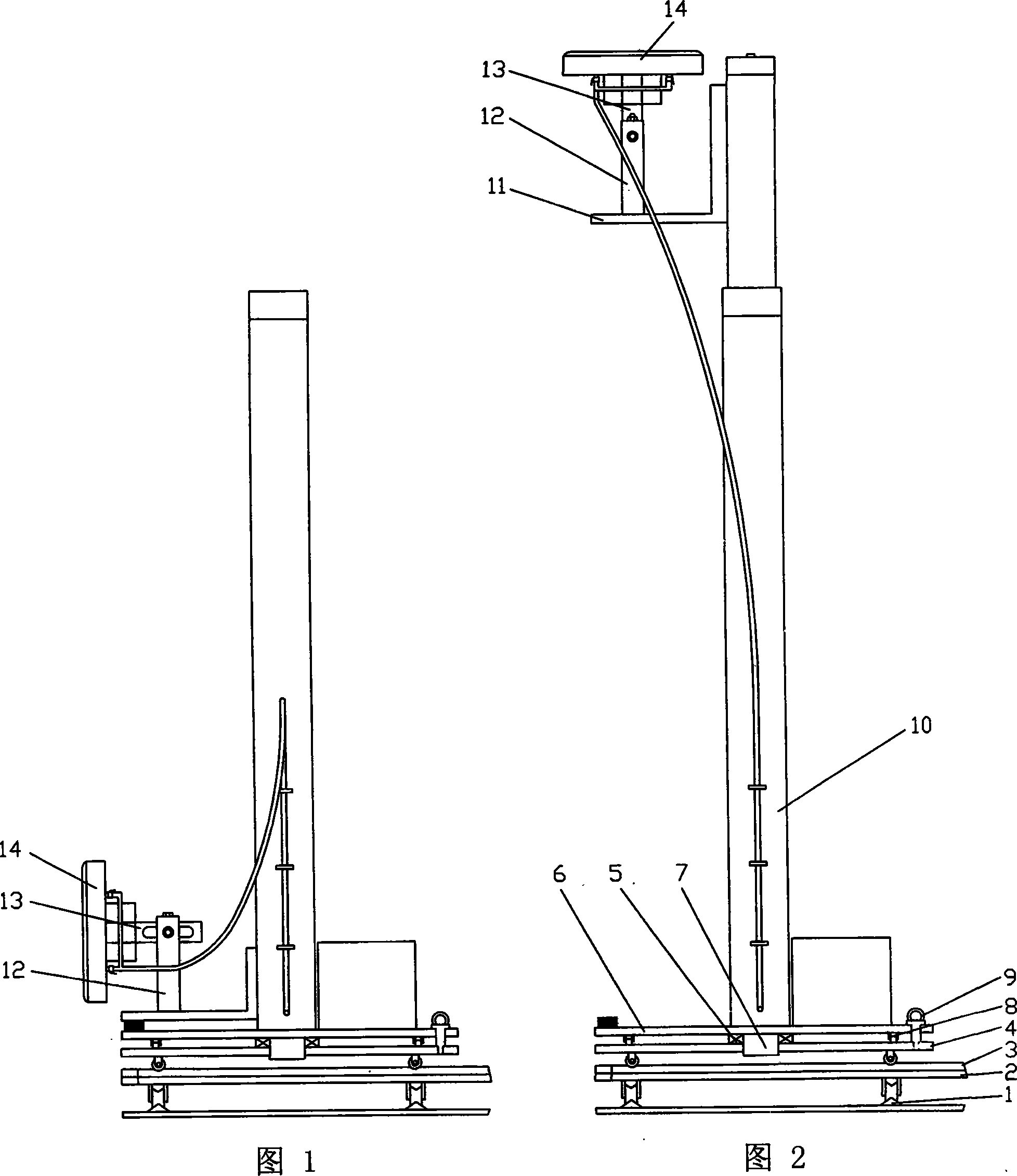

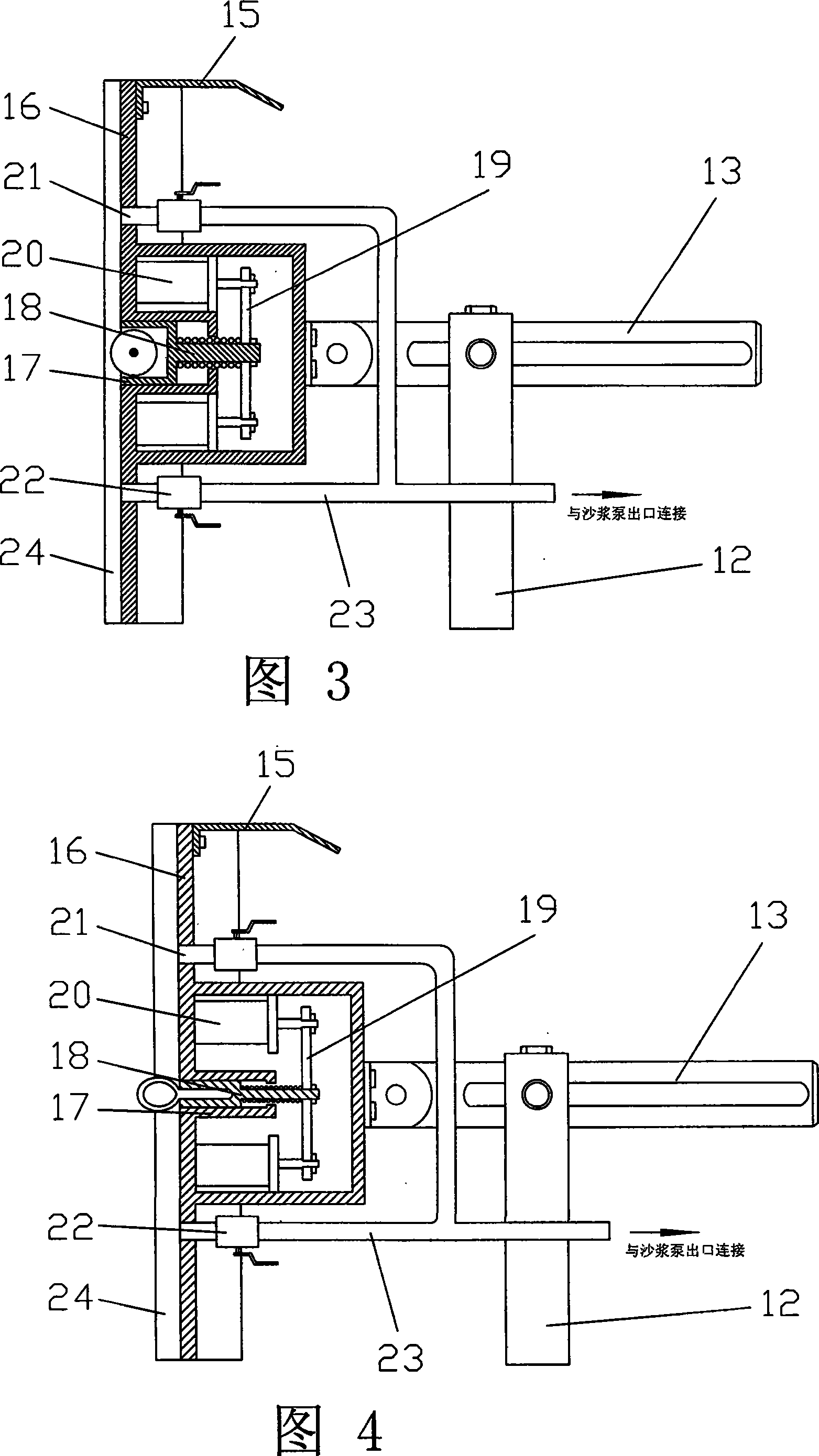

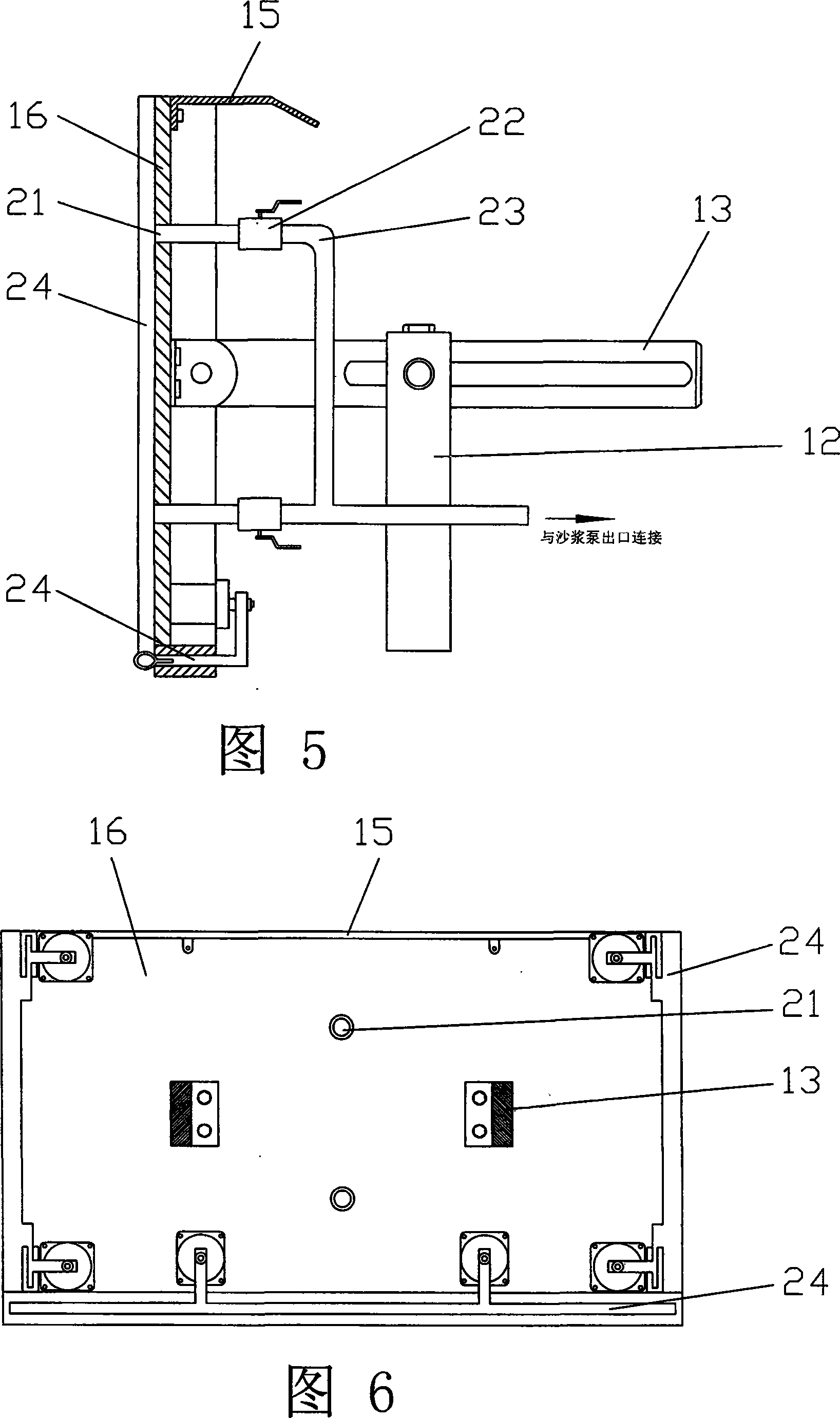

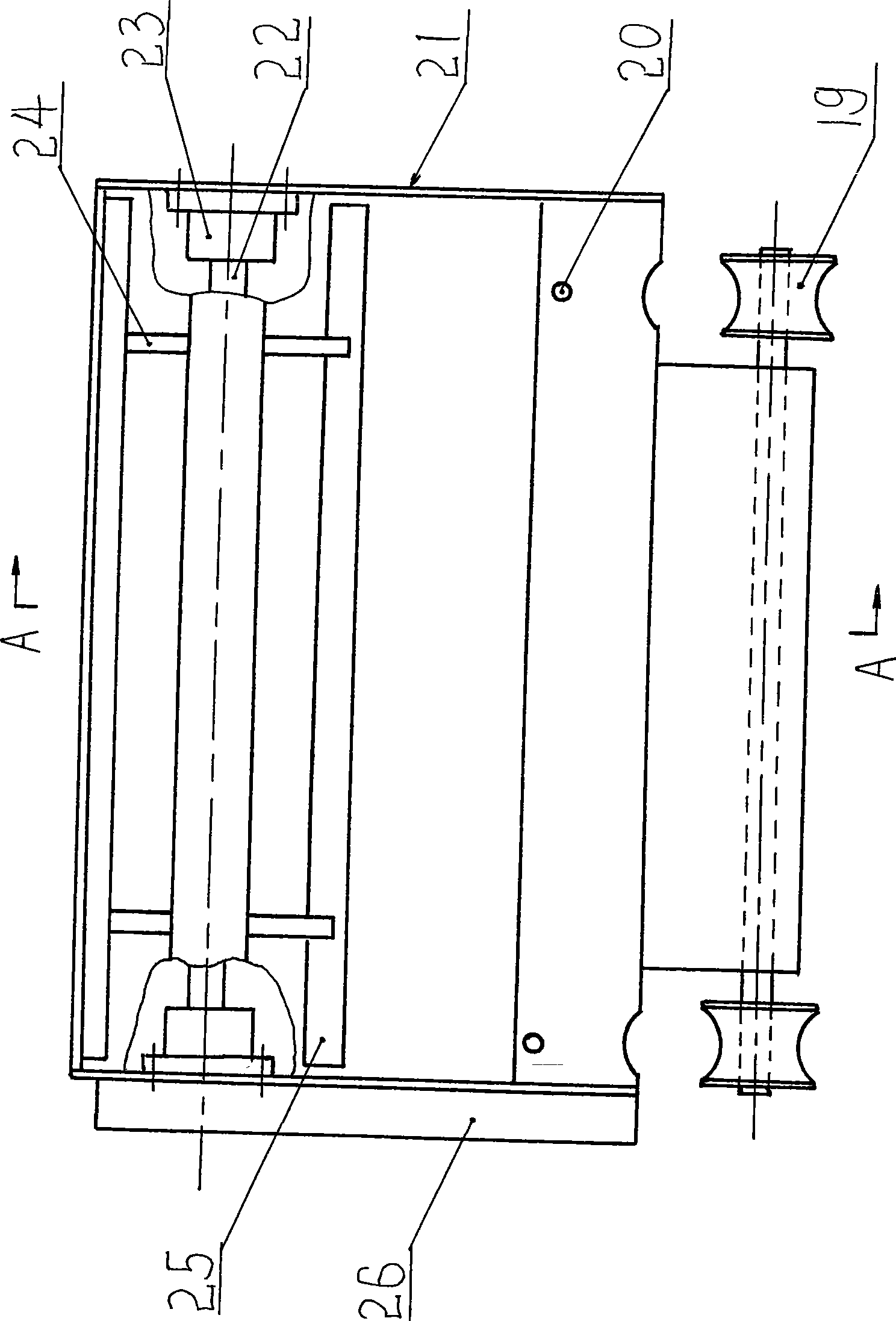

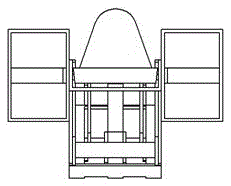

Pasting machine

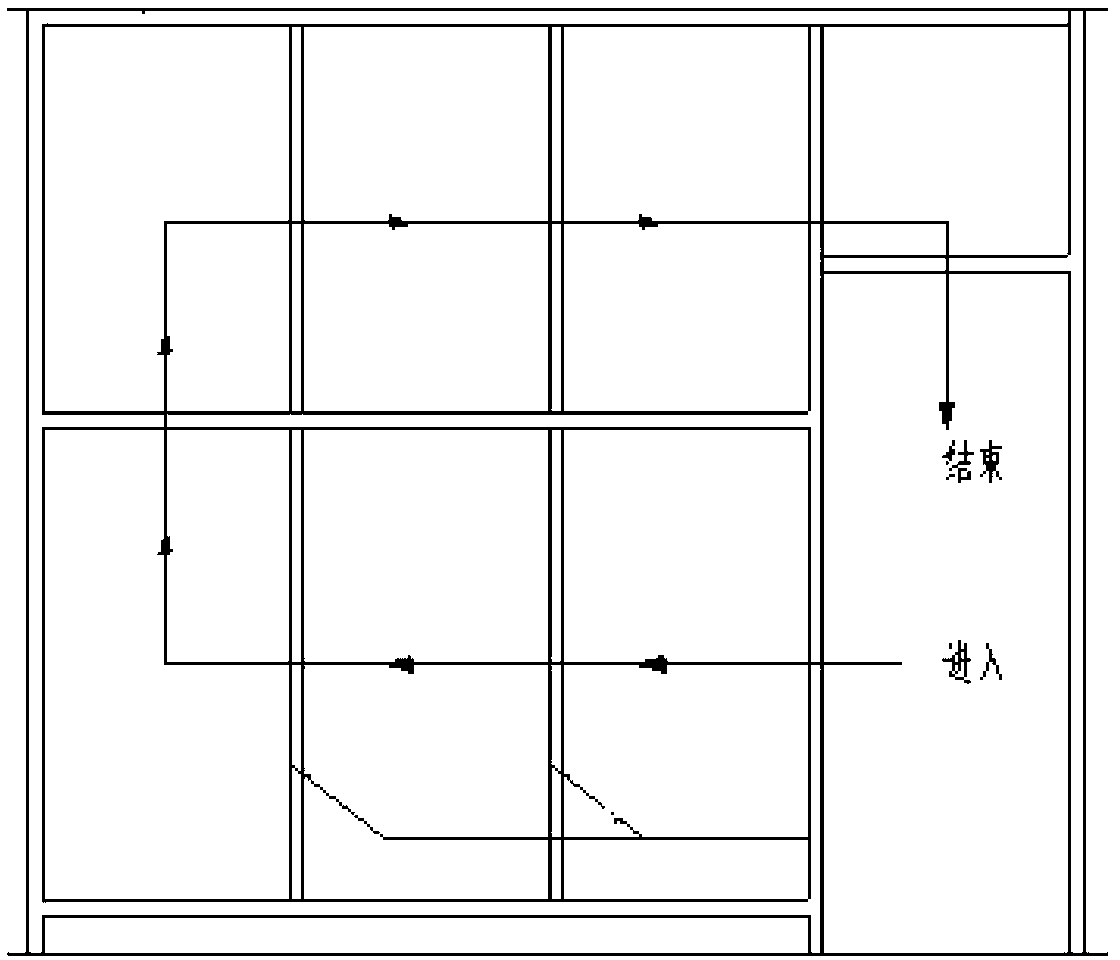

InactiveCN101126278AAddresses defects with narrow scope of workSolve the problem of difficult plasteringBuilding constructionsCouplingEngineering

The invention relates to a pasting machine, comprising a running mechanism, an elevating mechanism, a plastering device and a paste supply system; the running mechanism comprises a longitudinal rail and a longitudinal rail trolley, a transverse rail is arranged on the longitudinal rail trolley and a transverse rail trolley is arranged on the transverse rail, an axle bed is arranged at the middle of the transverse rail trolley and the axle bed is connected with the middle of a worktable by a coupling; a bearing wheel is arranged at the bottom edge of the worktable, and a location cross pin is arranged between the worktable and the rail trolley, the elevating mechanism is arranged on the worktable and the elevating mechanism comprises an elevating support and an elevating worktable; the elevating worktable is arranged in a slideway at the inner side of the elevating support and is connected with a winch of a windlass by a rope or is connected with a hydraulic lifting device by articulation; the plastering device is arranged on the elevating worktable and a slideway is arranged in a joint rocker of the plastering device and is connected with the elevating worktable by a coupling and a support. The invention is suitable for the plastering of various walls.

Owner:邓国飞

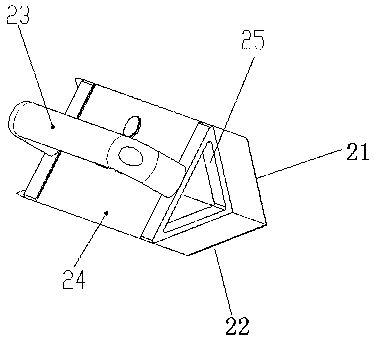

Plastering device of building wall

InactiveCN110094045AAvoid vibrationEven by forceBuilding constructionsEngineeringMechanical engineering

The invention belongs to the technical filed of plastering, and particularly relates to a plastering device of a building wall. According to the following scheme, the plastering device includes a bottom plate, a driving assembly is arranged at the top of the bottom plate, a feeding assembly is arranged at the top of the driving assembly, a plastering assembly located in an discharging opening of the feeding assembly is mounted at one end of the driving assembly, locating frames fixedly connected with the top of the bottom plate are mounted at the bottoms of the output ends of the two sides ofthe driving assembly, supporting assemblies are mounted on the sides, away from each other, of the two sets of locating frames, the interiors of the locating frames sleeve extensible assemblies, and the same top abutting against frame is mounted between the tops of the two sets of the extensible assemblies. According to the plastering device of the building wall, fixing solidity of the whole plastering device is improved to avoid shaking of the plastering device during running, the accuracy of plastering is improved, the problem that when a traditional plastering device uses a vibration mode for plastering, imbalance stress is between a plastering board and the wall is changed is changed, so that a plastering layer is overall flat and has balance stress, plastering layer falling off is avoided, and the quality and efficiency of plastering are improved.

Owner:LUAN VOCATIONAL TECHNOLOGICAL COLLEGE

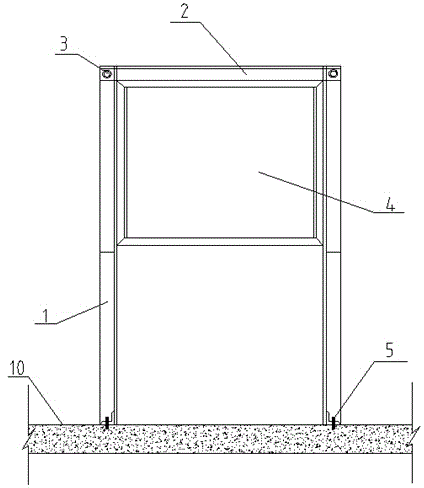

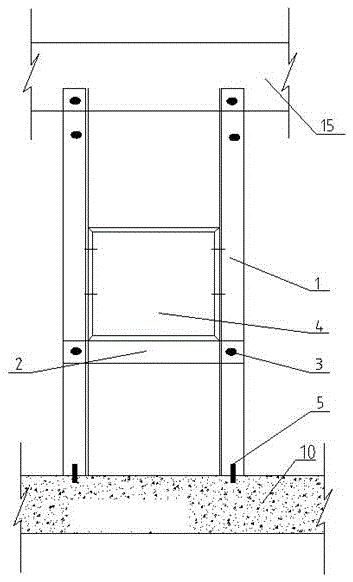

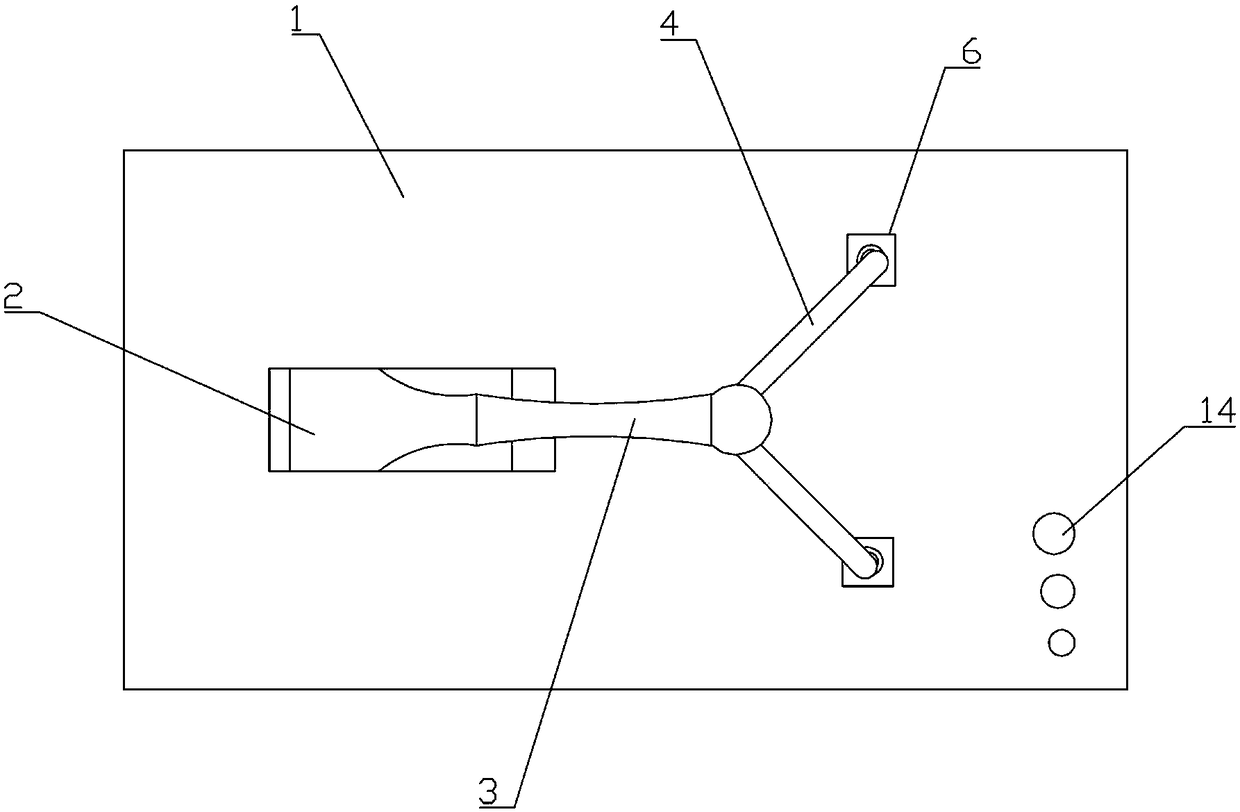

Automatic spraying positioning bracket

InactiveCN103015692AShort construction periodImprove efficiencyBuilding constructionsWork periodElectric machinery

The invention provides an automatic spraying positioning bracket, which comprises a lifting gear, a first limiting switch, a first guide rod, a first motor, a second limiting switch, a second guide rod, a spraying nozzle, a spraying nozzle fixing cart, a horizontal spraying track control framework, a transverse reciprocating traveling spraying positioning framework, a screw rod, a second motor, a gearbox, a falling ash recovering disc and a direction-adjustable traveling wheel. The automatic spraying positioning bracket has the beneficial effects that the work period is short, the efficiency is improved by 2 to 3 times, the labor is reduced, the cost is reduced, and one layer of neat cement mortar is saved; in the civil engineering of one building with an area of 10,000m<2>, the neat cement per 1m<2> needs approximate 3kg of cement, so approximate 30t of cement is saved; the adhering force of the spraying mortar is high, the density is high, the adhering is firm, the cement surface is firm, empty drums are avoided, the flatness of the wall surface is improved, and the plastering quality is ensured; and the pollution of air environment of a construction site is reduced, and the splashing amount of wastes of the plastering engineering can be controlled to be less than 2%.

Owner:天津一建建筑工程有限公司

Spray plastering technology

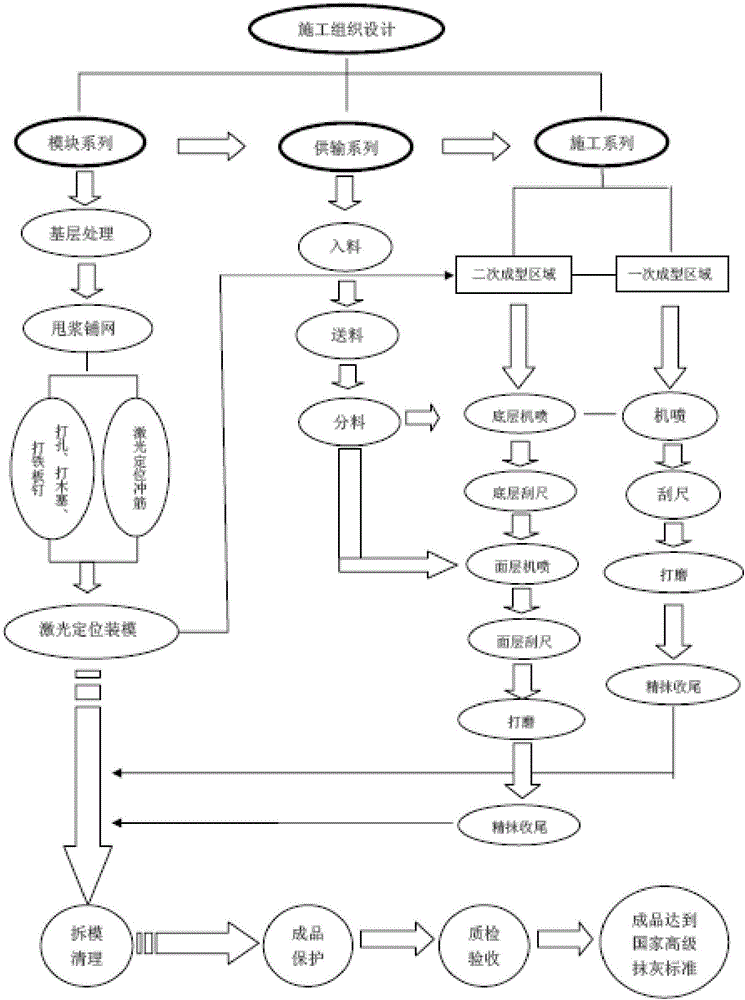

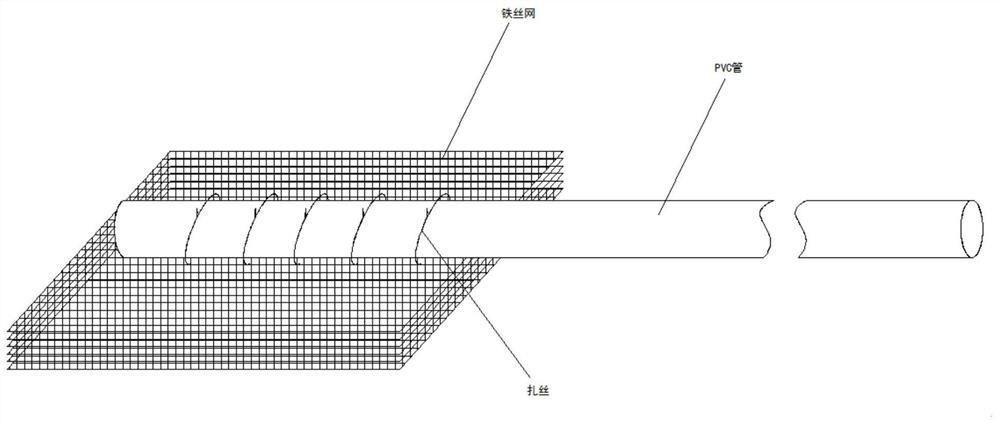

ActiveCN106256970AImprove plaster qualityEnsure construction efficiencyCovering/liningsSlurryStructural engineering

The invention provides a spray plastering technology. The spray plastering technology comprises the steps of base layer treating; slurry throwing and mesh laying, wherein steel wire meshes are laid at the boundaries of different material substrates, and an interface agent is painted in a to-be-plastered area; rib arranging on the wall surface, wherein ribs are arranged on the wall surface; form block installing, wherein form blocks are arranged at the positions, forming exposed corners, of the wall surfaces, each form block is closely attached to one side wall surface of the corresponding exposed corner of the wall surface, corrected and then fixed, one end of each form block protrudes towards the side where the other side wall surface of the exposed corner is located, the protruding thickness is the plastering thickness of the other side face of the exposed corner; layering plastering treating, wherein the perpendicularity, the flatness and the plastering thickness of wall surface plastering are controlled by taking the ribs and the form blocks as a standard; form removal treating. According to the spray plastering technology, the plastering quality and the plastering efficiency can be guaranteed, and the skill requirements on plasterers can be lowered.

Owner:湖南瑞吉达科技有限公司

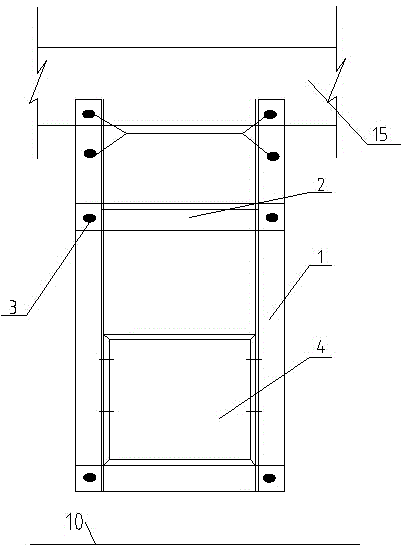

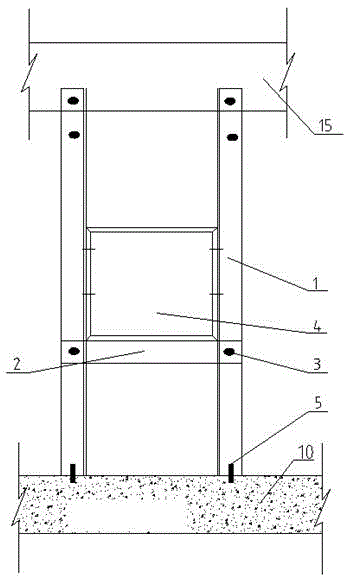

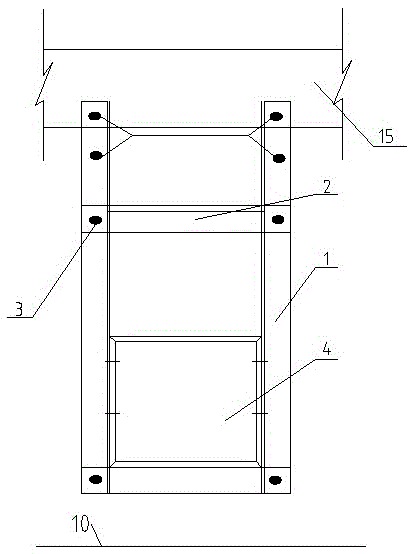

Earlier direct mounting method for concealed distribution box of filler wall

ActiveCN104405128AEasy to installFlexible adjustmentElectrical apparatusWallsSocial benefitsEngineering

The invention provides an earlier direct mounting method for a concealed distribution box of a filler wall. According to the technical scheme, the method comprises the following steps: preparing for construction; selecting a section bar bracket; making and mounting the section bar bracket; mounting the box; mounting inlet / outlet pipes of the box; building the filler wall; forming the wall masonry; after achieving design strength, removing the section bar bracket. According to the earlier direct mounting method for the concealed distribution box of the filler wall provided by the invention, the mounting is convenient, the adjusting is flexible, a large quantity of engineering practices prove that the mounting quality is greatly increased by the technique, and meanwhile, the quality of the filler wall and plastering is effectively increased, the construction is safe and environment-friendly, the construction period is effectively shortened, the cost is reduced, the excellent economic, technical and social benefits are achieved, and the method has positive popularization and application values.

Owner:CHINA MCC17 GRP

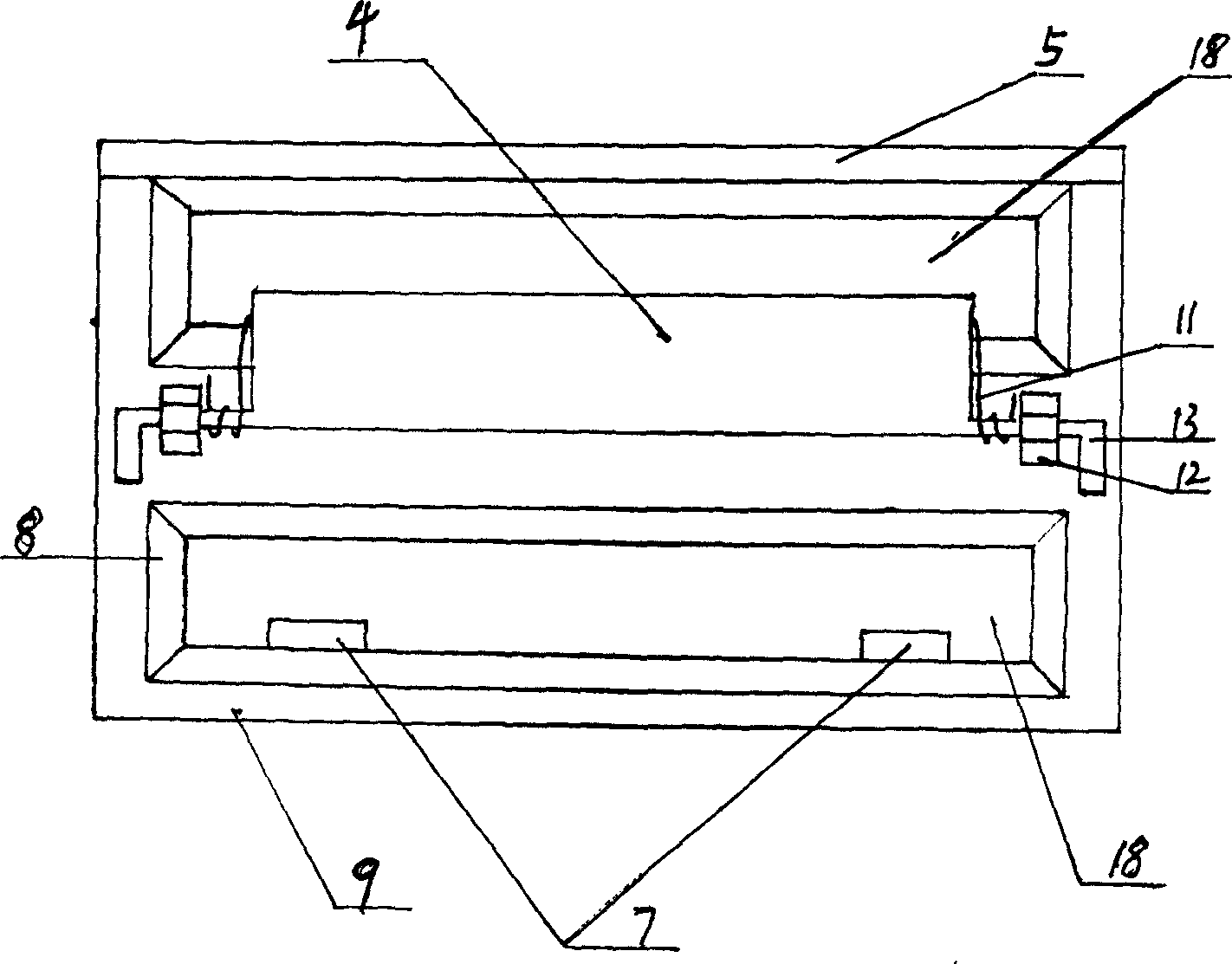

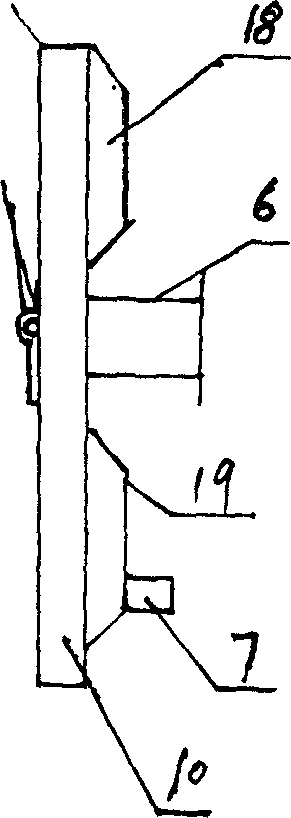

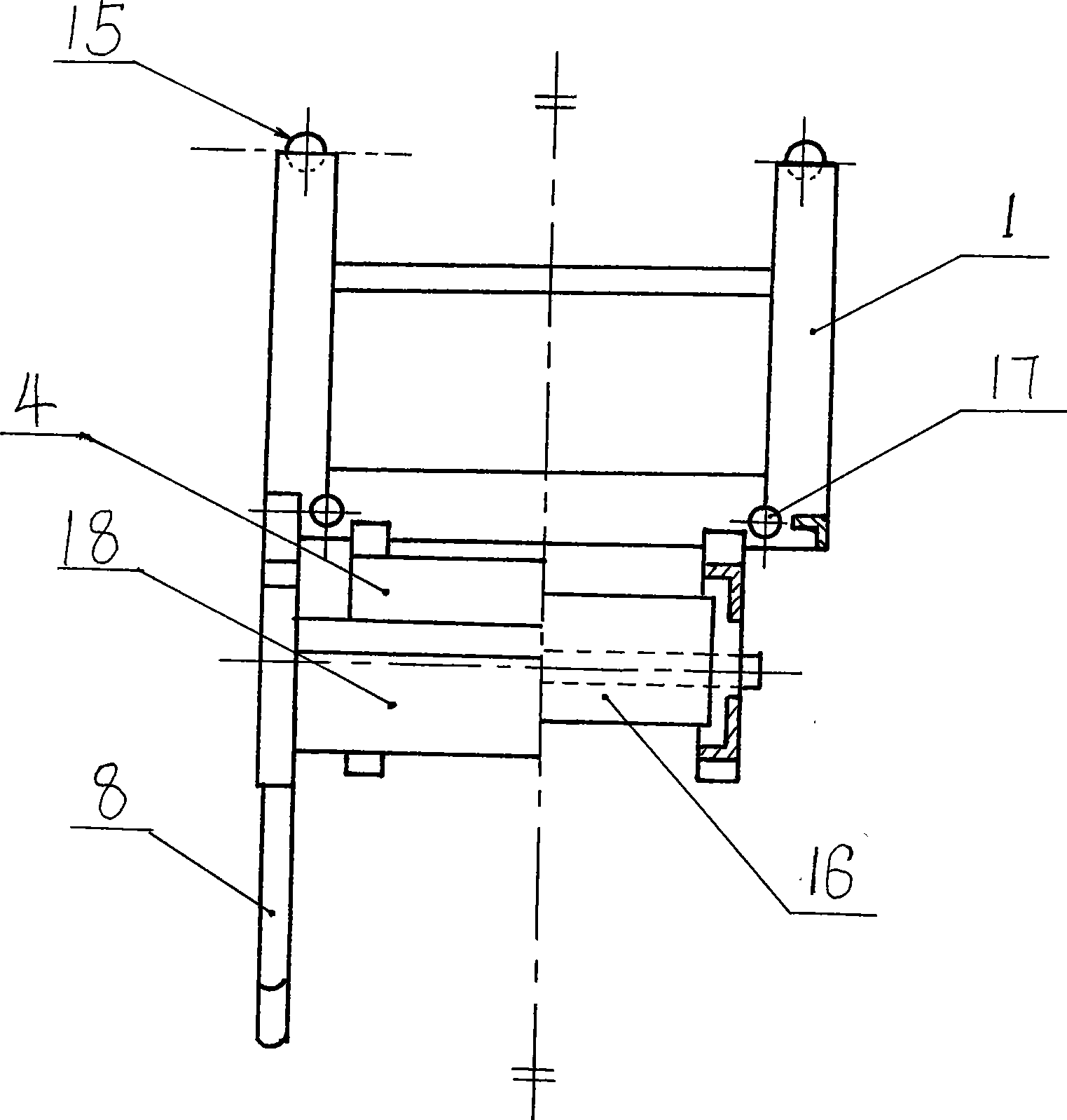

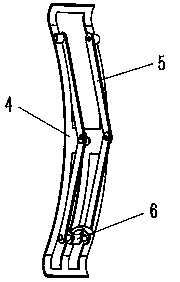

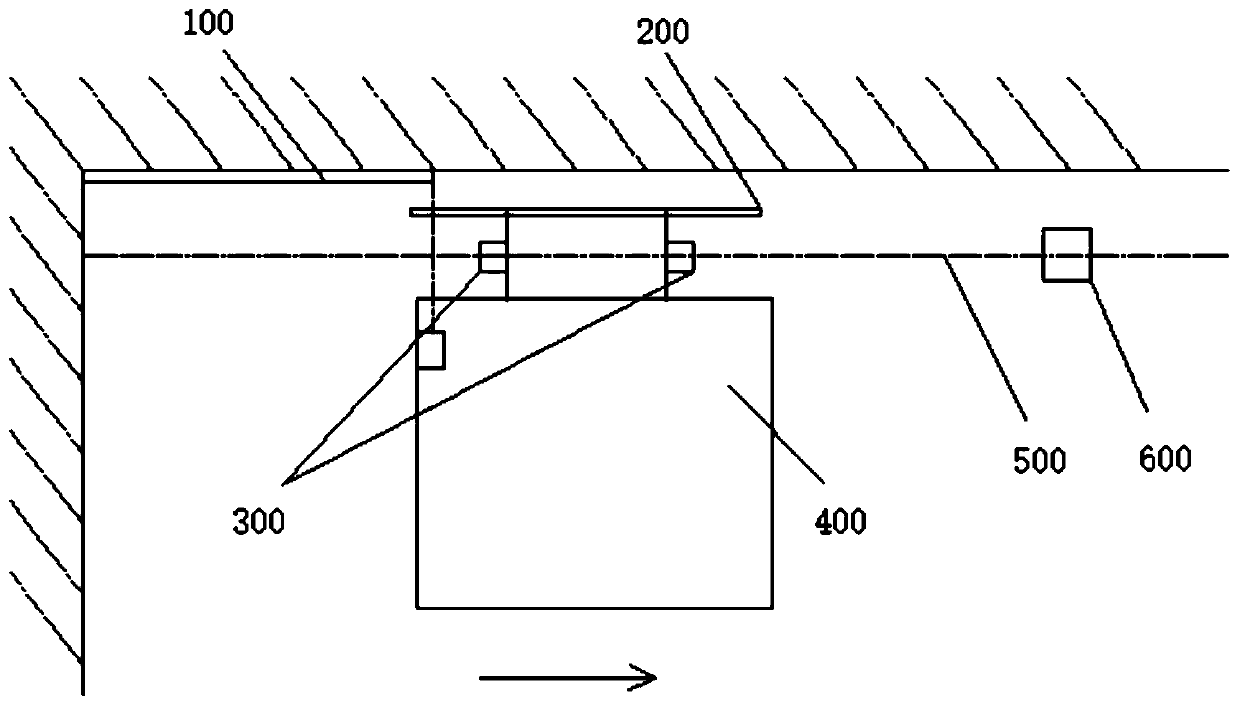

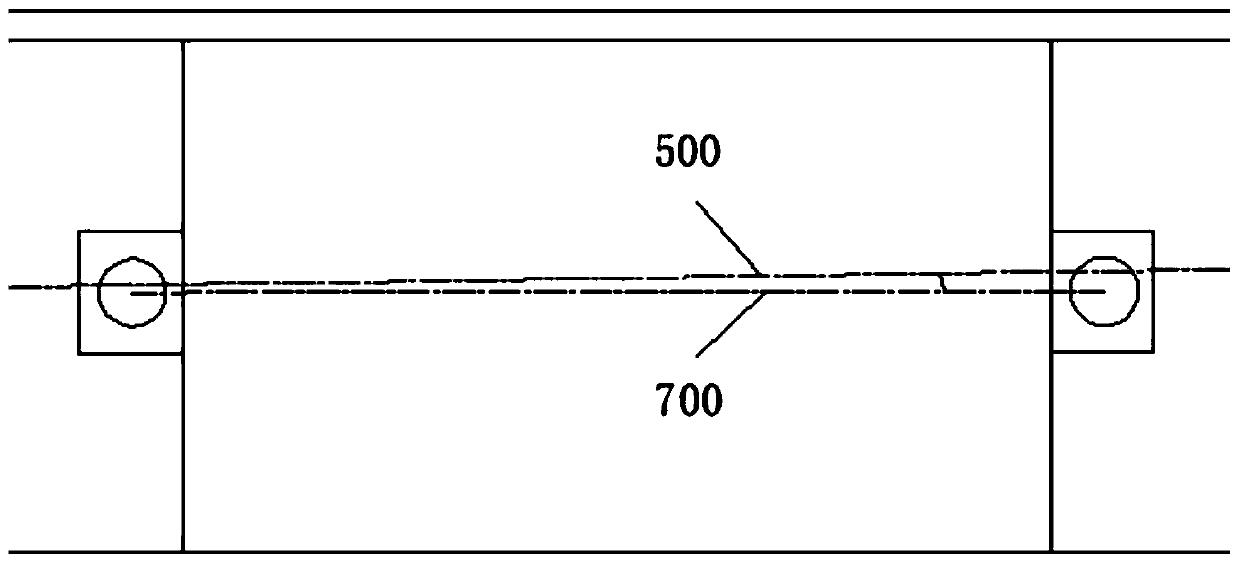

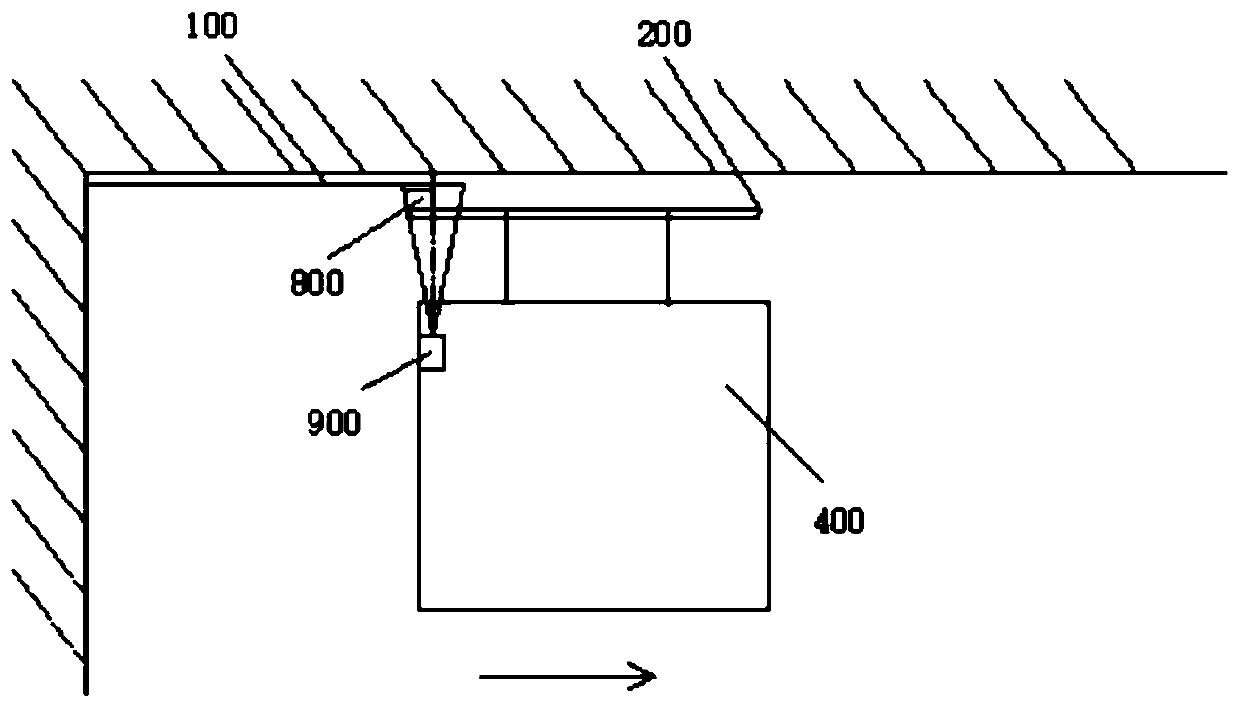

Suspension type sufficient-water plastering machine

InactiveCN103452300AVertical levelingVertical smoothBuilding constructionsEngineeringMechanical engineering

The invention provides a suspension type sufficient-water plastering machine which comprises a track frame. The track frame is suspended on a rack, a lifting frame capable of moving along the track frame up and down is arranged on the track frame, a plaster tank is mounted on the side, which is far away from the rack, of the lifting frame, two slide grooves are formed in the rear wall of the plaster tank, an overturn plaster tank cover is arranged on the top of the plaster tank, a residual plaster chamber is arranged on the upper portion of the plaster tank, a tool support capable of moving in the plaster tank up and down is arranged on the lower portion of the plaster tank, a plastering tool is placed on the tool support, and an affinity roll is positioned in the plaster tank, is horizontally arranged above the plaster tool and can move in the plaster tank up and down; two lifting chains are further arranged on the lifting frame, one end of each lifting chain is connected with the tool support, and the other end of each lifting chain is wound through the upper side of the lifting frame to be fixedly connected with the track frame. The suspension type sufficient-water plastering machine has the advantages that the plastering quality is obviously improved, plastered surfaces are perpendicular, flat and smooth, and the plastering speed and the plastering height are multiplied; plasters can be effectively adhered with wall surfaces and firmly and rigidly condensed in the wall surfaces, and the problem that plasters and a wall surface become two separate skins is solved; the suspension type sufficient-water plastering machine can be shifted conveniently, is safe and stable and can be operated easily and conveniently.

Owner:杨宝堂

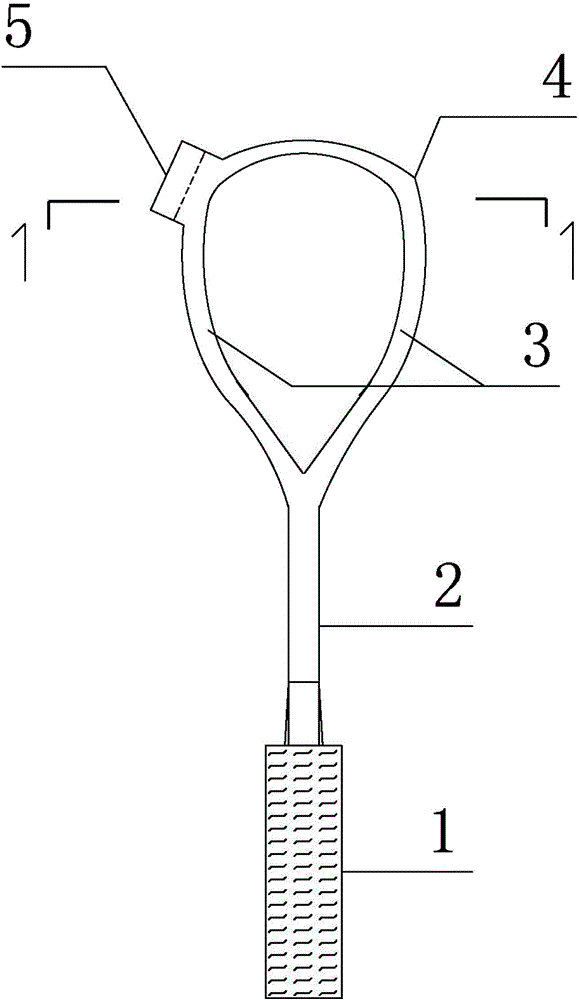

Automatic heating plastering trowel

InactiveCN107246130AEasy to splitImprove convenienceBuilding material handlingEngineeringElectric energy

The invention relates to an automatic heating plastering trowel. The plastering trowel includes a plastering trowel body, a bracket and a handle. The plastering trowel is characterized in that the bracket is vertically fixed in the middle of the plastering trowel body, and the handle is arranged on the upper portion the plastering trowel body and is in parallel with the plastering trowel body. One end of the handle and the bracket are fixedly connected, a heater is embedded in the handle, and the electric end of the heater is at the end, away from the bracket, of the handle. The electric end of the heater is connected with a temperature relay through a wire, and the temperature relay and a power supply are connected through a wire. Compared with the prior art, the automatic heating mud wiping plate is used in architectural engineering in winter. When the temperature drops to the set value, the temperature relay can be conductive, the electric energy of the power supply is transmitted to the heater, and the heater is controlled for heating, so that the handle keeps the set temperature and builders can comfortably work in winter.

Owner:重庆市润果五金有限公司

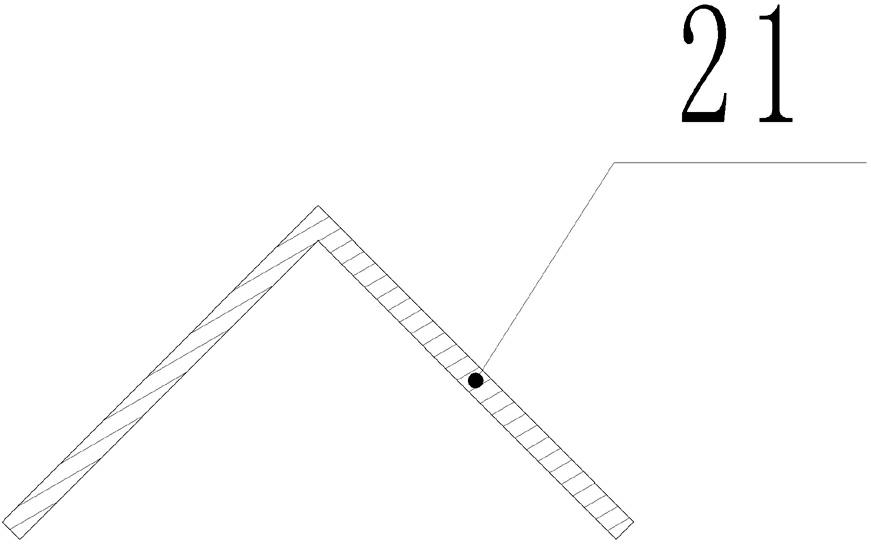

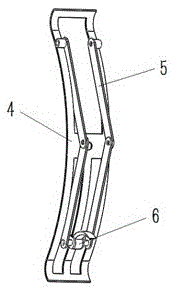

Method for improving plastering quality of wall corners

InactiveCN107859298AImprove plaster qualityAvoid damageBuilding constructionsCouplingComputer engineering

The invention discloses a method for improving the quality of plastering at the corners of a wall, comprising the following steps: Step A: matching the connecting block at one end of the limiting plate with the installation groove on the supporting plate, and fitting the connecting block at the other end of the limiting plate with the plastering plate Fit the installation groove on II; Step B: Hang the round hook at one end of the adjustment spring on the connection hole of the lug I on the wiping plate I, and hang the round hook at the other end of the adjustment spring on the support plate on the support plate Connecting hole of ear Ⅱ; step C: hold the handle and carry out plastering work on the wall. With one wave, the wall and ceiling can be painted at the same time, which not only avoids the damage to the other side of the painting surface when only one side is painted, resulting in repeated repairs in the later stage, but also increases the cost of time; it also improves work efficiency. The model of the adjustment spring can also be replaced, so that the wiper plate I and the wiper plate II are perpendicular to each other, and then the angle between the present invention and the wall and the ceiling is consistent, so that the present invention can be used to smear the wall and the ceiling simultaneously.

Owner:何茜

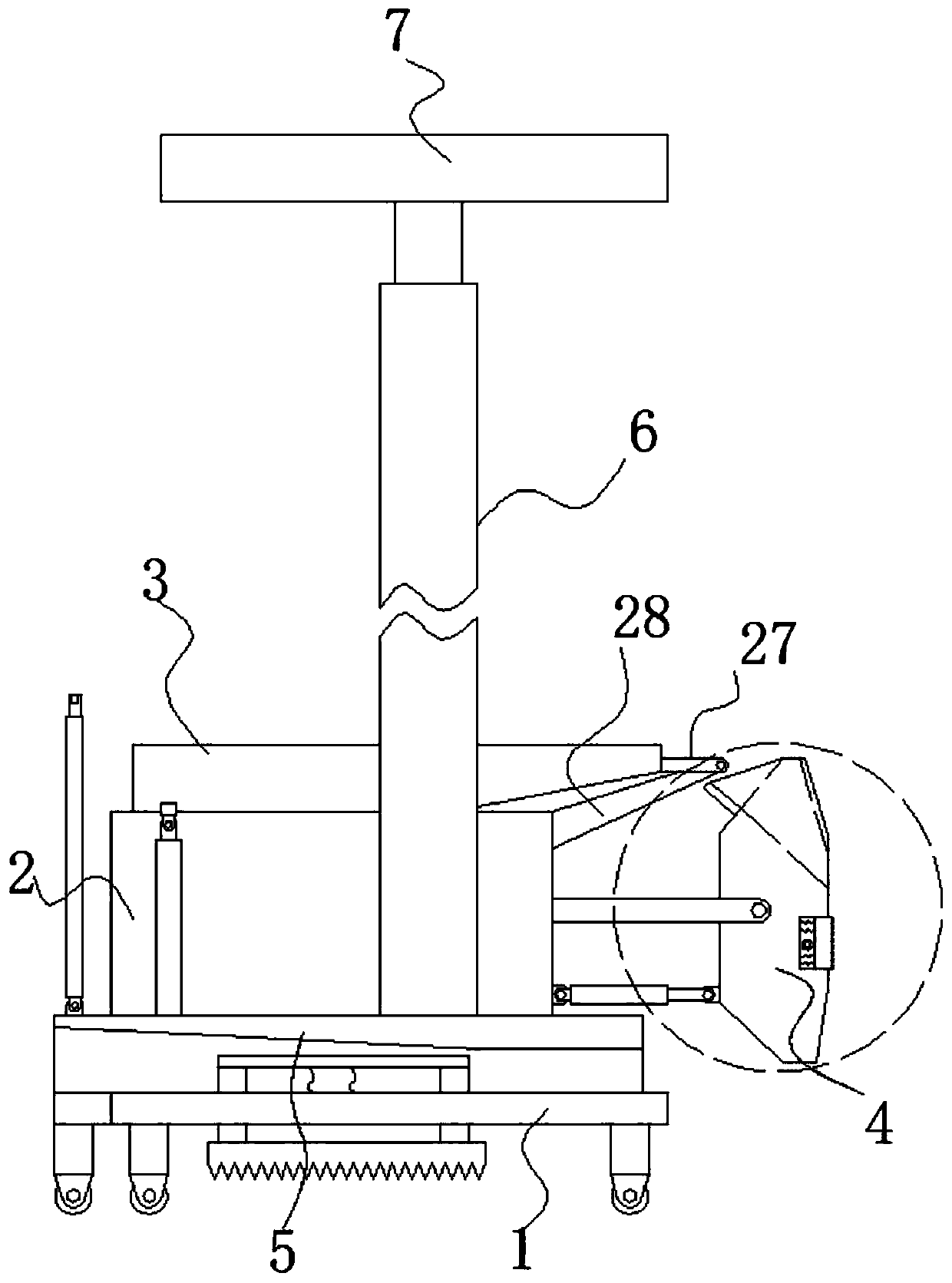

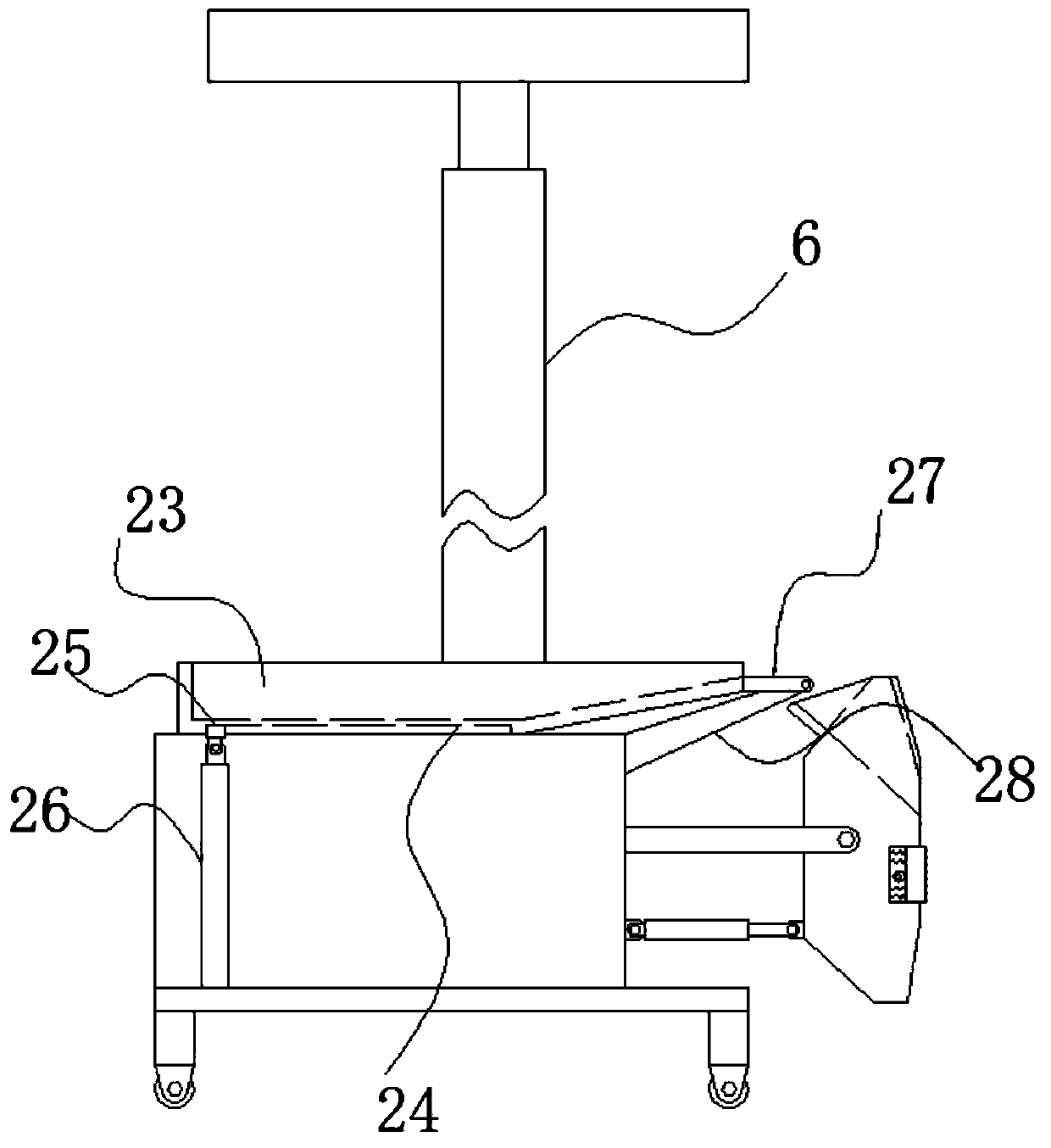

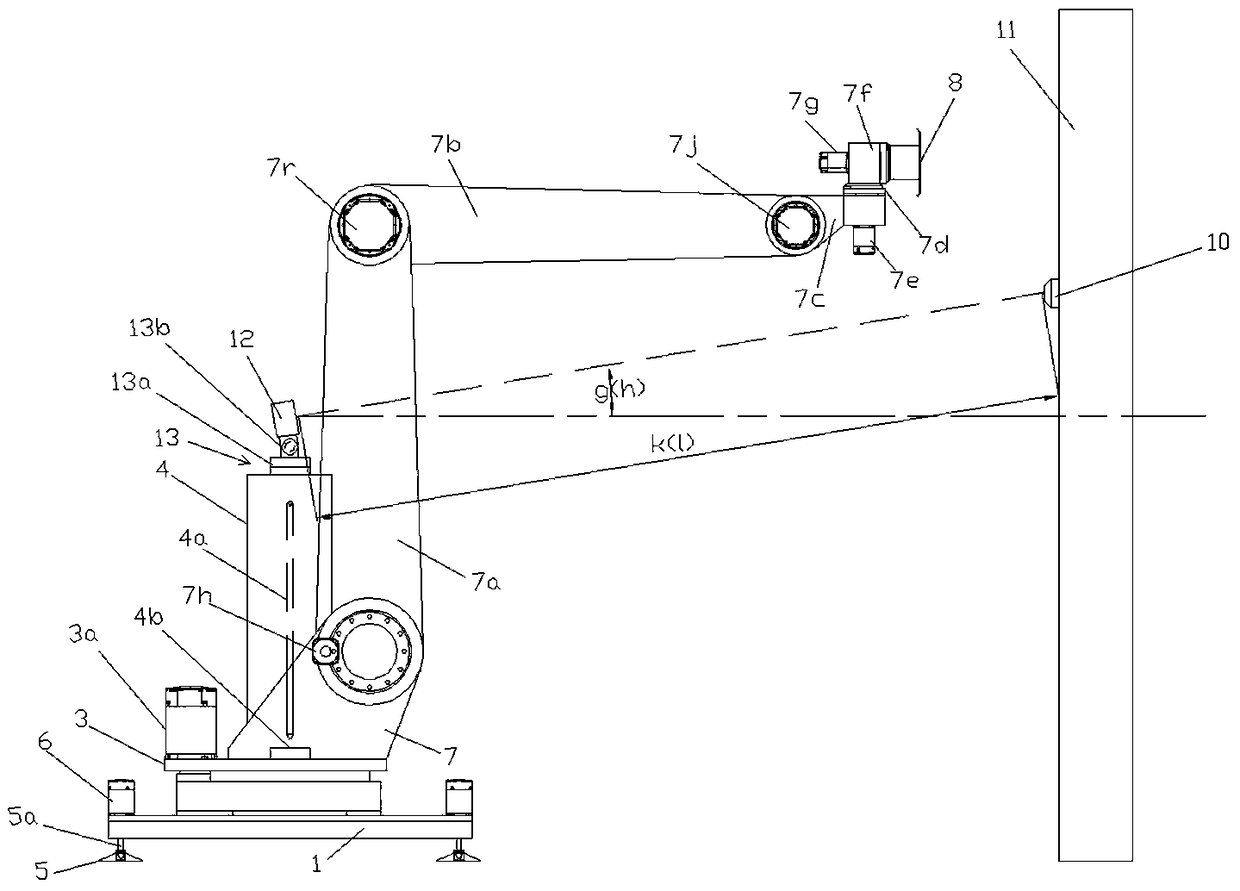

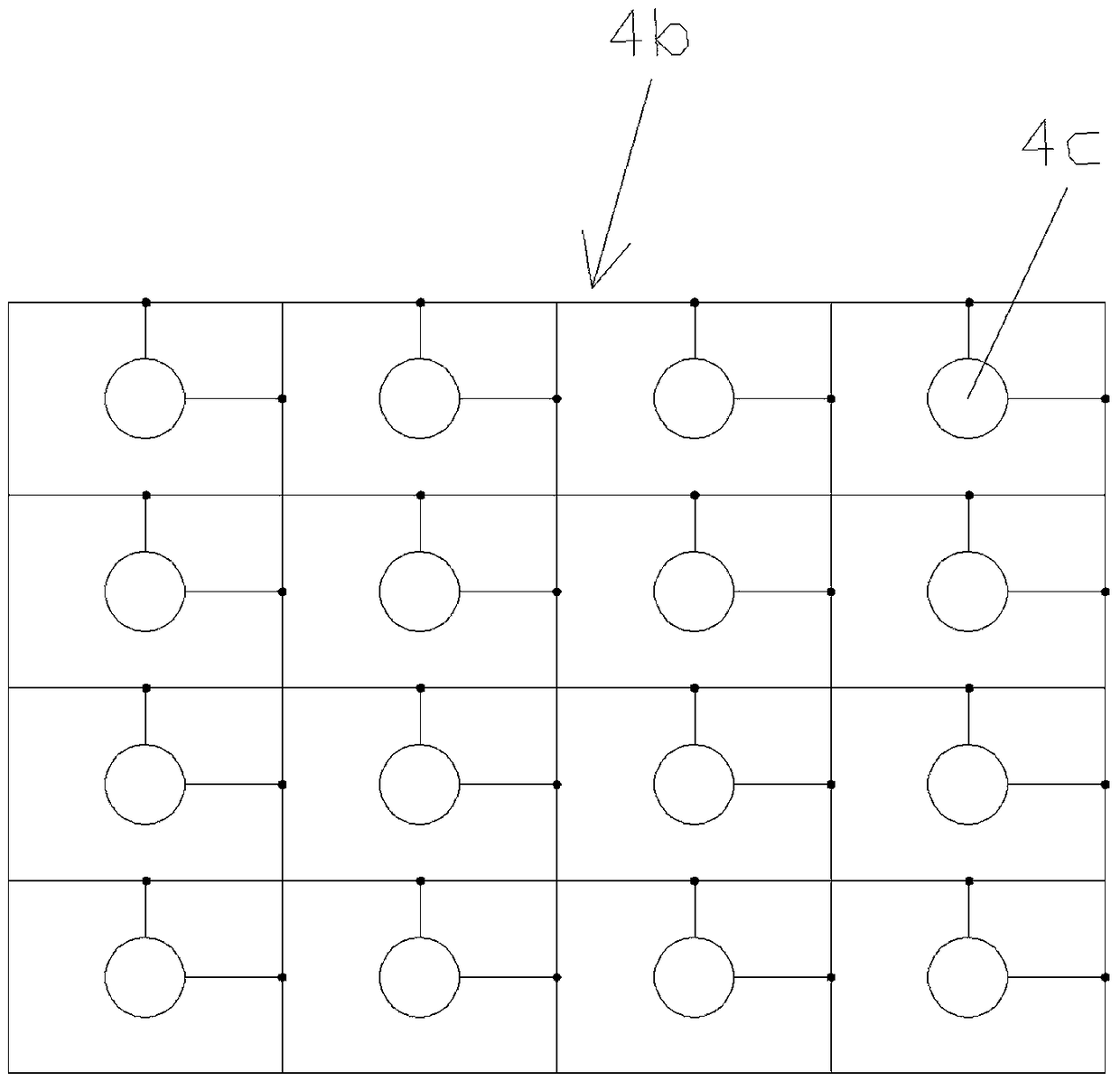

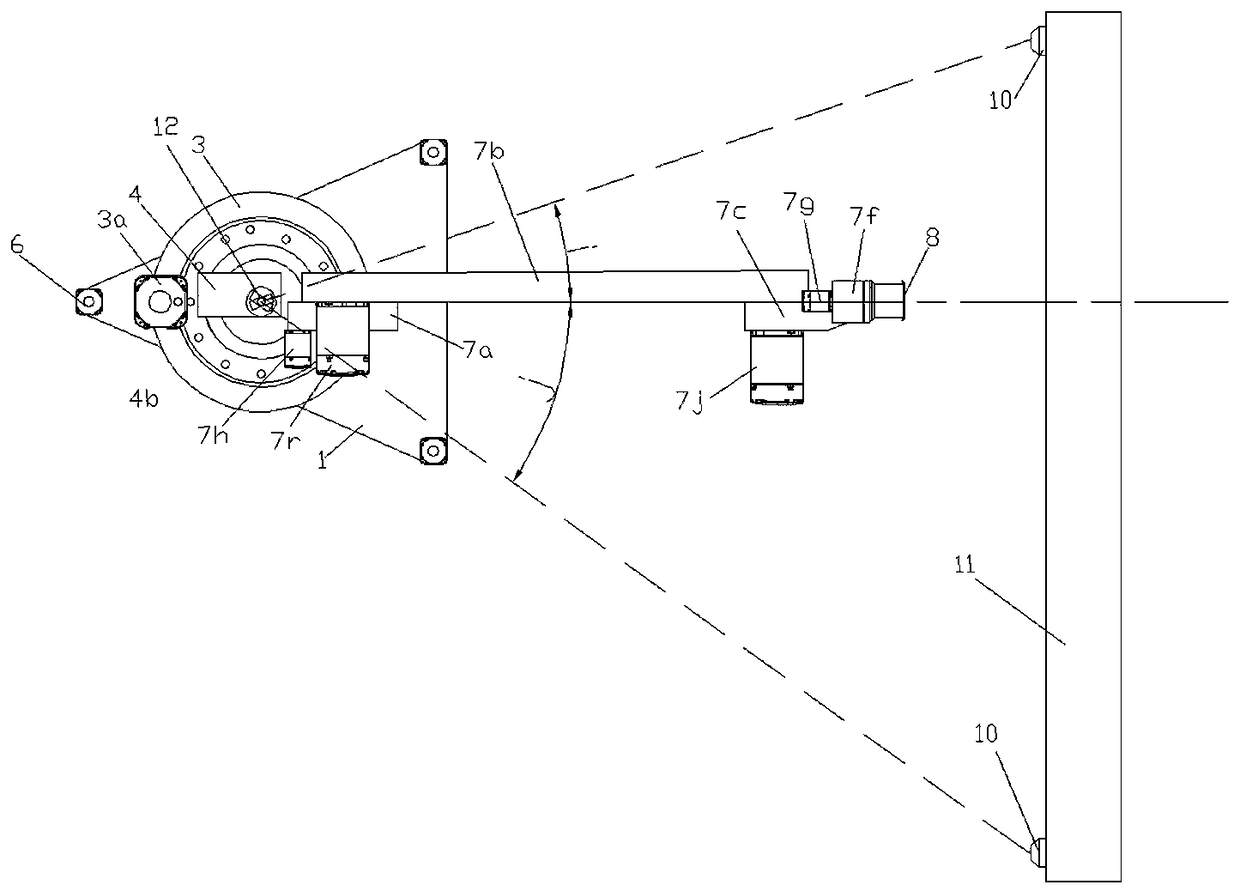

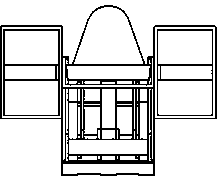

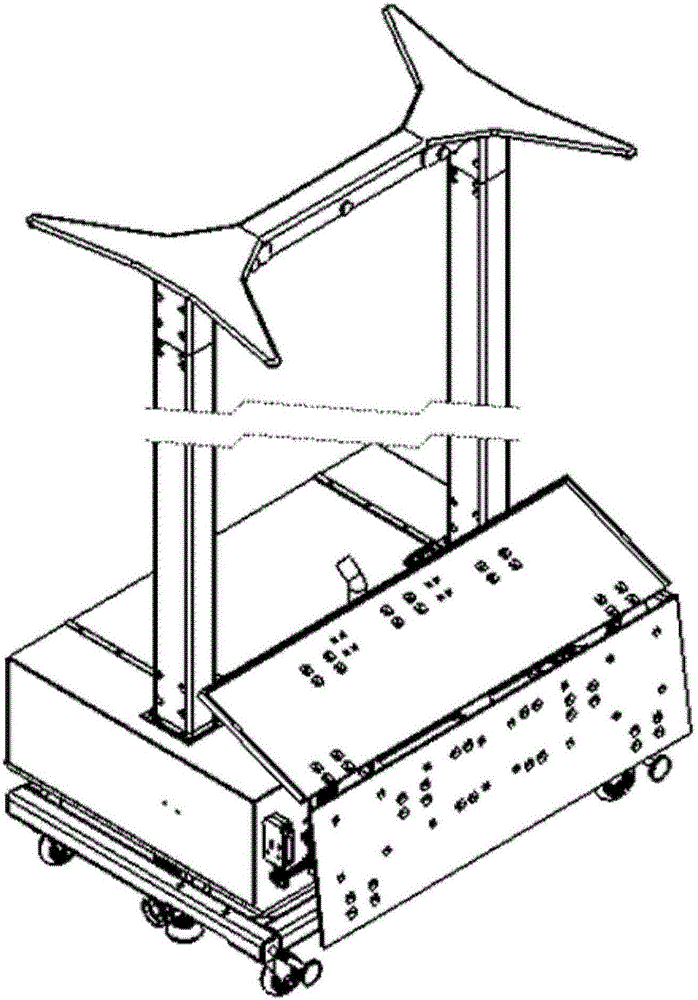

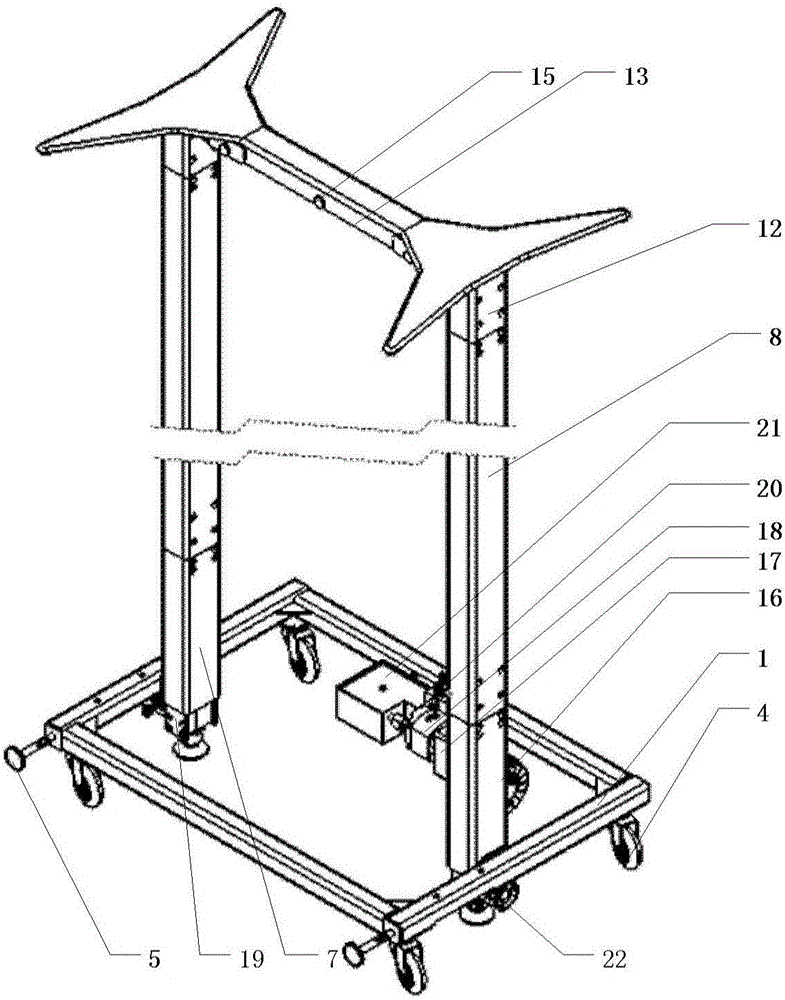

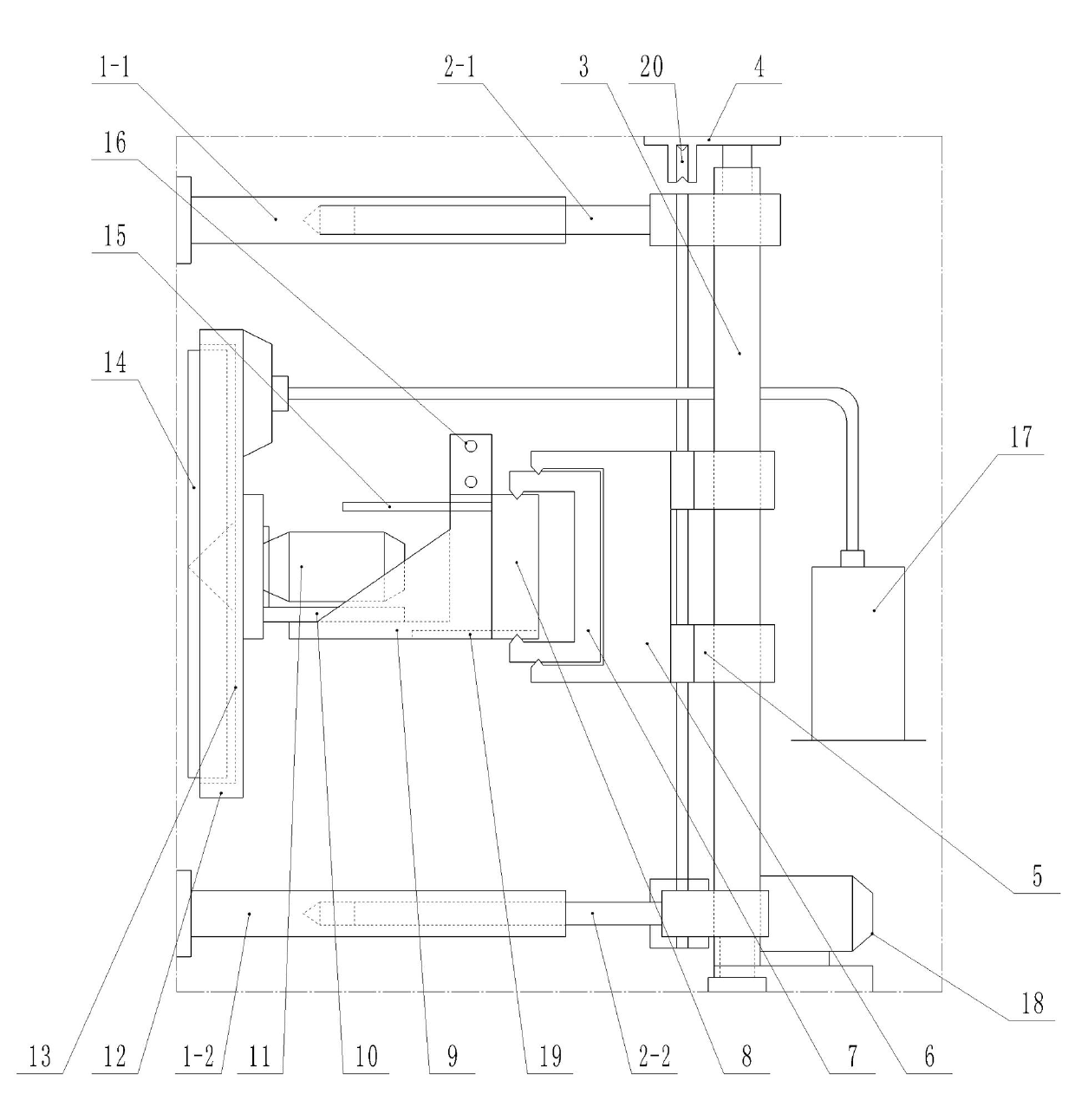

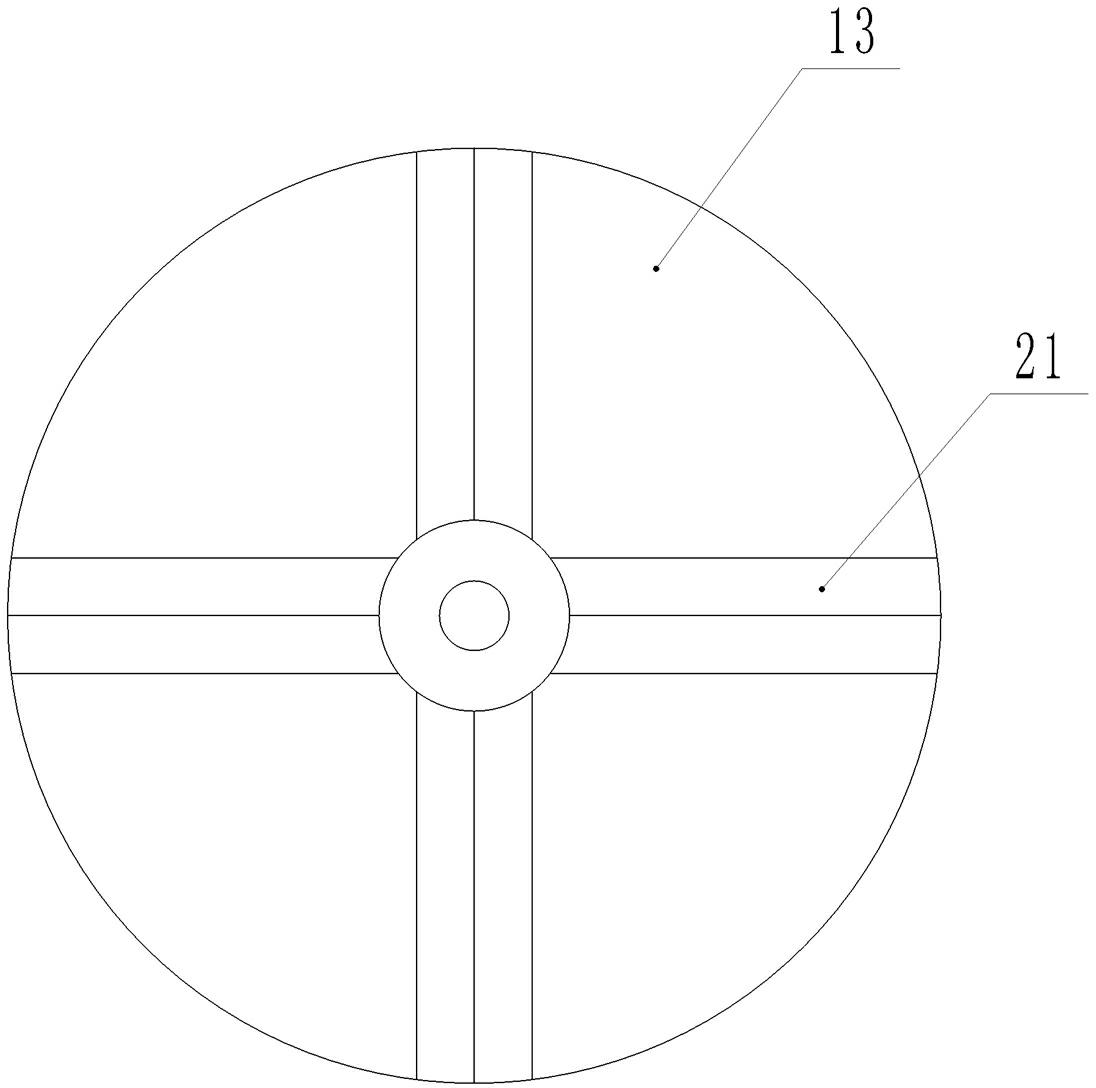

Robot capable of achieving building wall surface plastering

PendingCN108412160ASimple structureEasy to useBuilding constructionsEngineeringUltimate tensile strength

The invention provides a robot capable of achieving building wall surface plastering. The robot comprises a base (1) and is characterized in that a rotating disc (3) is arranged on the base (1), laserdistance measuring devices, a mechanical arm device and a control module are arranged on the rotating disc (3), and a plastering knife (8) is arranged at one end of the mechanical arm device; and atleast two recognizers (10) matched with the laser distance measuring devices correspondingly are further arranged on the construction wall surface. The robot capable of achieving building wall surfaceplastering has the advantages that the structure is simple, using is convenient, the work efficiency is high, the automation degree is high, and the labor intensity is effectively reduced.

Owner:BENGBU COLLEGE

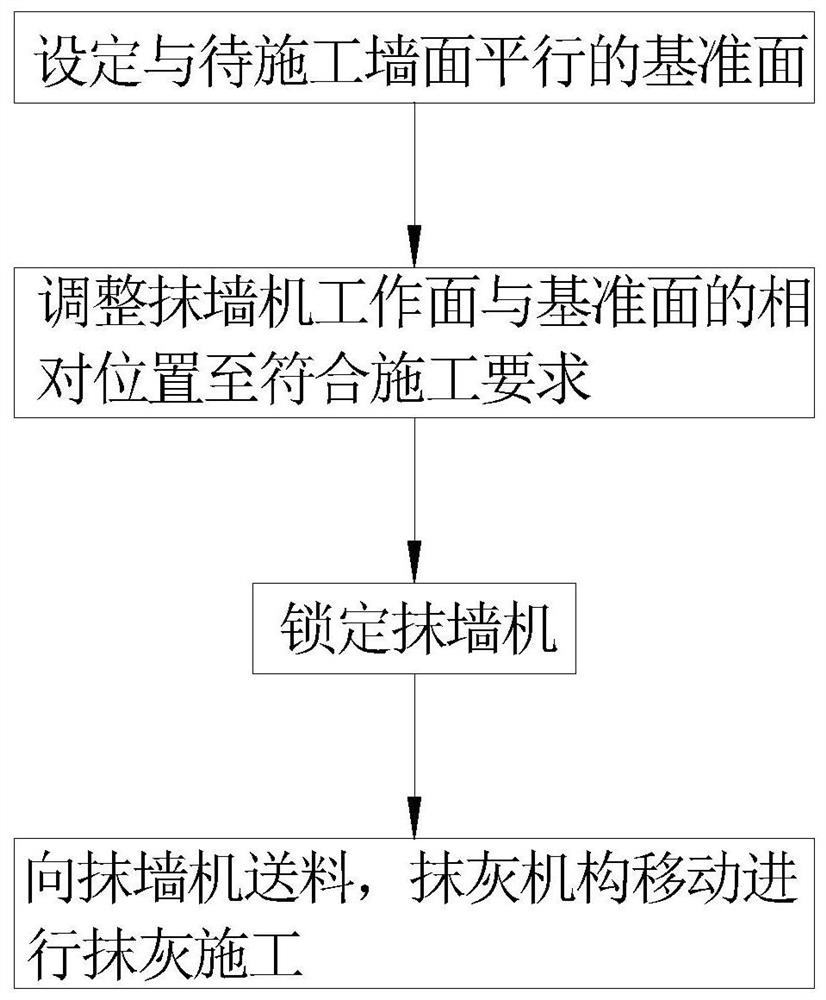

Interior wall plastering construction method based on wall plastering machine

InactiveCN112252679AAvoid falling off and crackingImprove plaster quality and efficiencyBuilding constructionsLight sourceStructural engineering

The invention discloses an interior wall plastering construction method based on a wall plastering machine. The interior wall plastering construction method comprises the following steps that firstly,an area light source is used for generating a datum plane parallel to a to-be-constructed wall surface on the outer side of the to-be-constructed wall surface; secondly, the wall plastering machine is close to the to-be-constructed wall surface, the distance between the wall plastering machine and the to-be-constructed wall surface is adjusted, and thus the working surface of the wall plasteringmachine is parallel to the datum plane, and the vertical distance between the working surface and the to-be-constructed wall surface meets the plastering construction thickness design; thirdly, the wall plastering machine is locked through a positioning system; and fourthly, materials are fed to a plastering mechanism through a feeding mechanism, and the plastering mechanism moves along the working face to conduct plastering construction. By the adoption of the scheme, it is guaranteed that the working surface of the wall plastering machine is parallel to the to-be-constructed wall face through the method of building the datum plane, and thus the thicknesses of all positions of the final plastered face are the same, the quality problems such as falling and cracking caused by different thicknesses are solved, plastering quality and efficiency are improved, and labor cost and material waste are reduced.

Owner:黎家宏

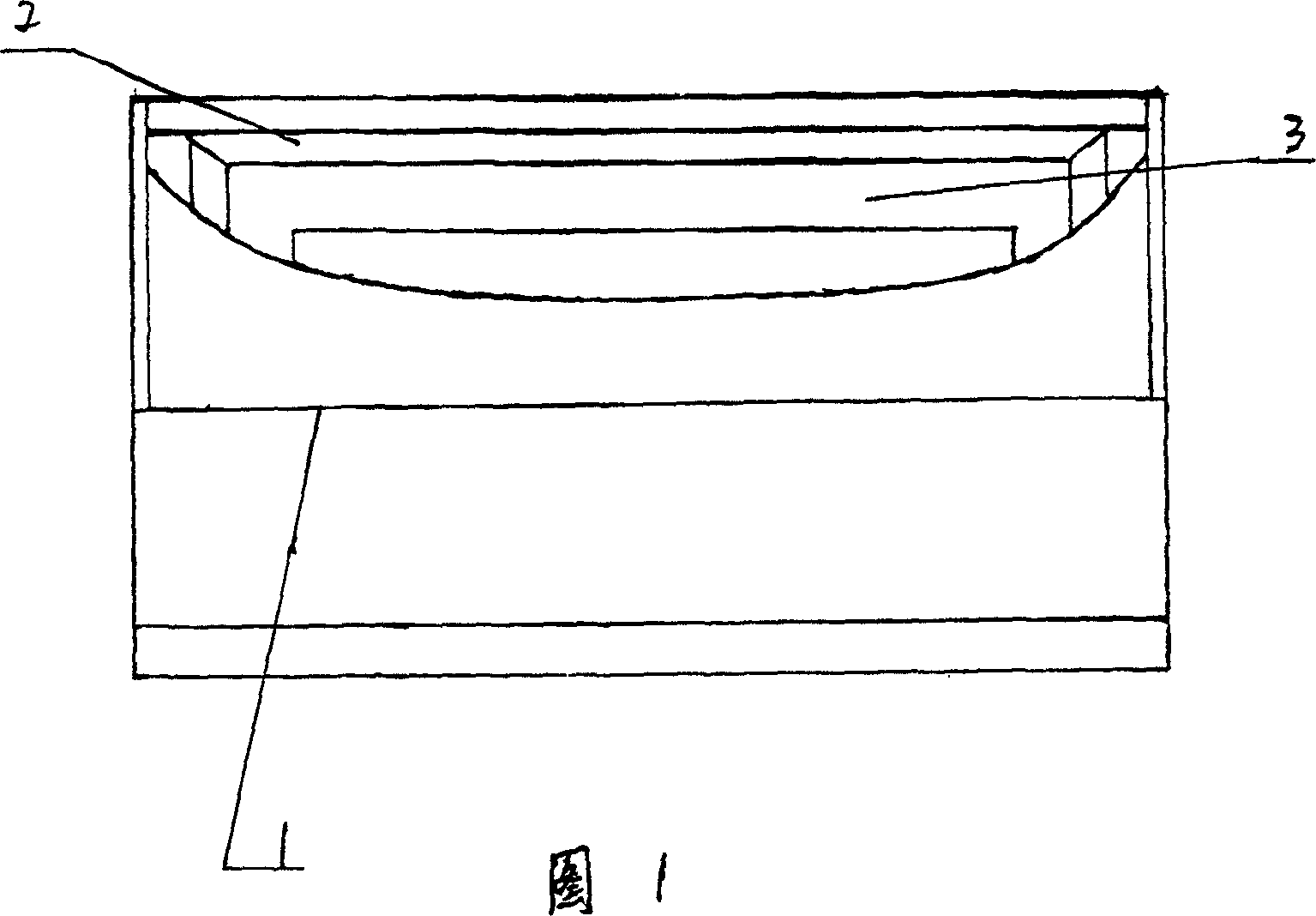

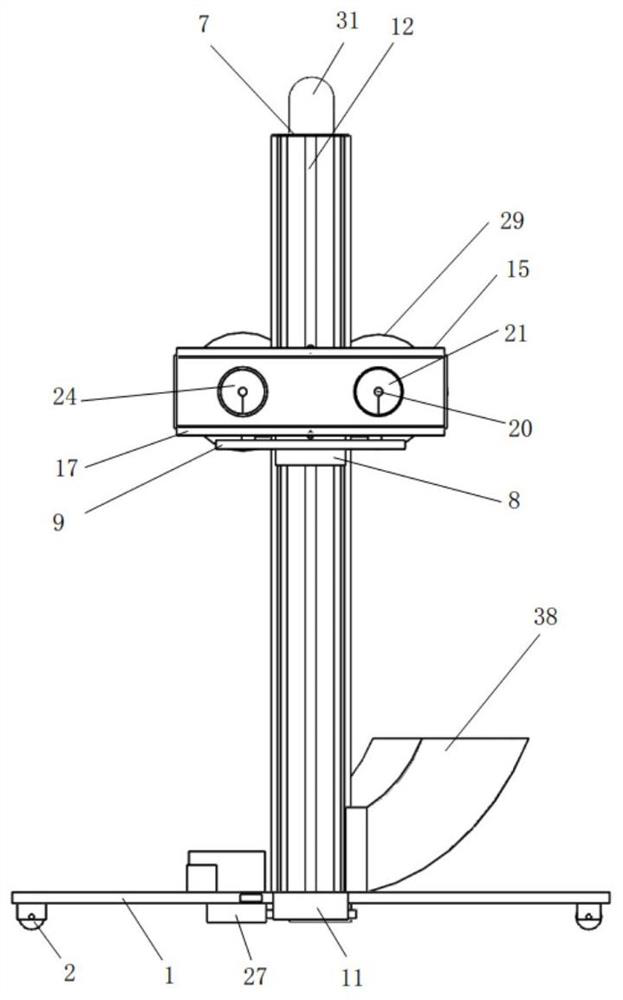

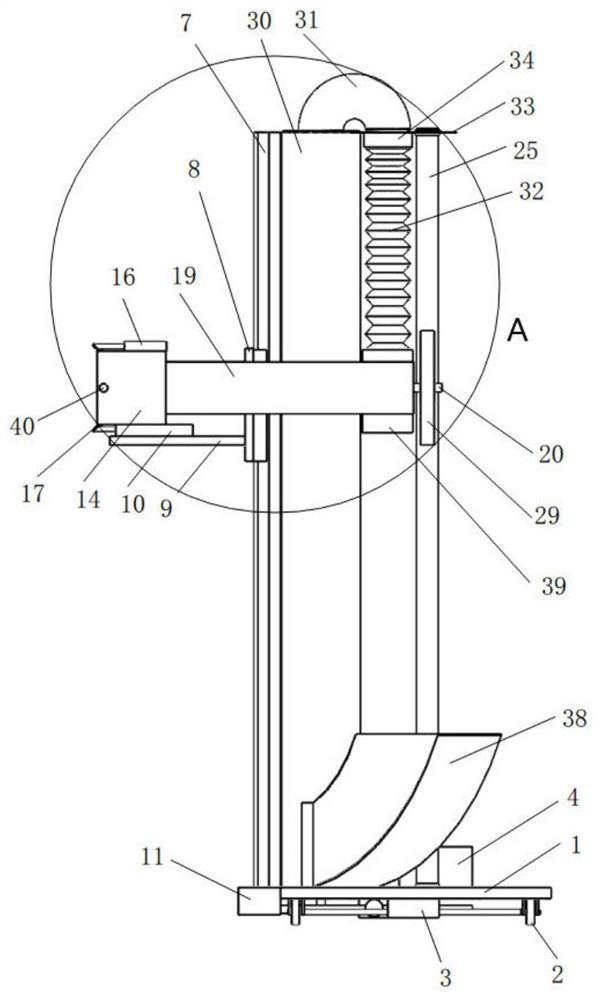

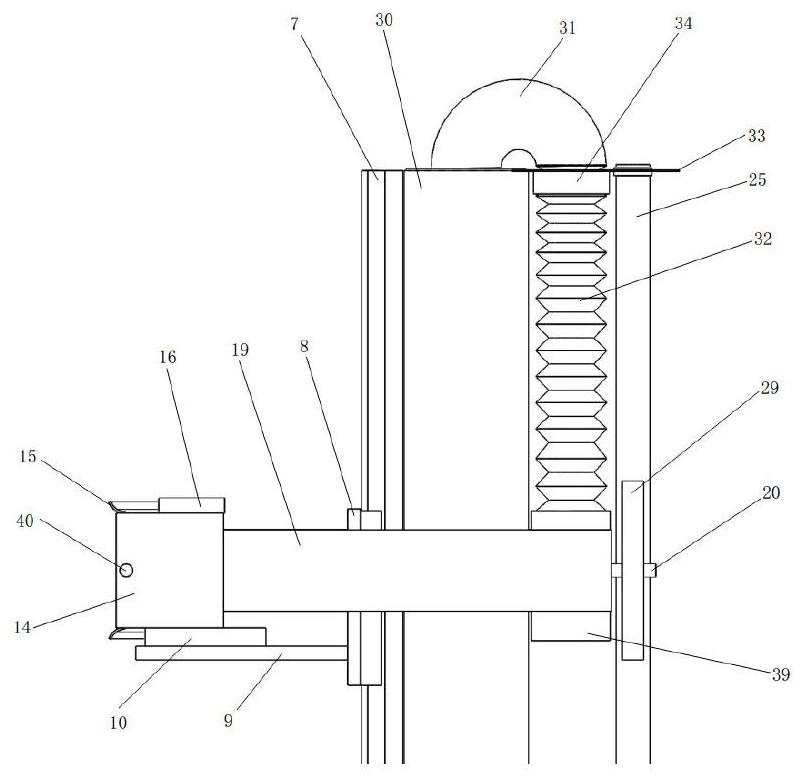

Plastering machine

The invention relates to a rendering machine, which comprises a lifter, an ash feeder, and a rendering device. Said rendering device comprises a bracket, a surface sealing, and a rendering plate with an inlet, a concave storage room formed by main frame and bottom plate, a pre-rendering blade and a molding rendering blade. The invention has simple and reasonable structure.

Owner:张兴波

Full-automatic continuous plastering device for decoration construction

ActiveCN112922279AHigh degree of automationImprove plastering efficiencyBuilding constructionsSlide plateIndustrial engineering

The invention discloses a full-automatic continuous plastering device for decoration construction. The full-automatic continuous plastering device comprises a moving part, a support piece and a continuous plastering part, wherein the moving part comprises a support plate and a moving power part, and the moving power part is arranged on the support plate; the support piece comprises a support sliding plate, a lifting sliding support seat and a lifting power part, the support sliding plate is arranged on the support plate, the lifting sliding support seat is arranged on the support sliding plate, and the lifting power part is arranged on the support sliding plate; and the continuous plastering part comprises a plastering part, a relay conveying part and a mortar conveying part, the plastering part is arranged on the lifting sliding support seat, the relay conveying part is arranged on the plastering part, and the mortar conveying part is arranged on the relay conveying part. The full-automatic continuous plastering device has the advantages of high degree of automation, high plastering efficiency, high plastering quality and stable plastering quality, the labor intensity of workers can be obviously reduced, and the construction period can be obviously shortened.

Owner:IANGSU COLLEGE OF ENG & TECH

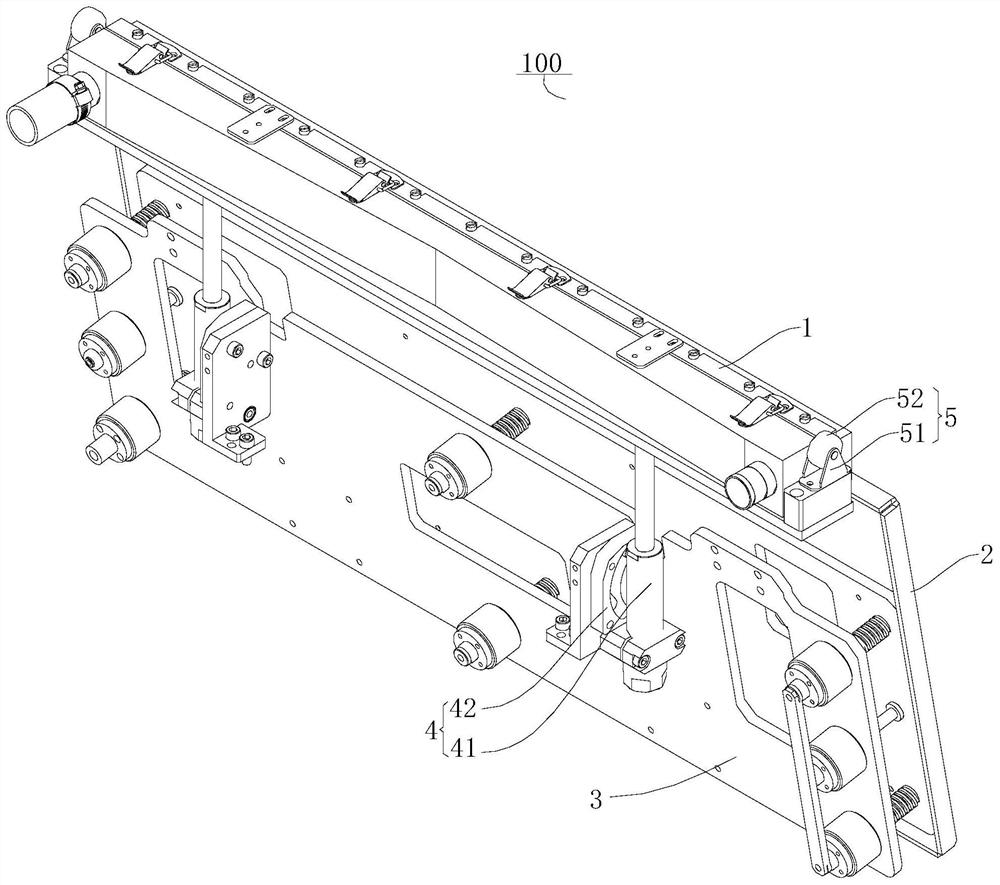

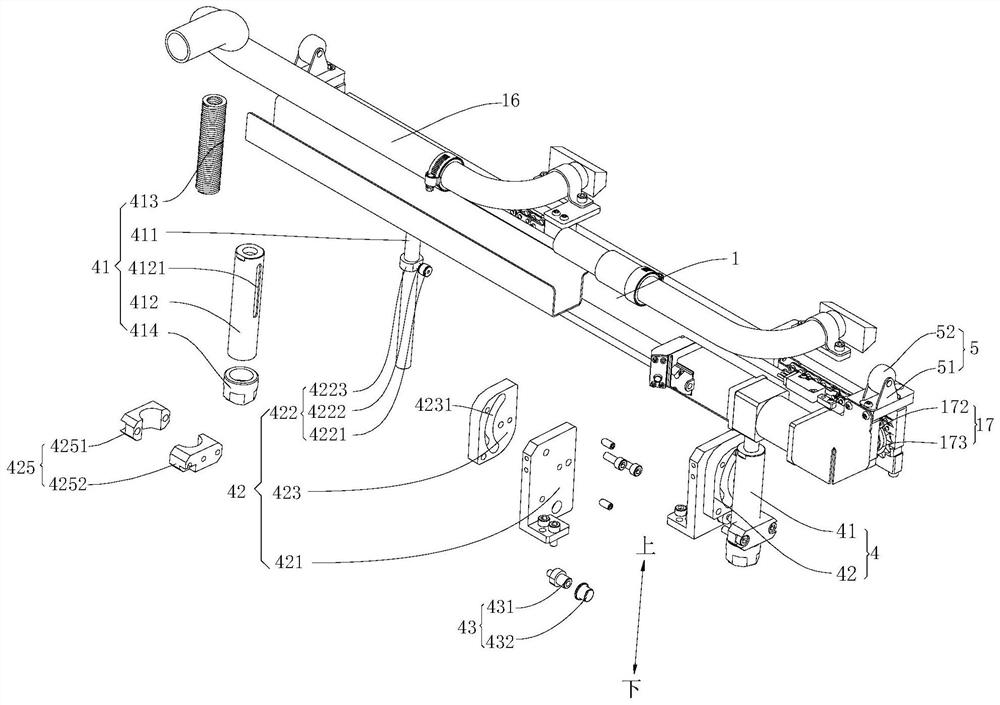

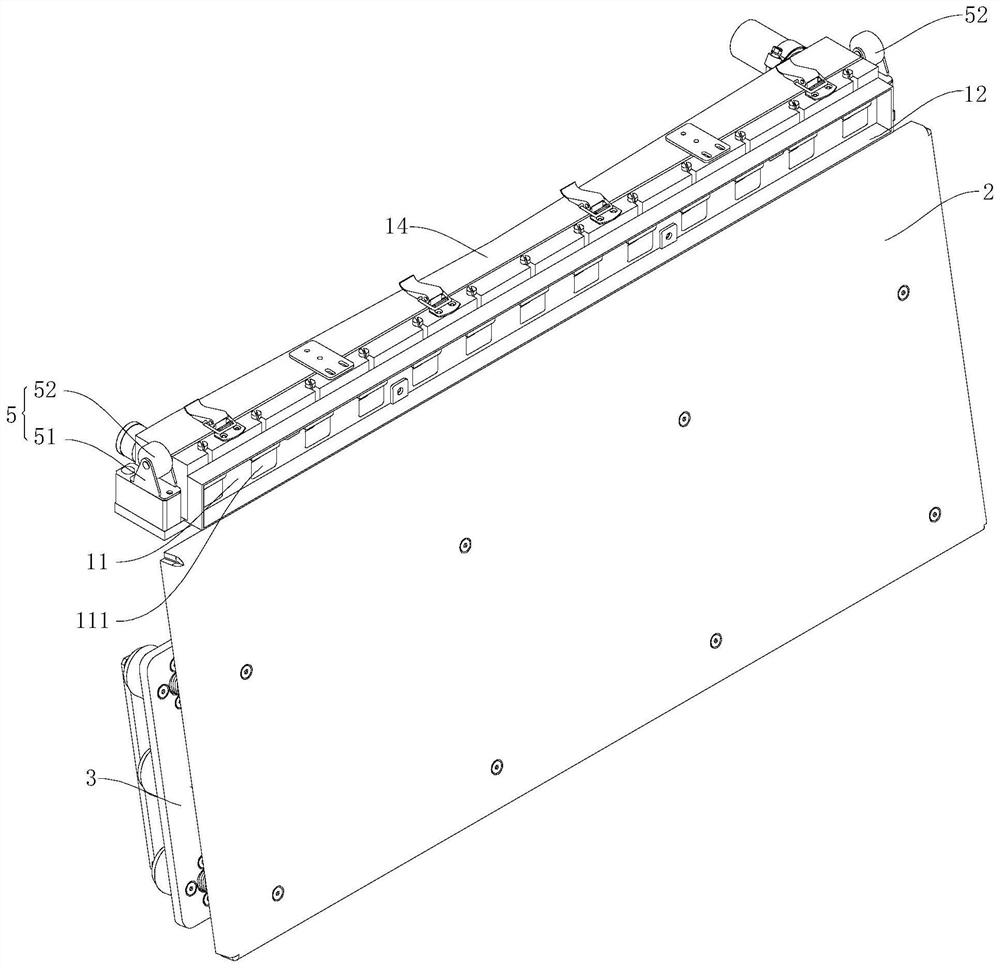

Plastering device and plastering robot

ActiveCN112012444AImprove plastering efficiencyImprove efficiencyBuilding constructionsStructural engineeringMaterial distribution

The invention discloses a plastering device and a plastering robot, wherein the plastering device comprises a plastering frame, a plastering plate, a material distribution mechanism and an avoidance mechanism. The plastering plate is mounted on the plastering frame and positioned in front of the plastering frame; the material distribution mechanism conveys mortar to the front of the plastering plate; and the material distribution mechanism is provided with a material distribution position located above the upper end of the plastering plate and an avoidance position located below the upper endof the plastering plate, the avoidance mechanism is rotatably installed on the plastering frame, the material distribution mechanism is installed on the avoidance mechanism, and the avoidance mechanism is capable of driving the material distribution mechanism to move between the material distribution position and the avoidance position. According to the plastering device, when the material distribution mechanism is located at the material distribution position and the plastering plate cannot continue to move upwards for plastering, the avoidance mechanism is capable of driving the material distribution mechanism to rotate relative to the plastering plate and contract downwards at the same time, so that the material distribution mechanism is switched to the avoidance position, the plastering plate is incapable of continuing to move upwards, the whole building is plastered continuously, the plastering quality is good, and the plastering efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

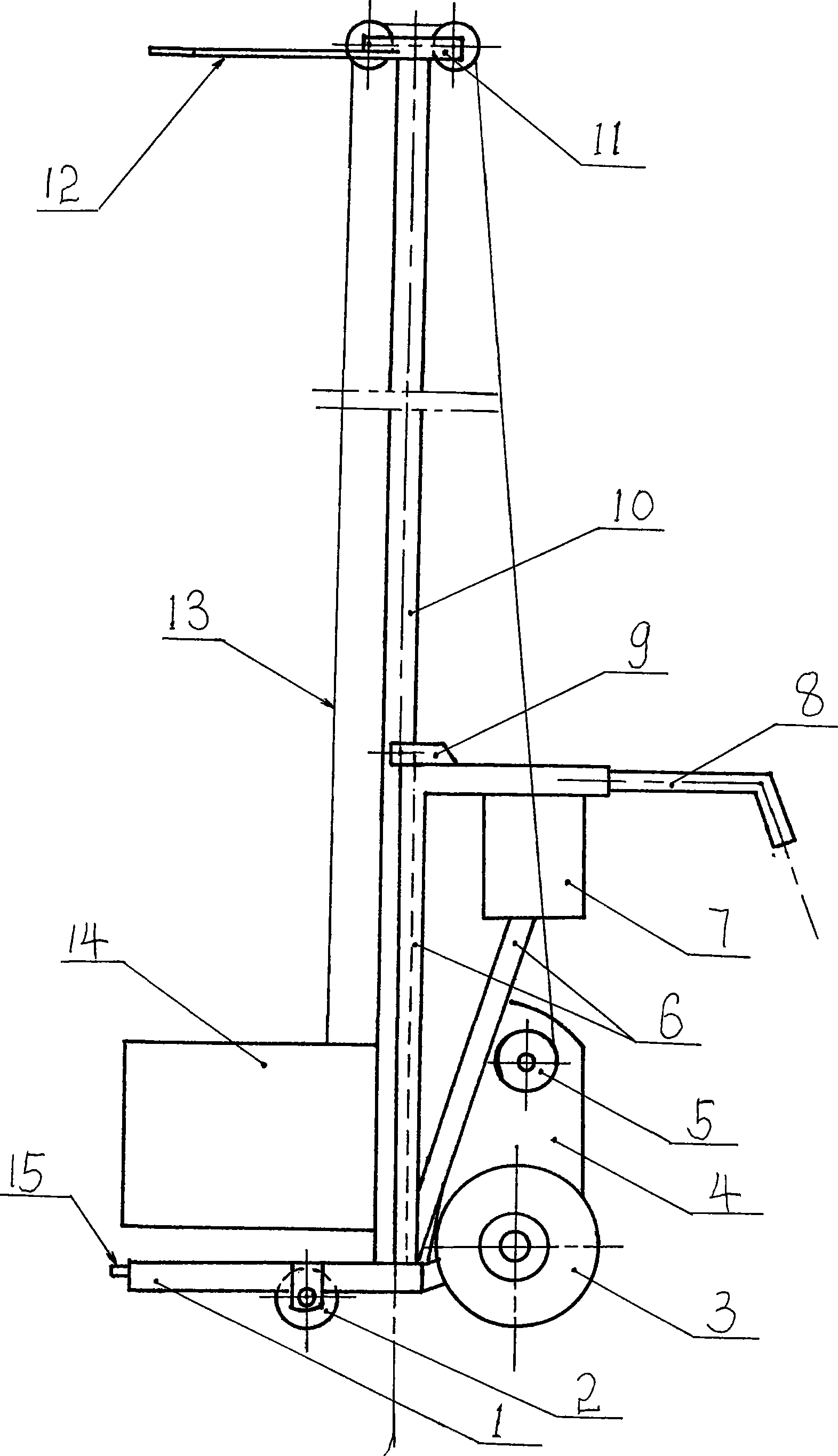

Grouting apparatus

InactiveCN101487339AEasy squeezeImprove plaster qualityBuilding constructionsSteel tubeVehicle frame

The invention relates to a pasting machine for building walls, which consists essentially of a hand-held frame, a pasting tool, a retractor, an upright post, an electric control system and a support, and has a vehicle-type frame and a six-wheel structure. The pasting machine mainly pushes mortar to paste the wall directly by arc-shaped movements of blades. The frame is provided with a handlebar support, a handlebar and an operating board, as well as an adjustable pasting thickness limit support and a lever type pedal frame outrigger. The pasting machine is provided with two steel-pipe upright posts, each of which is provided with a set of pulleys at the top end; and the two upright posts keep stable through the fixation with the handlebar support. The retractor is positioned at the rear part of the frame, and drives the pasting tool to move up and down along the upright posts by two wire cables through the pulley block at the top ends of the upright posts. The pasting machine has the advantages of reasonable design and simple operation.

Owner:姜中仁

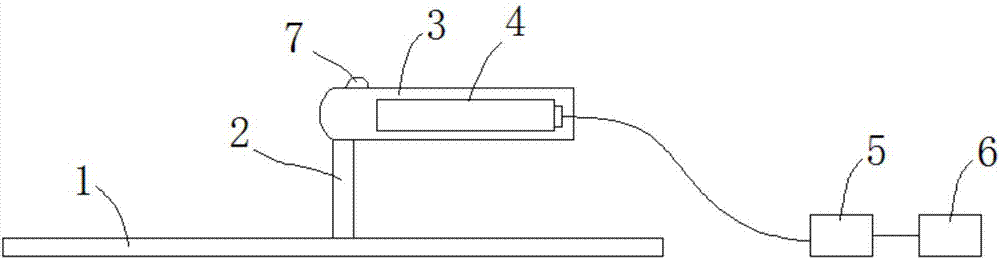

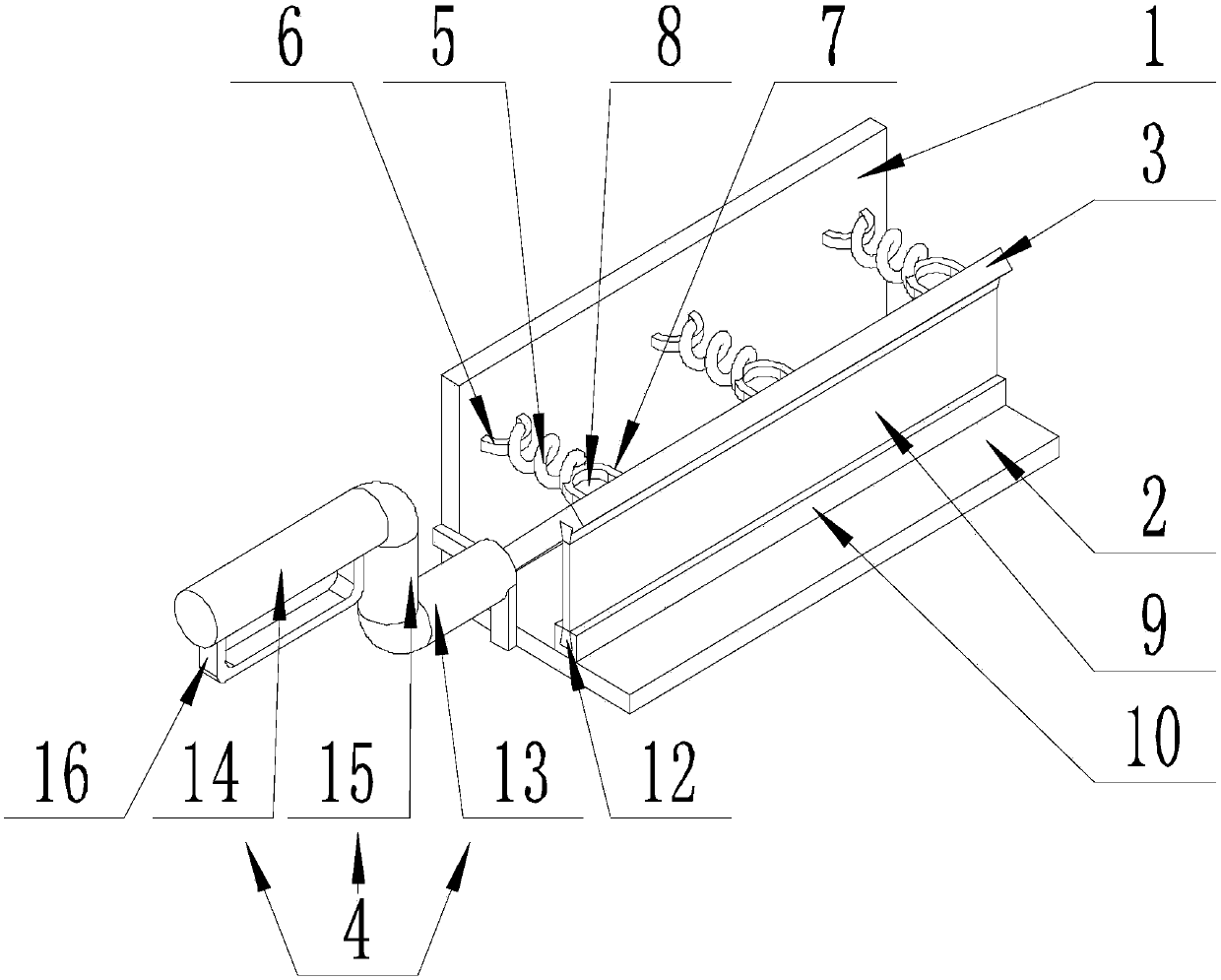

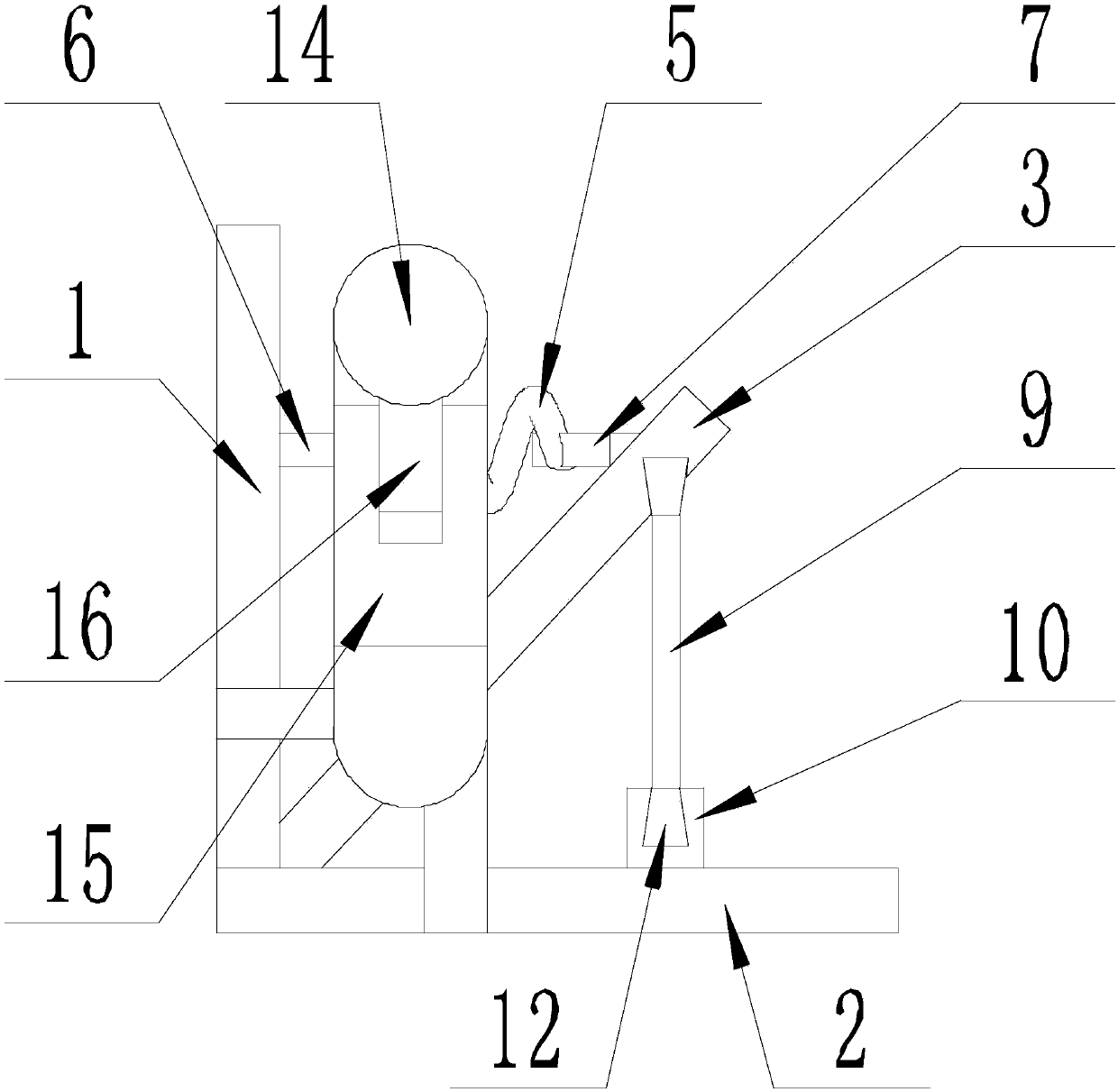

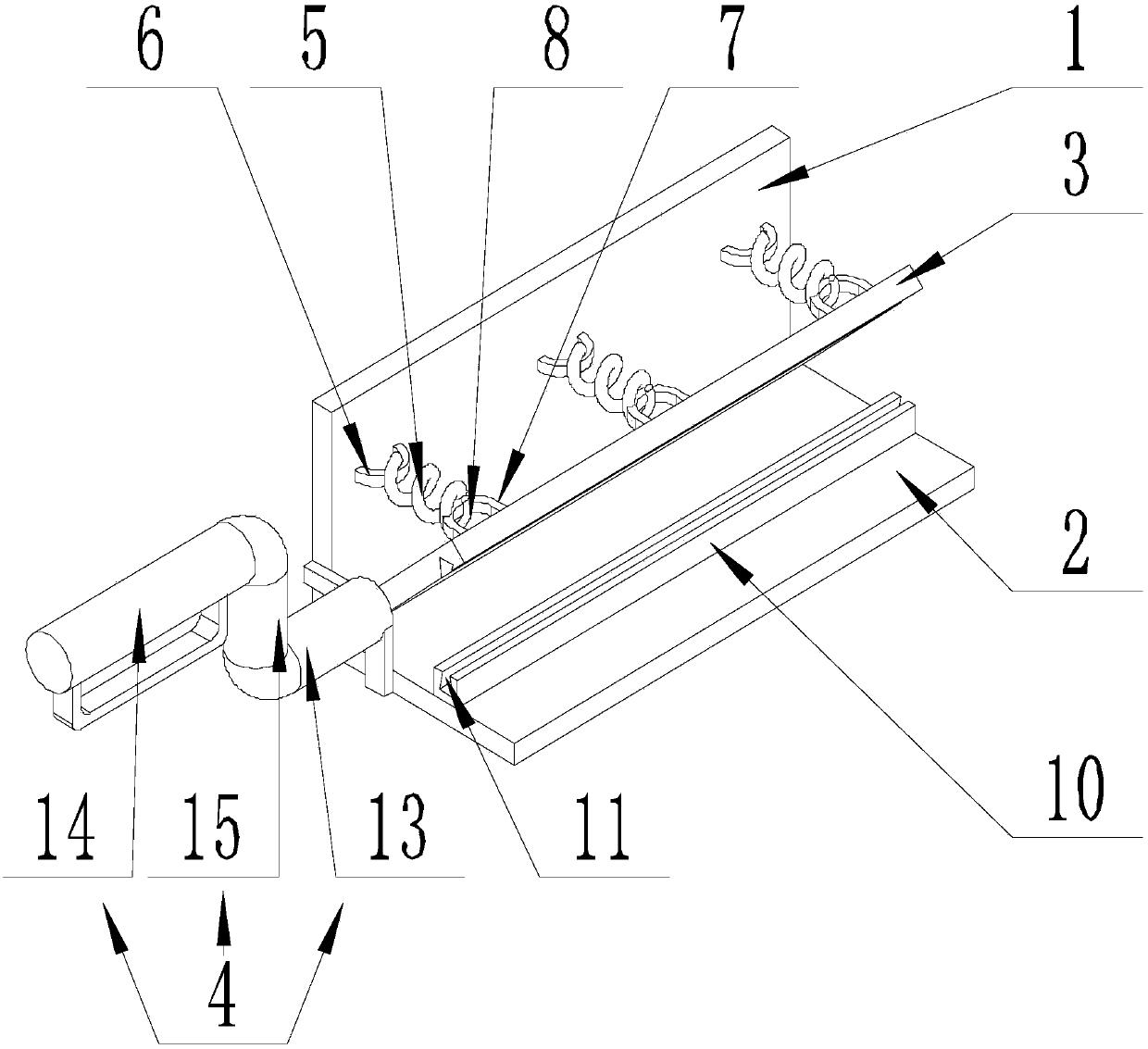

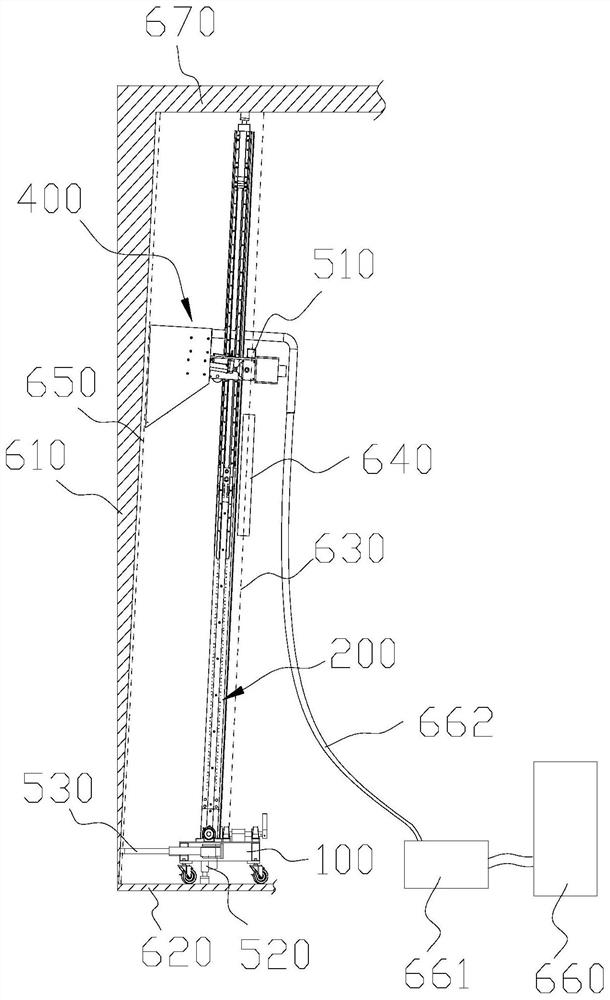

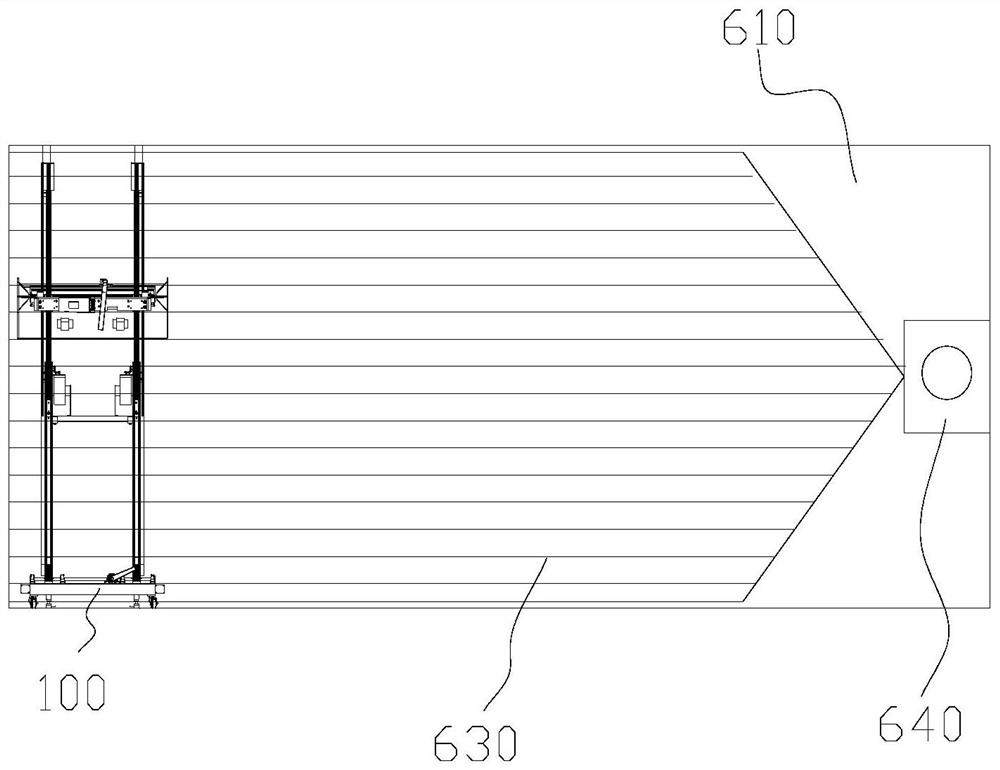

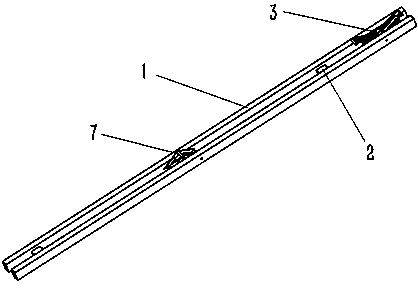

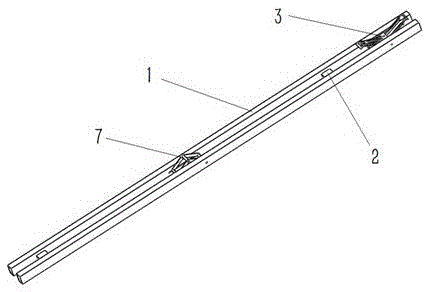

Guide rail type wall plastering machine

InactiveCN103821328AReduce physical laborControl verticalityBuilding constructionsOperabilityMechanical engineering

The invention relates to a guide rail type wall plastering machine. The guide rail type wall plastering machine comprises a guide rail system, a plastering system and a pumping machine, wherein the plastering system is arranged on the guide rail system and can move along the guide rail system back and forth, and the pumping machine is connected with the plastering system to convey raw material. The guide rail system comprises a guide rail rod, a fixed part and a supporting part used for supporting the guide rail rod, and the fixed part is arranged on the guide rail rod and used for being fixed on a wall space; the plastering system comprises a plastering plate, a conveying pipe, a hand shank and angle adjusting devices, the conveying pipe is connected with the plastering plate and used for conveying the raw material, the hand shank is used for fixing the plastering plate, and the angle adjusting devices are arranged on the hand shank and the plastering plate. The guide rail type wall plastering machine has the following advantages of relieving manual labor of workers, reducing construction cost, improving plastering quality, being small in size, light in weight, convenient to install and transport, flexible in operation, almost capable of meeting requirements of plastering construction operation in all areas of the wall space, easy to use, high in operability, capable of accurately controlling perpendicularity and flatness of plastered faces and convenient and rapid to install and commission, and the workers can operate the equipment expertly without any experience.

Owner:WUHAN UNIV

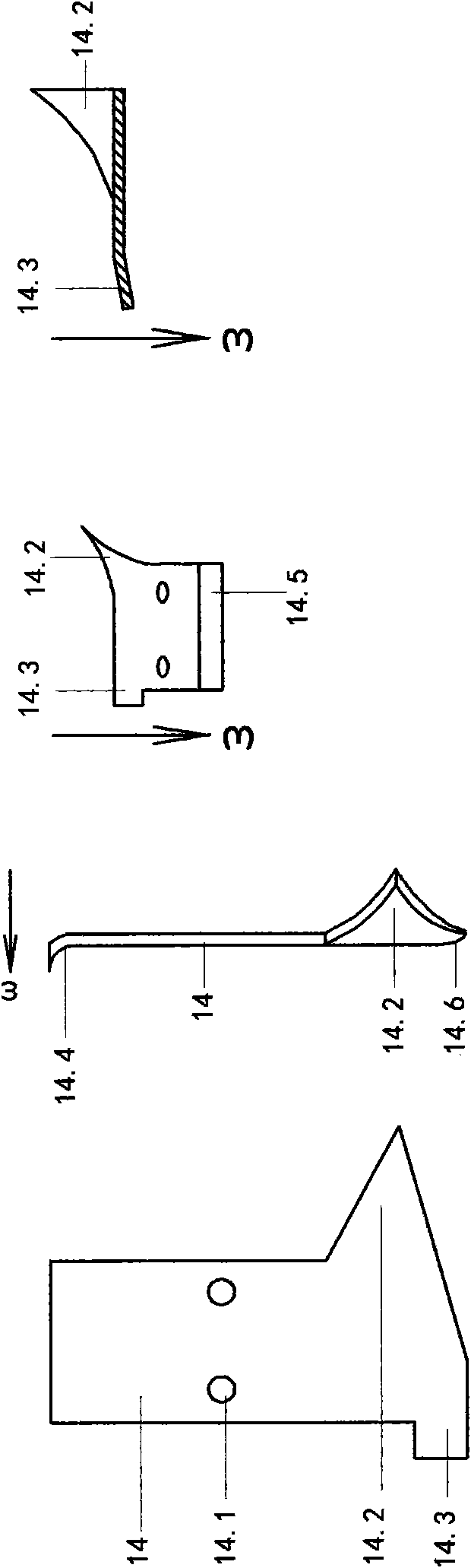

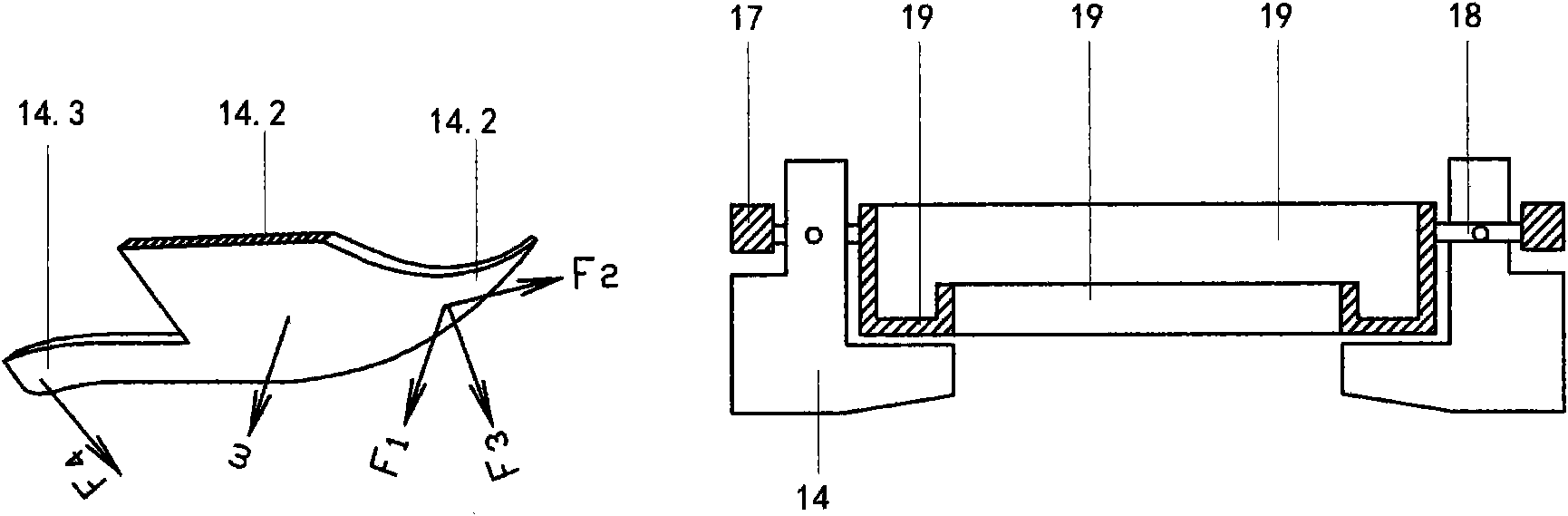

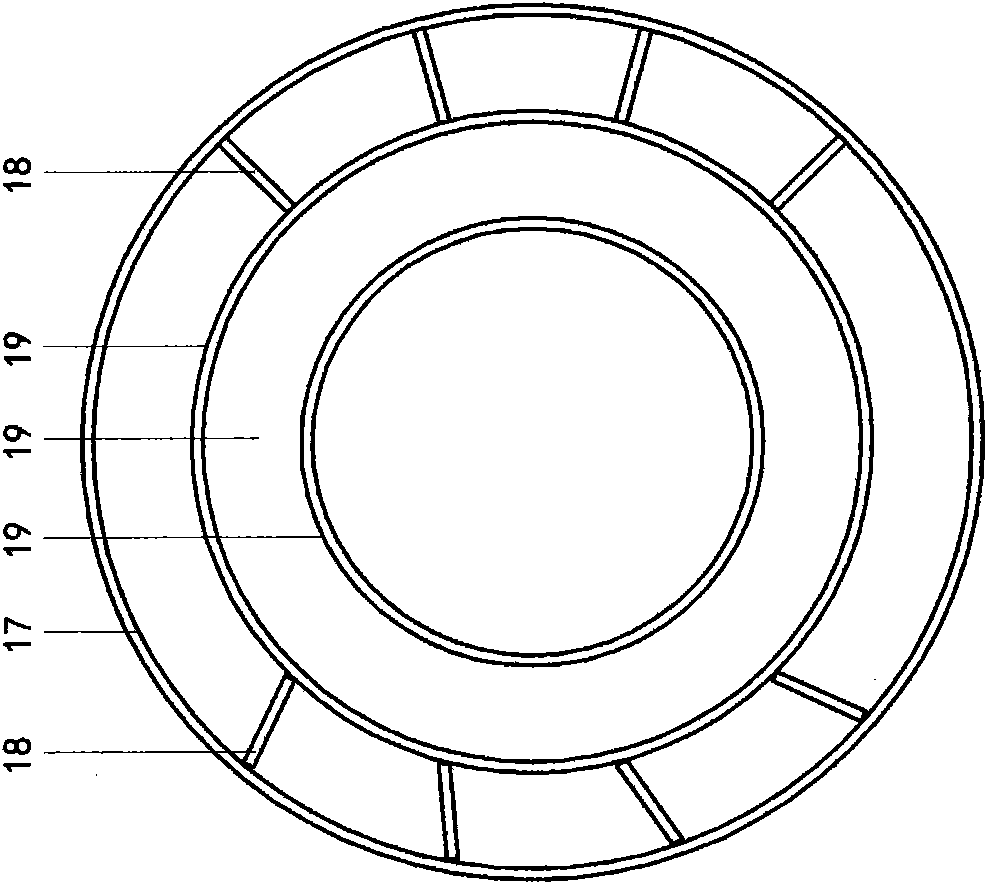

Plastering head

The invention relates to a plastering head, which is a plastering main part of a plastering machine, in particular to a plastering head of the plastering machine. The plastering head consists of a plurality of single bodies, wherein the single bodies comprise a fixed barrel, an inner barrel, an outer barrel, cutter bodies, a power system, a delivery barrel and the like; the inner barrel and the outer barrel of the single bodies adopt the fixed barrel as a skeleton and adopt a central shaft of the fixed barrel as a rotary axis; the fixed barrel consists of a main barrel and an auxiliary barrel; the inner barrel is arranged in the main barrel of the fixed barrel; the outer barrel is arranged outside the auxiliary barrel of the fixed barrel; a delivery pipe is arranged on the fixed barrel; a return pipe is arranged by adopting the fixed barrel as a bracket, and is butt-jointed with the inner barrel; the inner barrel and the outer barrel are respectively provided with a middle cutter and an edge cutter; the two cutter bodies rotate along with the respectively corresponding barrel bodies so as to form a rotary plastering surface; one plastering single body can form a plastering head; and the combined plastering head is formed after the plastering single bodies are combined.

Owner:孙元斌

Slurry patting construction process for building construction

InactiveCN112376854ASimple structureReduce processing difficultyBuilding constructionsRough surfaceConstruction engineering

The invention discloses a slurry patting construction process for building construction. The construction process comprises the following steps of a, operation preparation, b, tool manufacturing, c, slurry preparation, d, wall treatment, e, slurry patting construction and f, maintenance construction. Slurry is flatly laid on a meshed bat through a mortar scraper, the meshed bat is flush with the wall surface in the slurry patting process, a thorn-shaped rough surface with a thick bottom and sharp tops is formed, the purpose of uniform and firm base layer treatment is achieved, the defects of hollowing, cracking and the like of a painting layer caused by base layer treatment are basically avoided, the rework rate is reduced, and the plastering quality is improved.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Construction method for preventing hollowing and cracking of wall plastering

PendingCN112942709AAvoid secondary processingNo adhesionCovering/liningsArchitectural engineeringAdhesive glue

The invention discloses a construction method for preventing hollowing and cracking of wall plastering. The construction method comprises the following steps: (a) wall surface treatment is conducted, specifically, firstly, the surface of a to-be-constructed wall is cleaned to remove falling dust and residual soil blocks and dirt on the wall, and a plastering structural surface is watered and uniformly wetted; and (b) primary gluing is conducted on the wall surface, specifically, building glue is evenly mixed and then smeared on the to-be-constructed wall surface through a brush. The construction method has the beneficial effects that firstly, the building glue is smeared on the surface layer of the treated wall surface, it is guaranteed that the dust attachment phenomenon cannot occur in the using process of the wall surface, and the plastering quality is improved; a steel wire mesh is hung on the surface of the wall surface, so that the wall surface is smooth, mortar is attached to the wall surface, the hollowing phenomenon cannot occur in the later period, the anti-cracking effect is good, and the wall surface quality is improved; and spray-type moisturizing treatment is adopted, so that water is uniformly sprayed to the wall surface, the wall surface maintenance effect is improved, and wall surface cracking can be effectively avoided.

Owner:福建筑兆建设有限公司

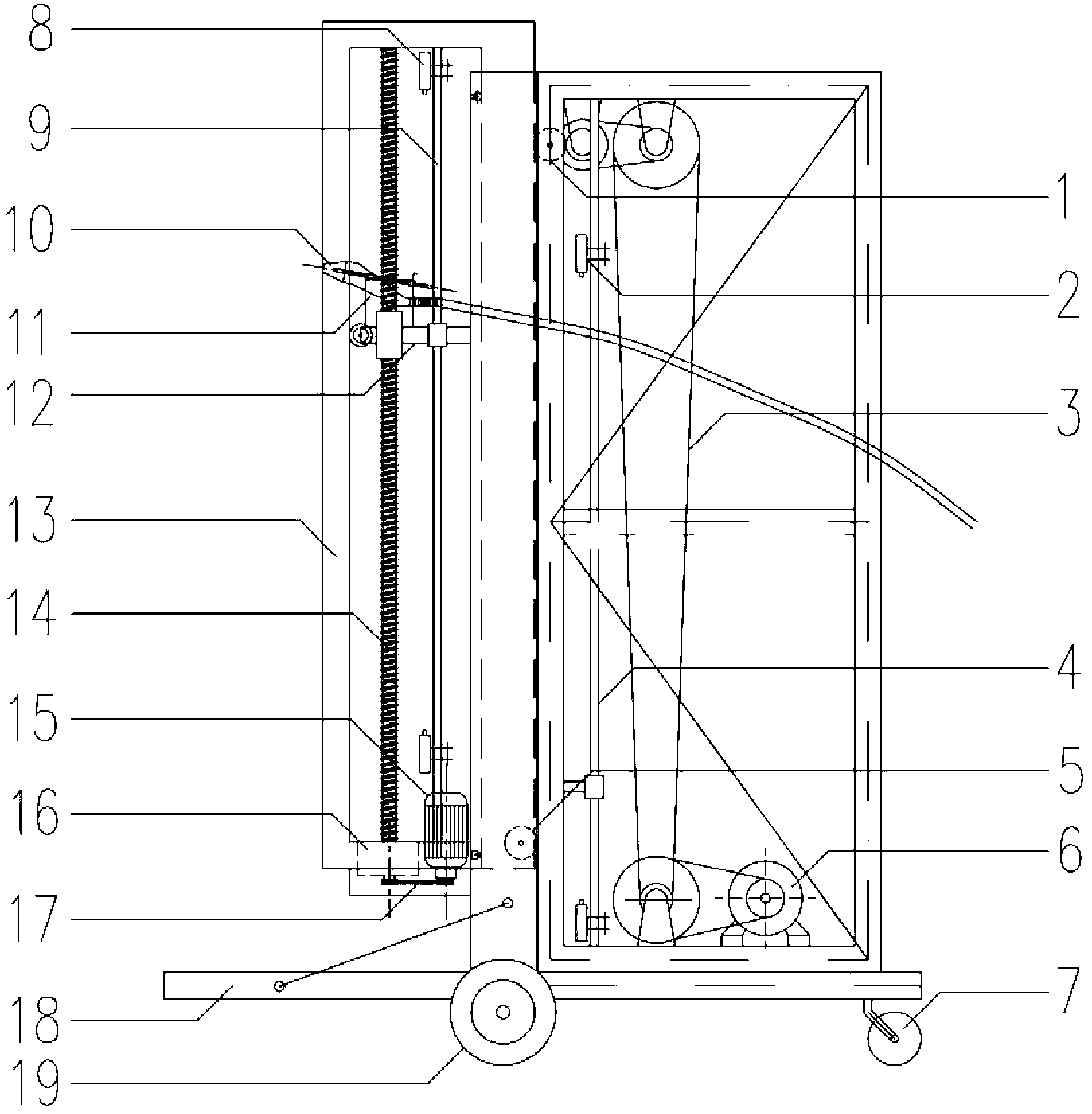

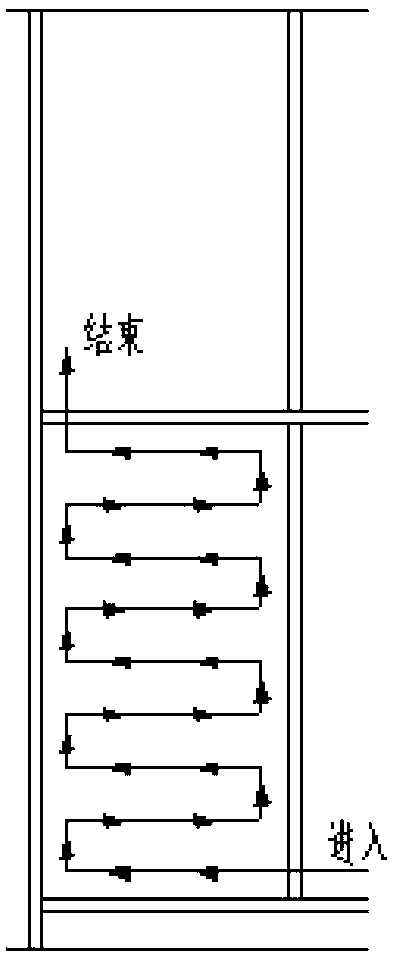

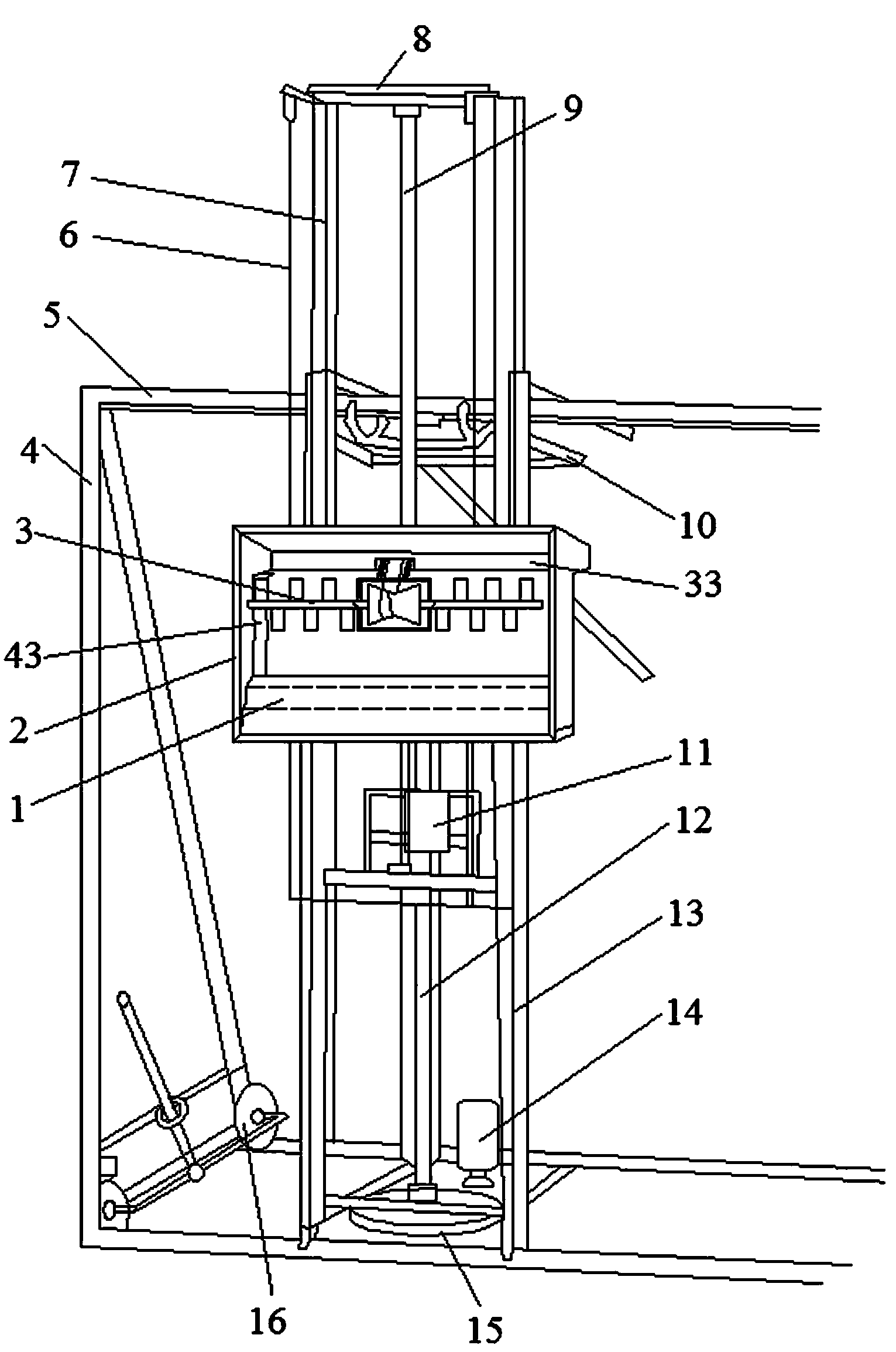

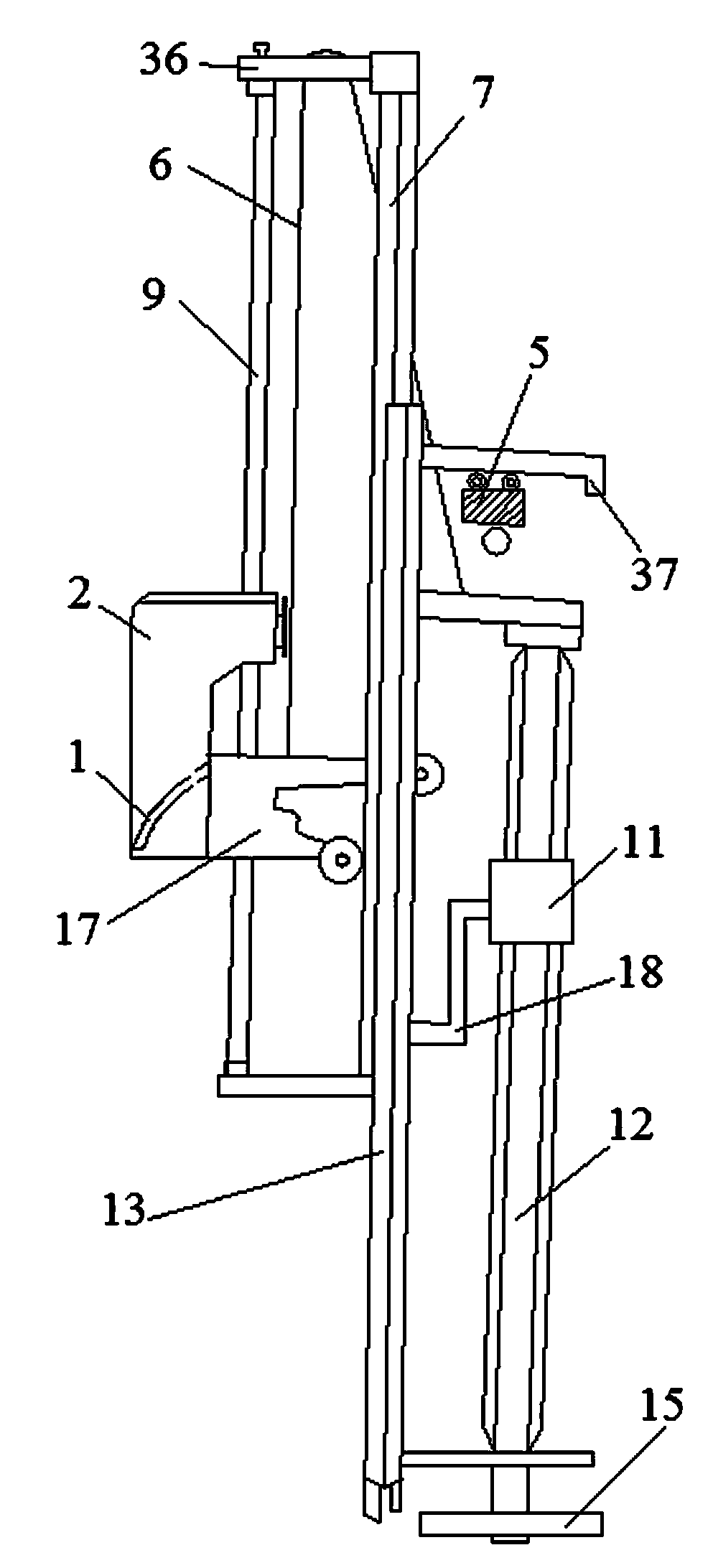

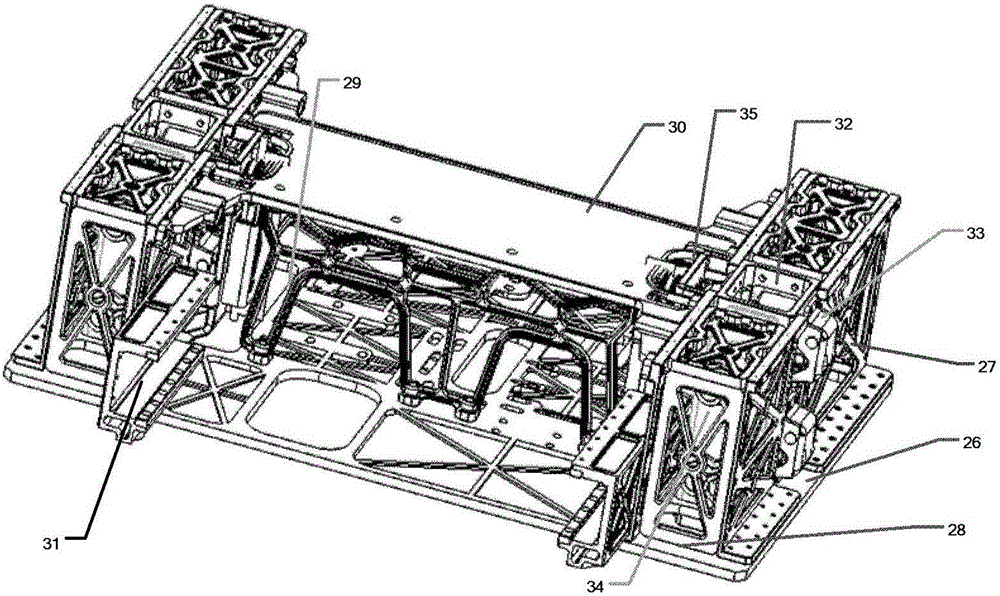

Intelligent wall plastering robot

InactiveCN105804376AImprove plaster qualityImprove work efficiencyBuilding constructionsControl engineeringRobot

The invention discloses an intelligent wall plastering robot which comprises a hydraulic system, a base stand column ejector rod device, a lifting frame device, an elevating device, a translation device, a rotating device and a plate turnover device.The devices are controlled by an ARM controller arranged in a control cabinet on an elevating frame.The robot is a precise and intelligent wall plastering machine, is applicable to a wall with a certain gradient, high in efficiency, convenient to operate and high in practicality, and the wall plastering quality is high.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

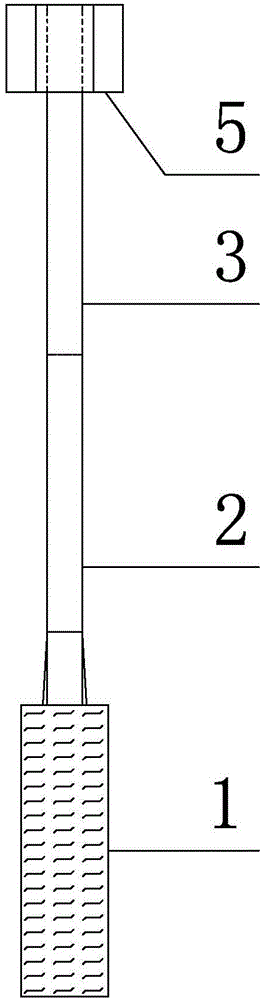

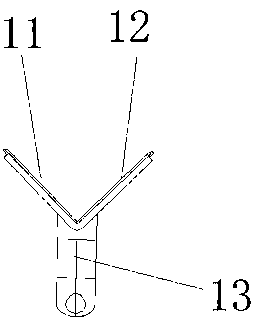

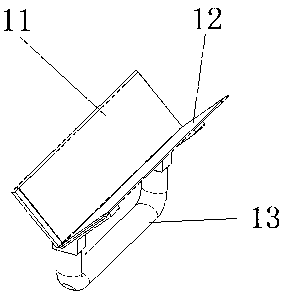

Plastering tool for arc-shaped internal and external corners

InactiveCN106284948ASimple structureSimple and fast operationBuilding constructionsEngineeringUltimate tensile strength

The invention discloses a plastering tool for arc-shaped internal and external corners. The plastering tool comprises a handle, a connecting rod and an oval plastering head, wherein the handle, the connecting rod and the oval plastering head are connected in sequence; and a convex arc used for hooking the internal corner is arranged on one side of the oval plastering head, and a concave arc used for plastering the external corner is arranged on the other side of the oval plastering head. The plastering tool is simple in structure, easy and convenient to operate, rapid and economical. From the aspect of the actual application condition of the plastering tool in engineering, the design requirement on plastering the internal and external corners into arc corners is met; meanwhile, the construction efficiency is improved, the labor intensity is relieved, and the construction progress is accelerated; and in addition, the appearance effect is good according to the finally-formed internal and external corners.

Owner:广西建工集团第四建筑工程有限责任公司

Pre-installation method of concealed electrical box for filling wall

ActiveCN104405128BEasy to installFlexible adjustmentElectrical apparatusWallsSocial benefitsEngineering

The invention provides an earlier direct mounting method for a concealed distribution box of a filler wall. According to the technical scheme, the method comprises the following steps: preparing for construction; selecting a section bar bracket; making and mounting the section bar bracket; mounting the box; mounting inlet / outlet pipes of the box; building the filler wall; forming the wall masonry; after achieving design strength, removing the section bar bracket. According to the earlier direct mounting method for the concealed distribution box of the filler wall provided by the invention, the mounting is convenient, the adjusting is flexible, a large quantity of engineering practices prove that the mounting quality is greatly increased by the technique, and meanwhile, the quality of the filler wall and plastering is effectively increased, the construction is safe and environment-friendly, the construction period is effectively shortened, the cost is reduced, the excellent economic, technical and social benefits are achieved, and the method has positive popularization and application values.

Owner:CHINA MCC17 GRP

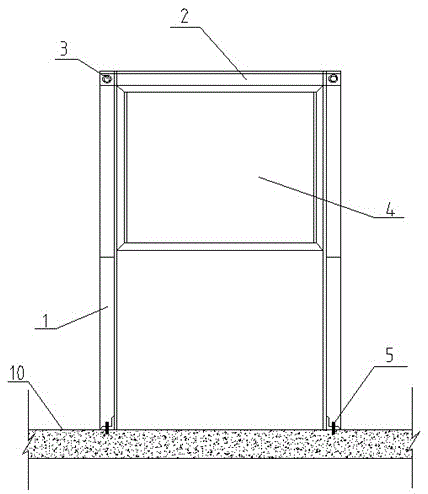

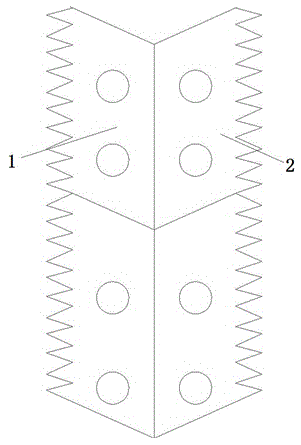

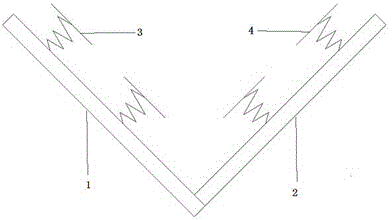

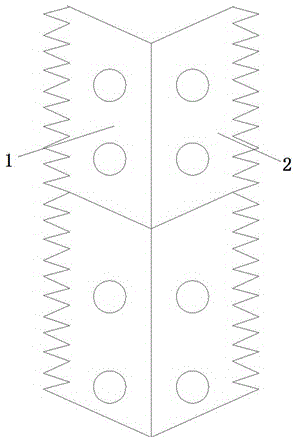

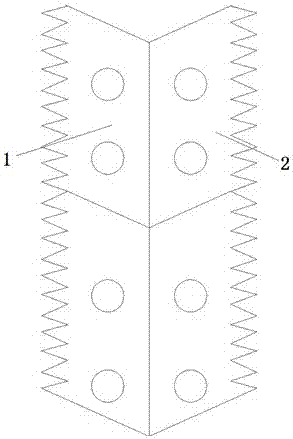

Sawtoothed wing external corner protective plate for plastering during construction

InactiveCN104947947APrevent being plastered by mistakeHigh strengthBuilding material handlingEngineeringBuilding construction

Owner:CHINA METALLURGICAL CONSTR ENG GRP

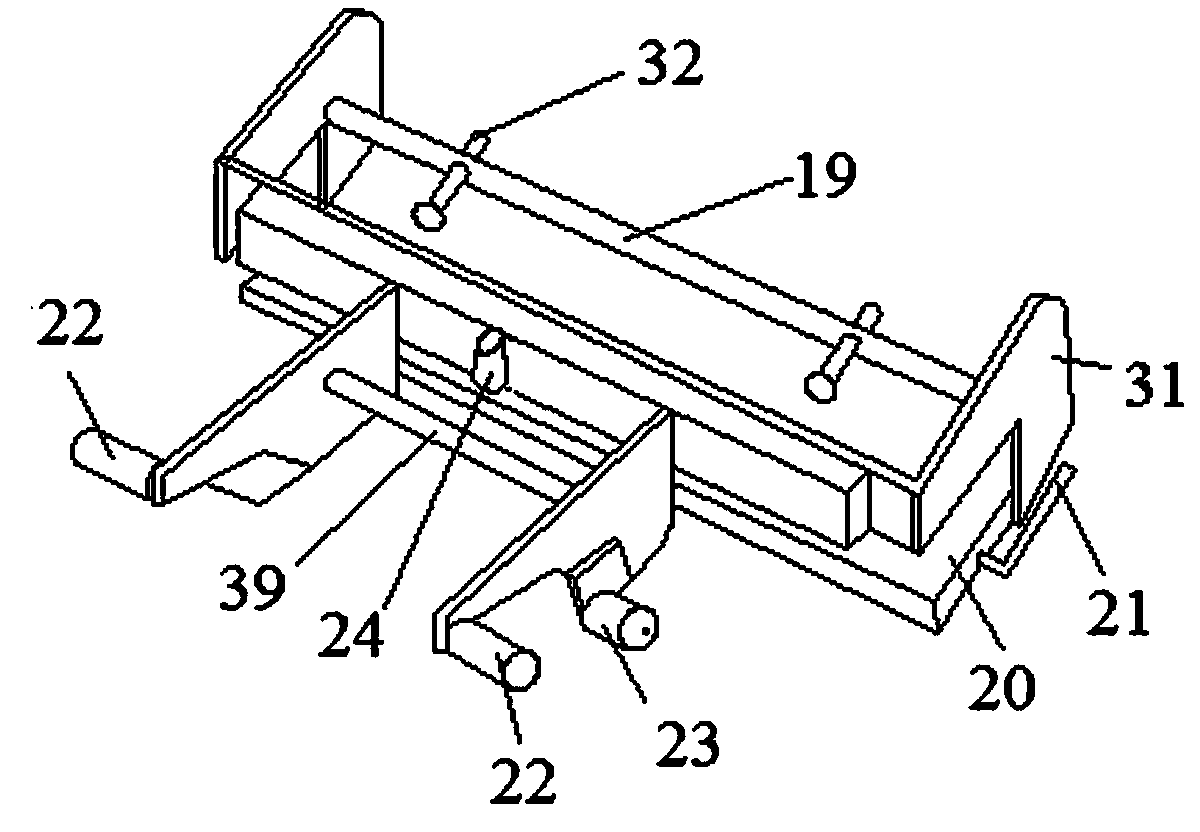

Rail-mounted millstone pasting machine

InactiveCN102677877AImprove plaster qualityImprove plastering efficiencyBuilding constructionsAgricultural engineeringMillstone

The invention discloses a rail-mounted millstone pasting machine, which includes a pasting device and is characterized in that the pasting device is arranged on a lateral movement assembly, the lateral movement assembly is glidingly arranged on a vertical guide rail, the vertical guide rail is connected with a positioning stander, and the pasting device is connected with a lifting device; the positioning stander includes two groups of positioning racks, and each group of positioning rack includes an upper wall connection piece and a lower wall connection piece, which are arranged horizontally and connected with two ends of the vertical guide rail respectively; the lateral movement assembly includes a main rail rack, a lateral track and a traveling dolly, which are arranged horizontally, wherein the lateral track is glidingly matched with the main rail rack, the traveling dolly is glidingly matched with the lateral track, and the main rail rack is glidingly matched with the vertical guide rail through a vertical rail pair; and the pasting device is arranged on the traveling dolly and is connected with the lifting device through the vertical rail pair. The rail-mounted millstone pasting machine can be suitable for various wall surface pasting, and has the advantages of high pasting quality, low labor intensity for works, high pasting efficiency, less leaked plaster, small plaster consumption, and low cost.

Owner:陶宝魁

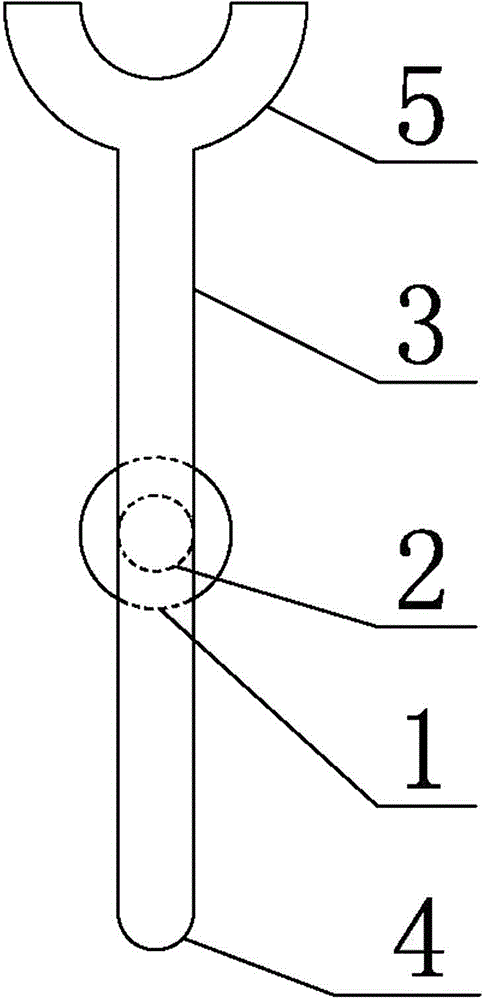

External-internal corner trowel

Owner:屠国权

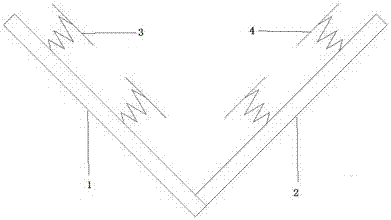

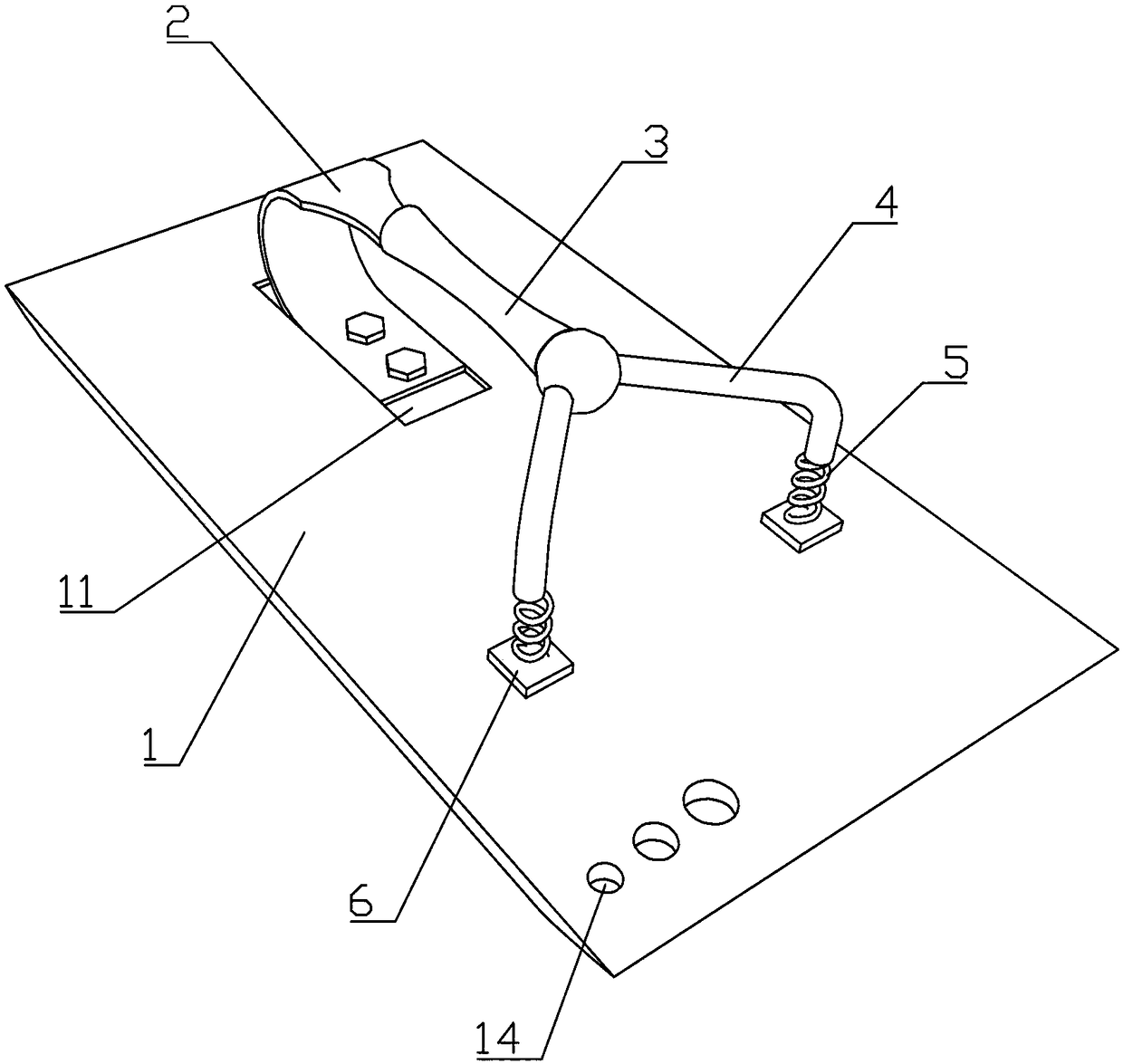

External corner guard board with adjustable sawtooth wings and used for plastering process

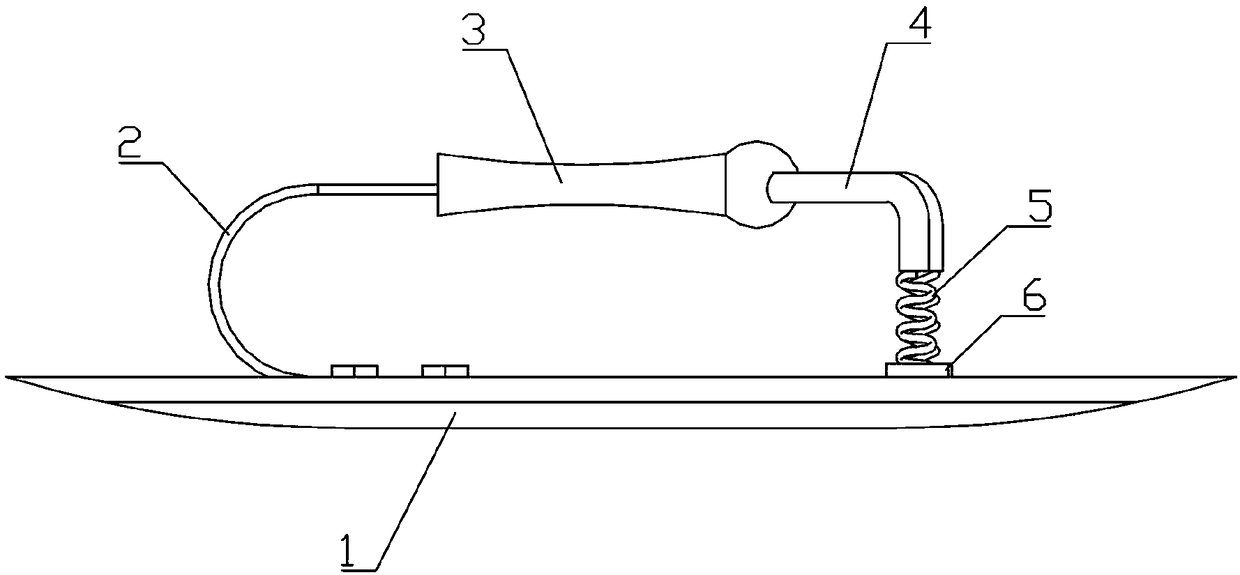

ActiveCN104963487APrevent being plastered by mistakeHigh strengthBuilding constructionsElastic componentEngineering

The invention relates to an auxiliary tool for building construction, in particular to an external corner guard board with adjustable sawtooth wings and used for a plastering process. The guard board comprises a guard board body I and a guard board body II. The guard board body I and the guard board body II are integrally rectangular. One long edge of each guard board body is in a linear shape, and the other long edge of each guar board body is in a sawtooth shape and forms the corresponding sawtooth wing. The long edge of each rectangle is larger than or equal to 2000 mm, and the distance between the tooth bottoms of the sawtooth wings and the linear long edges is larger than or equal to 50 mm. The linear long edges of the guard board body I and the guard board body II are fixed together. The inclined angle between the guard board body I and the guard board body II is equal to the external corner. Both the guard board body I and the guard board body II are provided with a plurality of mounting holes. The sides, facing walls, of the guard board body I and the guard board body II are further provided with a plurality of spacers I and spacers II, wherein the spacers I and the spacers II are parallel to the guard board body I and the guard board body II and attached to the corresponding walls. The spaces I and the spacers II are connected with the guard board body I and the guard board body II through elastic components. The external corner guard board is convenient to use and capable of preventing the external corner from being plastered by accident effectively, improving construction quality and lowering the construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Adjustable Serrated Wing Outside Corner Guards for Plastering Process

ActiveCN104963487BPrevent being plastered by mistakeHigh strengthBuilding constructionsEngineeringLinear distance

The invention relates to an auxiliary tool for building construction, in particular to an adjustable sawtooth wing external corner guard plate used in the plastering process, including guard plate I and guard plate II; the overall shape of guard plate I and guard plate II is rectangular, wherein One long side is linear, and the other long side is serrated to form a sawtooth wing. The long side of the rectangle is not less than 2000mm, and the distance from the tooth bottom of the sawtooth wing to the straight long side is not less than 50mm; guard plate I and guard plate The straight long sides of II are fixed together, and the included angle between guard plate I and guard plate II is the same as the male angle; both guard plate I and guard plate II are provided with several installation holes. The side of the guard plate I and the guard plate II facing the wall is also provided with a number of gaskets I and II parallel to the guard plate I and the guard II and attached to the corresponding wall, and the gasket I and the gasket II It is connected with guard plate I and guard plate II through elastic members. The invention is convenient to use, can effectively prevent the external corner from being plastered by mistake, improves the construction quality and reduces the construction cost.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

A rail type wall plastering machine

InactiveCN103821328BReduce physical laborControl verticalityBuilding constructionsOperabilityEngineering

Owner:WUHAN UNIV

Plastering method and device

ActiveCN111305514AGuaranteed flatnessGuaranteed parallelBuilding constructionsImage sensorLaser line

Embodiments of the application provide a plastering method and device, and relate to the technical field of plastering. The device comprises a laser demarcation device, a plastering panel and at leasttwo image sensors, wherein the laser demarcation device is installed on a parallel plane set at a fixed distance from a to-be-plastered wall surface, and is used for emitting laser rays parallel withthe to-be-plastered wall surface so as to form a laser ray beam surface and the laser ray beam surface serves as a reference datum for movement of the plastering panel; the plastering panel is used for performing mobile plastering on the to-be-plastered wall surface according to the reference datum; and the at least two image sensors are installed on a plane parallel with the plastering panel, and is used for photographing the laser rays, and acquiring deflection included angles between a straight line where the at least two image sensors are located and the laser rays through image data of the laser rays so as to adjust a horizontal angle of the plastering panel and / or the distance from the plastering panel to the laser ray beam surface. The problems that height difference is present between all plastered surfaces and the plastered surfaces incline and uneven due to a moving way of an existing plastering panel are solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Plastering tool for construction of outer walls of buildings

InactiveCN108547433AGuaranteed effectAvoid unevennessBuilding constructionsArchitectural engineeringBuilding construction

The invention relates to the technical field of buildings, in particular to a plastering tool for construction of outer walls of buildings. The plastering tool comprises a plastering plate, a connecting piece and a handle. The connecting piece is U-shaped and is an elastic connecting piece, one side of the connecting piece is connected to the back face of the plastering plate, the other side of the connecting piece is connected with the handle, the tail part of the handle is connected with an elastic supporting part, and the other end of the elastic supporting part is disposed on the plastering plate. The structure is simple. During use, compared with traditional plastering tools, the plastering tool has the advantages that under the action of the U-shaped connecting piece and the elasticsupporting part, the plastering tool is flexible and ductile, so that labor is saved and a flexible effect is achieved for construction workers during use, and the plastering quality and efficiency are improved. At the same time, first arc-shaped faces which are symmetric and second arc-shaped faces which are symmetric are arranged at the bottom edge of the plastering plate. According to the structural design, the smooth arc-shaped faces can avoid uneven plastering caused by imprints of plaster due to pausing in the plastering process, and the overall effect of plastering is ensured.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com