Plastering device of building wall

A wall and building technology, applied in the direction of architecture and building structure, can solve problems affecting flatness, unbalanced force, and weak support, so as to improve the quality and efficiency of plastering, balance force, and avoid vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

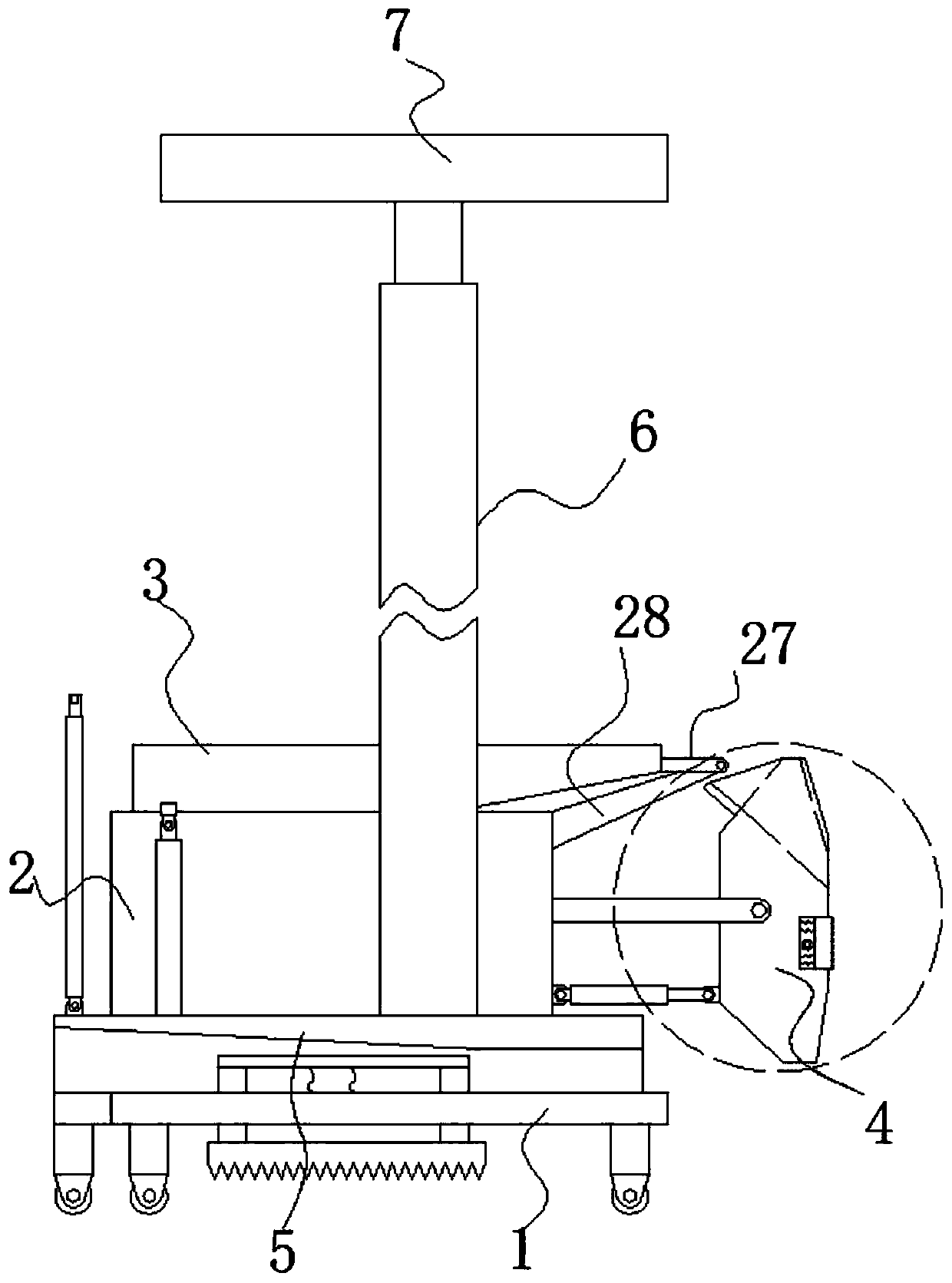

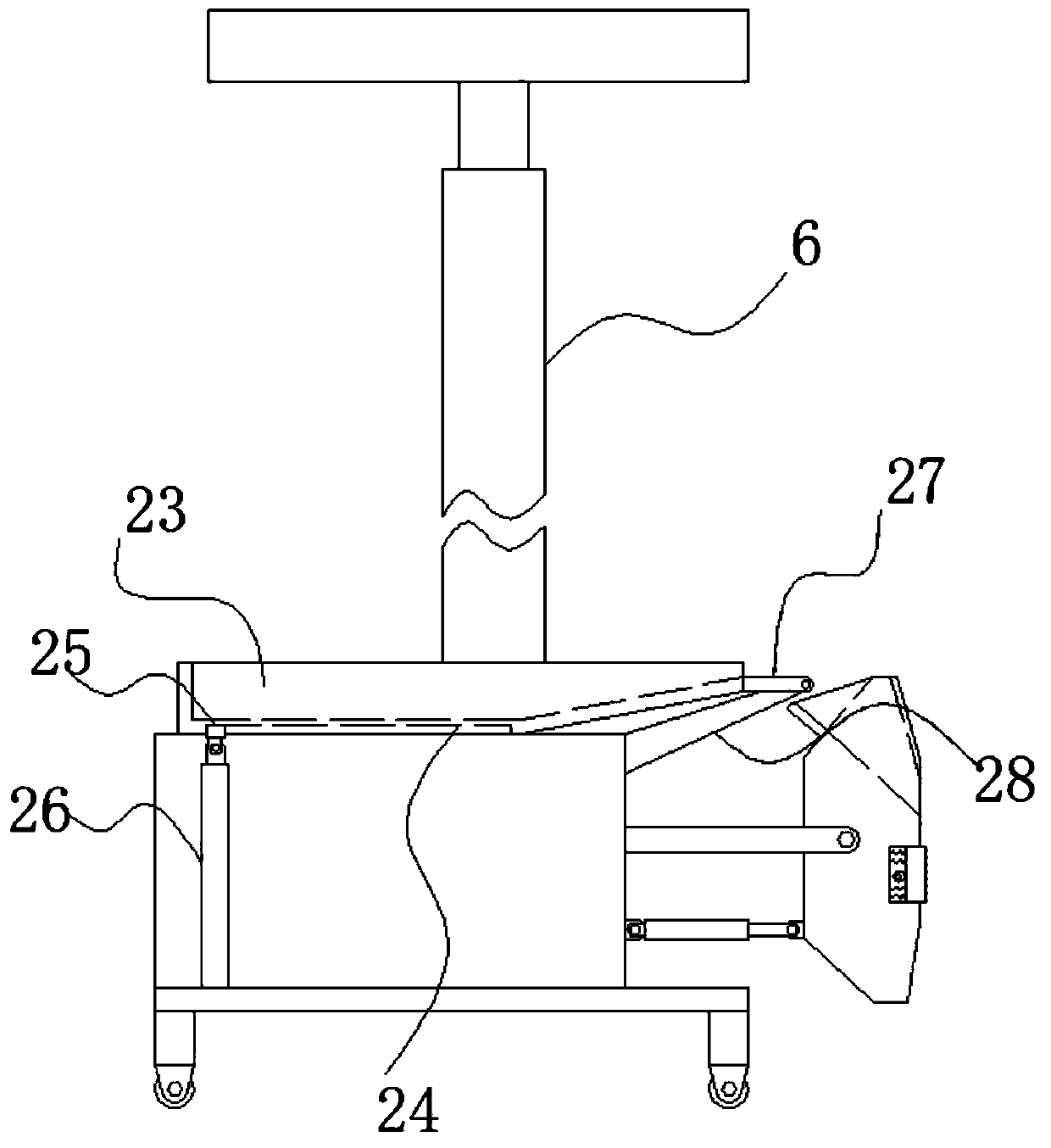

[0035] The feeding assembly 3 includes a hopper 23 located at the top of the box body 8 , one end of the hopper 23 close to the plastering assembly 4 is fixedly connected with an extension plate 27 , and the two sides of the end of the extension plate 27 away from the hopper 23 are rotatably connected with the box body 8 . The support bar 28, the bottom of the hopper 23 is provided with a chute 24 arranged along its length direction, the inside of the chute 24 is slidably connected with a slider 25, and the bottom of the slider 25 is hinged with a fourth drive mechanism fixedly connected to the top of the bottom plate 1 (26).

Embodiment 2

[0037] The plastering assembly 4 includes two sets of columns 29 fixedly connected to the box body 8 along the horizontal direction, and a plastering board 30 is movably socketed between the two groups of uprights 29, and the plastering board 30 is located at the side of the upright column 29 away from the box body 8. At one end, both ends of the plastering board 30 away from the box body 8 are provided with inclined plastering slopes 36, and two groups of plastering slopes 36 are arranged symmetrically along the plastering board 30, and the plastering board 30 is far away from the box body One side of 8 is provided with the feeding channel 31 on the plastering slope 36 of the upper end of the plastering board 30, and the opening of the upper side of the feeding channel 31 away from the casing 8 is equipped with a plastering joint with the upper end of the plastering board 30. Slope surface 36 flat scraping plate 32, feeding channel 31 near the opening on the side of the box bo...

Embodiment 3

[0039] The extruding mechanism 35 includes an extruding plate 38 slidingly sleeved with the installation groove 34, and the two ends of the side of the extruding plate 38 close to the box body 8 are equipped with a baffle plate 39 slidingly connected to the adjacent side of the plastering board 30, two groups One side of the baffle plate 39 close to each other is provided with a channel 40 arranged along its length direction, and one end of the extrusion plate 38 extending into the installation groove 34 is installed with a rotating rod parallel to it through the bearing seat, and the outer ring of the rotating rod is fixedly sleeved. There is a disk, the outer ring of the disk is fixedly connected with arc-shaped protrusions distributed in an array along the axis direction, and the protrusions are in conflict with the extrusion plate 38, and the two ends of the rotating rod are fixedly sleeved with slaves located inside the channel 40. The outer ring of the driven sprocket is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com