Intelligent wall plastering robot

A robot and intelligent technology, which is applied in the direction of construction and building construction, can solve the problems of uneven plaster thickness on the wall, loose joints of column guide rods, and incomplete parallelism of column guide rods, etc., so as to achieve high work efficiency, The effect of high plastering quality and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

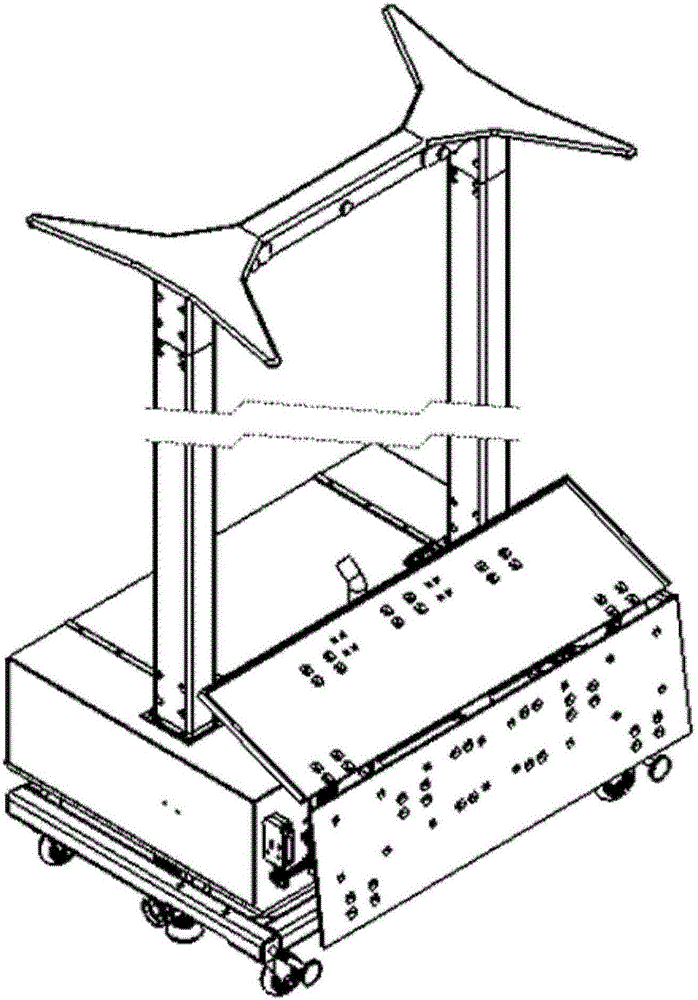

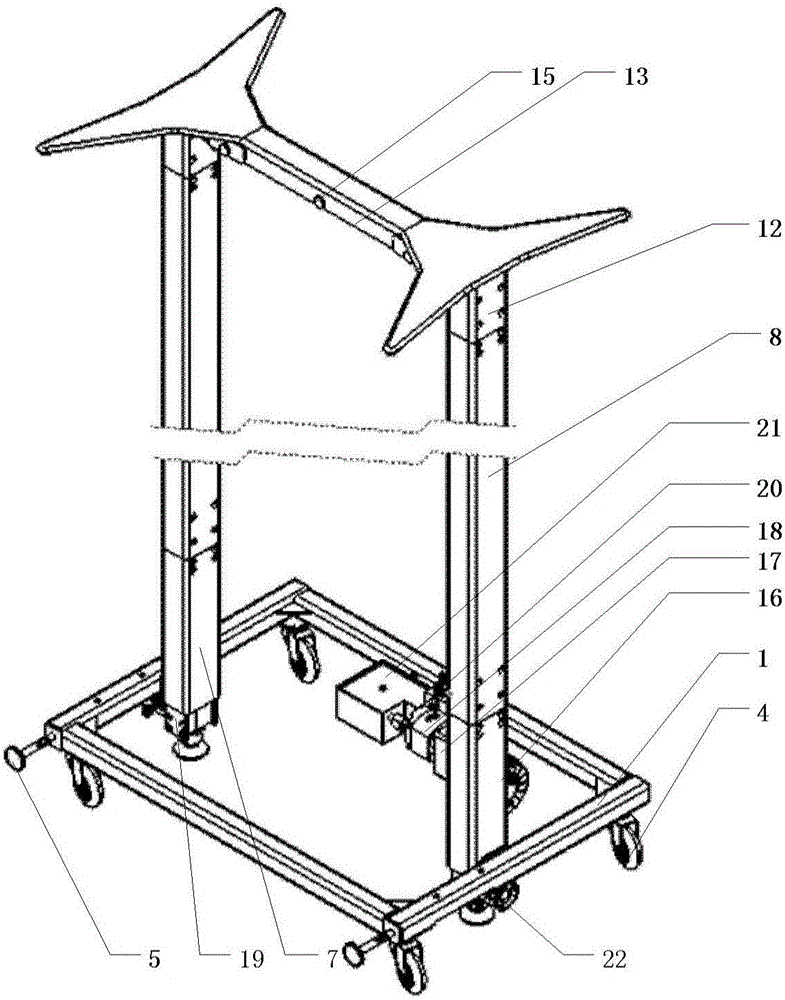

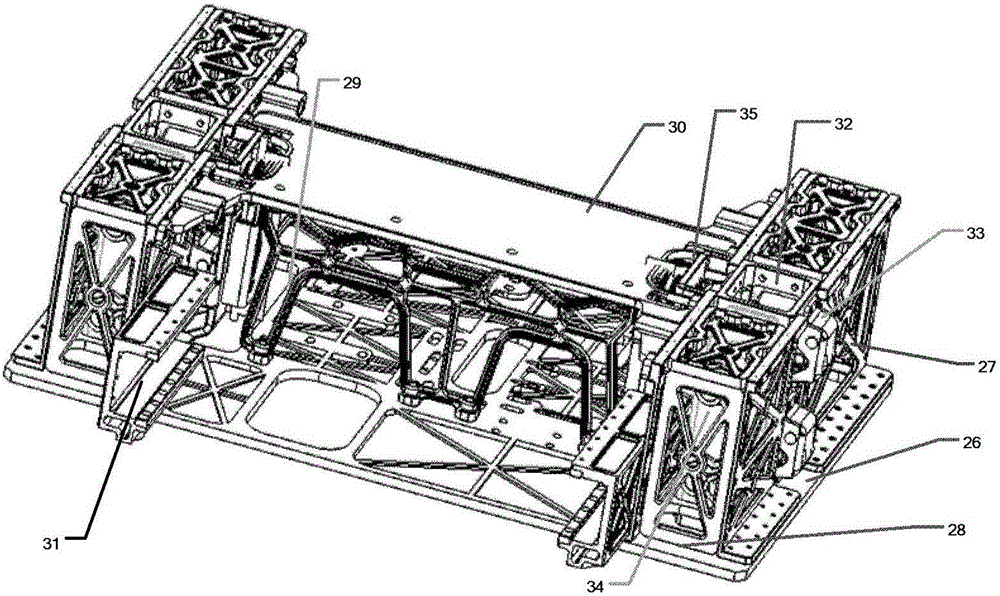

[0027] Such as Figure 1 to 9 As shown, the intelligent wall plastering robot in an embodiment of the present invention includes a base column jack device, a hydraulic system, a lifting frame device, a lifting device, a forward and backward moving device, a rotating device, and a flipping device. The above devices are controlled by the controller For control, preferably, the controller is an ARM controller arranged in a control box on the lifting frame.

[0028] The base column jacking device includes a base 1, a column guide rod, and a top support frame. The base 1 includes a quadrangular frame composed of four strip structures, front, rear, left, and right, and four universal wheels 4 are provided at the lower ends of the four corners. There is a distance adjustment rod 5 inside the top of the same side of the two-shaped structure on the left and right of the base. The length of the distance adjustment rod 5 can be selected according to actual work needs. The rod extends from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com