Plastering tool for construction of outer walls of buildings

A technology of building exterior walls and tools, which is applied in the direction of architecture and building construction, can solve the problems of rigid, inflexible, and labor-saving connection methods, and achieve the effects of simple structure, guaranteed overall effect, and improved plastering quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

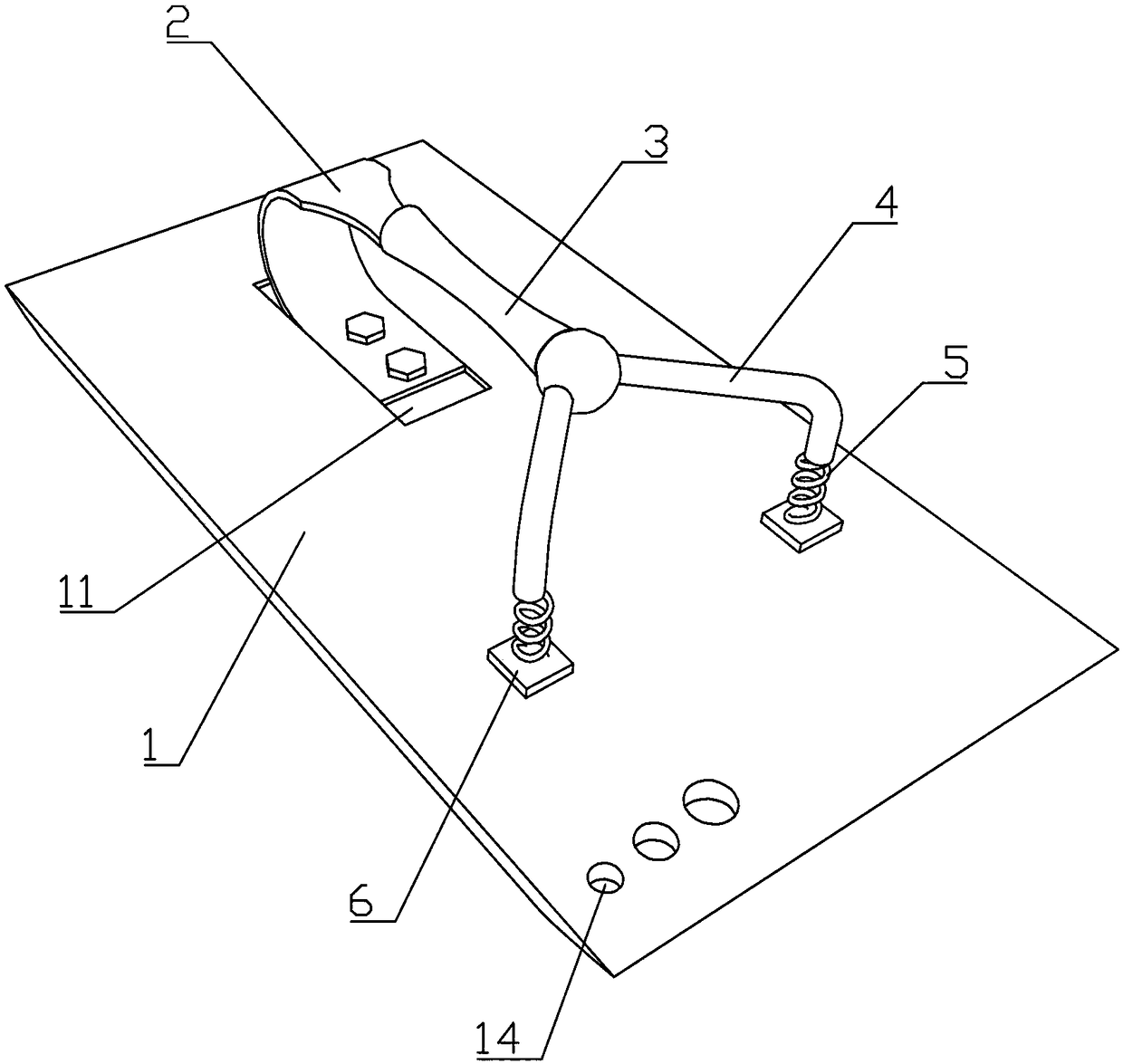

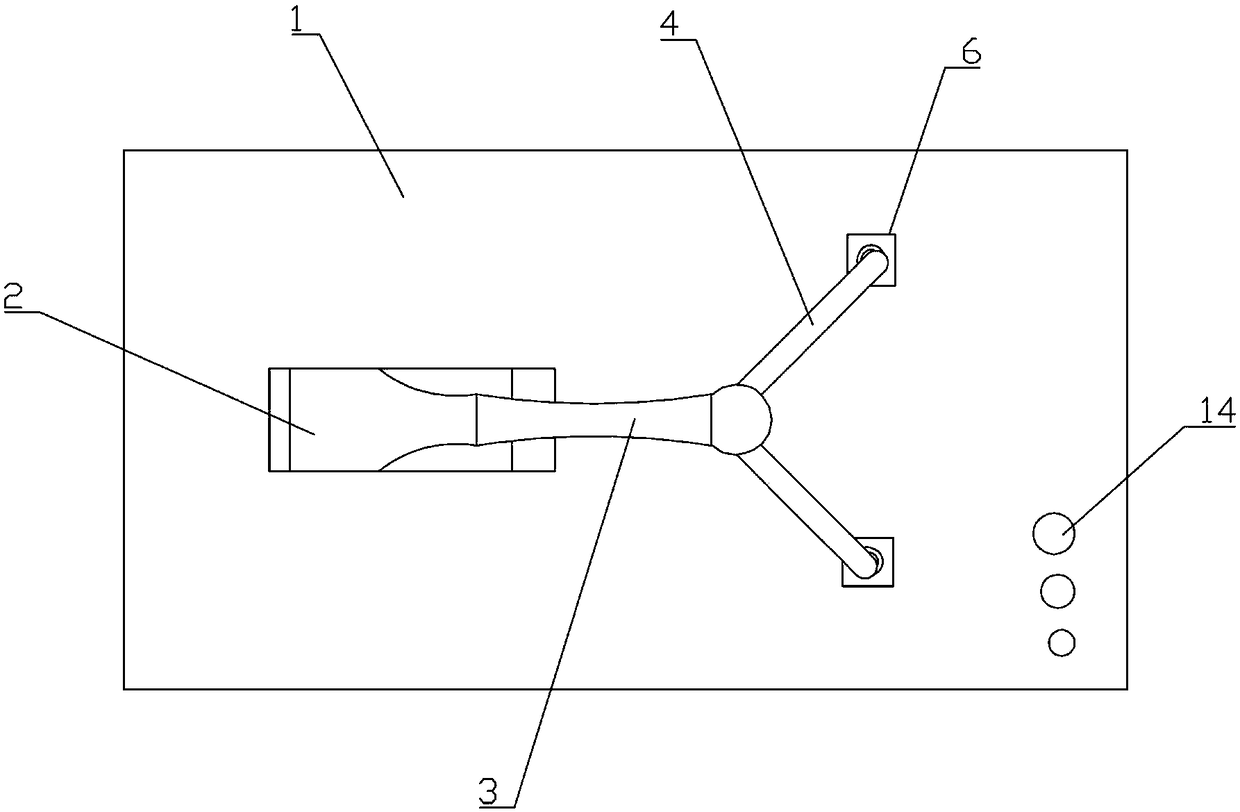

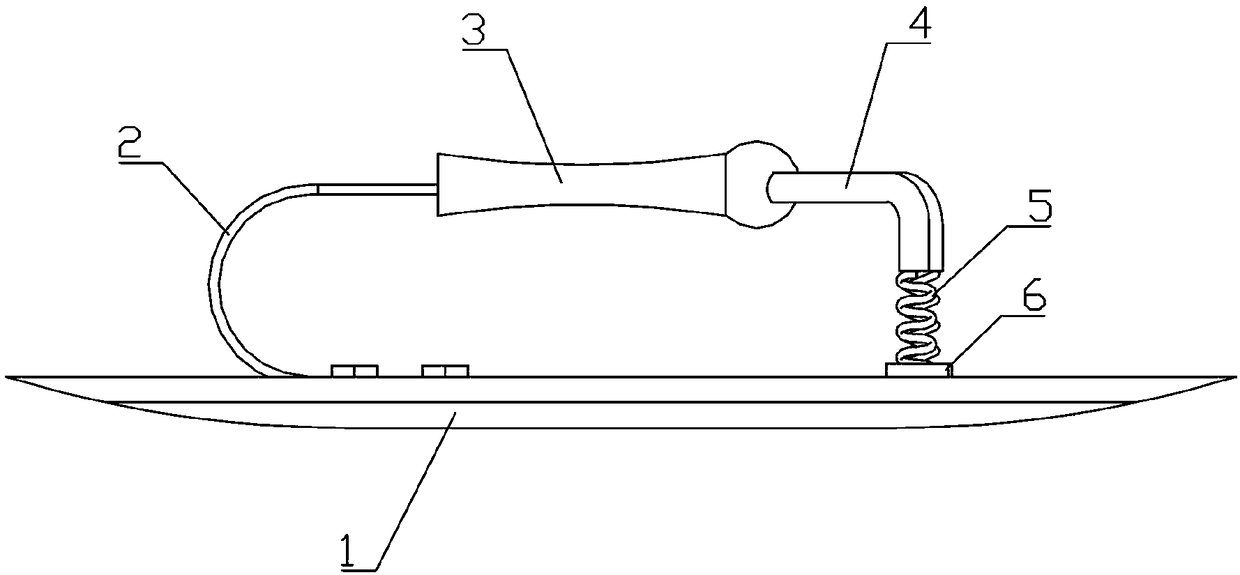

[0028] refer to figure 1 , figure 2 , image 3 with Figure 4 , a plastering tool for building exterior wall construction, including a plastering board 1, a connector 2 and a handle 3, a groove 11 is provided on the back of the plastering board 1, and there are different grooves along the long side direction of the groove 11 in the groove 11. Penetrating threaded holes, connecting piece 2 is provided with a through hole, and a hexagonal screw matched with the through hole, the wiper 1 and connecting piece 2 are connected through the threaded hole, through hole and hexagonal screw, and the connecting piece 2 is U-shaped , and is an elastic connector, one side of the connector 2 is connected to the groove 11 on the back of the wiper 1, so that the connector 2 is clamped in the groove 11, and fixed with threaded holes, through holes and hex screws, so that The connecting piece 2 does not move left and right (limited by the groove 11), nor can it move up and down during the pr...

Embodiment 2

[0034] On the basis of Embodiment 1, in this embodiment, a spacer 6 is provided between the spring 5 and the wiping board 1, the spacer 6 is fixedly bonded to the wiping board 1, the spring 5 is fixedly welded to the spacer 6, and the elastic There are two groups of branches, and they are arranged at 120° with the handle 3 . Here, the setting of the spacer 6 helps the spring 5 to transmit the force to the wiping board 1, so that the wiping board 1 is evenly stressed, and the spring 5 will not deviate from the orientation; The mutual angle of 120° further ensures that the force on the rear end of the wiper plate 1 is more uniform, making construction workers more convenient and quick to use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com