External corner guard board with adjustable sawtooth wings and used for plastering process

An adjustable and sawtooth technology, applied in the direction of construction and building structure, can solve the problems of insufficient sand and ash strength in the outer corner, insufficient understanding of construction requirements, and inconsistent sand and ash ratio, so as to save resource waste and improve construction. The effect of quality, plastering quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments.

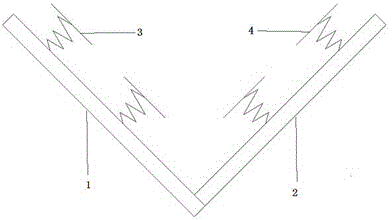

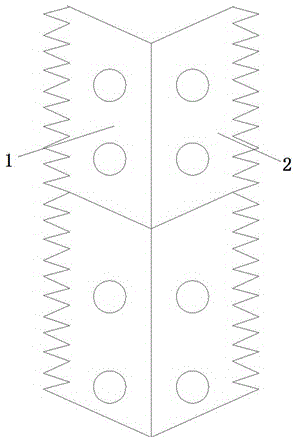

[0022] Such as figure 1 As shown, the adjustable sawtooth wing external corner guard plate used in the plastering process is characterized in that it includes guard plate I1 and guard plate II2; the overall shape of the guard plate I1 and guard plate II2 is rectangular, and one of the long sides It is linear, and the other long side is serrated to form a sawtooth wing. The long side of the rectangle is not less than 2000mm, and the distance from the tooth bottom of the sawtooth wing to the straight long side is not less than 50mm. The tooth height is designed according to different construction sites; The linear long sides of the guard plate I1 and the guard plate II2 are fixed together, and the angle between the guard plate I1 and the guard plate II2 is the same as the external corner of the building; the guard plate I1 and the guard plate II2 are both Several i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com