Plastering method and device

A plastering surface and corresponding position technology, which is applied in the direction of architecture and building structure, can solve the problems of plastering surface inclination, height difference, unevenness, and achieve the effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

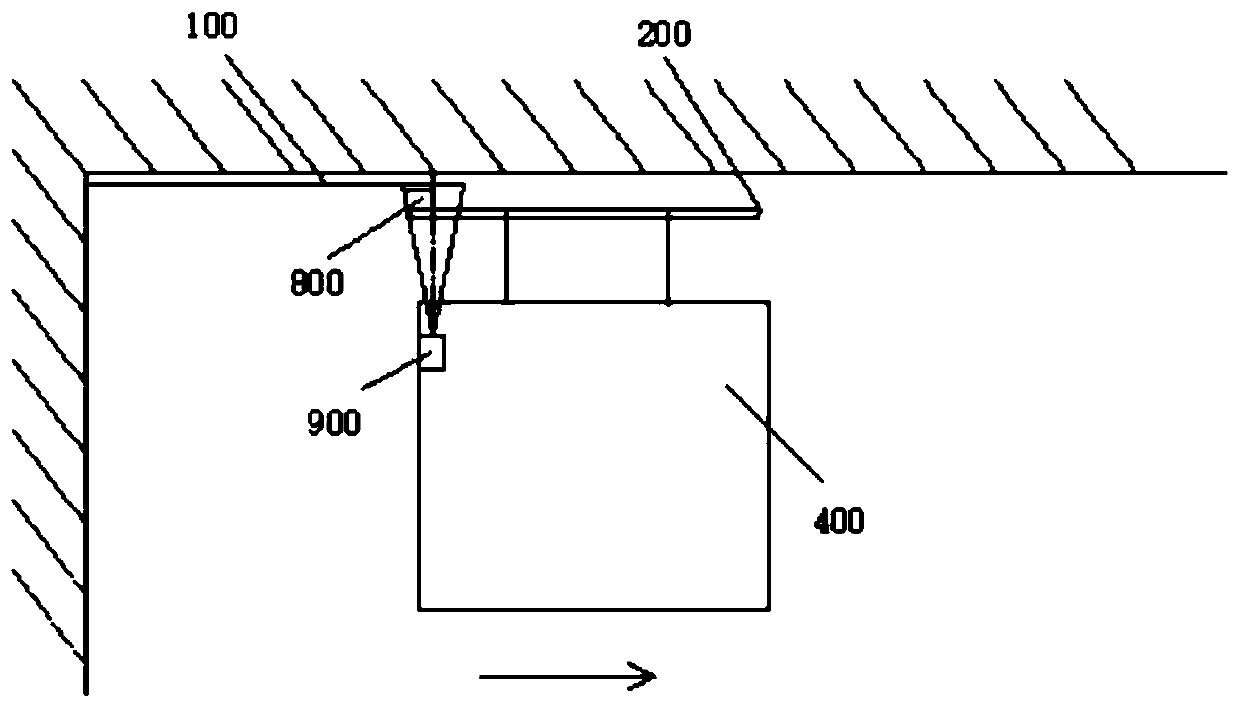

[0059] The embodiment of the present application also provides a plastering method, such as Figure 4 Shown is the flow chart of the plastering method. Applied to the plastering device described in embodiment 1, the method may specifically include the following steps:

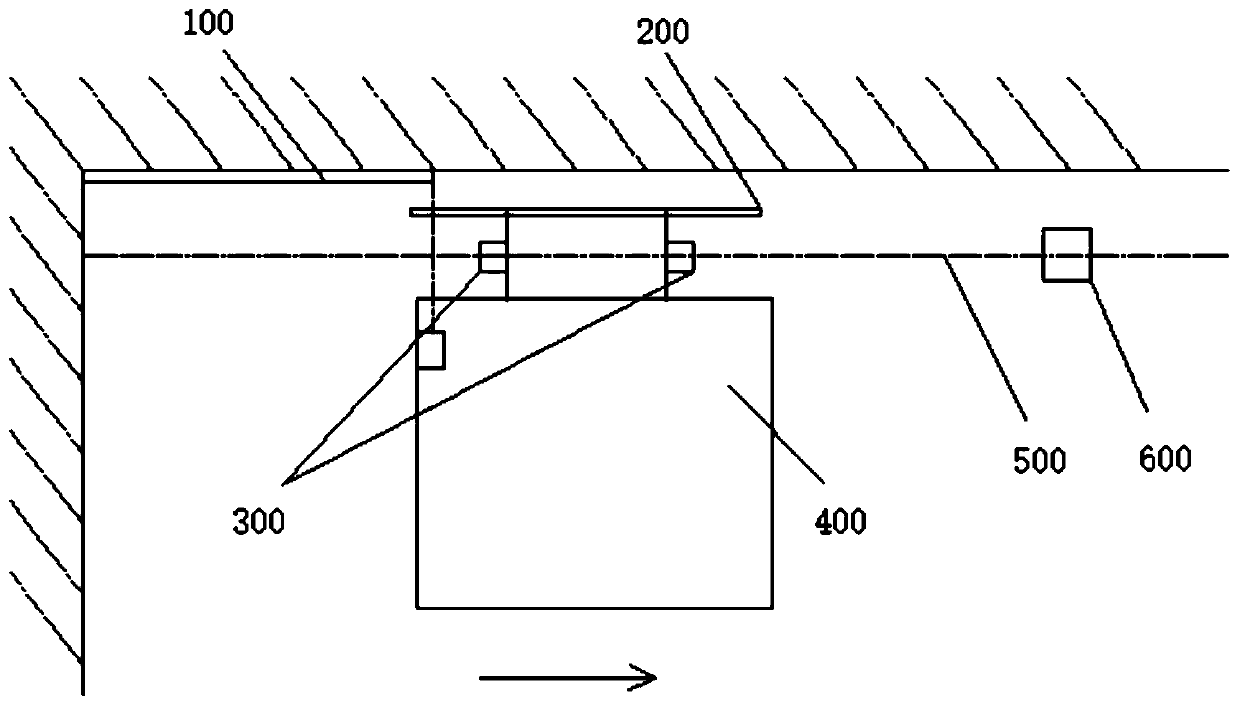

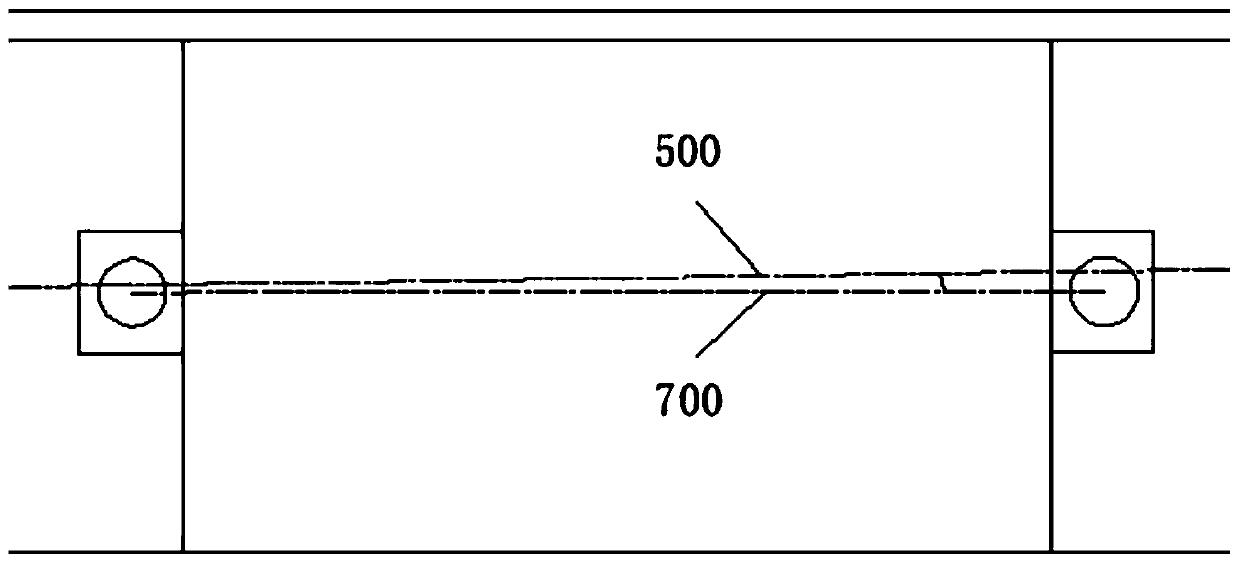

[0060] S100: Use the laser line projector 600 to emit laser lines 500 to the vertical wall surface of the plastered wall and form the laser line 500 into a laser beam surface, the laser beam surface is set at a fixed distance from the plastered wall surface, as A reference datum for the movement of the plastered panel 200;

[0061] S200: Use the plastering panel 200 to move and plaster the plastered wall surface according to the reference standard.

[0062] In the above implementation process, the laser line 500 emitted by the laser line projector 600 constitutes the laser line beam surface. Since the laser line beam surface is parallel to the plastered wall and the distance is fixed, the laser line beam surf...

Embodiment 3

[0073] The embodiment of the present application also provides an electronic device, the electronic device includes a memory and a processor, the memory is used to store a computer program, and the processor runs the computer program so that the computer device executes the method described in Embodiment 1. The plastering method described in any one.

[0074] The embodiment of the present application also provides a readable storage medium, where computer program instructions are stored in the readable storage medium, and when the computer program instructions are read and executed by a processor, any one of the steps described in Embodiment 1 is executed. The plastering method described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com