Method for improving plastering quality of wall corners

A corner and quality technology, applied in the direction of architecture, building construction, etc., can solve the problems of increasing time cost, easy to damage the painted surface, low efficiency, etc., to achieve the effect of increasing time cost and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

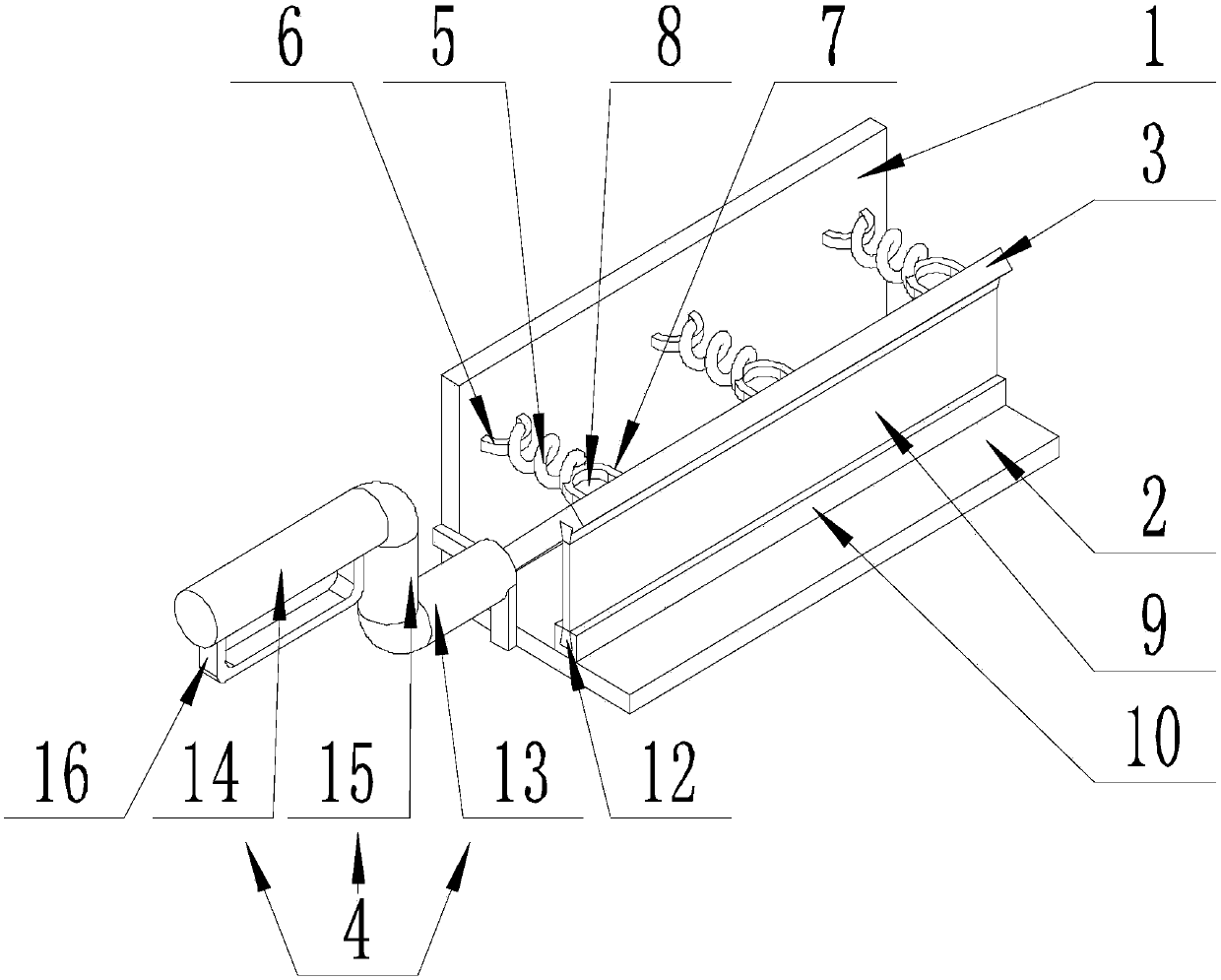

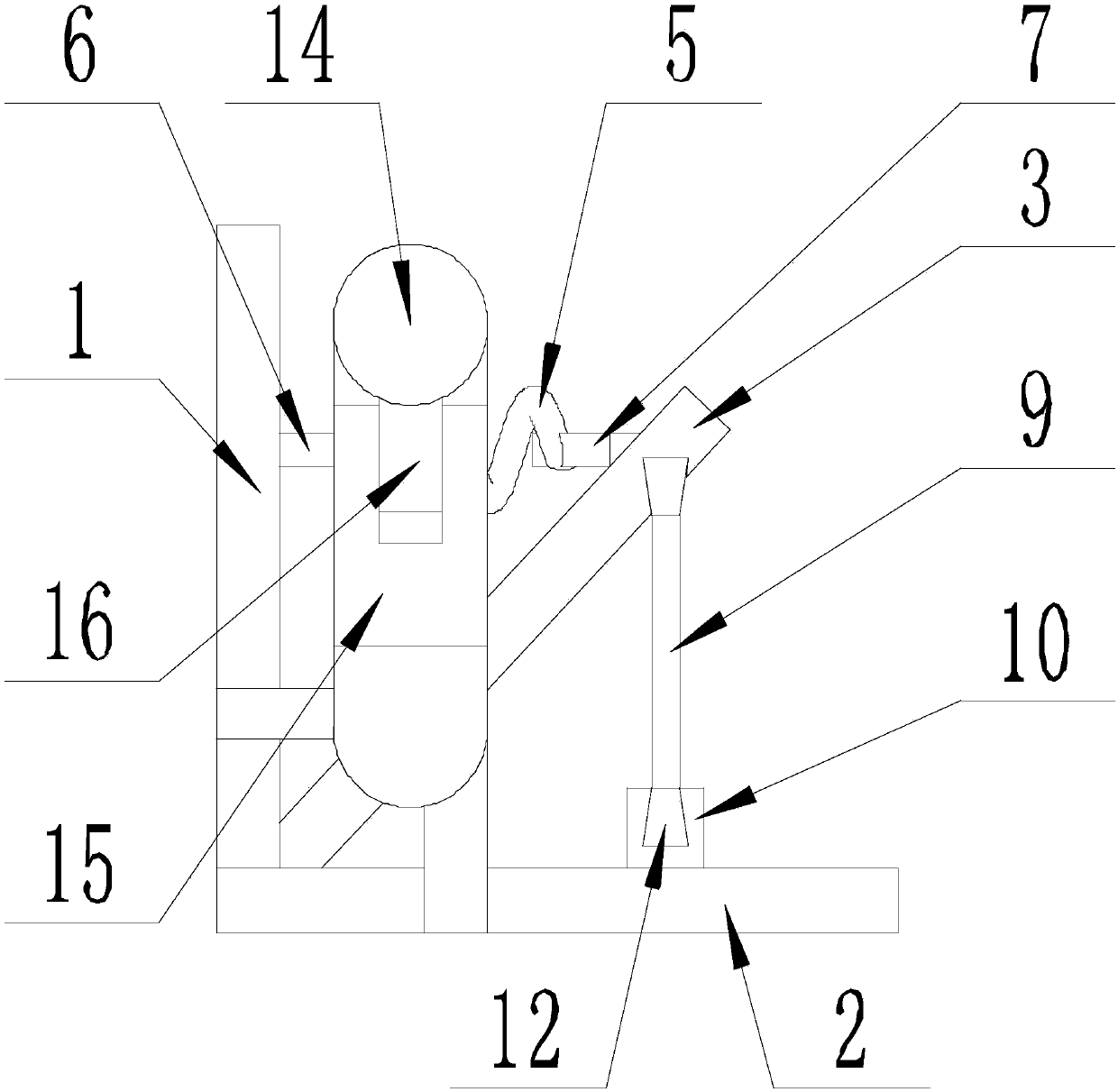

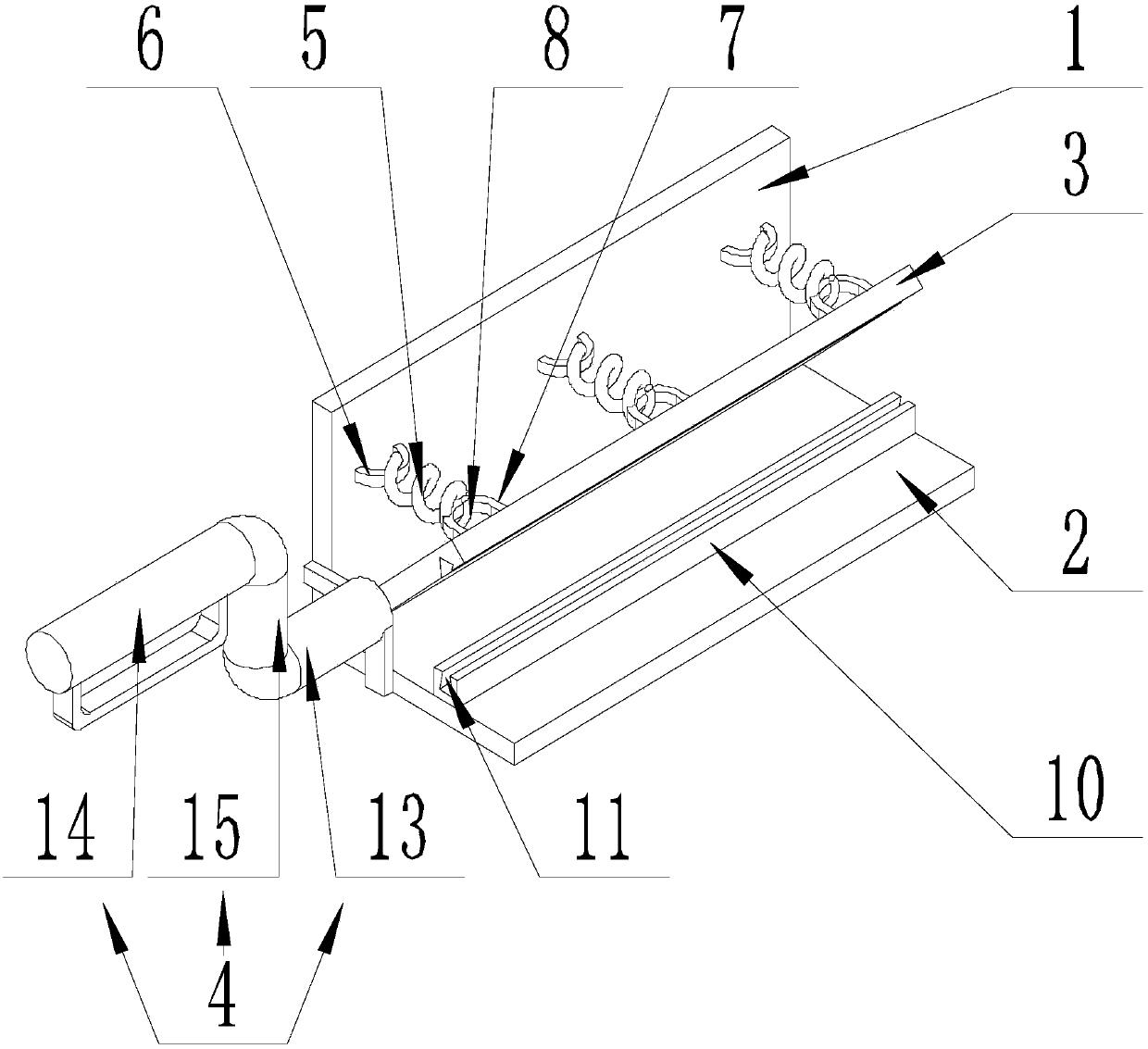

[0044] Such as Figure 1-Figure 5 As shown, the present invention improves the method for wall corner plastering quality, comprises the steps:

[0045] Step A installation: match the connecting block 12 at one end of the limiting plate 9 with the mounting groove 11 on the support plate 3, and match the connecting block 12 at the other end of the limiting plate 9 with the mounting groove 11 on the wiping plate II2;

[0046] Step B Adjustment: Hang the round hook at one end of the adjustment spring 5 in the connection hole 8 of the lug I6 on the wiping plate I1, and hang the round hook at the other end of the adjustment spring 5 on the lug II7 on the support plate 3 in the connecting hole 8;

[0047] Step C smearing: hold the handle 4 and carry out the plastering operation on the wall.

[0048] When smearing the joint between the wall and the ceiling, hold the handle 4 to make the wiper board I1 contact with the wall, and the wiper II2 contact with the ceiling to smear the wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com