Automatic heating plastering trowel

An automatic heating and plastering technology, which is applied in the fields of construction, building structure, and building materials processing, can solve the problems of poor comfort, easy to freeze hands, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

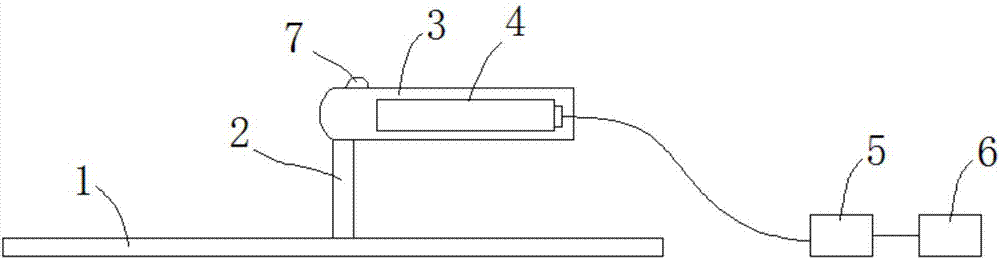

[0017] Such as figure 1 As shown, an automatic heating plasterboard includes a board body 1, a bracket 2 and a handle 3, the bracket 2 is vertically fixed in the middle of the board body 1, and the handle 3 is placed above the board body 1 , and parallel to the plate body 1, one end of the handle 3 is fixedly connected to the bracket 2; a heater 4 is embedded in the handle 3, and the energized end of the heater 4 is at the position where the handle 3 is away from the bracket 2; the energized end of the heater 4 is connected to a temperature relay 5 through a line, and the temperature relay 5 is connected to a power supply 6 through a line.

[0018] In the construction work in winter, when the temperature drops to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com