Automatic spraying positioning bracket

A positioning bracket and automatic spraying technology, which is applied in the direction of construction and building construction, can solve the problem that it is difficult to ensure the accuracy of the thickness of the sprayed surface and the uniformity of the mortar, it is difficult to maintain the distance and angle between the spray gun and the working surface stably, and it is impossible to guarantee The rules and order of the spray gun moving track can achieve the effect of shortening the construction period, ensuring the quality of plastering and reducing the amount of waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

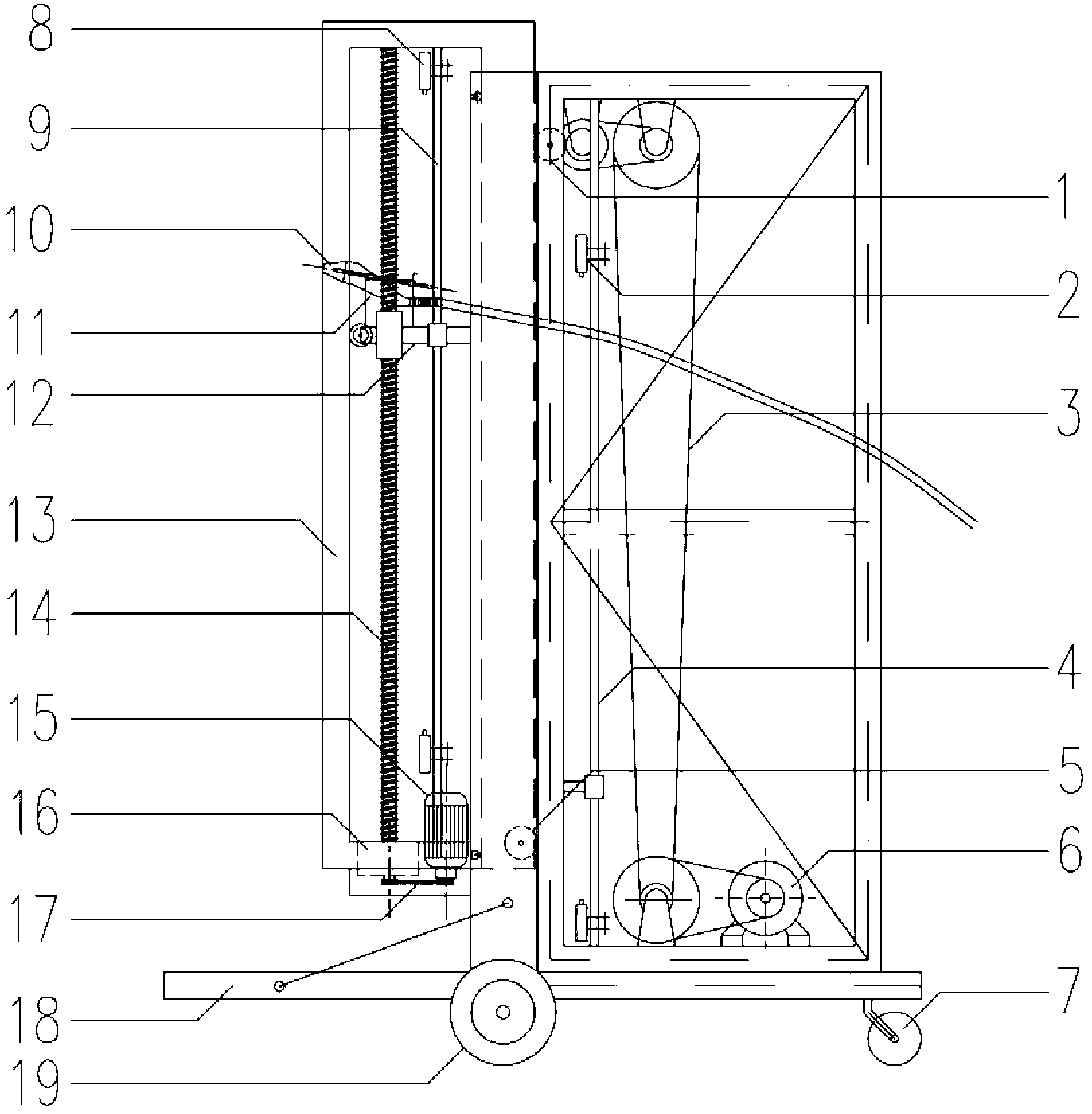

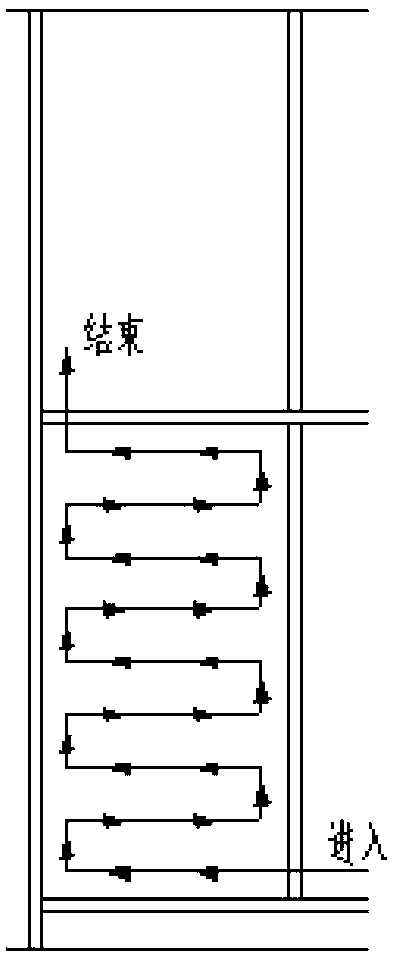

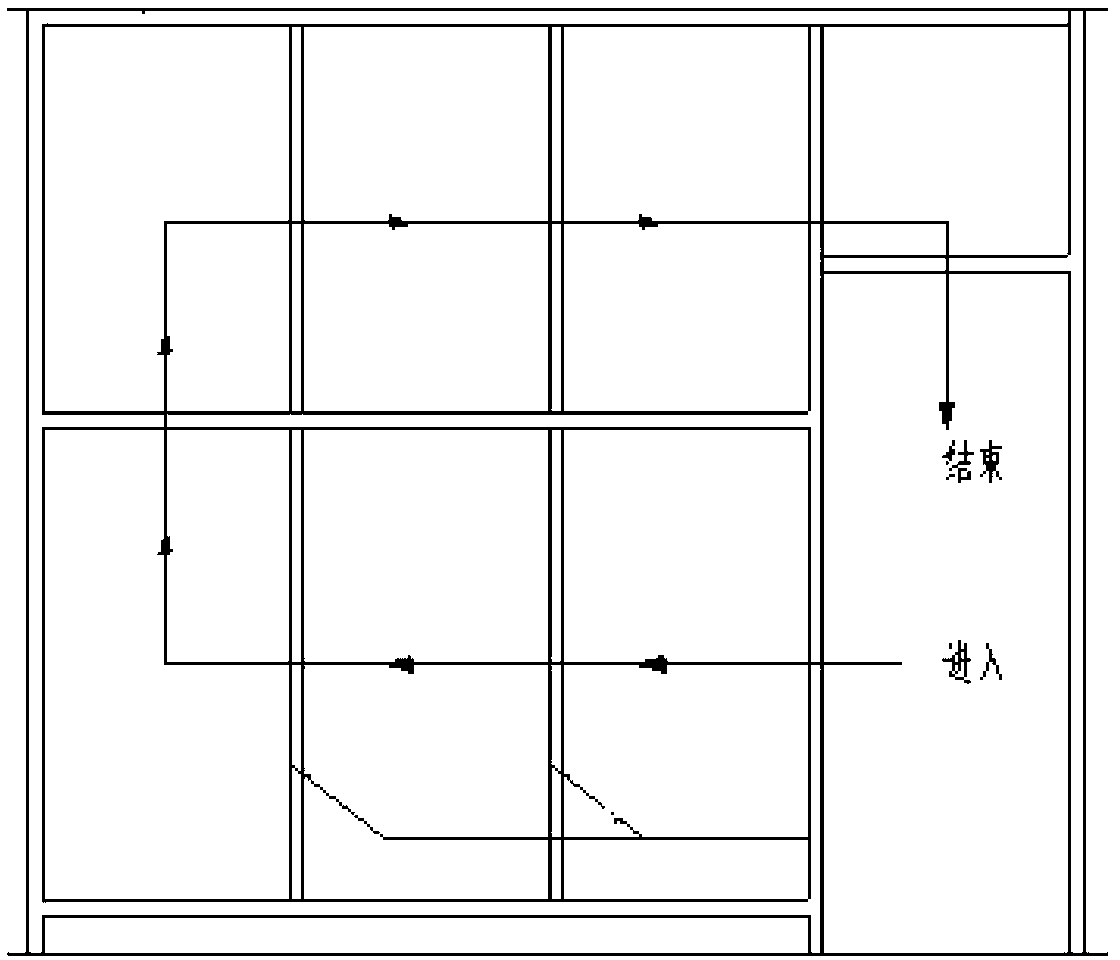

[0031] The structure of the automatic spraying positioning bracket of the present invention will be described with reference to the accompanying drawings.

[0032] The automatic spraying positioning bracket of the present invention includes a lifting gear 1, a first limit switch 2, a transmission belt 3, a first guide rod 4, a positioning wheel 5, a first motor 6, a flexible foot 7, The second limit switch 8, the second guide rod 9, the nozzle 10, the nozzle fixing car 11, the horizontal spraying track control frame 12, the horizontal reciprocating spraying positioning frame 13, the lead screw 14, the second motor 15, the gear box 16, the transmission Belt 17, floor ash recovery tray 18, adjustable direction walking wheel 19;

[0033] Removable feet 7 are installed at the lower rear end of the floor ash recovery tray 18, and adjustable direction walking wheels 19 are installed at both ends of the lower part of the floor ash recovery tray 18. The first guide rod 4 is vertically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com