Interior wall plastering construction method based on wall plastering machine

A construction method and technology of plastering machine, applied in the direction of construction, building structure, etc., can solve the problems of reducing construction quality, easily affecting the progress of the project, increasing construction costs, etc., to improve the quality and efficiency of plastering, reduce labor costs and The effect of material waste and prevention of falling off and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

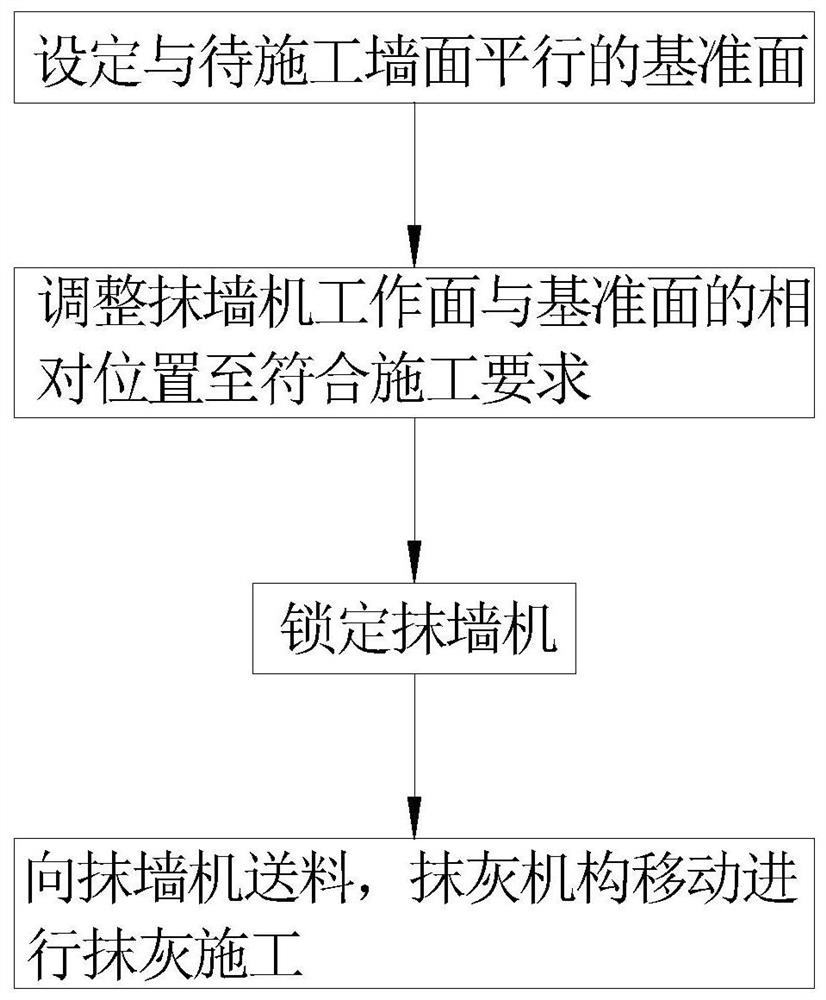

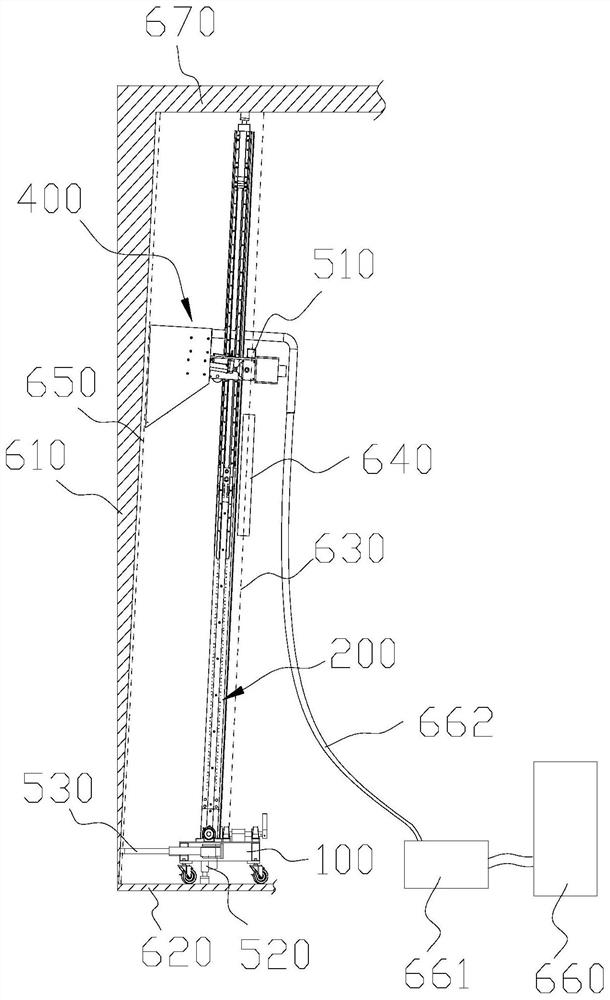

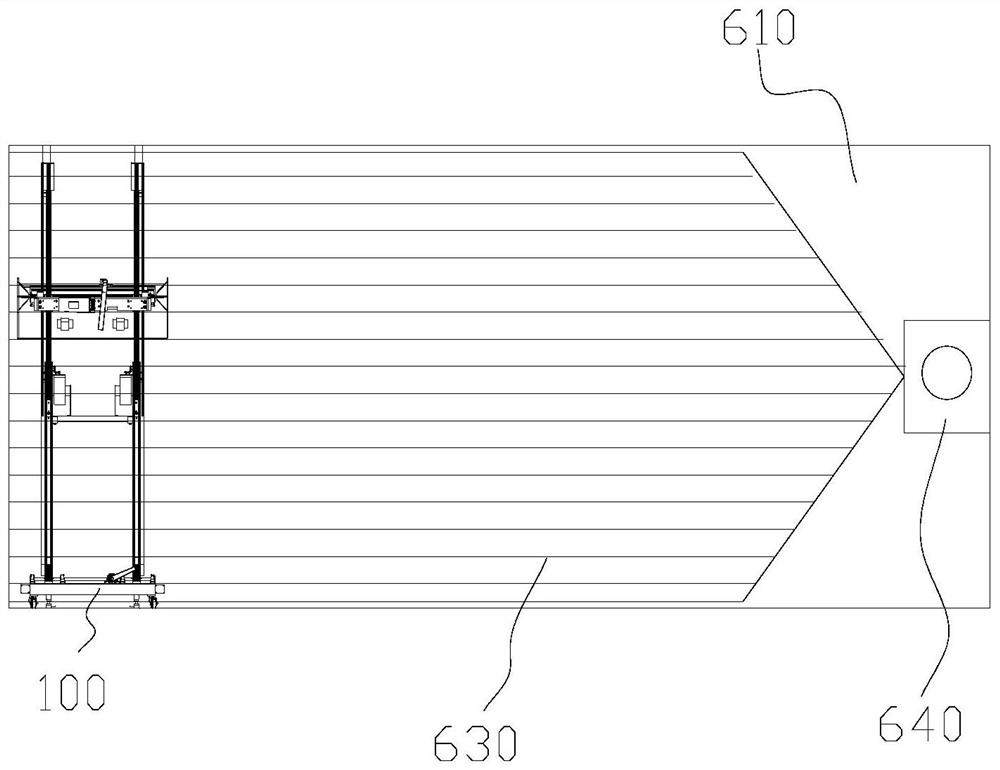

[0038] refer to Figure 1 to Figure 16 The shown interior wall plastering construction method based on the wall plastering machine mainly includes the following steps. In the first step, a surface light source 640 is used to generate a reference plane parallel to the wall surface to be constructed outside the wall surface 610 to be constructed. 630; in the second step, bring the wall plastering machine close to the wall surface 610 to be constructed, and adjust the distance between the wall plastering machine and the wall surface 610 to be constructed, so that the working surface 650 of the wall plastering machine is parallel to the reference surface 630, and the working surface 650 is parallel to the wall surface to be constructed. The vertical distance between the construction walls 610 meets the thickness design of the plastering construction; the third st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com