Method for testing color difference of natural mineral pigment in cooperation with colloidal water and polydimethylsiloxane

A technology of polydimethylsiloxane and dimethylsiloxane, which is applied in the field of color difference testing of natural mineral pigments, can solve the problems of low color fastness, uneven particle size distribution, uneven dispersion of pigments, etc. The effect of reducing the number of oxygen groups, avoiding shedding and cracking, and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

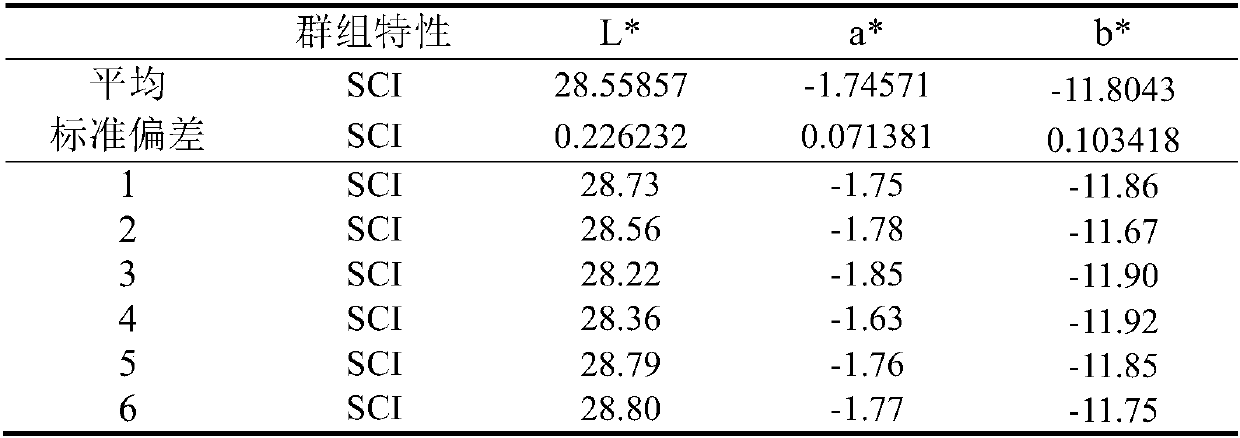

Embodiment 1

[0034] 1) To ensure that the mineral pigment is dry and free of impurities, use a mechanical powder machine to crush the large turquoise particles into powder, and the crushing time is 1-1.1min;

[0035] 2) Process the turquoise pigment powder obtained in step 1) for 10 minutes using a standard vibrating sieve machine, and use standard sieves with mesh numbers of 70 and 160 to screen out mineral pigment powders with a particle size of 100-200 nm;

[0036] 3) Mix polydimethylsiloxane main agent (agent A) and polydimethylsiloxane curing agent (B agent) uniformly, the mass ratio is B:A=1:19.5, weigh the polydimethylsiloxane Put 0.7g of silicone-based mixed solution on a biological surface dish with a diameter of 6cm, and use a spin coater to perform spin coating treatment, and set the instrument parameters: the rotation time is 330s, the rotation speed is 200r / min, and the rotation acceleration is 100m / min 2 ;

[0037] 4) Put the polydimethylsiloxane mixture spin-coated in step ...

Embodiment 2

[0044] 1) To ensure that the mineral pigment is dry and free of impurities, use a mechanical pulverizer to crush the large particles of lapis lazuli natural mineral pigment into powder, and the crushing time is 1.1min;

[0045] 2) using a standard vibrating sieve machine to process the lapis lazuli pigment powder obtained in step 1) for 12 minutes, and using a standard sieve with a mesh number of 70 and 160 to screen out a mineral pigment powder with a particle size of 100-200nm;

[0046] 3) Mix polydimethylsiloxane main agent (agent A) and polydimethylsiloxane curing agent (B agent) uniformly, the mass ratio is B:A=1:20.5, weigh the polydimethylsiloxane Put 1 g of base siloxane mixed solution on a biological surface dish with a diameter of 6 cm, and use a spin coater to perform spin coating treatment, and set the instrument parameters: the spin time is 360s, the spin speed is 220r / min, and the spin acceleration is 120m / min 2 ;

[0047] 4) Put the polydimethylsiloxane mixture s...

Embodiment 3

[0054] 1) To ensure that the mineral pigment is dry and free of impurities, use a mechanical pulverizer to crush large particles of malachite natural mineral pigment into powder, and the crushing time is 1.05min;

[0055] 2) using a standard vibrating sieve machine to process the malachite pigment powder obtained in step 1) for 11 minutes, and using a standard sieve with a mesh number of 70 and 160 to screen out a mineral pigment powder with a particle size of 100-200 nm;

[0056] 3) Mix polydimethylsiloxane main agent (agent A) and polydimethylsiloxane curing agent (B agent) uniformly, the mass ratio is B:A=1:20, weigh polydimethylsiloxane Put 0.85g of base siloxane mixed solution on a biological surface dish with a diameter of 6cm, and use a spin coater to perform spin coating treatment, and set the instrument parameters: the spin time is 350s, the spin speed is 210r / min, and the spin acceleration is 110m / min 2 ;

[0057] 4) Put the polydimethylsiloxane mixture spin-coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com