Patents

Literature

128results about How to "Meet the hardness requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled-release carbon source material for repairing polluted underground water organisms and preparation method thereof

ActiveCN102491497AGuaranteed uptimeNutritionally stableBiological water/sewage treatmentMicroorganismNutrition

The invention discloses a controlled-release carbon source material for repairing polluted underground water organisms and a preparation method thereof and belongs to the field of underground water repairing. The controlled-release carbon source material comprises a core and a shell wrapping the core, wherein the core comprises the following components in percentage by weight: 40 to 86 percent ofcarbon releasing raw material, 1 to 25 percent of nutritional raw material, 5 to 45 percent of plastic bonding raw material, 5 to 20 percent of high-permeability raw material and the balance of water; the shell comprises the following components in percentage by weight: 10 to 40 percent of carbon releasing raw material, 1 to 10 percent of nutritional raw material, 20 to 80 percent of plastic bonding raw material, 0 to 40 percent of high-permeability raw material and the balance of water; and the controlled-release carbon source material is prepared by a compound formula consisting of the carbon releasing raw materials, nutritional elements and multi-component inorganic combined raw materials. The controlled-release carbon source material meets a microbial nutrition demand and requirementsfor long-time stable material supply during underground water repairing, certain mechanism strength and uniform sphericity; furthermore, the defects of high carbon loss, uncontrollable releasing rateand the like in the conventional carbon source compensation method are overcome; and the continuity of the underground water organism repairing effect is realized.

Owner:HOHAI UNIV +1

Laser cladding repair process for cross shafts

InactiveCN102828181AImprove wettabilityImprove wear resistanceMetallic material coating processesOptoelectronicsHardness

The invention relates to a laser cladding repair process for cross shafts. The process comprises the following steps of: A. carrying out treatment on the surface of the cross shaft, and carrying out failure analysis; B. carrying out 80-150 DEG C overall preheating on the cross shaft; C. according to failure analysis results of the cross shaft, optimizing process parameters, and carrying out laser cladding, wherein adopted alloy powder comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 5-15% of TiO2, and the balance of Fe; and D. carrying out detection. According to the laser cladding repair process for the cross shafts, disclosed by the invention, through carrying out the laser cladding on the surface of the cross shaft, the size of the cross shaft can meet the application requirements, and the hardness and the wear resistance of the cross shaft subjected to repair exceed the original hardness and the original wear resistance of the cross shaft.

Owner:DANYANG HONGTU LASER TECH

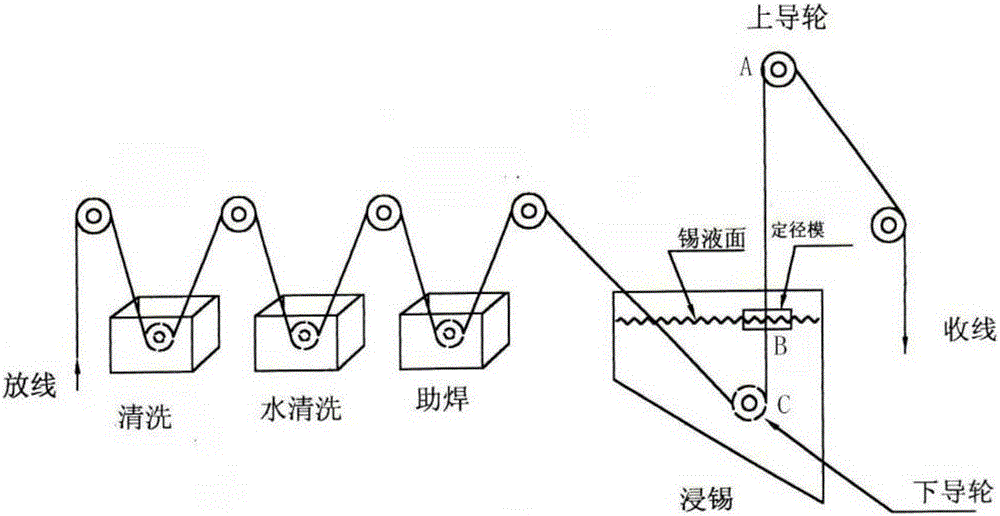

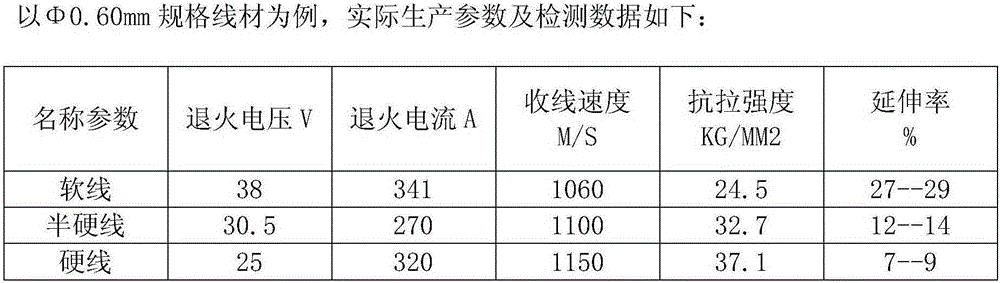

Hard and semi-hard tin-coated copper wire manufacturing method

InactiveCN105304221AEasy plugging and rivetingHas hardnessHot-dipping/immersion processesCable/conductor manufactureCopper wireVoltage

The invention provides a hard and semi-hard tin-coated copper wire manufacturing method. The method comprises the following steps: heavy-duty drawing: using a copper drawing stock for electrical purposes to make a bare copper wire; medium drawing: sending the qualified bare copper wire to a wire release support, enabling the bare copper wire to be stretched through hole mold drawing, preparing a copper wire with a required wire diameter, conducting annealing softening on the copper wire through a certain annealing voltage, and enabling the copper wire to be a circular soft copper wire with a required external diameter; and tinning: detecting the qualified copper wire and sending the copper wire to a wire feed support, cleaning oil stains, oxides and impurities on the surface of the wire by a cleaning agent, sending the cleaned copper wire to a tinning pan for tinning, scraping superfluous tin off the tinned wire through a specification hole mold, ensuring that a surface coating on the copper wire is smooth and even, cleaning the surface of the tin-coated copper wire after cooling, and making a finished product with a required specification by reeling the wire. The beneficial effects of the method are that tin-coated copper wires manufactured by the method exhibit certain hardness, meet the hardness requirement for some special industries, and are convenient to plug, unplug and rivet.

Owner:天津市宏远电子有限公司

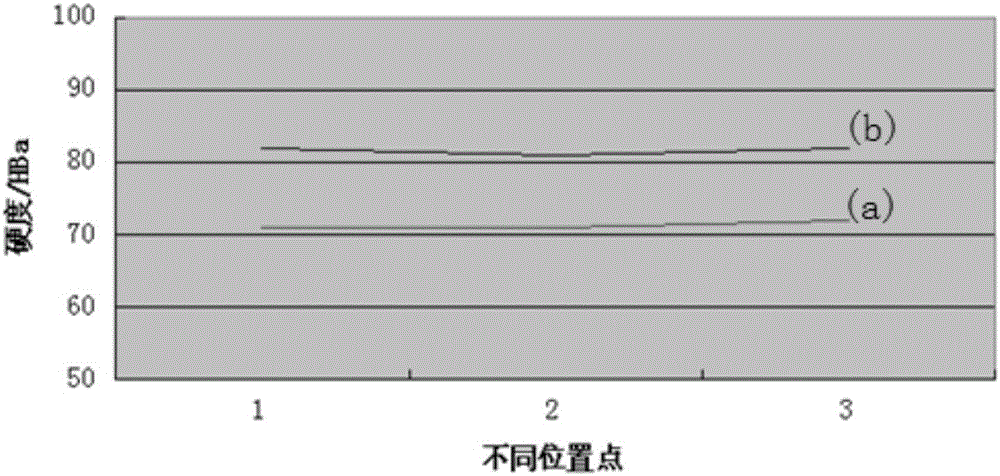

Prehardening treatment method of NAK80 mould steel

ActiveCN1718771AThe pre-hardening treatment process is simple and reasonableEasy to operateFurnace typesHeat treatment furnacesQuenchingForging

A method for prehardening the die steel NAK80 includes such steps as thermal forging with 860-920 deg.C for final temp and 15-20% for final deformation, quenching by directly putting the forged die steel at 900 deg.C in conventional quenching liquid to cool its temp to 200 deg.C, and tempering steps including heating it to 490-560 deg.C at the speed of 80-100 deg.C / h in the tempering furnace, holding the temp for 2-6 hr, and cooling in air. Its advantages are low cost and short period.

Owner:宝武特种冶金有限公司

Titanium alloy for manufacturing tool and preparation method thereof

The invention discloses a titanium alloy for manufacturing a tool and a preparation method thereof. The titanium alloy for manufacturing a tool consists of the following components in percentage by weight: 76.6 percent of Ti, 3 percent of Al, 4 percent of V, 5 percent of Cr, 2 percent of Fe, 7 percent of Mo, 1 percent of W, 1 percent of Zr, 0.2 percent of O and 0.2 percent of Si. The preparation method of the titanium alloy comprises the following steps of: I, mixing; II, manufacturing an electrode; III, smelting in a vacuum furnace for three times; IV, cogging; and V, rolling. The titanium alloy has the beneficial effects that the HRC (Rockwell Hardness) value of the tool produced by using the titanium alloy disclosed by the invention is over 55, and the titanium alloy is light and non-magnetic, is low in production cost, and has a wide market prospect; and the production benefit of an enterprise can be increased greatly.

Owner:陈国财

Belt pulley powder metallurgy formulation and process

ActiveCN104759614ANot easily deformedReduce use noiseTurbinesOther manufacturing equipments/toolsPowder metallurgyNickel

The invention discloses a belt pulley powder metallurgy formulation. The belt pulley powder metallurgy formulation is composed of the following ingredients (mass percentage): 0.3-0.7% of graphite, 1.5-2.5% of copper powder, 0.6-1.0% of zinc stearate, 0.1-0.3% of sulphur, 0.3-1.5% of nickel powder, 0.3-1.0% of molybdenum powder, and the rest is iron powder; the invention further discloses a process for preparing the belt pulley powder metallurgy formulation. The process comprises the following steps of mixing materials, pressing, sintering, cooling, shaping, removing oil, blasting sands, and blackening. In the formulation and the method, the formulation is reasonable, the belt pulley is proper in hardness, the process is simplified, the production efficiency is high and the production cost is low.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

On-line control method of banded structure and hardness of gear steel and post-rolling on-line controlled cooling bed device

InactiveCN103589843AInhibition formationReduce manufacturing costHeat treatment process controlCooling bedsGear wheelEngineering

The invention discloses an on-line control method of a banded structure and hardness of gear steel. The method comprises the steps: controlling the finishing temperature of a gear steel rod at 900-980 DEG C, controlling the cooling speed of the gear steel rod in a three-stage cooling manner after rolling: air-cooling the high temperature gear steel rod after the rolling, reducing the surface temperature of the rod to 800-830 DEG C, and controlling the difference between the core temperature and the surface temperature of the rod to be within 150 DEG C, performing forced air cooling on the precooled rod, controlling the surface temperature of the rod, air-cooling to 620-680 DEG C, keeping the rod after the forced cooling warm, slowly cooling, and stopping cooling for 15-50min. The invention further discloses a post-rolling on-line controlled cooling bed device. A cooling bed system of the device is formed by combining three stepped cooling beds, namely a precooling bed, an air cooling bed and a slow cooling bed. The method can control the banded structure within a second stage, the structural homogeneity of the gear steel rod is improved, and the hardness requirements during blanking of the gear steel rod are met.

Owner:SHANGHAI UNIV

Gear laser cladding repair process beneficial to improve hardness and wear resistance

ActiveCN103668176AGood self-fluxingIncrease contentMetallic material coating processesGear wheelAlloy

The invention relates to a gear laser repair process which comprises the following steps: A. treating the surface of a gear, and performing failure analysis on the gear; B, integrally preheating the gear at 80-120 DEG C, and locally preheating the to-be-repaired part of the gear at 180-220 DEG C at the same time; C, optimizing process parameters according to the failure analysis result of gear, performing layer-by-layer laser cladding, wherein the thickness of each cladding layer is less than or equal to 0.4 mm, the edge of the next cladding layer is extended outwards from the edge of the previous cladding layer by 4-6mm, and the used alloy powder comprises the following components in percentage by weight: no more than 0.5% of C, 38-52% of Cr, 1.5-2.5% of B, 0.5-1.5% of Si and the balance of Fe; and D, detecting. According to the gear laser repair process, the surface of the gear is subjected to laser cladding, so that the size meets the use requirements, and the hardness and wear resistance of the repaired gear exceed the original properties.

Owner:XINJIANG HUIXIANG LASER TECH

Laser repairing technology for aluminum foil roll crack

InactiveCN102677047AImprove tissue uniformityAvoid it happening againMetallic material coating processesLaser beam welding apparatusAlcladOptoelectronics

The invention relates to a laser repairing technology for an aluminum foil roll crack. The laser repairing technology for the aluminum foil roll crack comprises the following steps: A, cleaning up a roll; B, preheating the roll at a low temperature; C, optimizing technical parameters, and performing laser cladding on polished and cleaned pits on the roll, wherein in the process, the roll is vibrated, the temperature of the roll is kept to be 180-250 DEG C until the pits are filled, a cladding layer is higher than the roll surface, and used alloy powder comprises the following components by weight percent: 10-15% of Cr, 1-2% of B, 0.5-1.5% of Si and Fe in balancing amount; and D. detecting. The laser repairing technology for the aluminum foil roll crack can perform laser cladding on the roll crack and can effectively fill a very deep crack to making the deep crack meet a using requirement; the structural uniformity of the cladding layer is good; and the fusion rate of the cladding layer and a matrix is high.

Owner:DANYANG HONGTU LASER TECH

Large-diameter valve sealing ring surfacing method

The invention relates to a large-diameter valve sealing ring surfacing method. A transition layer is added between a valve sealing face and a hard alloy layer, the transition layer selects an ER310 welding wire, and hard alloy selects Co-Cr-Mo-Si-rare earth alloy powder. During surfacing the transition layer and the hard alloy layer, welding parameters and heat treatment temperature are reasonablyselected. Thus, the welding deformation is reduced, the hardness of a surfacing layer is improved, and the cracking phenomenon occurring during directly surfacing the hard alloy layer on the valve sealing face is avoided.

Owner:HEBEI UNIV OF TECH +1

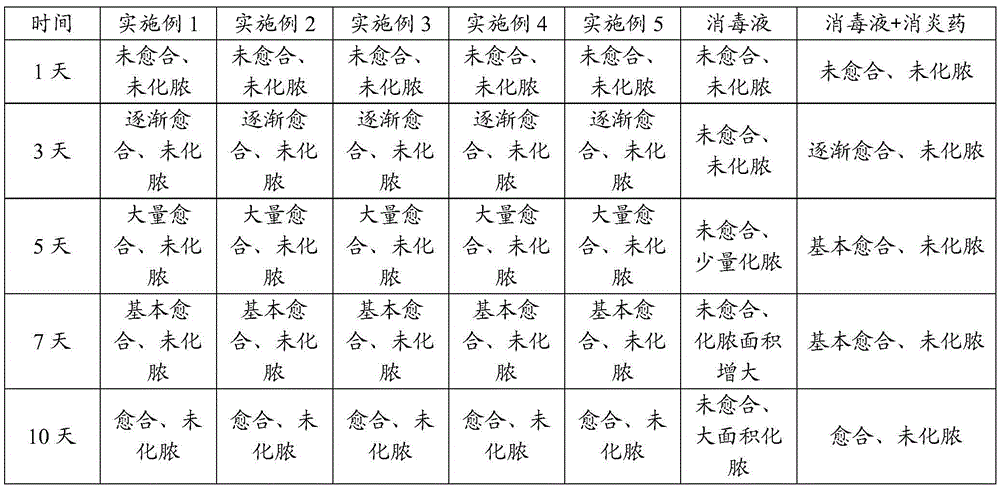

Povidone iodine effervescent tablets with anti-microbial, skin-care and anti-inflammation functions and production process of povidone iodine effervescent tablets

InactiveCN105640916ASolve the shortcomings of strong irritationSimplify using stimuliAntisepticsPill deliveryPolyethylene oxideIrritation

The invention relates to povidone iodine effervescent tablets with anti-microbial, skin-care and anti-inflammation functions and a production process of the povidone iodine effervescent tablets. The effervescent tablets comprise 10%-15% of povidone iodine, 51%-80% of an effervescent disintegrating agent, 1%-5.5% of a tablet disintegrating agent, 1.3%-5% of a compound polymer synergist, 0.01%-0.1% of zinc oxide, 0.05%-0.5% of dextrin, 0.5%-5% of polyethylene oxide, 0.1%-5% of a lubricant and the balance of filler. According to the effervescent tablets, a medicine integrating anti-microbial, anti-inflammation and skin-care functions and having complete functions is developed by carefully studying the function mechanism of medicines after multiple experiments, the anti-inflammation function is realized in the disinfection process, and the medicine administration step is simplified in the medical process. Besides, pain of a patient in the medicine use process is relieved, and detection shows that the irritation of the effervescent tablets in the formula is extremely small and is much lower than that of like products. The preparation process is simple and convenient to operate, the equipment is simple, and the product is convenient to use, transport and carry and suitable for industrial large-scale popularization and use.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

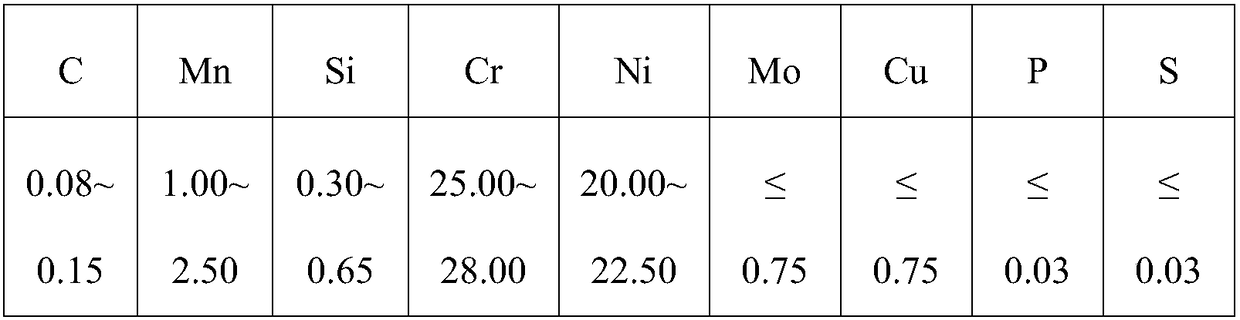

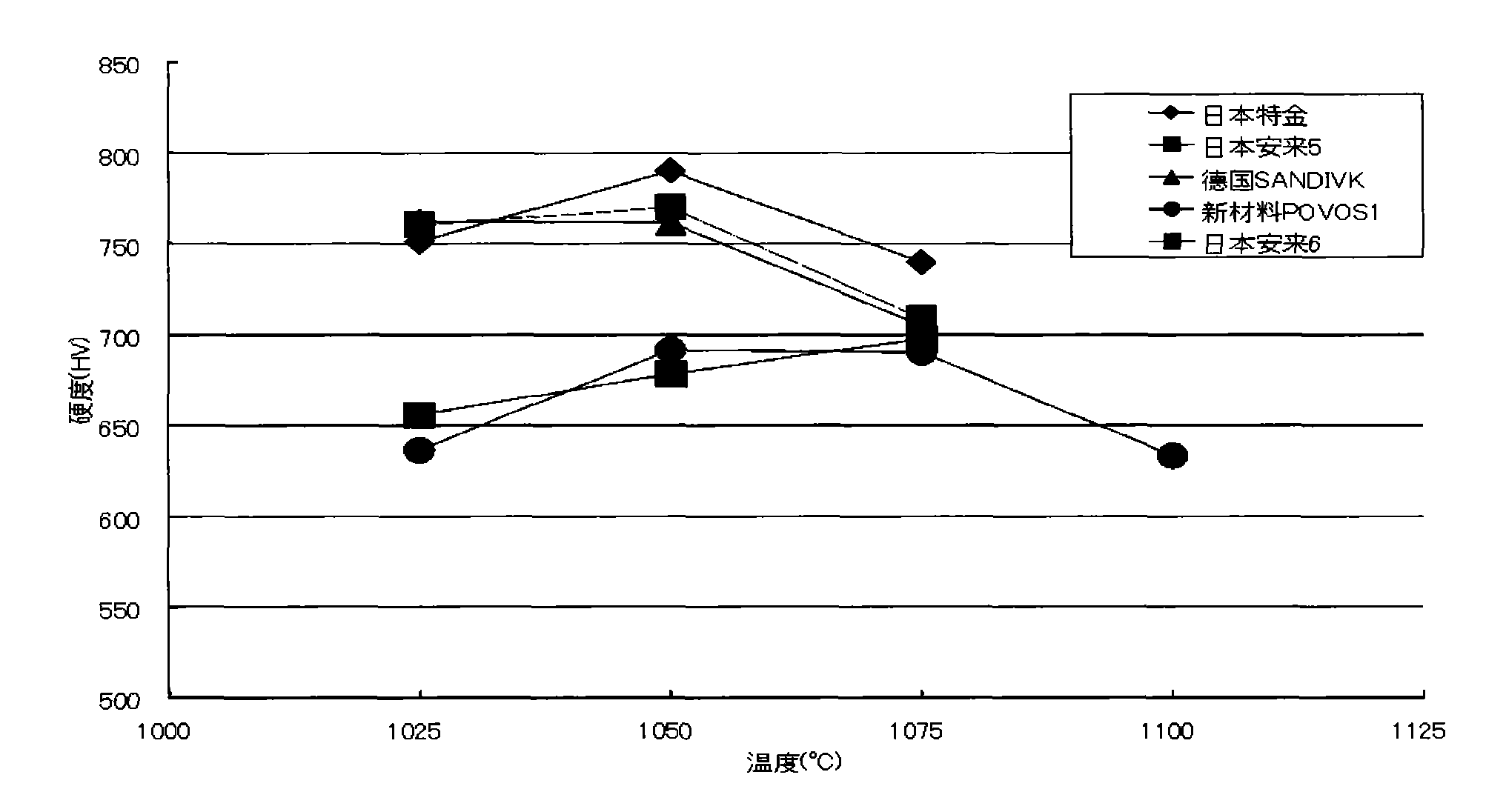

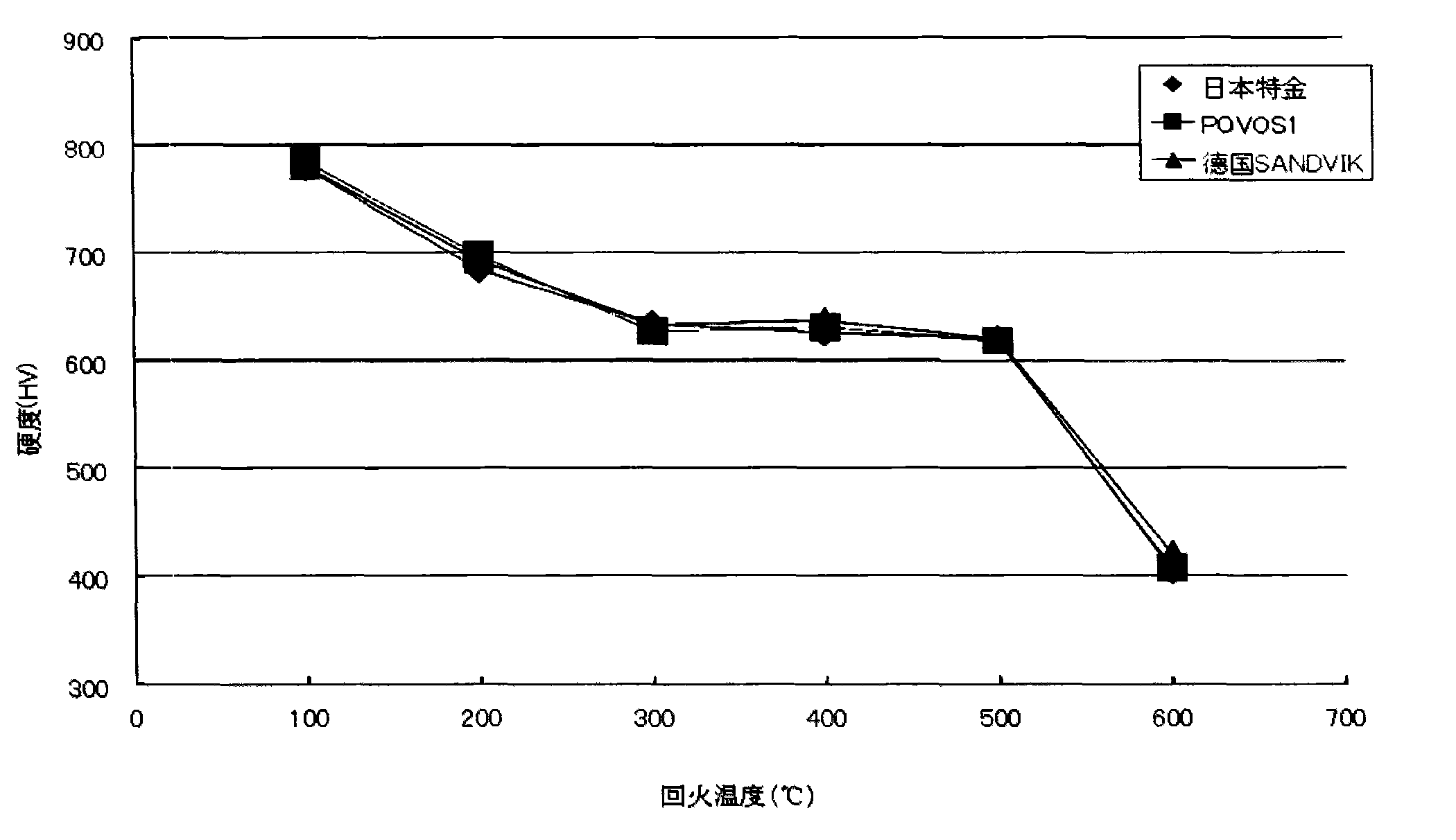

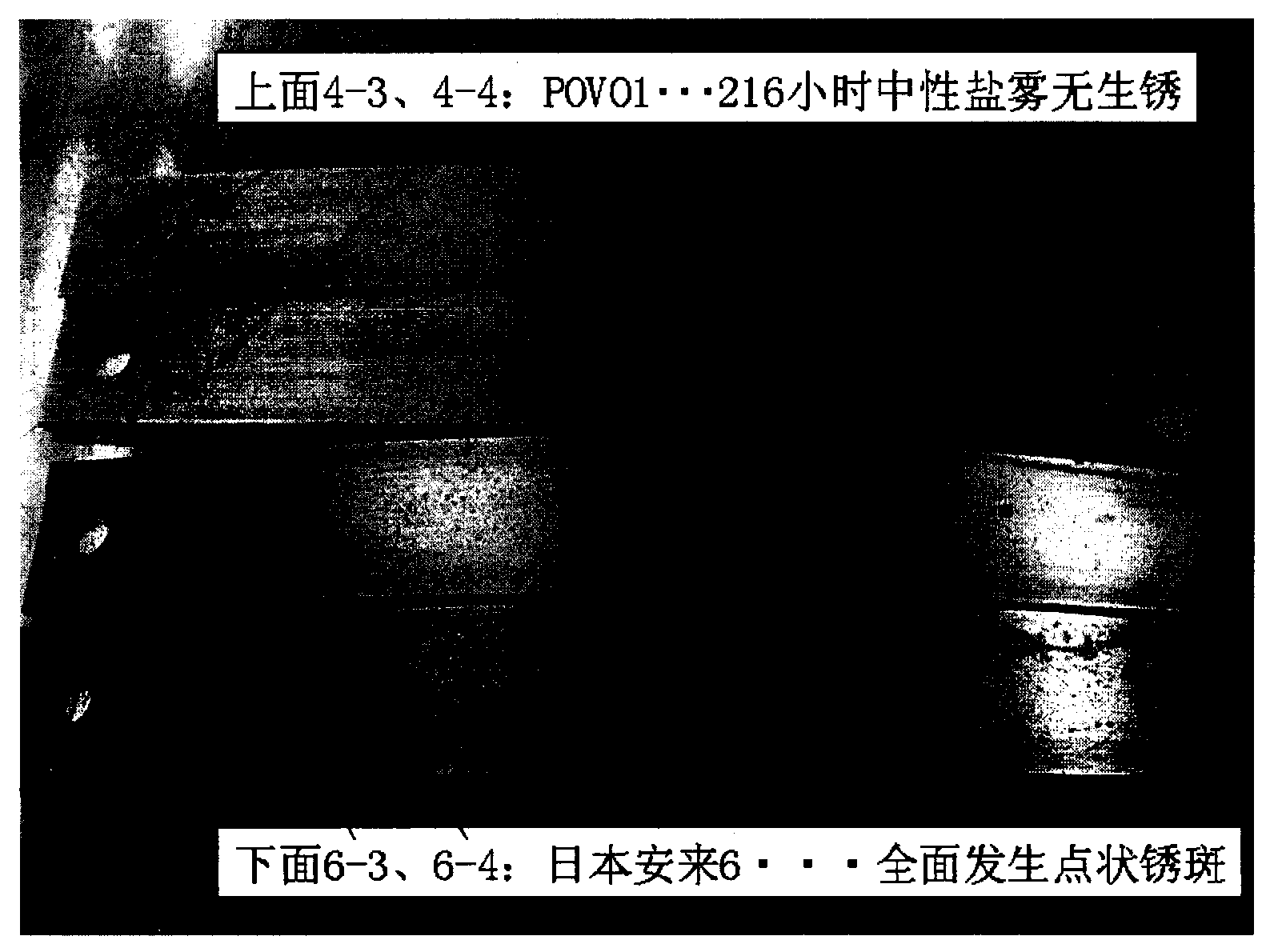

Martensite stainless steel material for electric shaver head

InactiveCN101886226AImprove performanceMeet the requirements of use characteristicsMetal working apparatusMartensitic stainless steelHigh wear resistance

The invention discloses a martensite stainless steel material for an electric shaver head. The martensite stainless steel material is formed by melting with a conventional melting method or fusing by taking the stainless steel material SUS420J2 as a mother material and removing impurities of the materials by using an electrolytic separation method. The material comprises the following components in percentage by weight: 0.33-0.45 percent of C, less than or equal to 1.00 percent of Si, less than or equal to 1.50 percent of Mn, less than or equal to 0.04 percent of P, less than or equal to 0.015 percent of S, 15.50-17.50 percent of Cr, 0.80-1.30 percent of Mo, less than or equal to 1.00 percent of Ni and the balance of Fe. Test shows that the material has the characteristics of high wear resistance, strong corrosion resistance, stable thermal treatment characteristic, excellent grinding processing performance and the like and is an excellent material for producing the electric shaver head.

Owner:SHANGHAI POVOS ELECTRIC WORKS

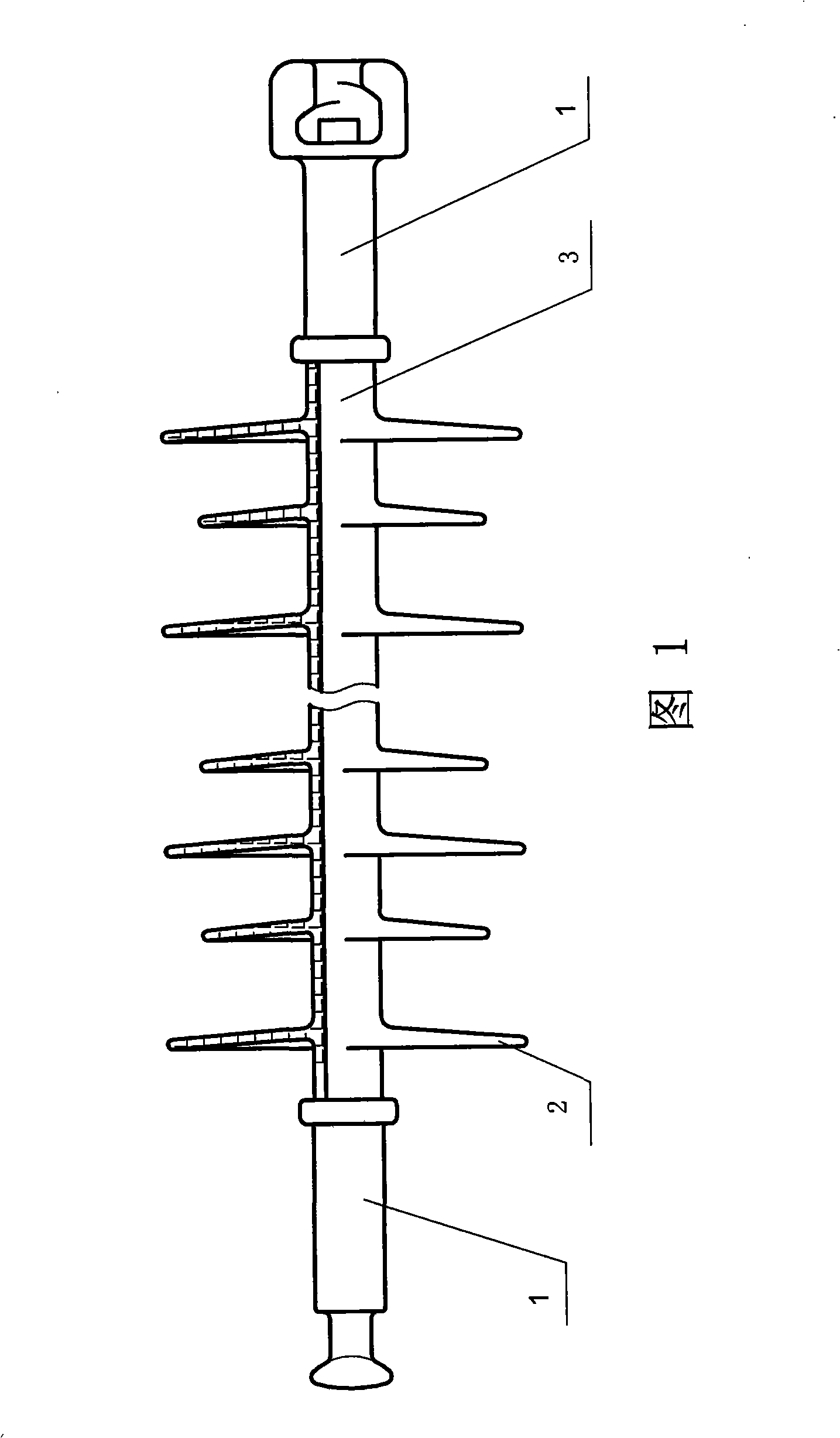

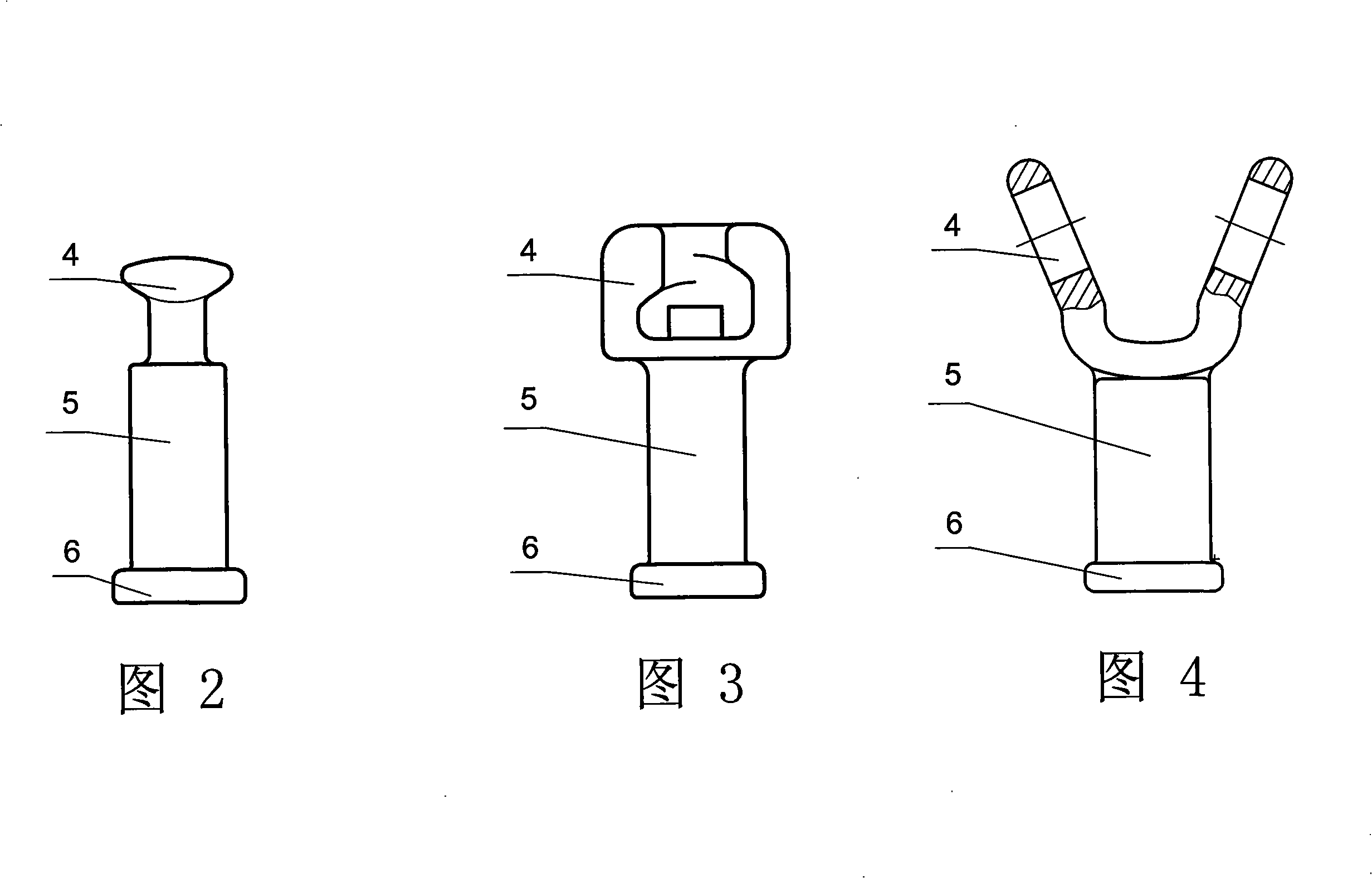

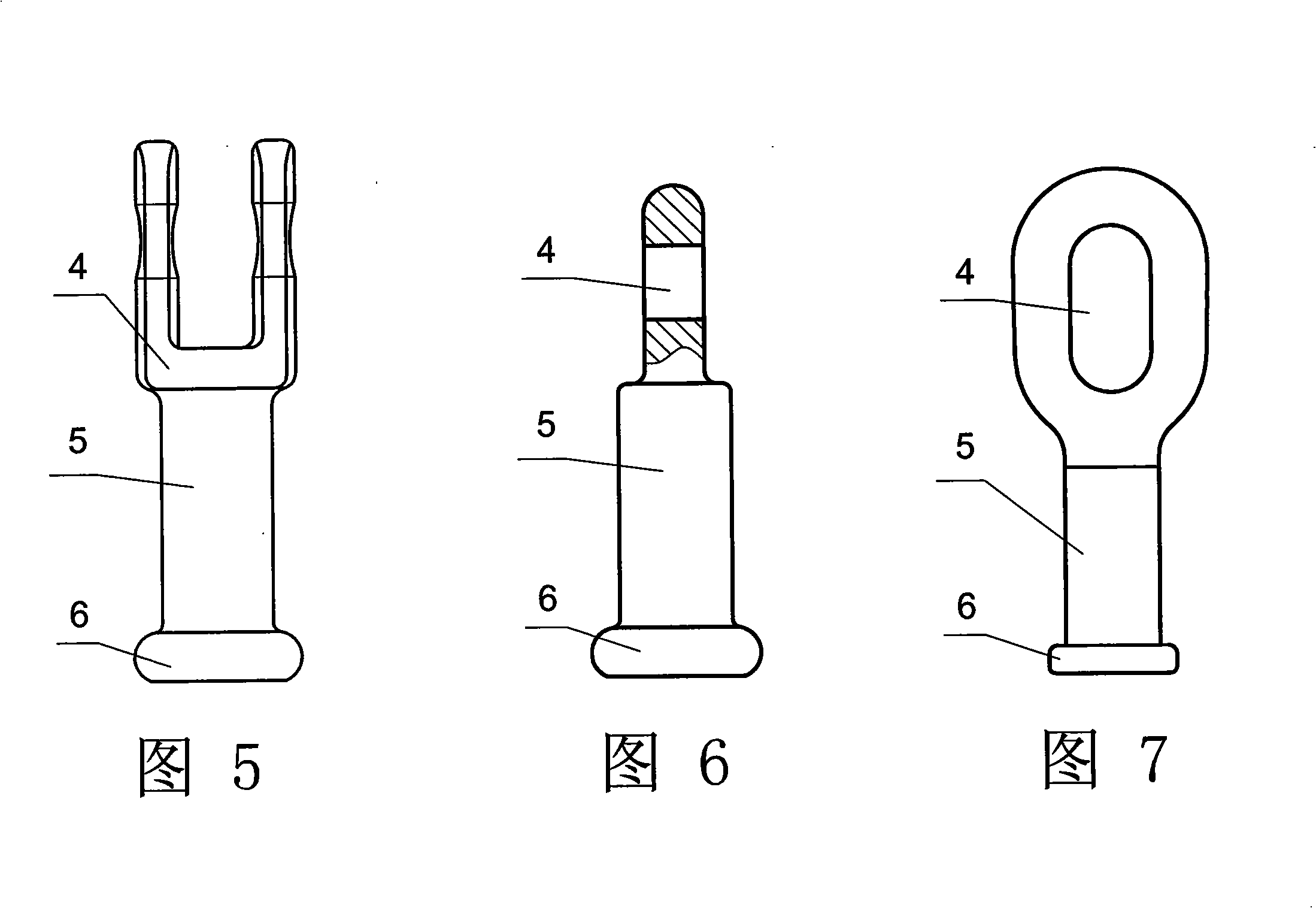

Combined insulator gold tool and method for manufacturing the same

InactiveCN101303925AEasy to industrializeImprove qualitySuspension/strain insulatorsFriction weldingEngineering

The invention discloses a piece of combined insulator hardware and a production method thereof. A standard joint of the combined insulator hardware and a connection bar adopt a split type structure and are fixed together by friction welding. The connection bar and a seal-adhesive seat of the insulator adopt an integrated structure or a split type structure; the connection bar and the seal-adhesive seat are fixed together by friction welding if the connection bar and the seal-adhesive seat adopt a split type structure. The standard joint is a Y-shaped double-ear or a ball head or a ball socket or a U-shaped double-ear or a straight line shaped single ear or a hanging ring-shaped single ear. The production method is that: according to the application characteristics of the specific parts of the hardware, a piece of hardware is divided into two or three parts and respectively produced to satisfy different strength and hardness requirements; then all the parts are fixedly welded together by friction welding technique. By adopting the invention, industrialization of the production of the insulator hardware can be easily realized, product quality and qualified rate in production are enhanced, the working efficiency is improved, the management difficulty in production is reduced and good social and economical benefits can be achieved.

Owner:ZHENGZHOU JINGWEI ELECTRIC POWER TECH

Formula and production method for low-grammage paper

InactiveCN103628349AImprove evennessImprove smoothnessCoatings with pigmentsWater-repelling agents additionFiltrationHeat treated

The invention relates to the technical field of paper making, in particular to a formula and a production method for low-grammage paper. In the formula, paper pulp, an additive and a painting are included, wherein the additive comprises 100-550 ppm of nano attapulgite crystal, 300-800 ppm of fluorescent brightener, 20-40 ppm of staining agent, 3-6 percent of filler and 1.0-1.4 percent of amylum according to proportions; the painting comprises 50-80 ppm of heavy calcium carbonate and 65-70 ppm of amylum according to proportions. The production method for the low-grammage paper adopts the formula and comprises the steps as follows: after pulping, the additive is added to the paper pulp, agitated, placed in a strong magnetic field and thermally treated for 1 hour at a high temperature; formation water filtration making, pressing dehydration, front section drying, glue coating, painting coating, smooth pressing and rolling are sequentially performed. The paper foundation paper made by adopting the formula and the production method is 80g / m<2> to 84g / m<2> in weight, can satisfy requirements of a printing machine on the hardness of the paper, and effectively improves the paper opaqueness.

Owner:福建希源纸业有限公司

Completely biodegradable bamboo microstructure unit and polylactic acid biomass composite and preparation method thereof

The invention relates to a completely biodegradable bamboo microstructure unit and polylactic acid biomass composite which is a biomass composite with high content of bamboo material which is prepared by using bamboo material and biodegradable polylactic acid as raw materials and adopting high-speed mixing method. The preparation method comprises the following steps: chipping or cutting bamboo material or bamboo material processing residues in other modes to prepare bamboo chips or bamboo sections; performing flaking separation, fiber pulping or other technologies to bamboo chips or bamboo sections to prepare bamboo microstructure units; weighting bamboo microstructure units and polylactic acid in a weight ratio of 60:40 to 90:10; then performing high-speed mixing in a high-speed mixer to heat materials through friction heating and external heating, mixing with bamboo microstructure units evenly; and using the prepared mixture of bamboo microstructure units and polylactic acid to prepare various high-intensity board or moulded products under the hot pressing technological conditions that the temperature is 150-200 DEG C, the pressure is 1-6MPa and the time is 5-30min.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

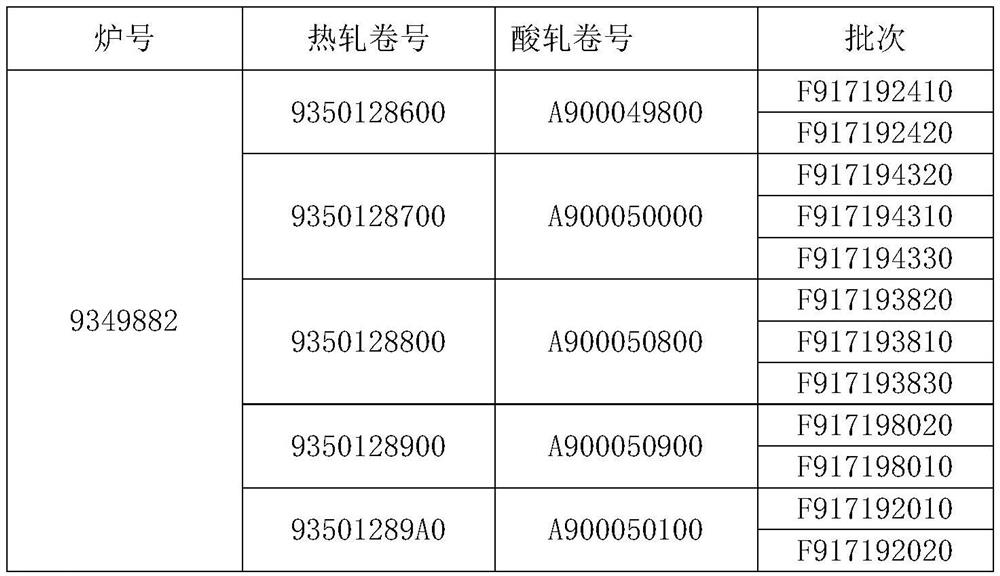

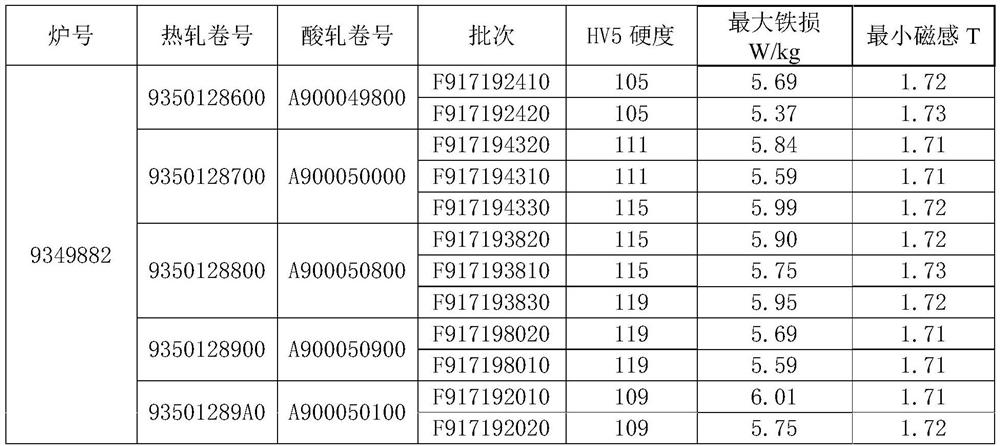

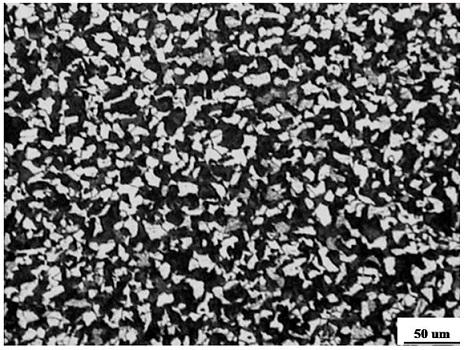

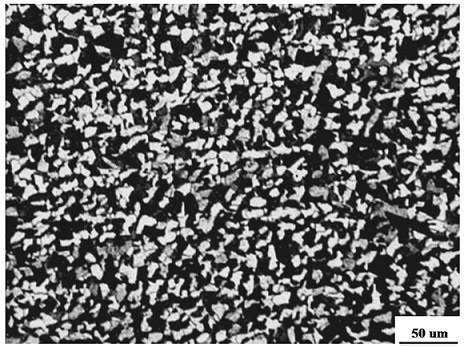

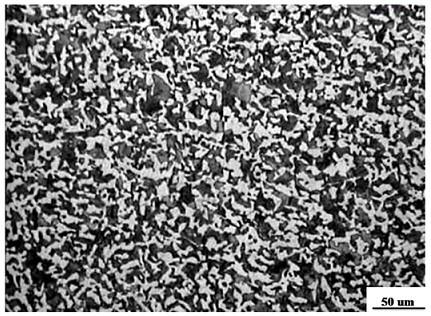

Low-hardness 50W800 electrical steel and production method

The invention provides low-hardness 50W800 electrical steel which consists of the following elements in percentage by mass: less than or equal to 0.005% of C, greater than or equal to 0.45% and less than or equal to 0.60% of Si, greater than or equal to 0.25% and less than or equal to 0.40% of Mn, greater than or equal to 0.15% and less than or equal to 0.35% of Al, greater than or equal to 0.03%and less than or equal to 0.05% of P, less than or equal to 0.06% of S, greater than or equal to 0.045% and less than or equal to 0.060% of Sb, less than or equal to 0.0030% of N, less than or equal to 0.0030% of Ti, and the balance of iron and inevitable impurity elements. Through reasonable component designs, micro-alloy Sb element is added while content of Si and Al is regulated, a corresponding cover type furnace annealing temperature and corresponding annealing time can be matched to realize equiaxial annealing of crystalline grains, so that electrical steel is reduced to reasonable hardness, hardness and magnetic performance requirements of full-process electrical steel products are met, and therefore, the all-process non-oriented electrical steel is produced through the cover type annealing process.

Owner:湖南华菱涟钢特种新材料有限公司 +1

Hot-rolled wire rod for hardening-tempering-free hot galvanizing bolt and production technology of hot-rolled wire rod

ActiveCN109402522AReduce the amount of alloyIncrease productivityTemperature control deviceMetal rolling arrangementsChemical compositionHot rolled

The invention discloses a hot-rolled wire rod for a hardening-tempering-free hot galvanizing bolt and a production technology of the hot-rolled wire rod. The wire rod is prepared from the following chemical components in percentage by mass: 0.30-0.40% of C, 0.15-0.35% of Si, 0.45-0.85% of Mn, less than or equal to 0.025% of P, less than or equal to 0.025% of S, 0.8-1.10% of Cr and the balance of iron and unavoidable impurity elements. In the production technology, after a continuous casting process is finished, a casting blank is heated to 1,090-1,130 DEG C, and the heat preservation is performed for 100-140 min; in a rolling process, the temperature at a finish rolling entrance is controlled at 760-830 DEG C; after the rolling, the process enters a Stelmor cooling line, and a fan heat cover and a fan are completely closed. According to the hot-rolled wire rod and the production technology disclosed by the invention, easy-to-deform ferrite and pearlitic structure are obtained through low-temperature rolling, thus the wire rod can be subjected to cold heading deformation without annealing; on the basis, by adding a proper amount of C, Si, Mn and Cr reinforcing elements, the bolt cansurely meet the requirements of 8.8-class hot galvanizing standard without hardening and tempering treatment; the bolt hardening and tempering treatment process of traditional technology is saved, the cost of deep processing is remarkably lowered, and the production efficiency is improved.

Owner:HANDAN IRON & STEEL GROUP +1

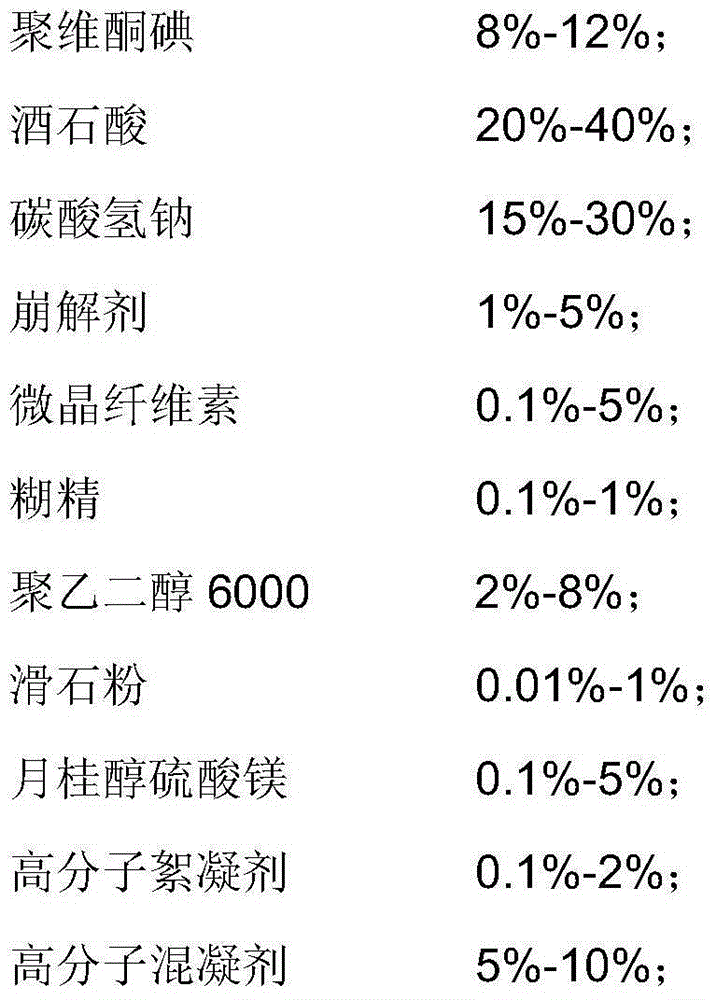

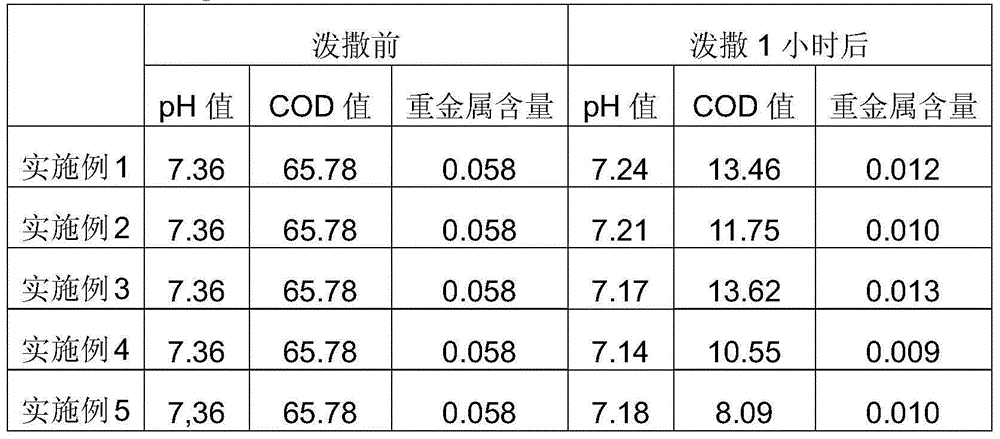

Disinfection effervescent tablet with water quality purification effect and preparation method of disinfection effervescent tablet

ActiveCN105084475AGood sedimentation performanceImprove efficiencyWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationChemistrySodium bicarbonate

The invention provides a disinfection effervescent tablet with a water quality purification effect. The disinfection effervescent tablet comprises, by mass, 8-12% of povidone iodine, 20-40% of tartaric acid, 15-30% of sodium bicarbonate, 1-5% of disintegrating agents, 0.1-5% of microcrystalline cellulose, 0.1-1% of dextrin, 2-8% of polyethylene glycol 6000, 0.01-1% of talcum powder, 0.1-5% of laurinol magnesium sulfate, 0.1-2% of polymeric flocculant, 5-10% of polymeric coagulant and the balance filler. The invention further provides a preparation method of the disinfection effervescent tablet with the water quality purification effect. By means of the effervescence technology, povidone iodine and flocculant are combined together, the disinfection effervescent tablet can be more uniformly dissolved in a water body, and the optimal disinfection and water body purification effects are achieved. The effervescent tablet can be basically completely disintegrated and uniformly dispersed within 5 min. The preparation method is easy and convenient to operate and simple in device requirement. The product is convenient to use, transport and carry. Meanwhile, the pH value of the water body can not be changed, the ecological balance of the water body can not be damaged, and the disinfection effervescent tablet and the preparation method are suitable for industrialized large-scale production, application and popularization.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

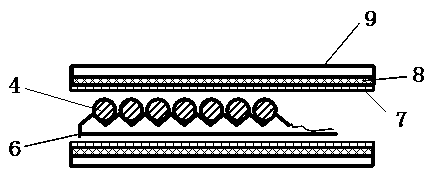

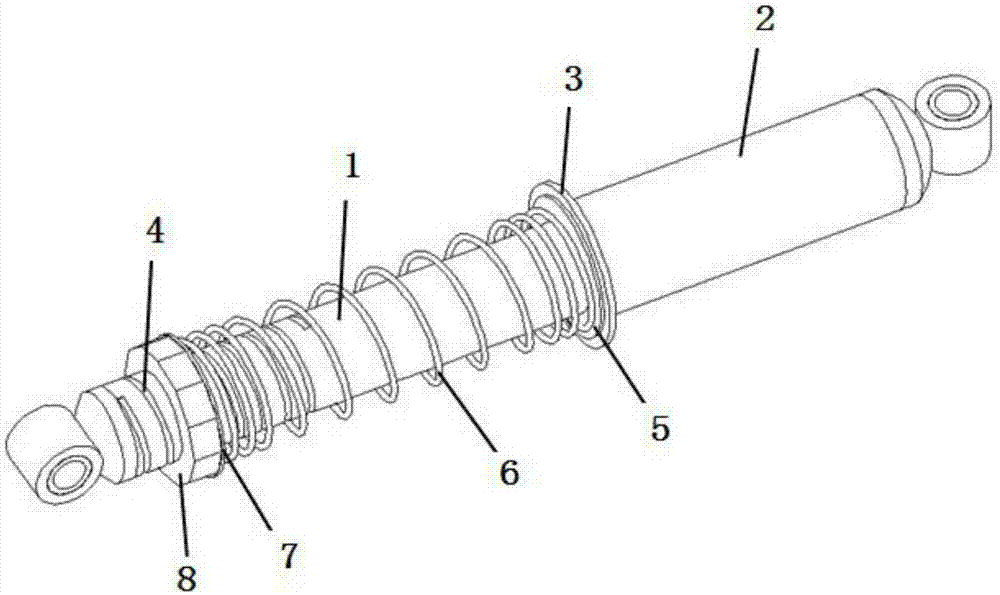

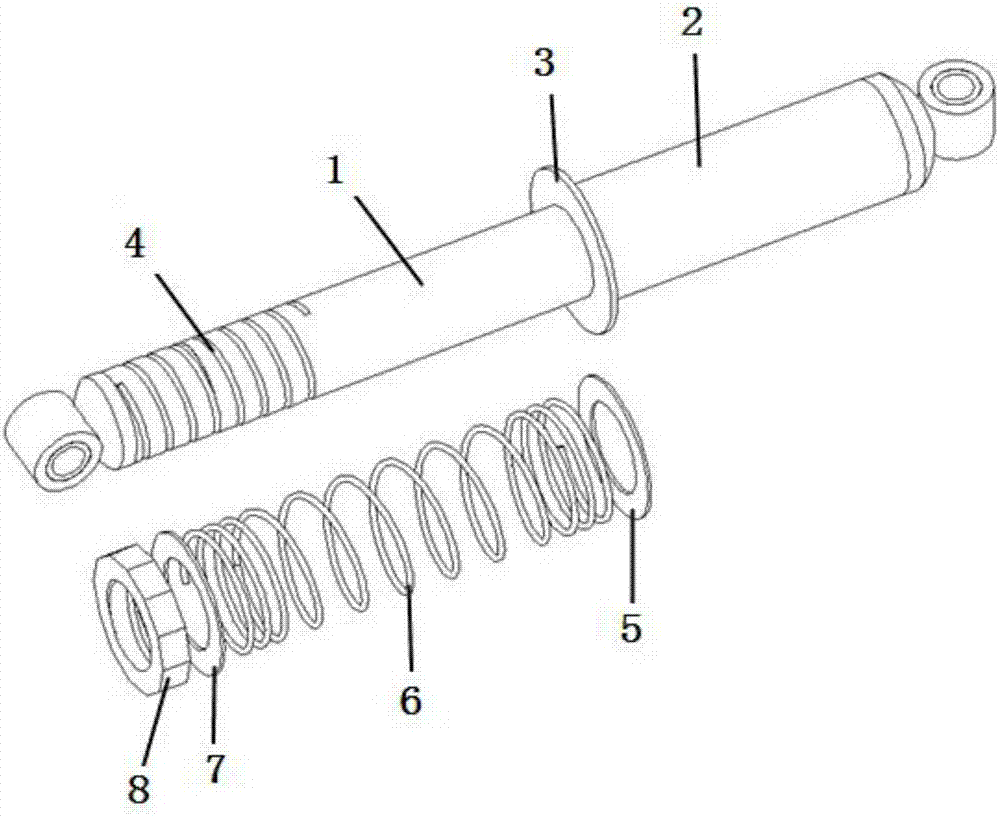

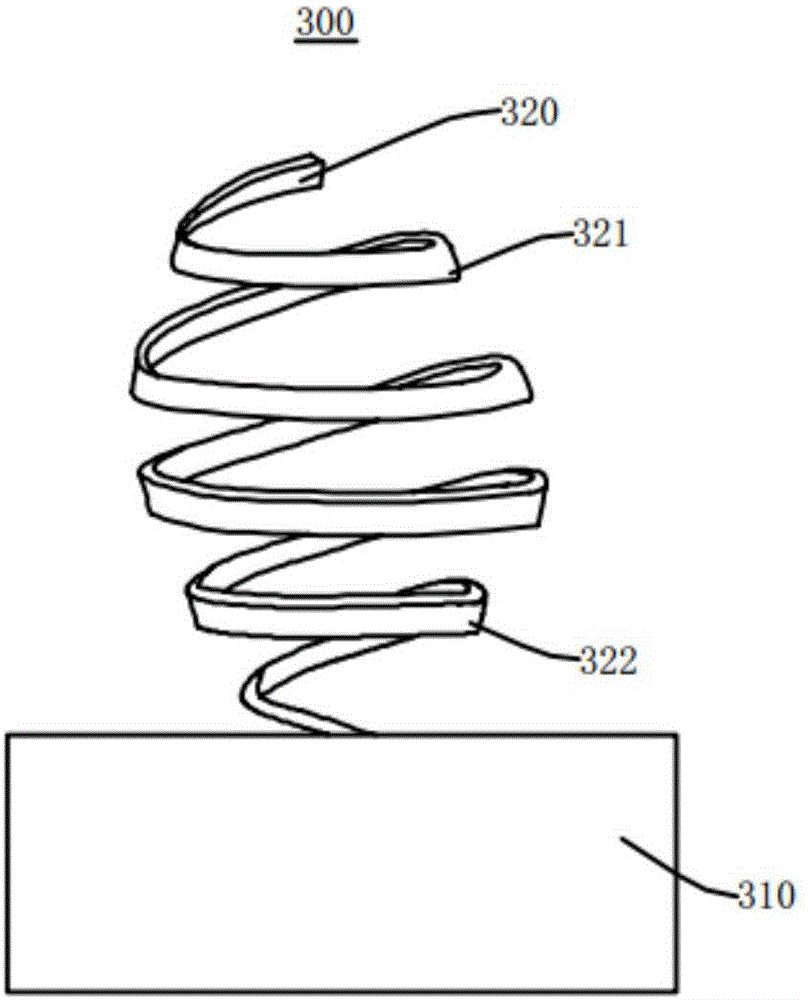

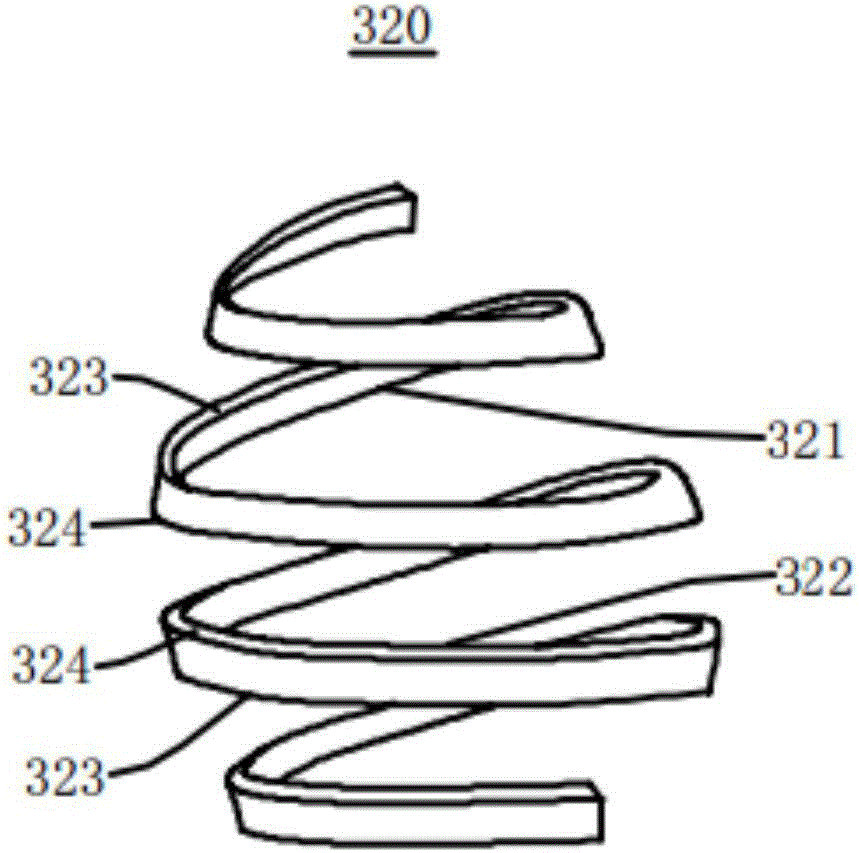

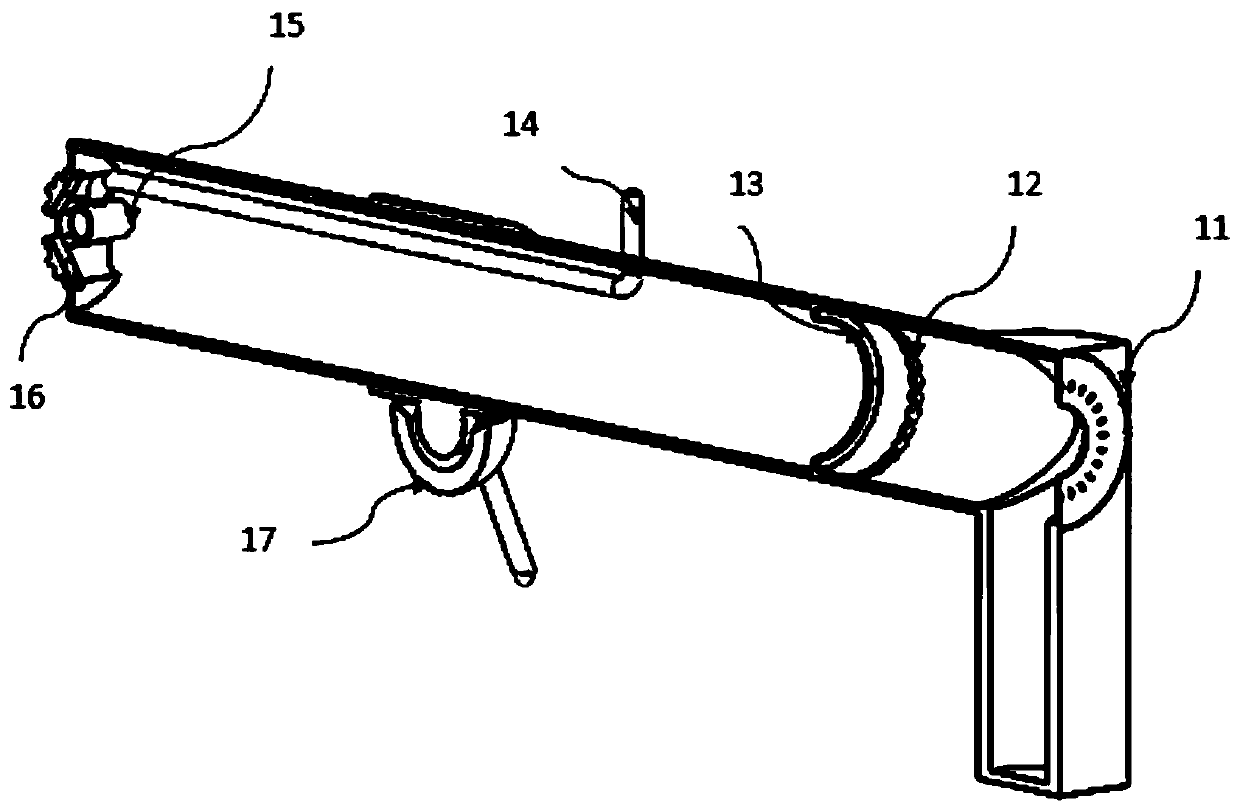

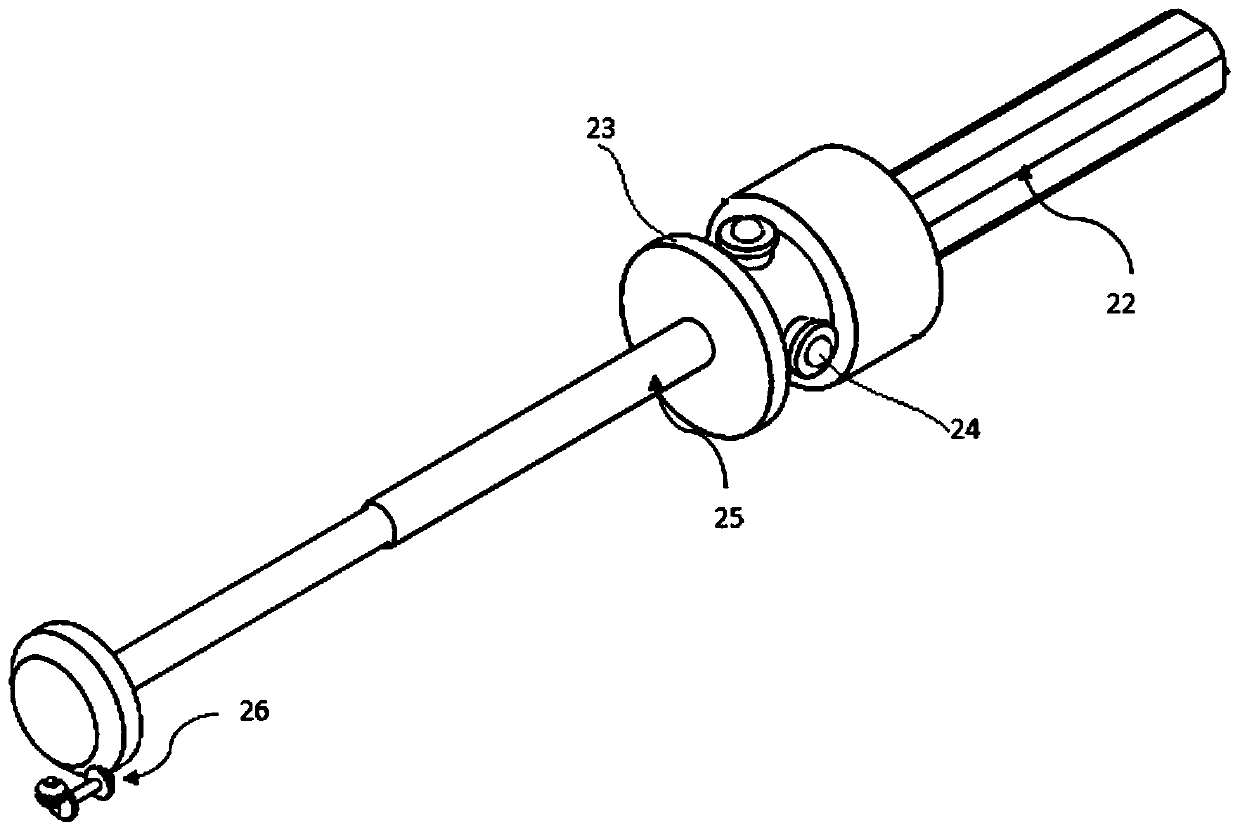

Vehicle vibration reducer with adjustable spring

InactiveCN107387647AMeet the hardness requirementsReasonable designSpringsSprings/dampers functional characteristicsReducerEngineering

The invention discloses an automobile shock absorber with an adjustable spring. The shock absorber is composed of an inner cylinder and an outer cylinder. The end of the outer cylinder close to the inner cylinder extends outward to form a front limit ring. The inner cylinder The surface of the side away from the outer cylinder is provided with external threads, and the outer side of the inner cylinder is sequentially provided with a front spring washer, a spring, a rear spring washer, and a hardness adjusting nut, and the two ends of the spring are respectively connected to the front spring washer 1. The rear spring gasket is fixedly connected, and the hardness adjusting nut is provided with an internal thread part that cooperates with the external thread. The invention has a reasonable design. By adding a spring on the structural basis of the traditional two-way acting shock absorber, and using the hardness adjustment nut screwed with the inner cylinder to drive the spring to expand and contract in advance, the hardness can be adjusted by changing the preload of the spring. It is easy to operate and meets the hardness requirements of vehicles of different weights on elastic elements.

Owner:浙江鼎信航天科技有限公司

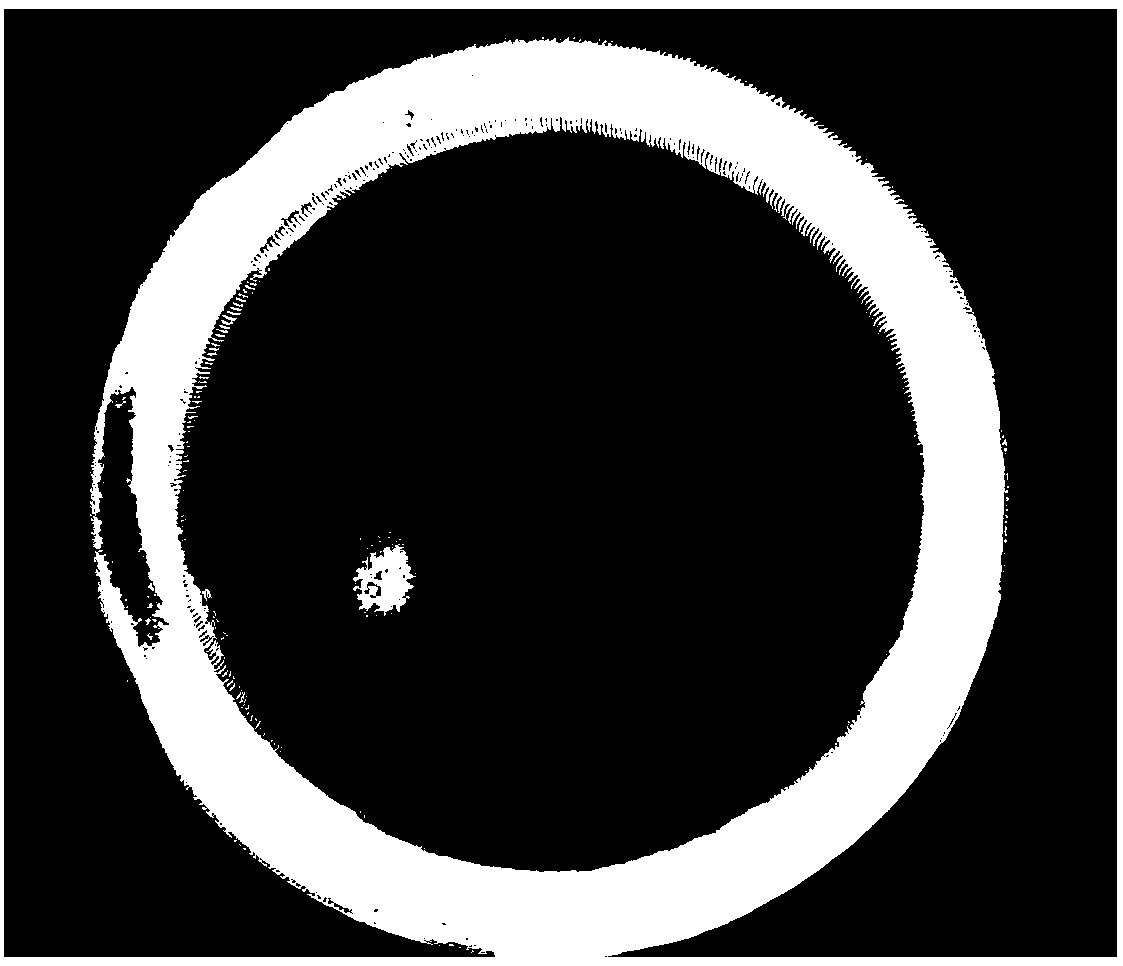

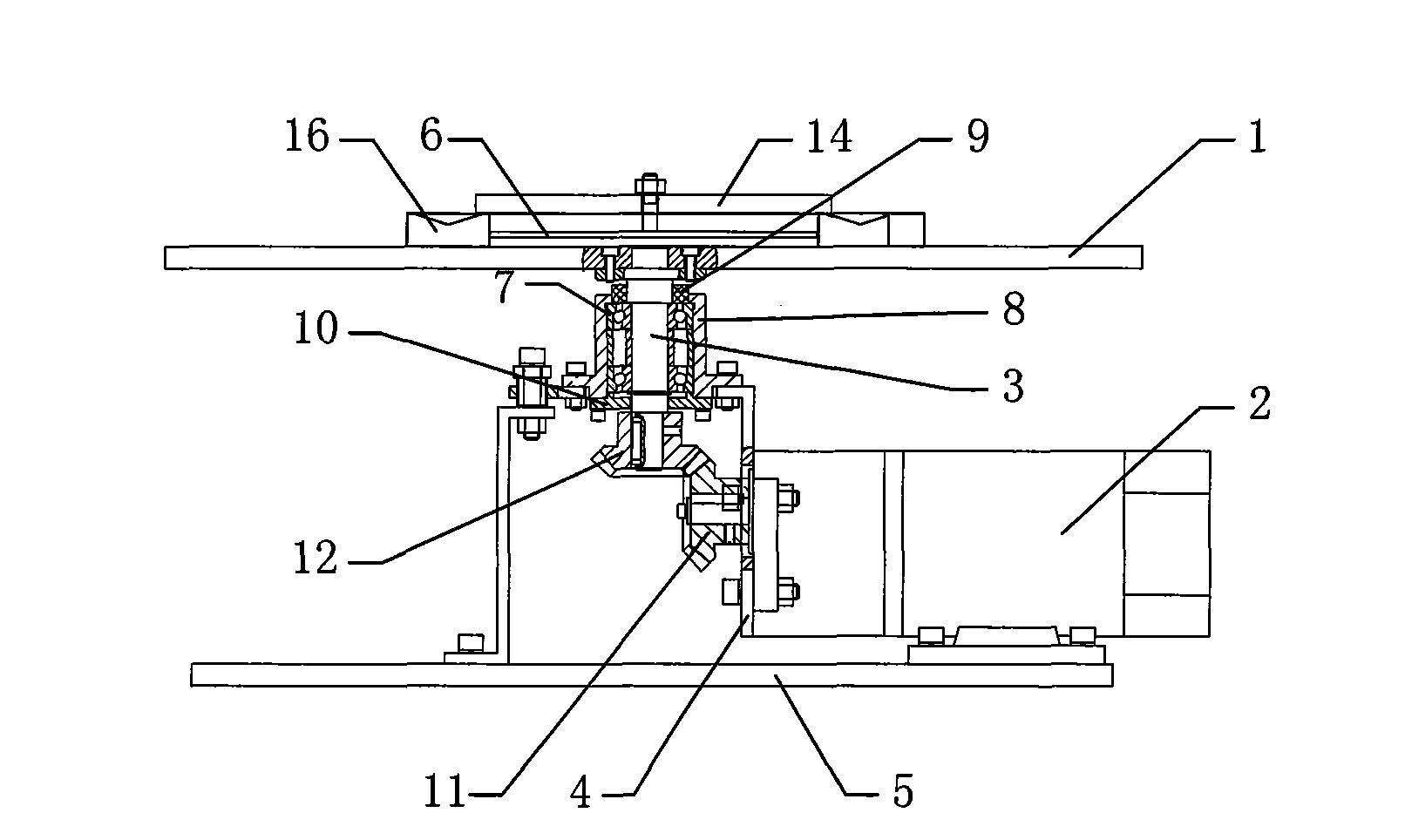

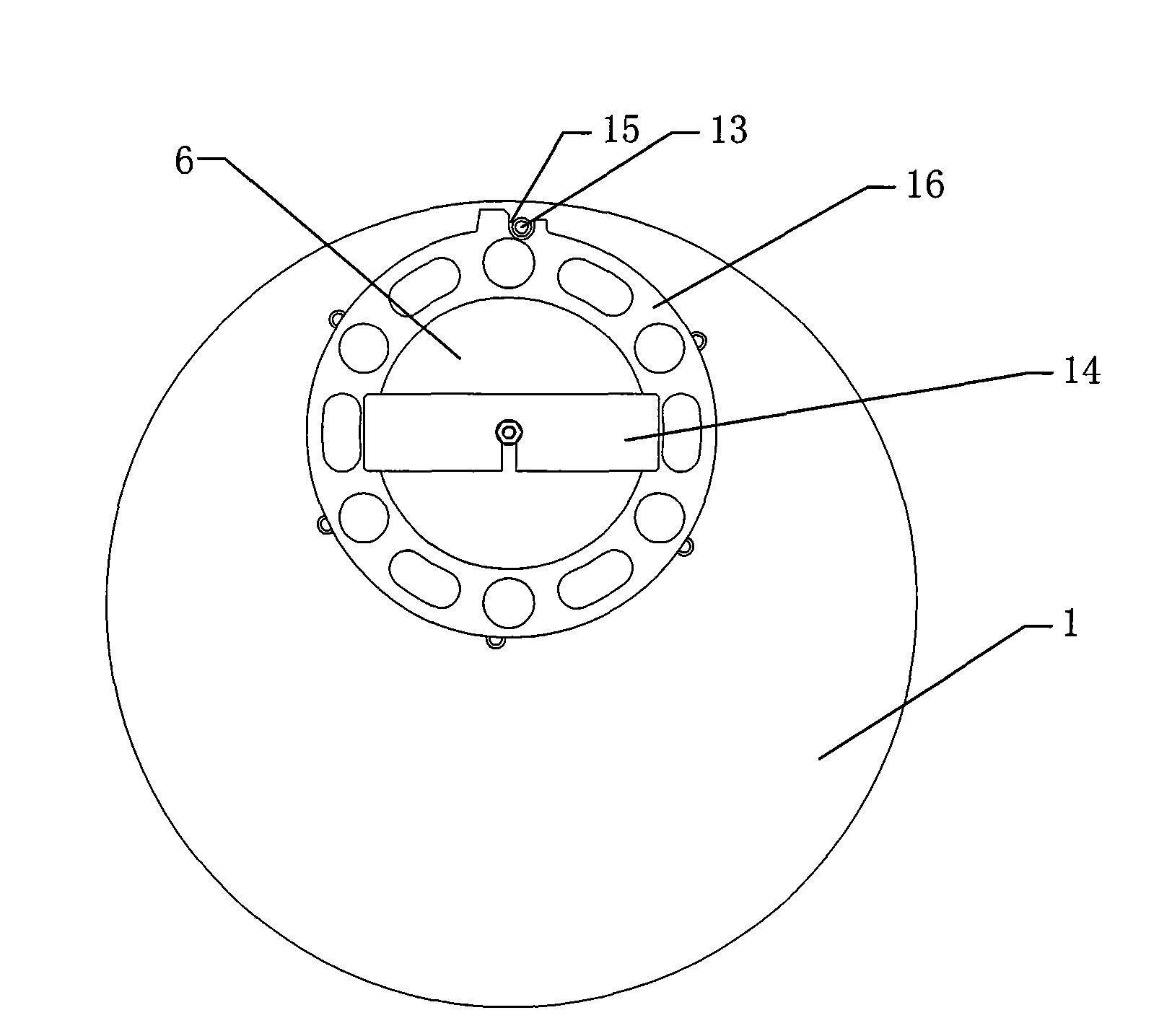

Local centering and rotating device of cone socket

ActiveCN101649382ASolve the stability of hardening depth and hardness differenceGap stabilityFurnace typesIncreasing energy efficiencyQuenchingDrive motor

The invention relates to a local centering and rotating device of a cone socket, which can keep a clearance between a high-frequency induction coil and the cone socket surface according to the requirements of a quenching process stable, thereby solving the problems of effective hardening depth and stable hardness difference. The local centering and rotating device is characterized by comprising arotating disc and a driving motor, wherein the rotating disc is arranged on a rotating shaft which is arranged on a bracket through a bearing, the bracket is arranged on a bottom plate, the rotating shaft is connected with the driving motor by a driving mechanism, and an eccentric positioning disc is arranged on the surface of the rotating disc.

Owner:WUXI POWER ENG

Aluminum alloy heat radiator profile as well as application and on-line quenching process thereof

ActiveCN106834984AAvoid deformationPrevent precipitationFurnace typesHeat treatment furnacesHardnessIngot

The invention provides an aluminum alloy heat radiator profile as well as application and an on-line quenching process thereof, and relates to the technical field of aluminum alloy processing. The on-line quenching process of the aluminum alloy heat radiator profile comprises the following steps: under conditions that the heating temperature of a mold is 480-520 DEG C and the temperature of an extrusion cylinder is 430-460 DEG C, extruding aluminum alloy ingots, and blowing the bottom of an aluminum alloy heat radiator profile by utilizinga blowing device, wherein the aluminum alloy heat radiator profile is made in an extrusion mode, the air speed of the bottom of the aluminum alloy heat radiator profile is 40-50m / s, and the air speeds of the top and two sides of the aluminum alloy heat radiator profile are all 0m / s. By adopting the on-line quenching process of the aluminum alloy heat radiator profile provided by the invention, hardness requirements of the bottom of the profile can be ensured, and meanwhile profile tooth pieces can be prevented from deformation.

Owner:SHANDONG NANSHAN ALUMINUM +2

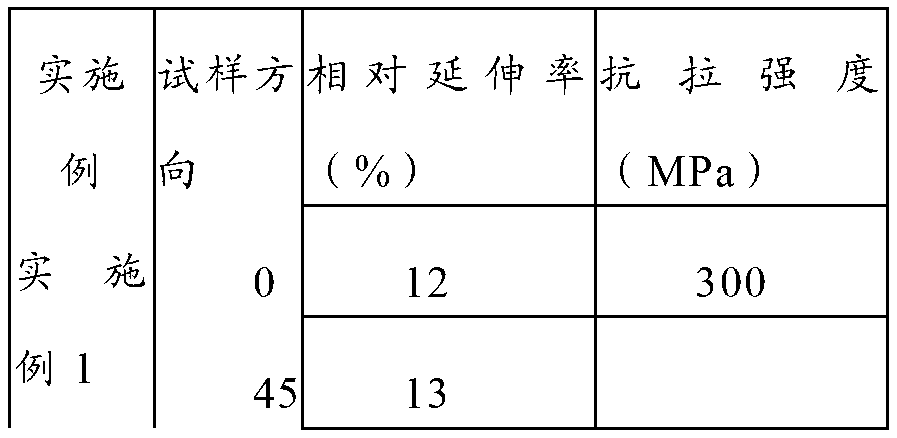

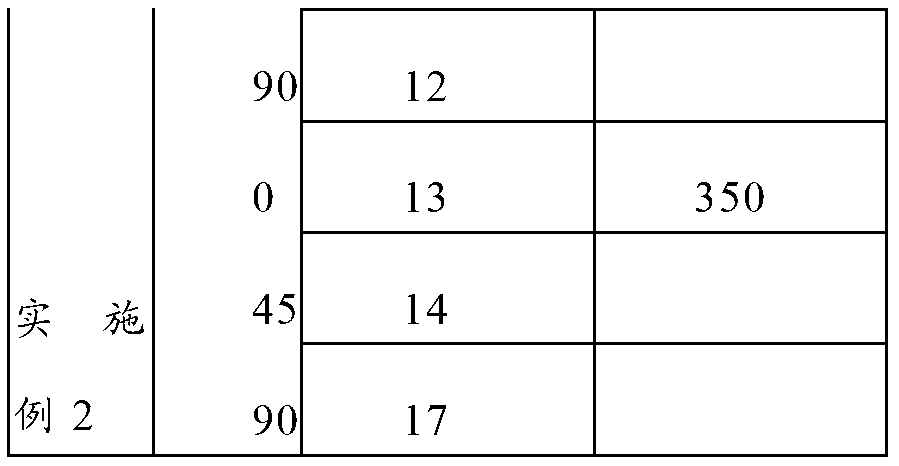

Aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof

ActiveCN103290282AHigh hardnessMeet strength requirementsUpperBootlegsHardnessUltimate tensile strength

The invention provides an aluminium alloy sheet material for labour protection leather shoes head and preparation method thereof, and the aluminium alloy sheet material is 7xxx series aluminium alloy, and concretely comprises the following components by weight percent: 0.50-1% of Fe, 0.40-1.0% of Mn, 0.4-0.80% of Mg, 0.20-0.80% of Si, 0.2-0.3% of Zr, 0.10-0.2% of Ti, 3.5-4.5% of Cu and Al the rest amount. The aluminium alloy contains Zr, Ti, Si, Cu and Mg, and has a high hardness and intensity, and belongs to the superhard aluminium alloy, the invention has a good wear resistance, and after the stress is relieved by processing, the product does not deform and warp, thereby shortening the moulding time and improving the work efficiency. The aluminium alloy sheet material provided by the invention can satisfy the requirements of intensity and hardness, and ensure the thickness of the aluminium alloy sheet material is the lowest.

Owner:SOUTHWEST ALUMINUM GRP

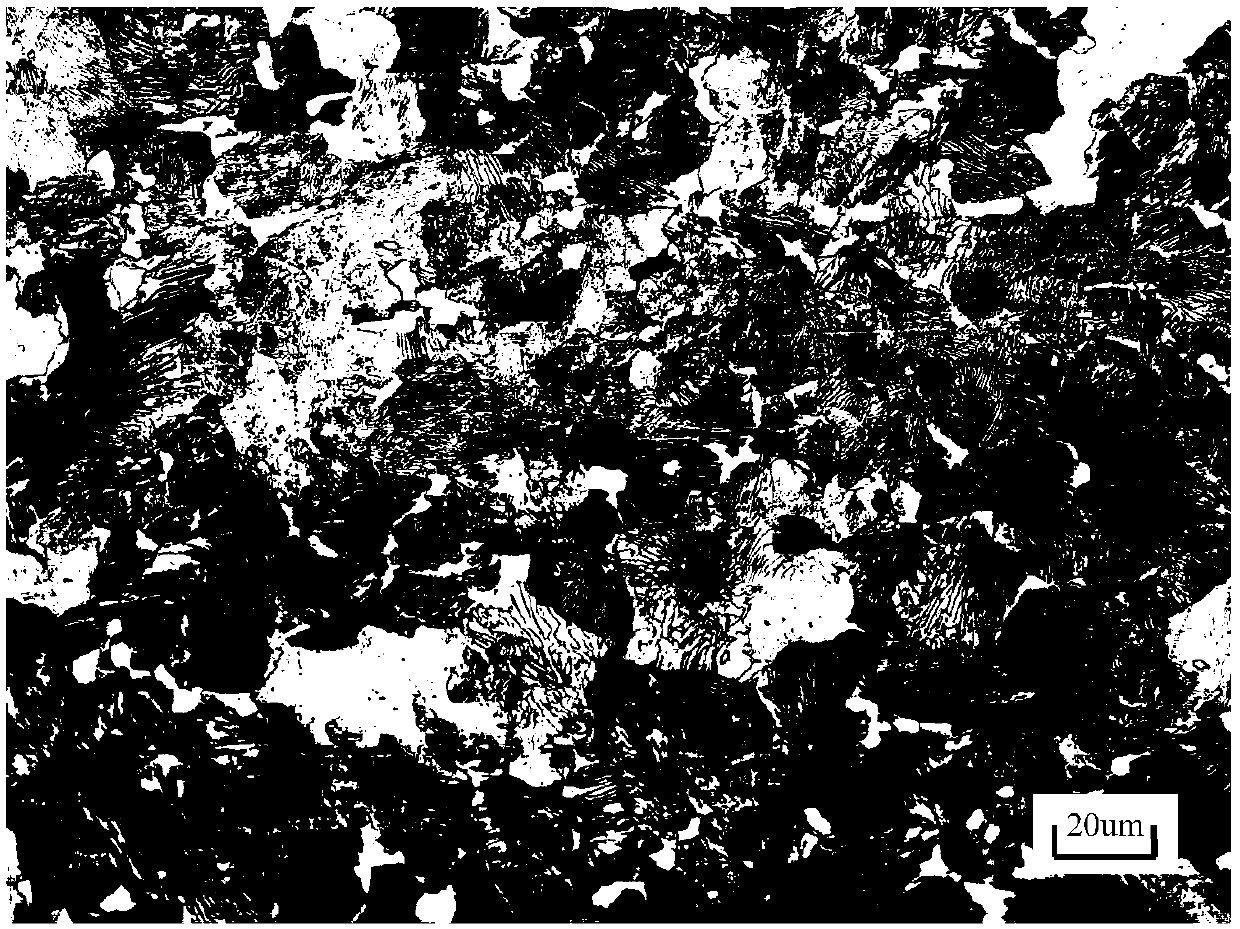

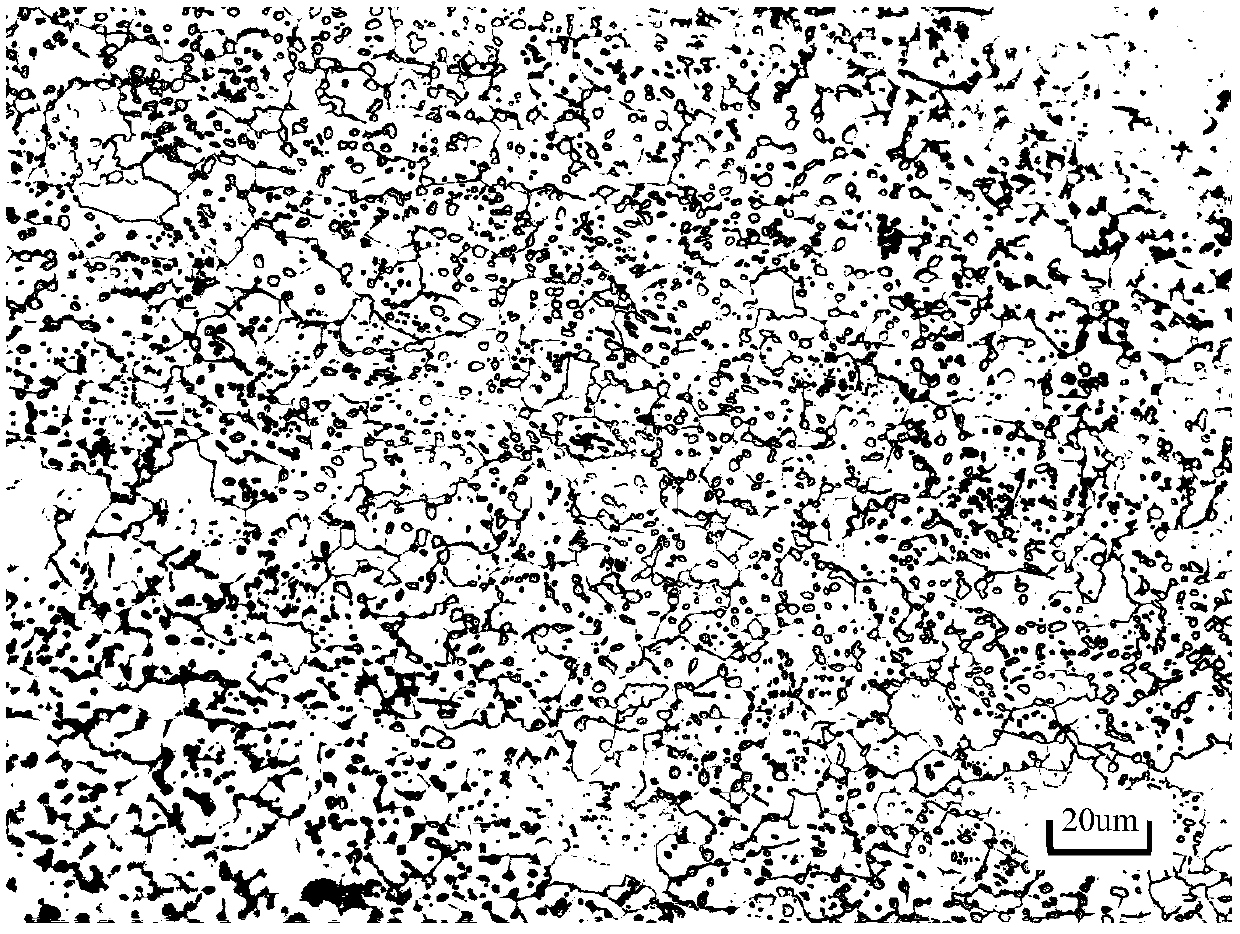

Cold-roll steel plate used for precise punching of automobile safety belt buckles and manufacturing method of precise punching cold-roll steel plate

The invention discloses a cold-roll steel plate used for precise punching of automobile safety belt buckles and a manufacturing method of the precise punching cold-roll steel plate. The technical problems that an existing cold-roll steel plate used for precise punching of automobile safety belt buckles is high in hardness, low in ductility and not suitable for high-speed precise punching are solved. The cold-roll steel plate used for precise punching of automobile safety belt buckles comprises the chemical components including, by weight, 0.56%-0.64% of C, smaller than or equal to 0.20% of Si,0.3%-0.5% of Mn, 0.01%-0.04% of Al, 0.15%-0.25% of Cr, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S and the balance Fe and inevitable impurities. The yield strength RP 0.2 of the cold-roll steel plate is 300 MPa to 350 MPa, and the after-fracture elongation A 50 mm is 32% to 38%. The cold-roll steel plate is used for high-speed precise punching manufacturing of components such as automobile safety belt buckles.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

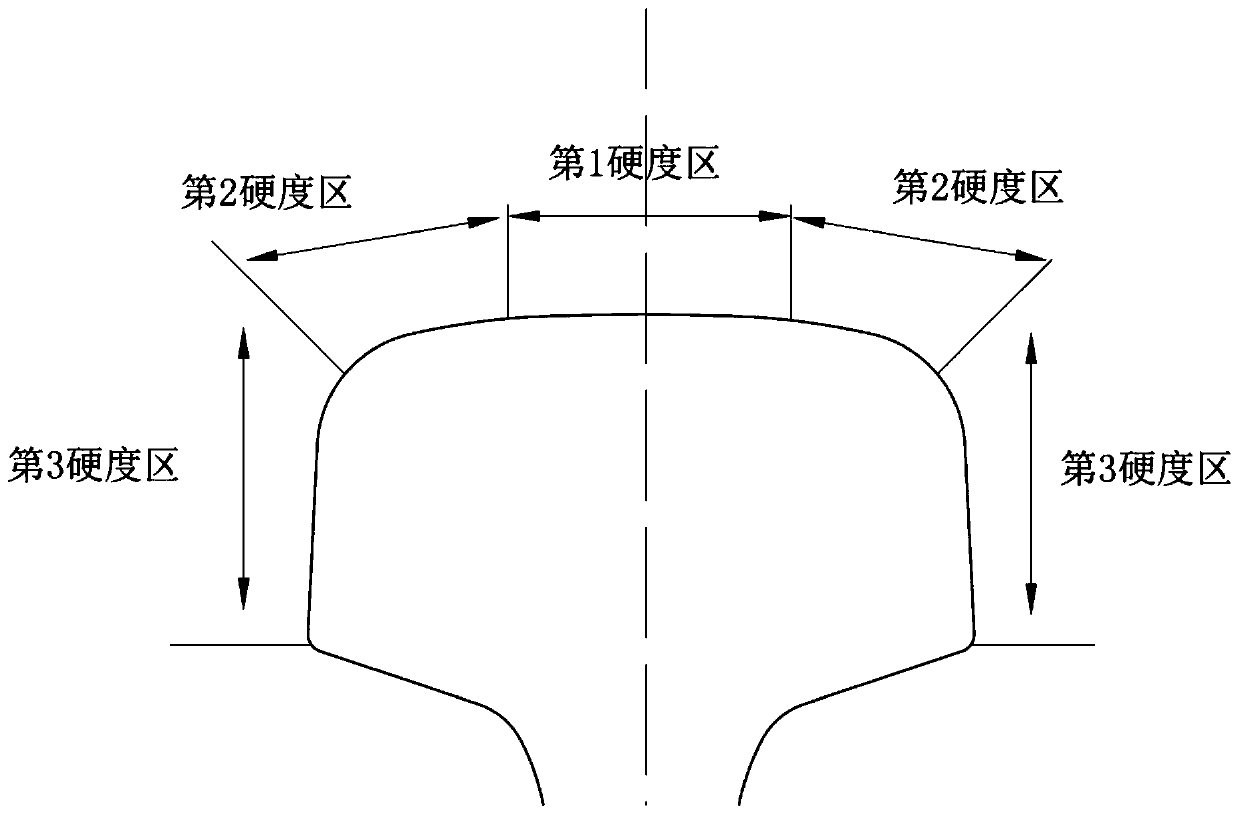

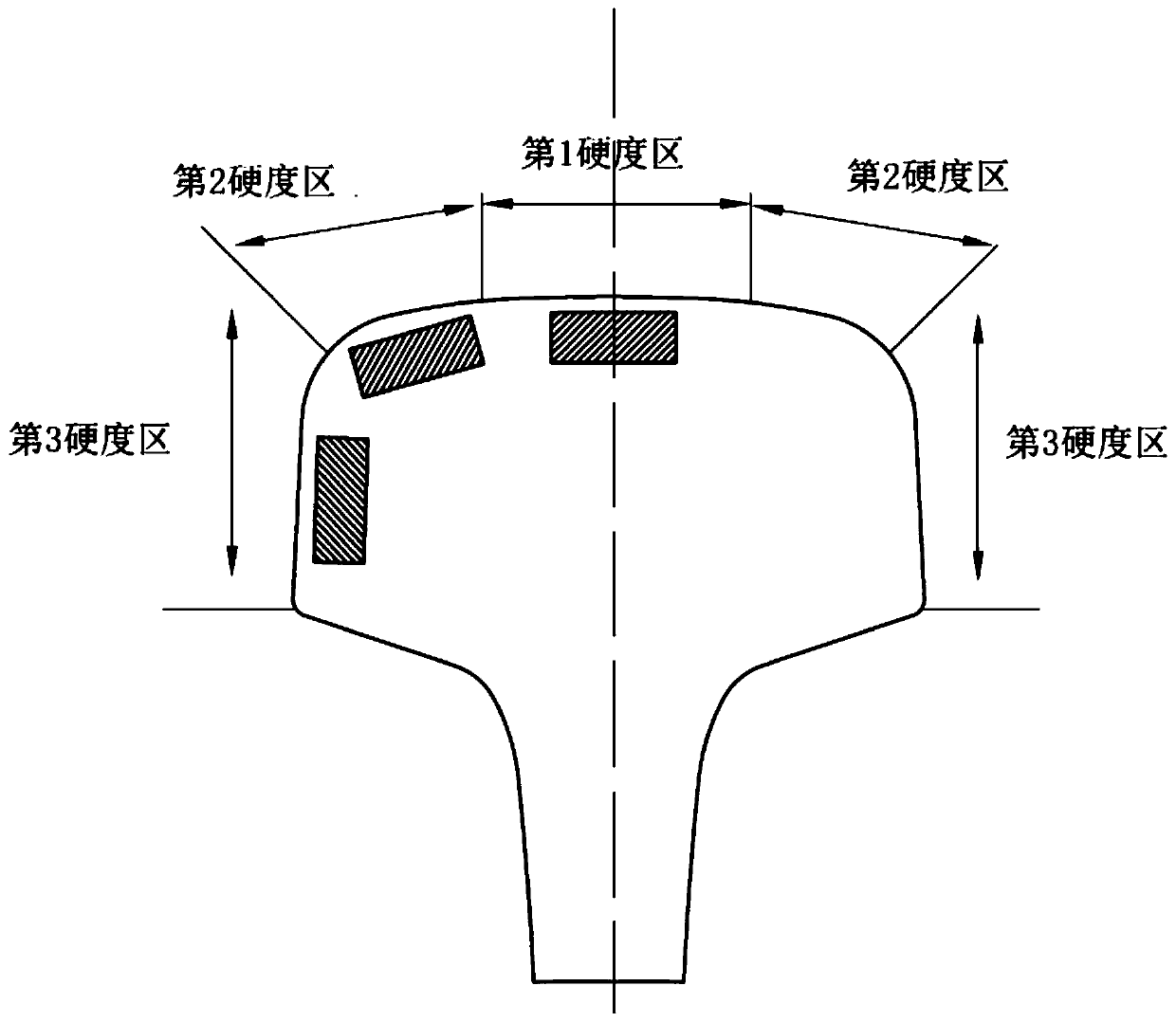

Rail for straight-curve transition section and production method of rail

ActiveCN110468632AMeet the hardness requirementsExtended service lifeRailsFurnace typesHardnessFatigue cracking

The invention relates to a rail for a straight-curve transition section and a production method of the rail. The rail includes a rail, the rail is provided with three hardness zones from a rail head to a lower jaw area, respectively and namely the first hardness zone, the second hardness zone and the third hardness zone, wherein the first hardness zone is distributed in the middle position of a rail head rolling face, the second hardness zone is distributed from the boundary of the first hardness zone to the rail angle, the third hardness zone is distributed from the boundary of the second hardness zone to a rail head lower jaw, the brinell hardness number in the first hardness zone is 305 HB-340 HB, the brinell hardness number of the second hardness zone is 340 HB-375 HB, and the brinellhardness number of the third hardness zone is 375 HB-410 HB. According to the rail, the defects such as excessive wear, fatigue crack, peeling and chipping on the transition section from a straight line to a curve or from the curve to the straight line can be effectively alleviated, the service life of the rail is significantly prolonged, and traffic safety is significantly improved.

Owner:武汉钢铁有限公司

Carbon structural steel controlled rolling and controlled cooling method

ActiveCN111760907AMeet the hardness requirementsReduce generationTemperature control deviceMetal rolling arrangementsTemperature controlSlow cooling

The invention relates to a carbon structural steel controlled rolling and controlled cooling method, and belongs to the technical field of steel rolling technologies. The problem that an existing carbon structural steel hot rolling material cannot meet the hardness index of annealing materials is solved. The carbon structural steel controlled rolling and controlled cooling method comprises the steps of heating of continuous casting, initial rolling, intensive pressure water cooling for the first time, finishing rolling, intensive pressure water cooling for the second time, cover buckling of acooling bed and slow cooling of lowering a pit. The intensive pressure water cooling for the first time controls the finishing rolling temperature at 850-880 DEG C; the intensive pressure water cooling for the second time controls the steel temperature on a cooling bed at 720-750 DEG C; and the cooling bed is provided with an insulation cover. According to the carbon structural steel controlled rolling and controlled cooling method, the hardness of the obtained carbon structural steel hot rolling materials reaches 194-199 HB, and the hardness requirement of the annealing materials is met. Through the accuracy control of the finishing rolling temperature and the cooling bed cooling rate, the generation of oxidized scales can further be reduced, the annealing cost and the coping cost of thesurfaces of the steel materials are saved, and the cost decreasing and benefit increasing are realized.

Owner:建龙北满特殊钢有限责任公司

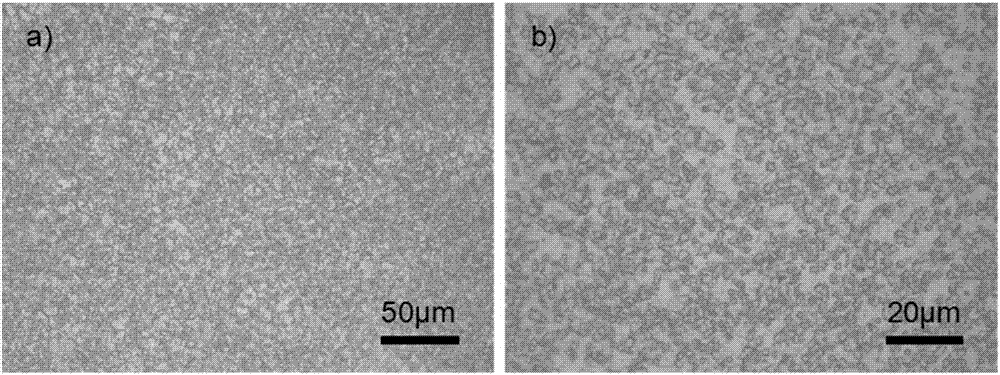

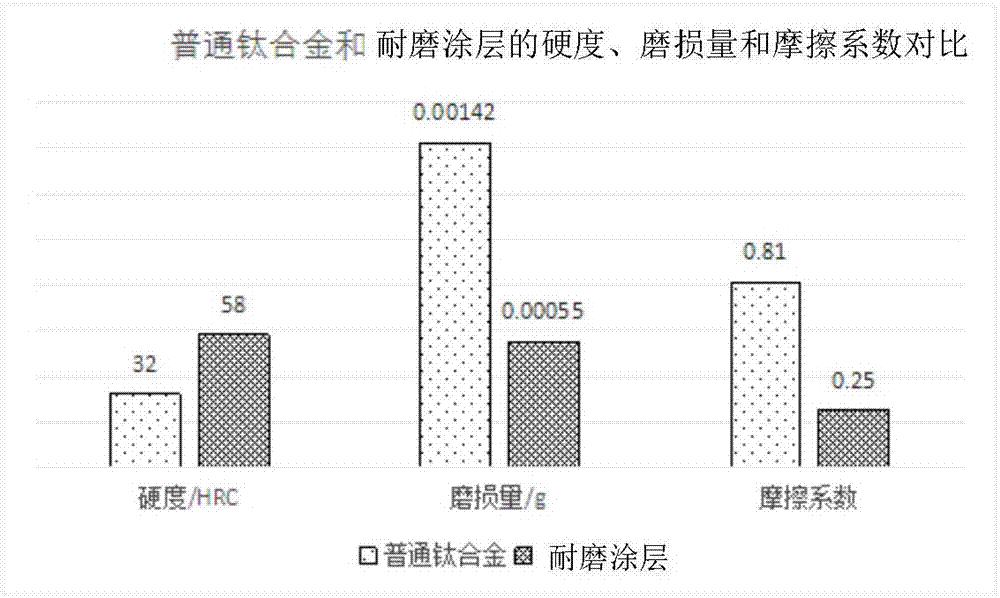

Wear resistant coating layer of titanium alloy cutter and preparation method thereof

ActiveCN107475711AImprove wear resistanceHigh hardnessMetallic material coating processesWear resistantHardness

The invention provides a wear resistant coating layer of a titanium alloy cutter and a preparation method thereof. The wear resistant coating layer comprises the components of Ti, Cr, C, Al and Si, wherein the mass percentages of all the components are as follows: 84.76-89.80% of Ti, 8.67-13.00% of Cr, 1.25-2.26% of C, 0.018-0.027% of Al, and 0.013-0.020% of Si. In the wear resistant coating layer of the titanium alloy cutter and the preparation method thereof, a laser cladding method is adopted to clad titanium alloy mixed powder on the surface of the titanium alloy cutter for in-situ generation of a complete TiC network skeleton structure on the surface of the titanium alloy cutter, so that the wear resistance and the hardness of the titanium alloy cutter are improved, and the effective service life of the titanium alloy cutter is prolonged.

Owner:沈阳钛成科技合伙企业(有限合伙)

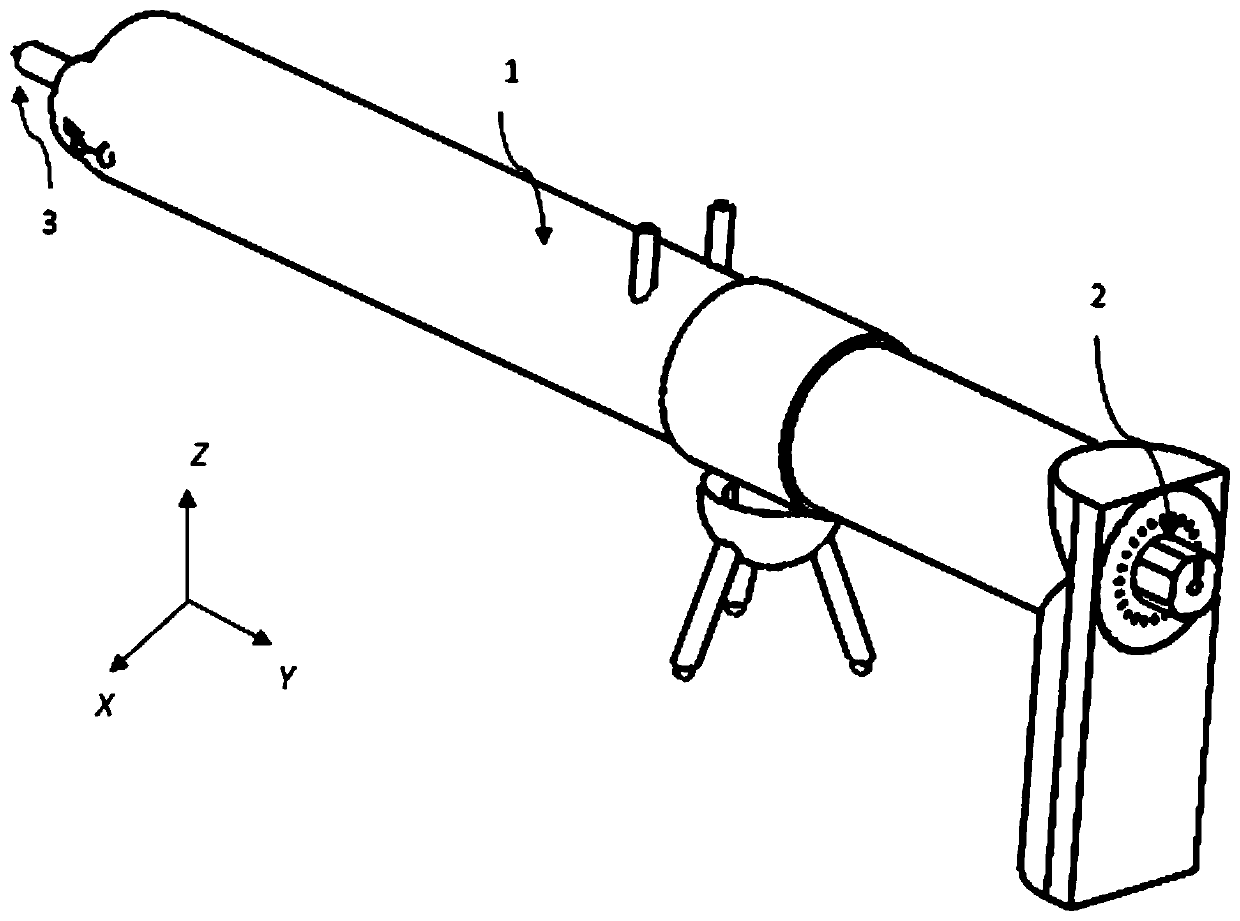

Photo-cured hydrogel conveying device for minimally invasive surgery and in-situ printing method

ActiveCN110101448AReduce wound areaReduce the risk of cross-infectionOsteosynthesis devicesEngineeringInvasive surgery

The invention discloses a photo-cured hydrogel conveying device for minimally invasive surgery and an in-situ printing method. The device comprises a shell, a rotary steering structure and a coaxial spraying nozzle, wherein the rotary steering structure and the coaxial spraying nozzle are installed in the shell, the coaxial spraying nozzle is installed in the shell, and the outlet of the coaxial spraying nozzle is located outside. The posture is changed and adjusted through the transmission of an internal bevel gear group, the rotation of a handle around the Y axis is converted into the rotation of the coaxial spraying nozzle around the X axis, and the rotating range of the coaxial spraying nozzle is 0-180 degrees. The posture is indicated by scale lines on the outer handle, the rotating angle of the handle is indicated by the outer circle, and the rotating angle of the coaxial spraying nozzle at the tail end is indicated by the inner circle. The coaxial spraying nozzle is in a round tube shape. The outlet of the coaxial spraying nozzle is located on the longitudinal axis of a round tube. An embedded curing light source is adopted for one part of the coaxial spraying nozzle. The outer circle of the coaxial spraying nozzle has a material outlet effect and a light shielding effect. Illumination light sources are evenly distributed on the periphery of the coaxial spraying nozzle.By means of the continuous illumination and interval feeding segmented curing strategy, the material curing uniformity is ensured, and efficiency is improved.

Owner:XI AN JIAOTONG UNIV

A process of powder metallurgy formula for belt pulley

ActiveCN104759614BSurface Hardness SimplifiedHardness simplifiedTurbinesOther manufacturing equipments/toolsSulfurGraphite

The invention discloses a pulley powder metallurgy formula, which is characterized in that it is composed of the following components in mass percentage: iron powder balance, graphite 0.3-0.7%, copper powder 1.5-2.5%, zinc stearate 0.6-1.0% , sulfur 0.1~0.3%, nickel powder 0.3~1.5%, molybdenum powder 0.3~1.0%; the invention also discloses a process for the powder metallurgy formula of the pulley, the process steps include: mixing, pressing, sintering, cooling, shaping, Degreasing, sandblasting, blackening and other steps. The technical process of the powder metallurgy formula of the belt pulley provided by the invention has reasonable formula, suitable hardness of the belt pulley, simplified process, high production efficiency and low production cost.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

Laser cladding repairing process of valve seat with high hardness and less deformation

ActiveCN103668036AImprove corrosion resistanceImprove wear resistanceMolten spray coatingLaser beam welding apparatusHardnessAlloy

The invention relates to a laser cladding repairing process of a valve seat. The process comprises the following steps: A, treating the surface of the valve seat, and carrying out failure analysis on the valve seat; B, optimizing the technical parameters for laser cladding according to the failure analysis results of the valve seat, wherein the alloy powder adopted comprises the following components in percentage by weight: 0.5-1% of C, 19-23% of Cr, 1.5-2% of B, 1-3% of Si, 0.05-0.5% of Mo, 0.05-0.5% of Mn, 7-9% of W, 2.5-4% of Ni and the balance of C; and C, detecting. According to the laser cladding repairing process of the valve seat, laser cladding is carried out on the surface of the valve seat, so that the size of the valve seat is recovered to meet the using demands, and the corrosion resistance and wear resistance of the repaired valve seat exceed the original performances.

Owner:临沂人才数字科技集团有限公司

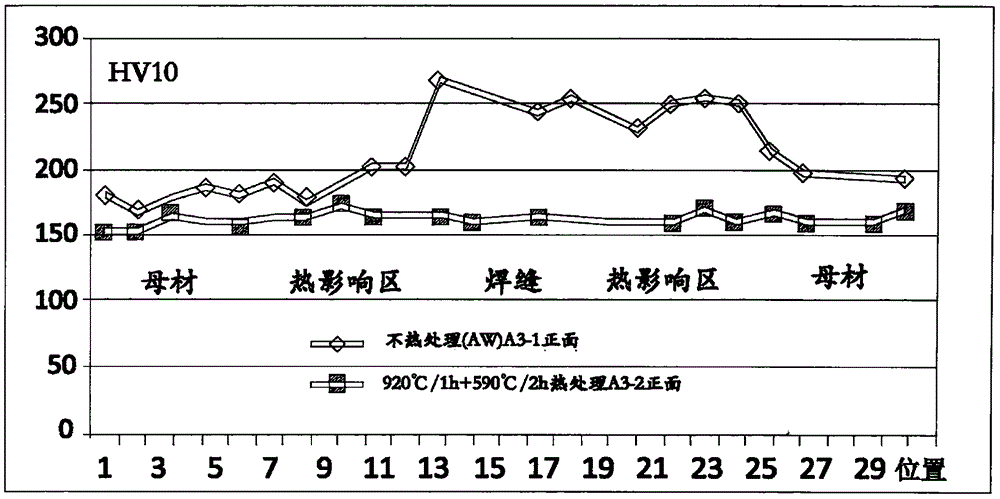

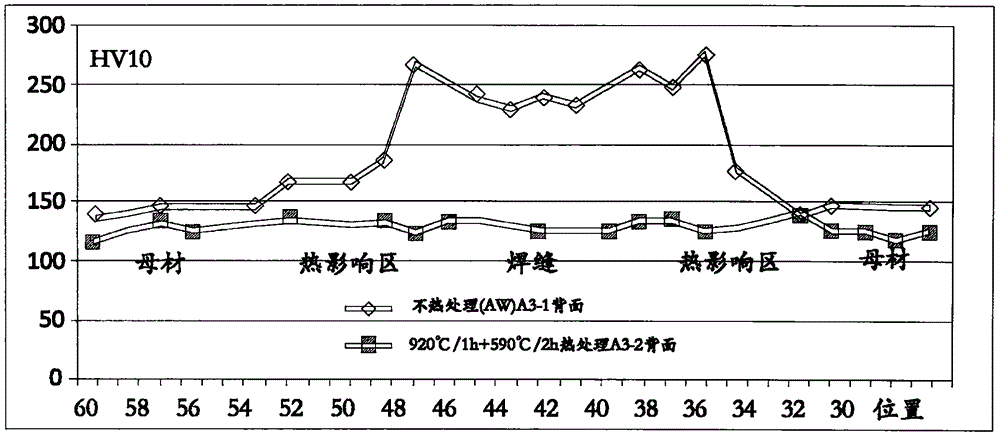

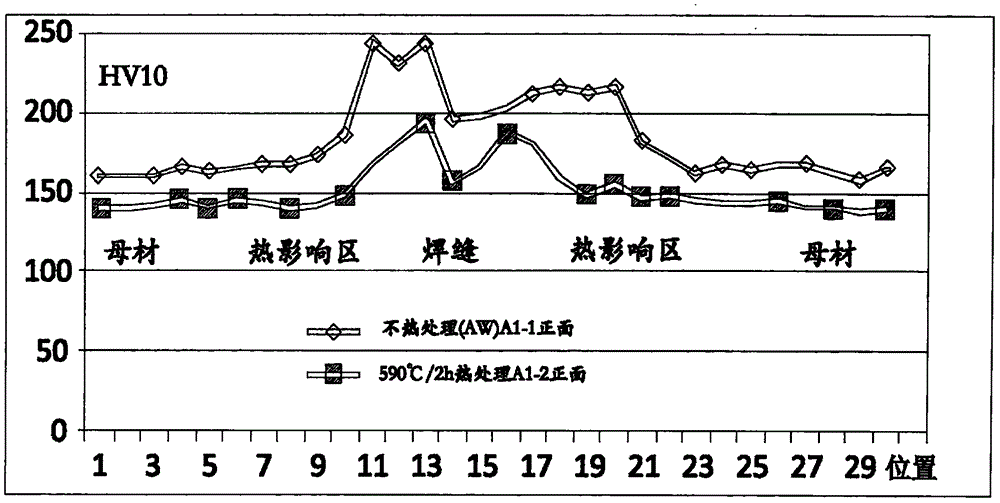

Treatment method capable of enabling harness of steel welding joints to be uniform

InactiveCN106350654AMeet hardness uniformityMeet the hardness requirementsFurnace typesHeat treatment furnacesHeat-affected zoneHardness

The invention provides a treatment method capable of enabling the harness of steel welding joints to be uniform. Steel welding pieces are subjected to normalizing heat treatment under the condition of 920 DEG C per hour and then are subjected to tempering heat treatment at 590 DEG C. The treatment method adopts a normalizing and tempering combining method, so that the aims of eliminating the welding stress of the steel welding piece and stabilizing the size of the welding piece can be fulfilled successfully, the difference between Vickers hardness values of any two points of a welding line on the same section of the steel (low-alloy steel) welding joints, a heat affected zone and a parent metal can be guaranteed to be less than or equal to 20 HV10, and the hardness of the welding line of the welding joints of the steel welding piece, the heat affected area and the parent metal is uniform, so that the requirements of a special welding structure (such as mirror plate parts in hydroelectric equipment) on the hardness uniformity of the welding joints and high size precision are met.

Owner:四川迪瑞机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com