Treatment method capable of enabling harness of steel welding joints to be uniform

A technology of uniform hardness and welded joints, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems such as the inability to guarantee the maximum Vickers hardness difference, inability to guarantee uniformity, etc., to achieve uniform hardness, stable weldment size, eliminate welding effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0019] The invention provides a processing method for uniform hardness of steel welded joints. The low-alloy steel welded parts with a thickness of 40mm are subjected to normalizing heat treatment at 920°C / 1h, and then tempered at 590°C / 2h.

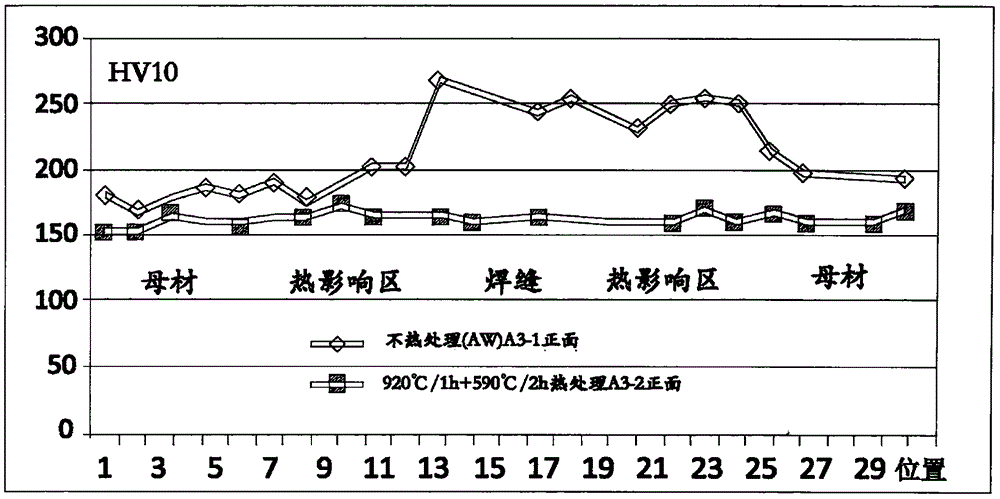

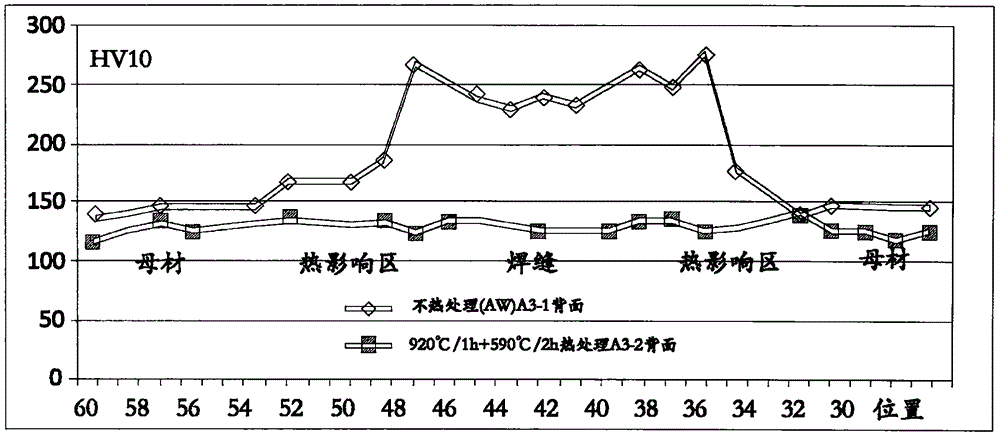

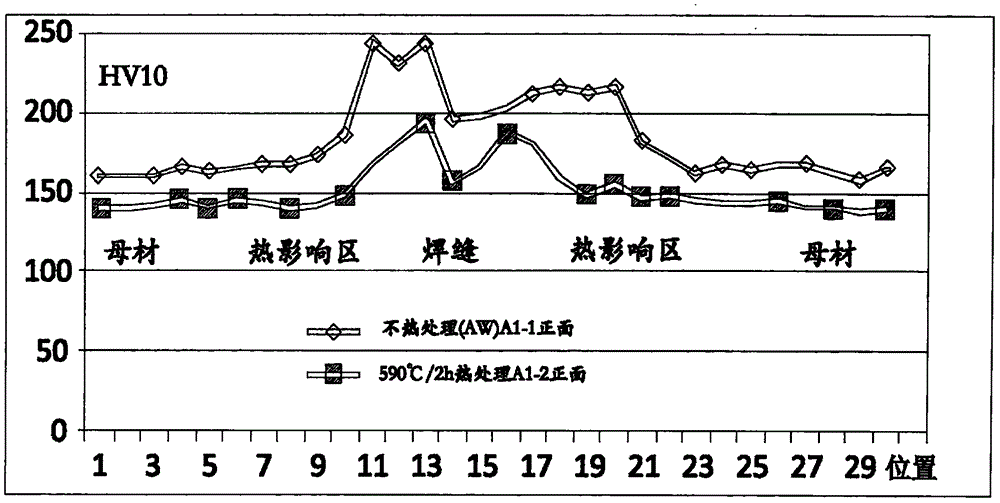

[0020] In order to verify the effect of this embodiment, the welded parts of the same material and the same welding process were subjected to tempering heat treatment at 590°C / 2h, tempering heat treatment at 640°C / 2h, and no post-weld heat treatment (that is, AW in the welded state). Sample, carry out Vickers hardness comparative measurement together with the sample of this embodiment, the measurement result is as follows Figure 1 to Figure 6 shown.

[0021] from Figure 1 to Figure 2 It can be seen from the test results that the weld seam, heat-affected zone and base metal The HV10 hardness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com