Hot-rolled wire rod for hardening-tempering-free hot galvanizing bolt and production technology of hot-rolled wire rod

A hot-rolled wire rod and production process technology, applied in metal rolling, temperature control, etc., can solve the problems of restricting the normal production of bolts, achieve the effects of easy control of the production process, reduce production costs, and shorten the incubation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Production of φ20mm hot-rolled wire rod, converter smelting molten steel, LF refining, RH refining, continuous casting into a square billet, the size is 150*150mm, the chemical composition of the billet is: C 0.30%, Si 0.40%, Mn 0.85%, P 0.025%, S0.008%, Cr 0.80%, the rest are iron and unavoidable impurity elements;

[0029] Heating the square billet to 1090°C and keeping it warm for 100 minutes, descaling the square billet with high-pressure water, the descaling high-pressure water pressure is not lower than 15MPa, after the surface is descaled, it undergoes rough rolling, intermediate rolling, finish rolling, and sizing in sequence. Among them, the temperature at the entrance of the final rolling is controlled at 760 ° C ~ 780 ° C;

[0030] Entering the Stelmore cooling line, the fan insulation cover and the fan are all closed.

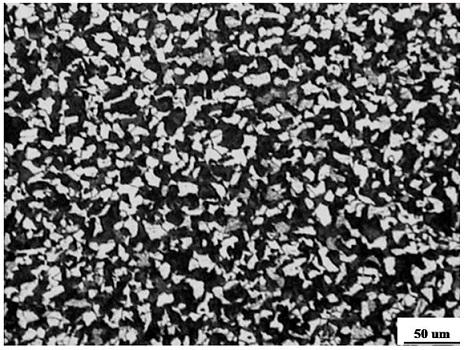

[0031] For the φ20mm hot-rolled wire rod produced in Example 1, the inspection structure is basically ferrite+pearlite, and the tensile str...

Embodiment 2

[0033] Production of φ12mm hot-rolled wire rod, converter smelting molten steel, LF refining, RH refining, continuous casting into a square billet, the size is 150*150mm, the chemical composition of the billet is: C 0.40%, Si 0.15%, Mn 0.45%, P 0.011%, S0.025%, Cr 0.92%, the rest are iron and unavoidable impurity elements;

[0034] Heating the square steel billet to 1120°C and keeping it warm for 120min, descaling the surface of the square billet with high-pressure water, the water pressure is not lower than 15MPa, and going through rough rolling, intermediate rolling, finish rolling, reducing and sizing in sequence, and the final rolling temperature is controlled at 790°C ~810°C;

[0035] Entering the Stelmore cooling line, the fan insulation cover and the fan are all closed.

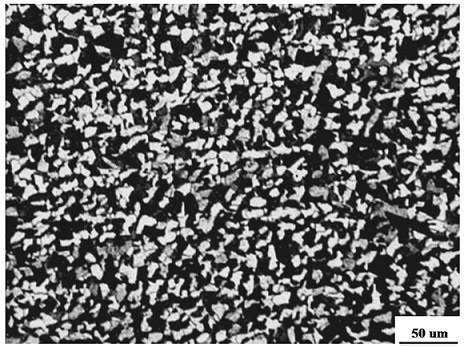

[0036] For the φ12mm hot-rolled wire rod produced in Example 2, the inspection structure is basically ferrite + pearlite, and the tensile strength is 660MPa-680MPa. After drawing, cold heading and que...

Embodiment 3

[0038] Production of φ16mm hot-rolled wire rod, converter smelting molten steel, LF refining, RH refining, continuous casting into a square billet, the size is 150*150mm, the chemical composition of the billet is: C 0.35%, Si 0.23%, Mn 0.56%, P 0.012%, S0.009%, Cr 1.10%, and the rest are iron and unavoidable impurity elements.

[0039]Heating the square billet to 1130°C and keeping it warm for 140 minutes; descaling the surface of the square billet with high pressure water, the pressure of the high pressure water is not lower than 15MPa, and then going through rough rolling, intermediate rolling, finish rolling, reducing and sizing in turn, after rolling, the final The rolling temperature is controlled at 800℃~820℃;

[0040] Entering the Stelmore cooling line, the fan insulation cover and the fan are all closed.

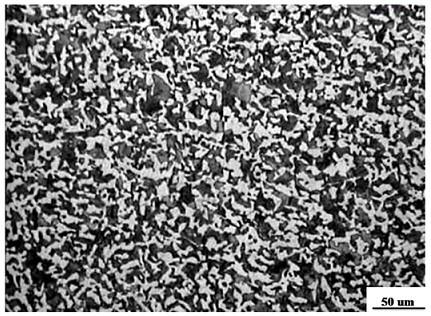

[0041] The φ16mm hot-rolled wire rod produced in Example 3 has a ferrite+pearlite inspection structure and a tensile strength of 655MPa to 685MPa. After drawing, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com