Production method of wear-resistant steel plate

A wear-resistant steel plate and a production method technology, applied in the field of iron and steel smelting, can solve the problems of reducing the internal stress of the wear-resistant steel plate, unable to achieve direct heating of hot blanks, reducing the impact toughness of materials, etc., to eliminate organizational stress and thermal stress, reduce The natural cracking tendency of steel plate and the effect of improving low temperature impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

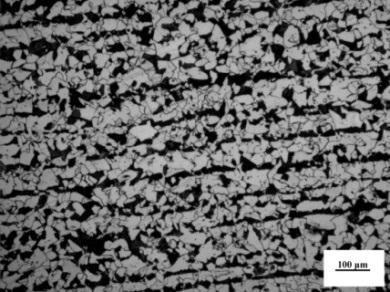

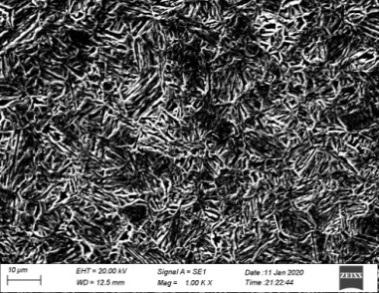

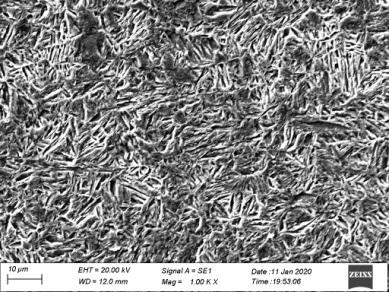

[0058] The production process of NM400 wear-resistant steel plate is as follows:

[0059] The mass percentage of chemical composition of steel is: C=0.20, Si=1.05, Mn=1.33, P=0.015, S=0.003, Ti=0.078, B=0.0020, Ni=0.18, and the balance is Fe and unavoidable impurities.

[0060] Production process route: hot metal desulfurization→converter smelting→refining→vacuum treatment→continuous casting→rolling→quenching→tempering.

[0061] (1) Desulfurization of molten iron: ensure that the slag removal is clean before the molten iron enters the converter; the sulfur content of the molten iron after treatment is S=0.009%;

[0062] (2) Converter smelting: End point control target: C=0.10%, P=0.010%, S=0.001%; ensure C-T coordinated tapping, T: 1563°C, end point O: 664ppm; tapping time 5min; use slag stop cone Combined with the sliding plate to stop the slag and tap the steel, the slag thickness is 40mm; during the tapping process, add 1720Kg of ferrosilicon, 1600Kg of metal Mn, 300Kg o...

Embodiment 2

[0089] The production process of NM450 wear-resistant steel plate is as follows:

[0090] The mass percentage of chemical composition of steel is: C=0.20, Si=1.05, Mn=1.33, P=0.015, S=0.003, Ti=0.078, B=0.0020, Ni=0.18, and the balance is Fe and unavoidable impurities.

[0091] Production process route: hot metal desulfurization→converter smelting→refining→vacuum treatment→continuous casting→rolling→quenching→tempering.

[0092] (1) Desulfurization of molten iron: ensure that the slag removal is clean before the molten iron enters the converter; the sulfur content of the molten iron after treatment is S=0.009%;

[0093] (2) Converter smelting: End point control target: C=0.10%, P=0.010%, S=0.001%; ensure C-T coordinated tapping, T: 1563°C, end point O: 664ppm; tapping time 5min; use slag stop cone Combined with the sliding plate to stop the slag and tap the steel, the slag thickness is 40mm; during the tapping process, add 1720Kg of ferrosilicon, 1600Kg of metal Mn, 300Kg o...

Embodiment 3

[0121] The production process of NM500 wear-resistant steel plate is as follows:

[0122] The mass percentage of chemical composition of steel is: C=0.20, Si=1.05, Mn=1.33, P=0.015, S=0.003, Ti=0.078, B=0.0020, Ni=0.18, and the balance is Fe and unavoidable impurities.

[0123] Production process route: hot metal desulfurization→converter smelting→refining→vacuum treatment→continuous casting→rolling→quenching→tempering.

[0124] (1) Desulfurization of molten iron: ensure that the slag is cleaned before the molten iron enters the converter; the sulfur content of the molten iron after treatment is S=0.009%.

[0125] (2) Converter smelting: End point control target: C=0.10%, P=0.010%, S=0.001%; ensure C-T coordinated tapping, T: 1563°C, end point O: 664ppm; tapping time 5min; use slag stop cone Combined with the sliding plate to stop the slag and tap the steel, the slag thickness is 40mm; during the tapping process, add 1720Kg of ferrosilicon, 1600Kg of metal Mn, 300Kg of nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Rm | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com