Battery grid and casting method thereof

A casting method, storage battery technology, applied in the direction of electrode manufacturing, electrode carrier/collector, etc., can solve the problems of poor battery performance, uneven current distribution, increased lead consumption, etc., to overcome early capacity decay and improve acceptance , the effect of reducing the amount of alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail through specific embodiments below.

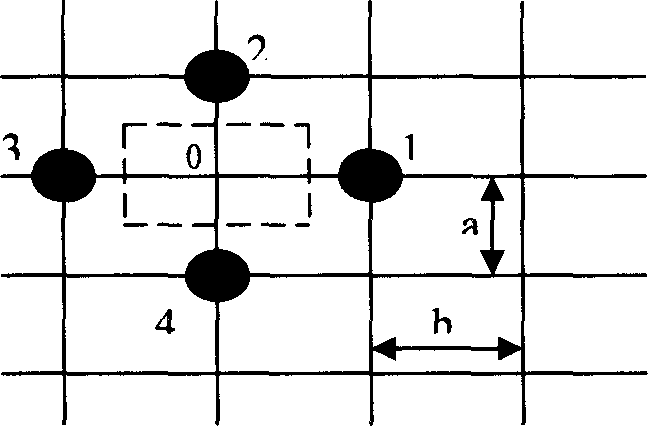

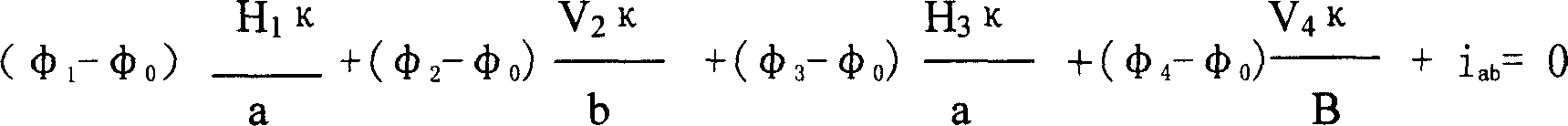

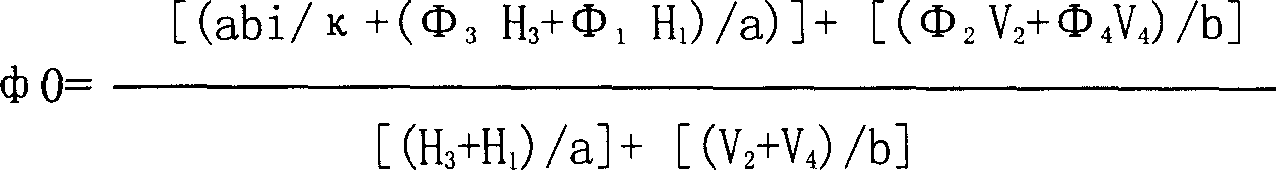

[0033] A grid used for a valve-regulated lead-acid battery, the grid includes a grid frame, and horizontal and vertical ribs fixed in the grid frame, there are 5 horizontal ribs and 3 vertical ribs, and the cross-sectional area of each horizontal rib is 1.5mm 2 , the cross-sectional area of the vertical rib is 1.83mm 2 , the total cross-sectional area of transverse reinforcement / total cross-sectional area of vertical reinforcement (k value) is 1.37.

[0034] The manufacturing process of the grid is as follows: set the temperature of the lead pot in the casting machine to 490°C, the temperature of the lead spoon to 520°C, the temperature of the lower part of the movable mold to 220°C, the temperature of the upper part of the movable mold to 230°C, spray the mold The temperature is set at 170°C, the mold is sprayed 4-5 times, the casting speed is kept at 4-5 grids per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com