Low-alloy proportioning steelmaking method

A low-alloy, silicon-manganese alloy technology, applied in the field of metallurgy, can solve problems such as the large increase in the cost of billet smelting, and achieve the effects of reducing the smelting cost, the amount of alloy, and the labor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

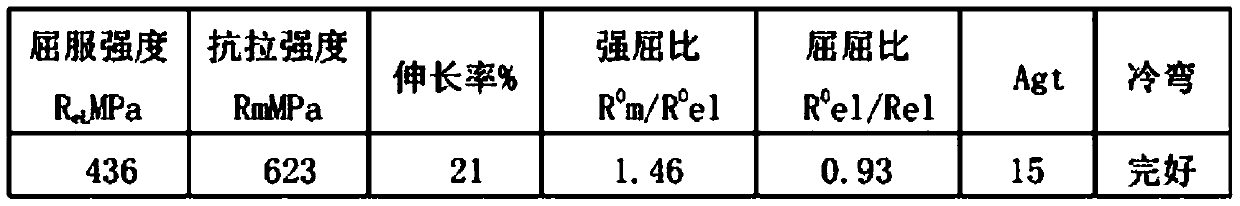

Embodiment 1

[0023] A low-alloy ratio steelmaking method, the method comprises the following steps:

[0024] S1: Crushing the vanadium-titanium iron ore through a crusher, and then melting the vanadium-titanium-iron ore in a blast furnace;

[0025] S2: Desulfurize the smelted vanadium-titanium molten iron, and the sulfur content in the desulfurized steel is less than 0.020%;

[0026] S3: Smelting the desulfurized vanadium-titanium molten iron in a converter;

[0027] S4: Adjust the ingredients, add silicon carbide and stir evenly when tapping the steel in converter smelting, then add silicon-manganese alloy and stir evenly, then add ferrochromium and stir evenly, finally add vanadium-nitrogen alloy and stir evenly, after all ingredients are added completely, Tap steel within 7 minutes -8 minutes;

[0028] S5: blowing argon to the molten steel, the adjusted molten steel is tapped into the ladle, and the argon gas is blown into the molten steel in the ladle through the porous refractory pl...

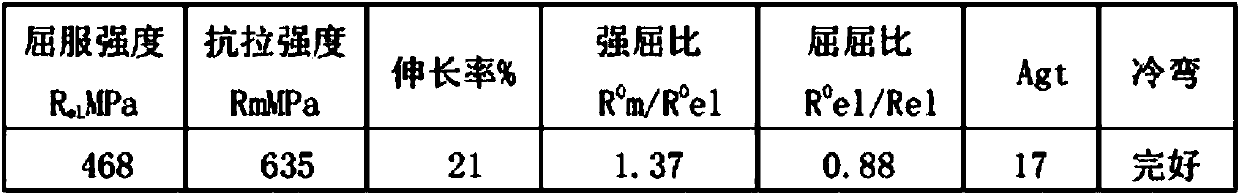

Embodiment 2

[0042] A low-alloy ratio steelmaking method, the method comprises the following steps:

[0043] S1: Crushing the vanadium-titanium iron ore through a crusher, and then melting the vanadium-titanium-iron ore in a blast furnace;

[0044] S2: Desulfurize the smelted vanadium-titanium molten iron, and the sulfur content in the desulfurized steel is less than 0.020%;

[0045] S3: Smelting the desulfurized vanadium-titanium molten iron in a converter;

[0046] S4: Adjust the ingredients, add silicon carbide and stir evenly when tapping the steel in converter smelting, then add silicon-manganese alloy and stir evenly, then add ferrochromium and stir evenly, finally add vanadium-nitrogen alloy and stir evenly, after all ingredients are added completely, Tap steel within 7 minutes -8 minutes;

[0047] S5: blowing argon to the molten steel, the adjusted molten steel is tapped into the ladle, and the argon gas is blown into the molten steel in the ladle through the porous refractory pl...

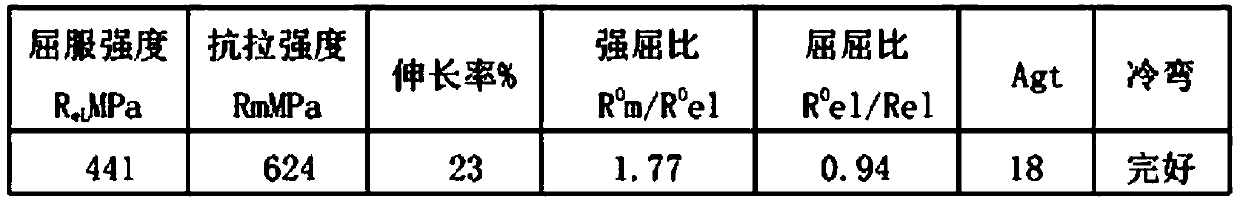

Embodiment 3

[0061] A low-alloy ratio steelmaking method, the method comprises the following steps:

[0062] S1: Crushing the vanadium-titanium iron ore through a crusher, and then melting the vanadium-titanium-iron ore in a blast furnace;

[0063] S2: Desulfurize the smelted vanadium-titanium molten iron, and the sulfur content in the desulfurized steel is less than 0.020%;

[0064] S3: Smelting the desulfurized vanadium-titanium molten iron in a converter;

[0065] S4: Adjust the composition, add silicon carbide and stir evenly when tapping the steel in converter smelting, then add silicon-manganese alloy and stir evenly, then add ferrochrome and stir evenly, finally add vanadium-nitrogen alloy and stir evenly, after all ingredients are added, Tap steel within 7 minutes -8 minutes;

[0066] S5: blowing argon to the molten steel, the adjusted molten steel is tapped into the ladle, and the argon gas is blown into the molten steel in the ladle through the porous refractory plug to push the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| strong bend ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com