Steel for heat-resisting casing pipe and manufacturing method thereof

A manufacturing method and casing technology, applied in manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of not meeting the production and use requirements of steam drive wells in oil and gas fields, reduce manufacturing costs, poor high temperature performance, etc., and achieve creep resistance Obvious, reduce production cost, improve the effect of creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

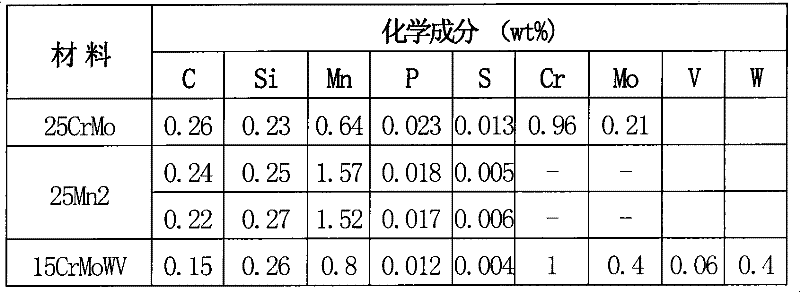

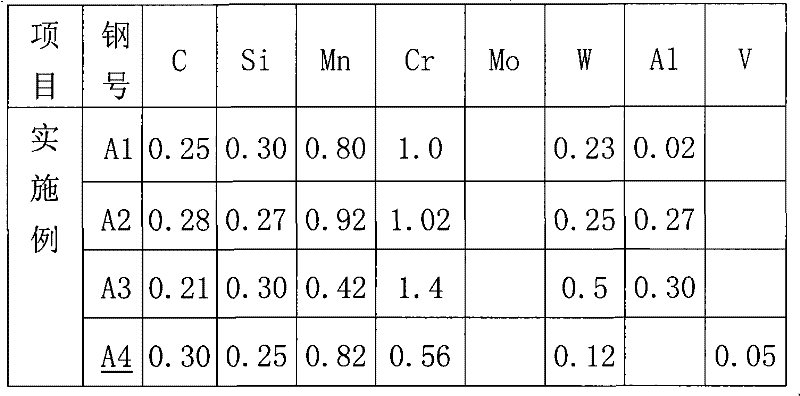

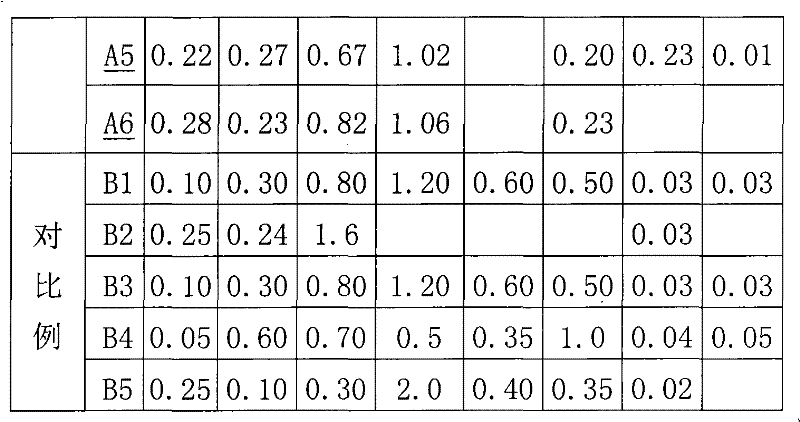

[0041] Table 2 shows the chemical composition of the test steels, A1-A6 are alloy steels of the present invention, and B1-B5 are control steels.

[0042] Table 2 The chemical composition (wt%) of steel of the present invention and existing thermal recovery casing steel

[0043]

[0044]

[0045] The seamless steel pipes of the above-mentioned test steels that have been smelted, cast and hot-rolled are first fully austenitized in the temperature range of 820°C to 920°C and then water quenched. After the steel pipes are kept at the above temperature for 30-60 minutes, the water Quenching can get more than 95% martensite structure. The quenched tube is then tempered at a temperature range of 580° C. to 720° C. and held for 30-90 minutes to obtain a uniform and fine sorbite structure. This type of tissue is stable in structure and performance at high temperature for a long time, and has good high-temperature durability. The yield strength at room temperature of the pipe bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com