Local centering and rotating device of cone socket

A rotary device, local technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of effective hardening depth and hardness difference stability, and achieve the effect of solving the effect of hardening depth and hardness difference stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

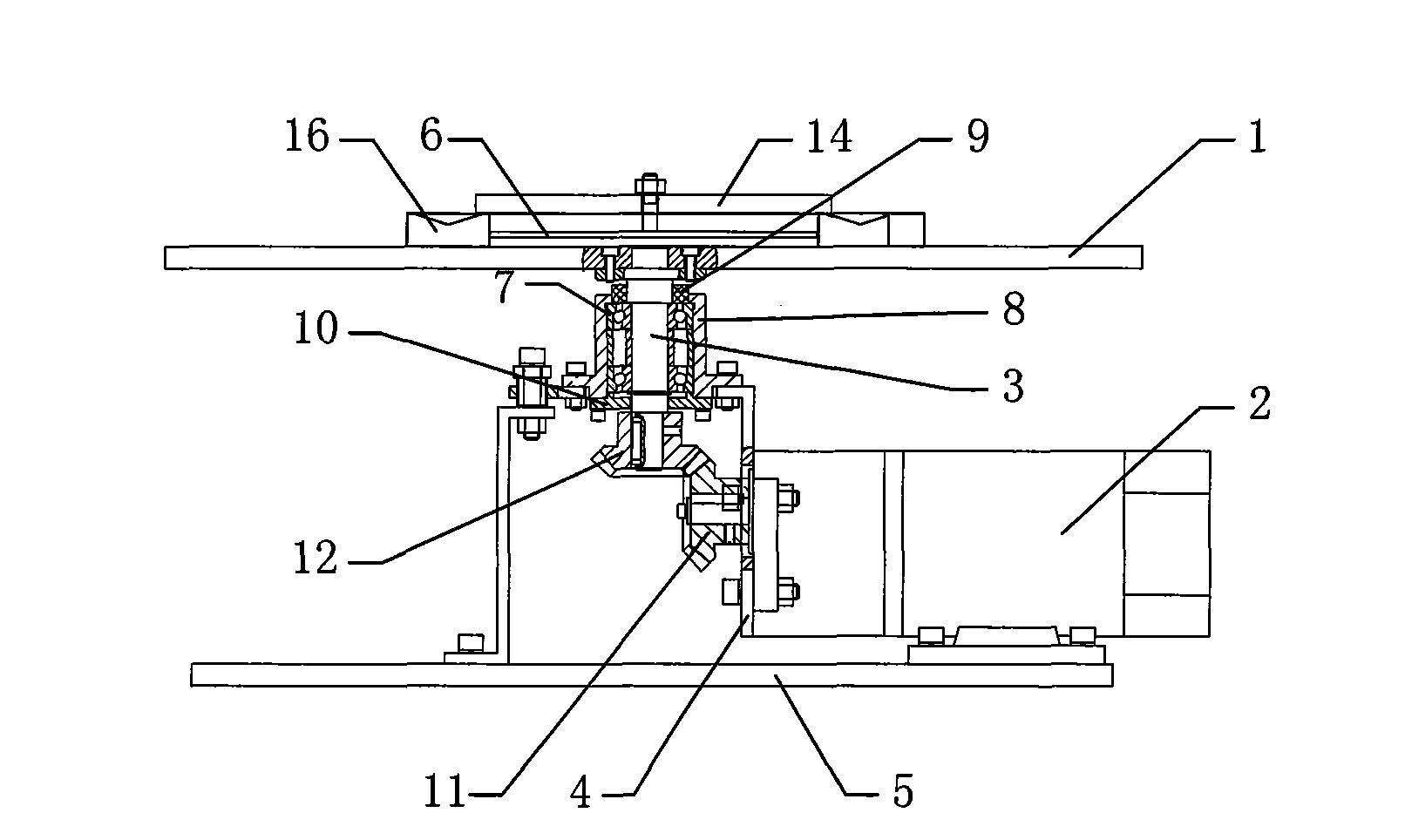

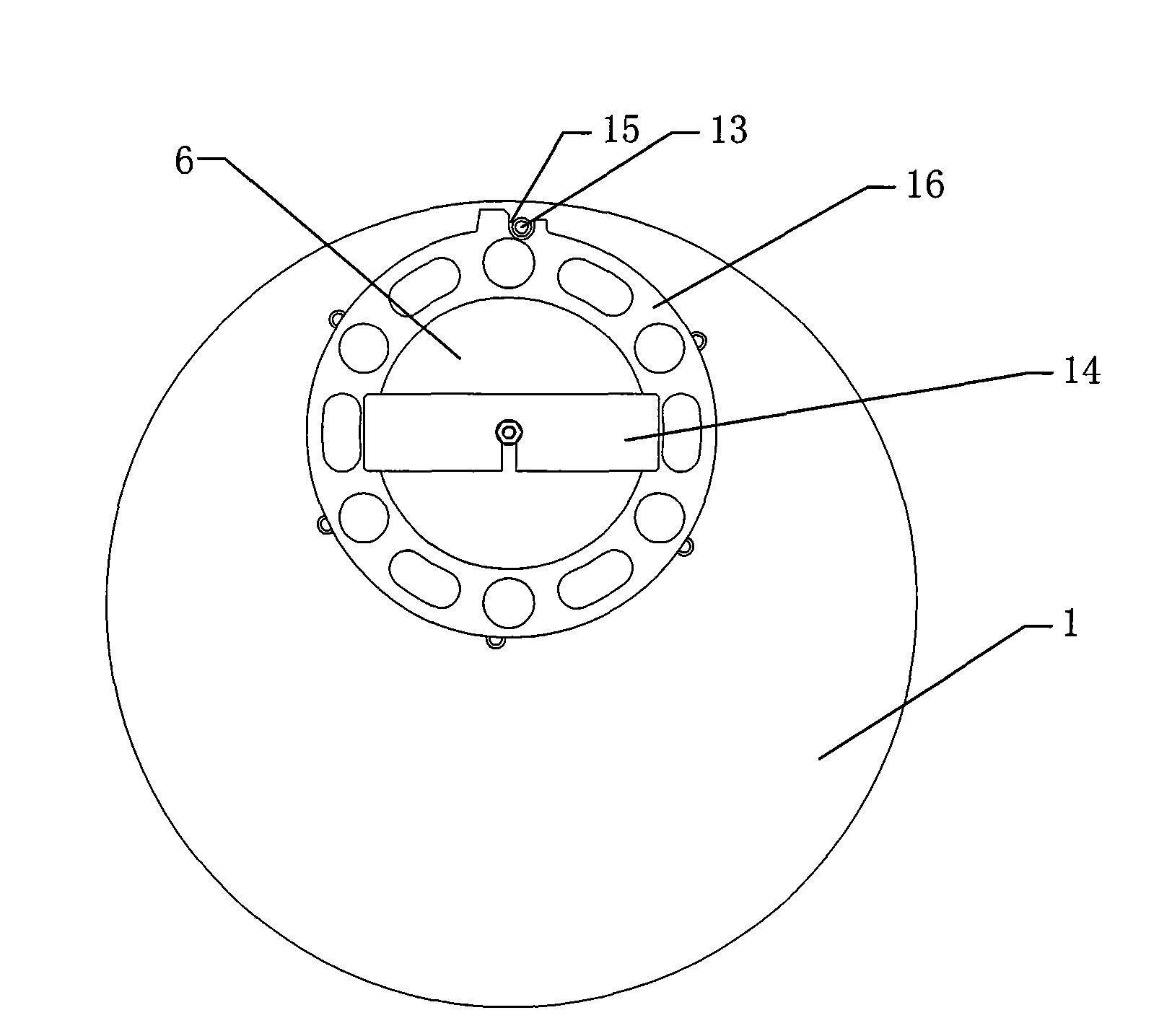

[0009] See figure 1 , figure 2 , the structure of the present invention includes a rotary disk 1 and a drive motor 2, the rotary disk 1 is installed on the rotating shaft 3, the rotating shaft 3 is installed on the bracket 4 through the bearing 7, the bracket 4 is installed on the bottom plate 5, and the rotating shaft 3 is driven by the transmission mechanism. The motor 2 is connected, and the eccentric positioning disc 6 is installed on the surface of the rotary disc 1; the rotating shaft 3 passes through the bearing 7; the bearing 7 is provided with two groups; the two groups of bearings 7 are installed in the bearing cavity of the bearing seat 8; the upper part and the lower part of the bearing cavity They are respectively sealed by skeleton sealing ring 9 and cover plate 10; the bearing housing 8 is installed on the bracket 4 by screws; the transmission mechanism includes a transverse bevel gear 11 and a longitudinal bevel gear 12; the transverse bevel gear 11 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com