Aluminum alloy heat radiator profile as well as application and on-line quenching process thereof

An aluminum alloy and radiator technology, applied in the field of aluminum alloy processing, can solve the problems of lack of online quenching process, shape asymmetry, tooth surface deformation, etc., and achieve the effect of extending trouble-free running time, ensuring overall performance, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]The on-line quenching process for aluminum alloy radiator profiles provided in this example includes the following steps: Extruding a large-sized 6061 aluminum alloy round ingot under the conditions of a mold heating temperature of 480°C and an extrusion barrel temperature of 430°C, When extruding, the extrusion ratio is 9.0, and the extrusion speed is 1m / min. After extrusion, the blower is used to blow the bottom of the extruded aluminum alloy radiator profile to ensure that the wind speed at the bottom of the aluminum alloy radiator profile is 40m / s, the wind speed on the top and both sides of the aluminum alloy radiator profile is 0m / s.

[0043] The present invention also provides the aluminum alloy radiator profile produced by the above online quenching process.

Embodiment 2

[0045] The online quenching process of the aluminum alloy radiator profile provided in this embodiment includes the following steps:

[0046] The holding temperature of large-size aluminum alloy round ingots starts at 495°C, and gradually increases to 520°C from near the extrusion to far away from the extrusion;

[0047] Under the conditions of mold heating temperature of 520°C and extrusion cylinder temperature of 460°C, large-scale 6063 aluminum alloy round ingots were extruded with an extrusion ratio of 9.2 and an extrusion speed of 1.4m / min;

[0048] After extrusion, the bottom of the extruded aluminum alloy radiator profile is blown by a fan. The wind speed at the bottom of the aluminum alloy radiator profile is 50m / s, and the wind speed at the top and both sides of the aluminum alloy radiator profile is 0m / s.

[0049] The present invention also provides the aluminum alloy radiator profile produced by the above online quenching process.

Embodiment 3

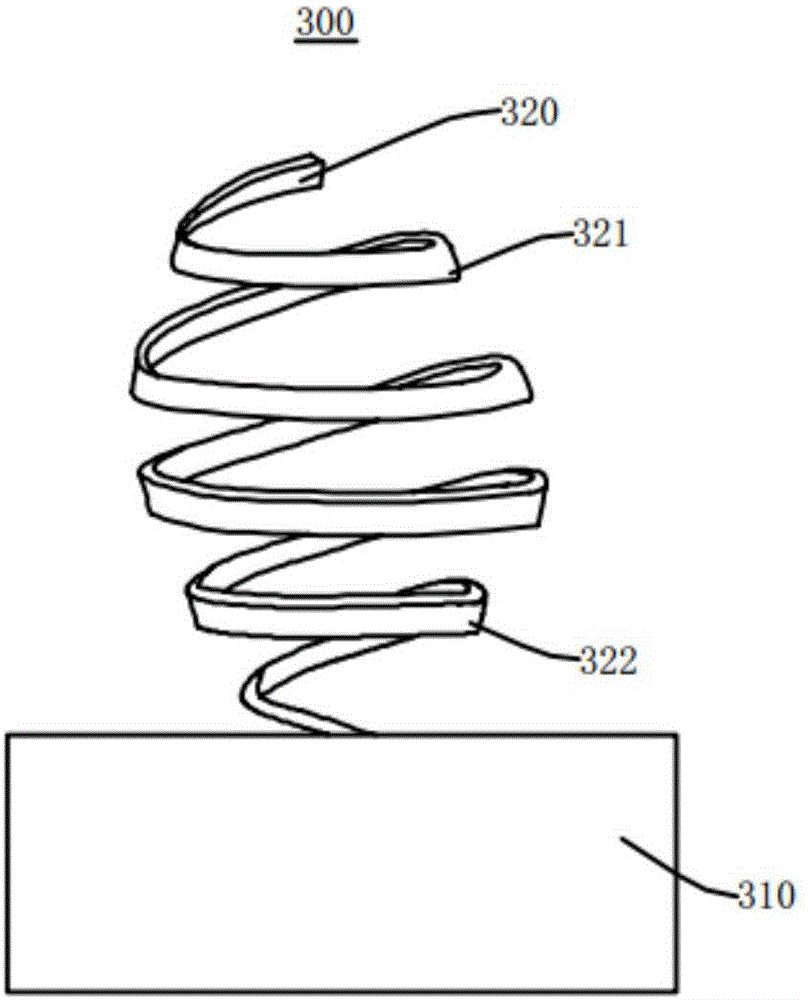

[0051] The on-line quenching process of aluminum alloy radiator profiles provided in this embodiment includes the following steps: under the conditions of mold heating temperature of 490°C and extrusion cylinder temperature of 450°C, extruding large-sized 6061 aluminum alloy round ingots, During extrusion, the extrusion ratio was 9.1, and the extrusion speed was 1.1m / min. After extrusion, the blowing device 300 was used to blow the bottom of the extruded aluminum alloy radiator profile, and the bottom of the aluminum alloy radiator profile The wind speed is 45m / s, and the wind speed on the top and both sides of the aluminum alloy radiator profile is 0m / s.

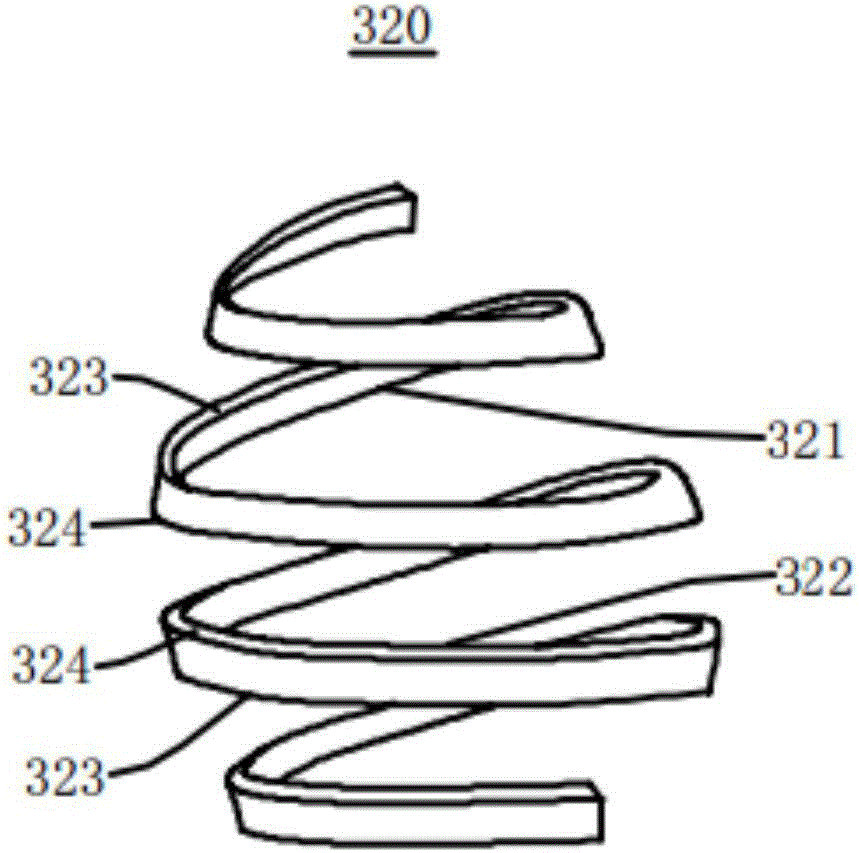

[0052] Wherein, the blowing device 300 is arranged under the profile of the aluminum alloy radiator, and the blowing device 300 includes a fan body 310 and a drainage piece 320, see figure 1 One end of the flow guide 320 is connected to the central position of the fan body 310, the other end is a free end and extends spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com