Patents

Literature

86results about How to "Improve precipitation strengthening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

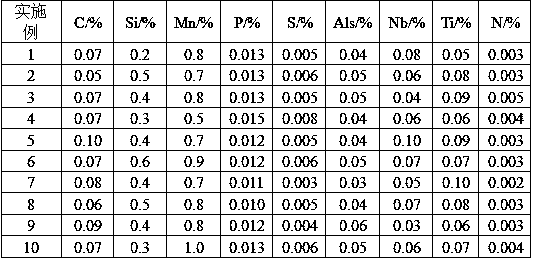

Ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level and manufacturing method thereof

ActiveCN102839321AIncrease the effective Ti contentImprove precipitation strengthening effectCold formedLaminar cooling

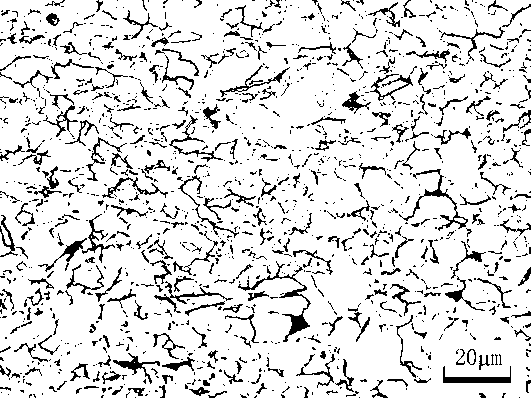

An ultrathin hot-rolled sheet strip with yield strength more than or equal to 500MPa level comprises the chemical components by weight: 0.02-007%of C, less than or equal to 0.50% of Si, 0.50-1.40% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.11% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O, or 0.17-0.20% of C, less than or equal to 0.50% of Si, 0.50-0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.03-0.08% of Ti, 0.01-0.20% of Als, less than or equal to 0.005% of N, less than or equal to 0.004% of O. The process comprises melted iron desulfuration, converter blowing, argon blowing, LF furnace refining, continuous casting, rotary descaling, soaking pit soaking, descaling, seven-frame finish rolling, stream cooling and coiling. The ultrathin hot-rolled sheet strip has the advantages that the addition of the alloying element is low, the mechanical property is as follows: the yield strength is more than or equal to 500MPa, the product thickness is less than or equal to 1.4mm, the sheet shape is good, the production flow is short, and excellent cold forming and welding performances are achieved.

Owner:武汉钢铁有限公司

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-strength wrought magnesium alloy and preparation method thereof

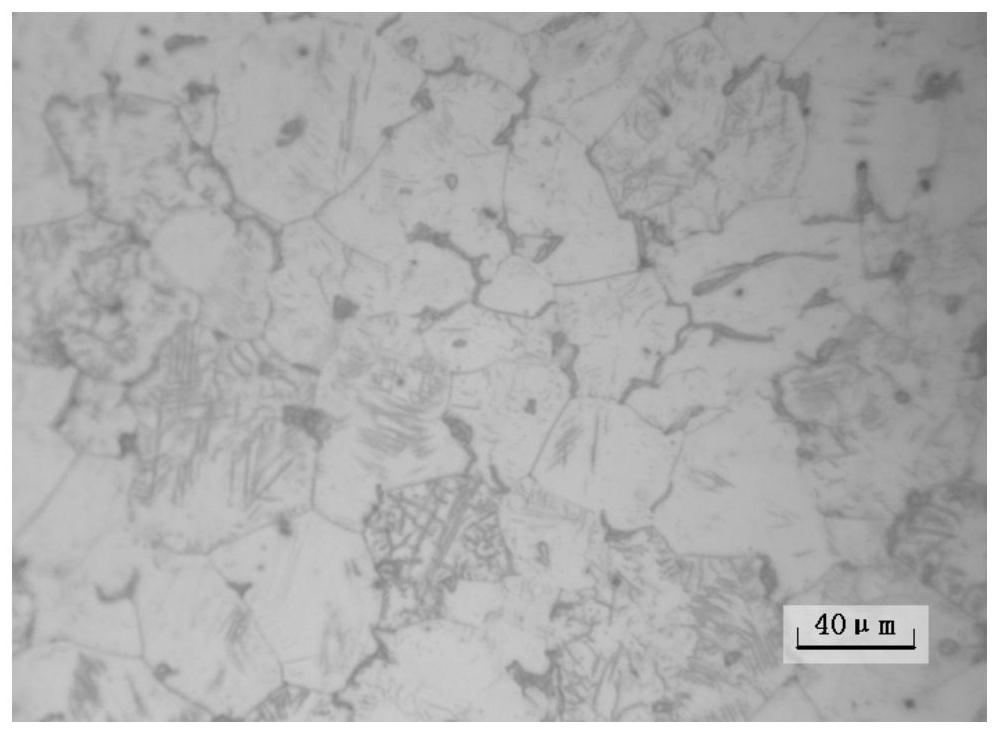

ActiveCN105220041AHigh strengthImprove precipitation strengthening effectRare-earth elementCrystallite

The invention discloses high-strength wrought magnesium alloy and a preparation method thereof and belongs to the technical field of light metal materials. The high-strength wrought magnesium alloy comprises the following components in percentage by weight: 2.0-6.5% of Zn, 0.1-3.0% of RE, 0.1-2.0% of Ca and the balance of Mg and inevitable impurities; the high-strength wrought magnesium alloy also can comprise grain refiners Mn and / or Zr. Zn is a main strengthening element in the alloy, and can improve the room temperature strength of magnesium alloy through solid solution strengthening and aging precipitation strengthening; Ca is used for promoting precipitation, refining grains and improving high-temperature strength of alloy; and a small amount of RE is used for restraining recrystallization, refining deformed alloy grains, regulating texture and improving plasticity of alloy. According to the invention, by replacing expensive rare earth elements with cheap common alloying elements, a strengthening effect similar to that of rare earth is generated, the rare earth content is completely replaced or lowered and the cost of alloy is reduced while strength is guaranteed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

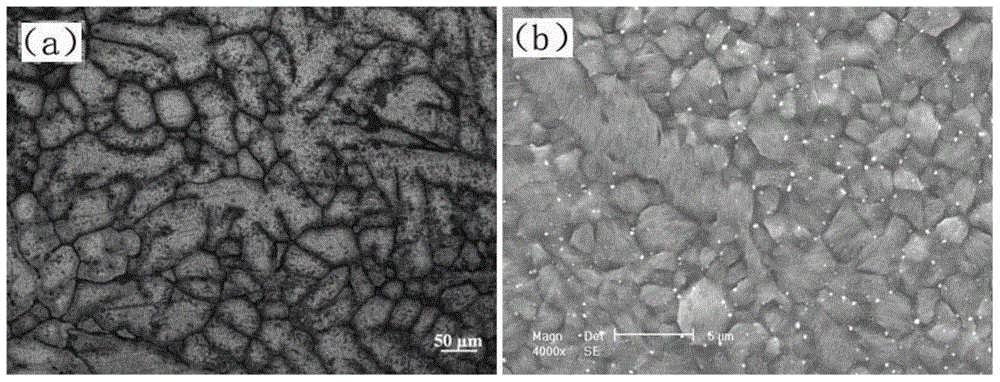

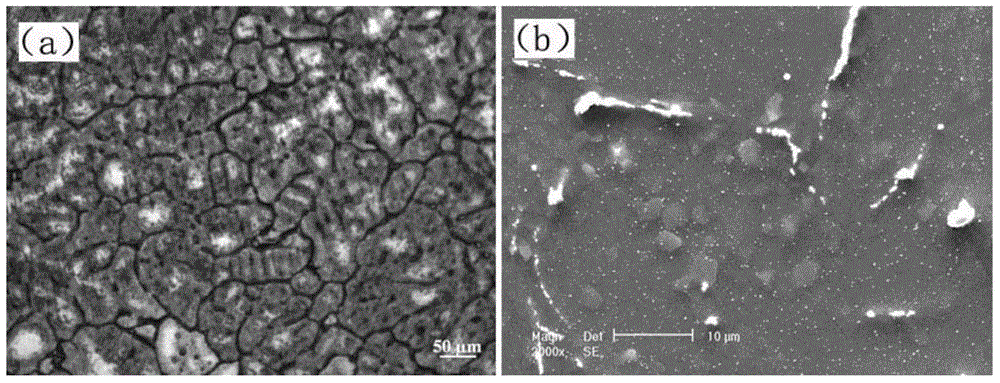

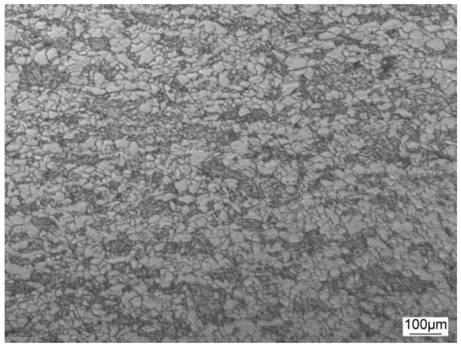

V-N microalloyed Q550 grade medium plate and preparation method thereof

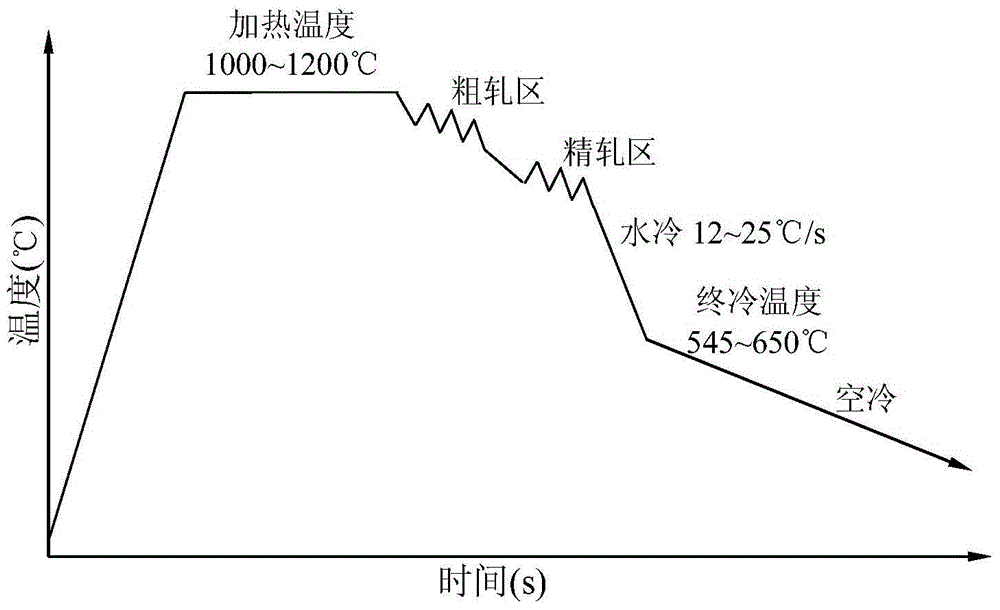

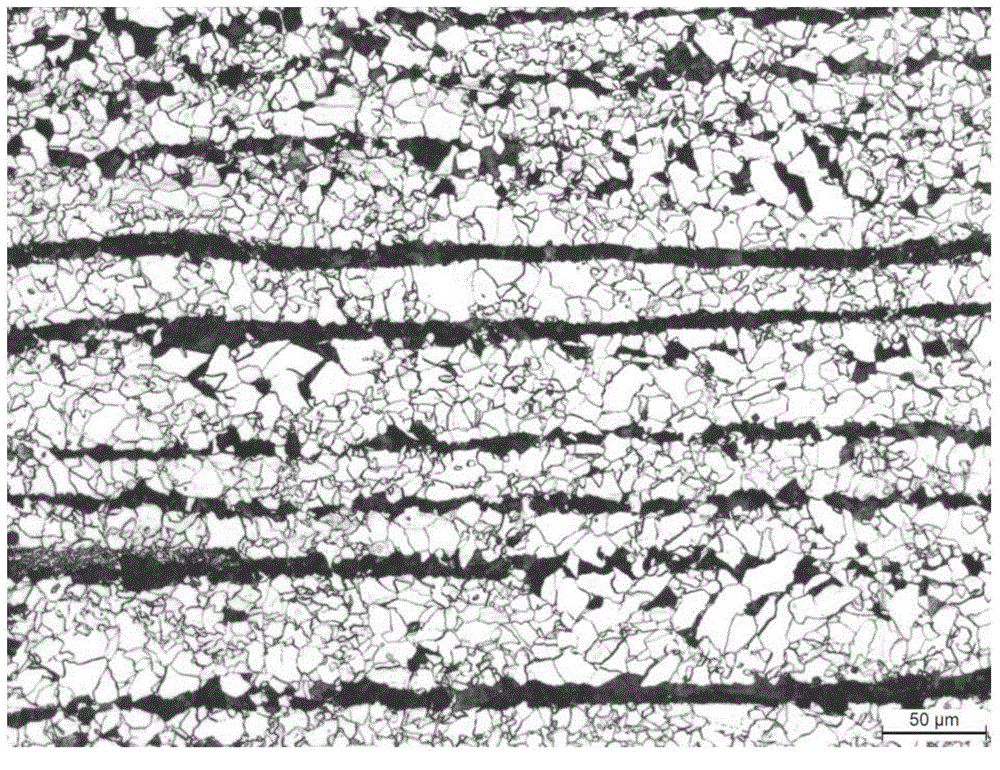

The invention aims at providing a V-N microalloyed Q550 grade medium plate and a preparation method thereof which are specific to the condition that in the prior art, the Q550 grade medium plate expensive alloy is in large consumption and the preparation process is complex. The chemical constitutions of the steel are as follows by weight percentage: 0.06 to 0.12 percent of C, 1.20 to 2.00 percent of Mn, 0.10 to 0.50 percent of Si, 0.002 to 0.01 percent of S, 0.003 to 0.01 percent of P, 0.01 to 0.05 percent of Al, 0.06 to 0.15 percent of V, 0.01 to 0.02 percent of N and the balance of Fe and other unavoidable impurities; the preparation method comprises the steps of heating a steel billet to 1000 to 1200 DEG C along with a furnace and performing heat preservation for 3 to 4 hours, and further carrying out hot rolling on the steel billet to form a hot rolled plate being 20 to 50mm in thickness, wherein the beginning temperature and the finishing temperature in a rough rolling stage are respectively 1030 to 1150 DEG C and 980 to 1020 DEG C, and the beginning temperature and the finishing temperature in a finish rolling stage are respectively 908 to 925 DEG C and 820 to 845 DEG C; cooling the plate by water to 545 to 650 DEG C after the hot rolling, and then cooling by air to room temperature. The plate is a high-toughness ultra-low-carbon medium-manganese medium plate, and the metallographic structure of the plate is a fine crystalline ferrite, a pearlite and an acicular ferrite; the method is simple in operation process, has no need of quenching and tempering treatment, and is easy to realize industrial production.

Owner:NORTHEASTERN UNIV LIAONING

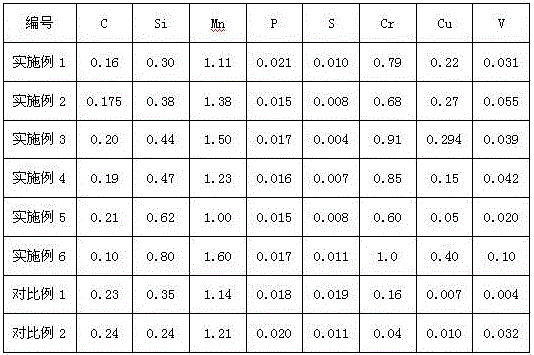

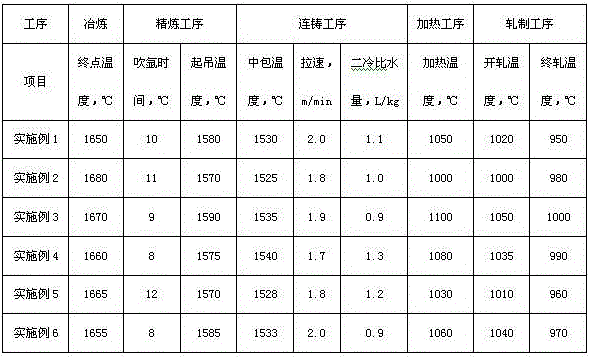

400MPa-level vanadium-containing anti-seismic anti-corrosion rebar and production method thereof

InactiveCN105886902AImproved strength and hydrogen corrosion resistanceStable corrosion resistance and mechanical propertiesRebarCorrosion resistant

The invention discloses a 400MPa-level vanadium-containing anti-seismic anti-corrosion rebar and a production method thereof. The rebar is prepared from, by weight, 0.10-0.21% of C, 0.30-0.80% of Si, 1.0-1.60% of Mn, 0.6-1.0% of Cr, 0.05-0.40% of Cu, 0.020-0.10% of V, and the balance Fe and unavoidable impurities, the amount of P is smaller than or equal to 0.030%, and the amount of S is smaller than or equal to 0.030%. The production method includes converter or electric furnace smelting, steel ladle microalloying, external refining, continuous casting, casting blank heating, rolling and cooling bed air cooling. The corrosion resistance of the rebar is improved by controlling the content of Cr and Cu in steel, technological parameters are controlled strictly, the V(C,N) precipitation strengthening effect is promoted under the condition of ensuring steel-plastic tenacity, and the 400MPa-level vanadium-containing anti-seismic anti-corrosion rebar excellent in performance is obtained.

Owner:HEBEI IRON AND STEEL

Tensile strength 800-MPa-class hot rolling complex phase steel and production method thereof

InactiveCN110343961AHigh expansion rateQuality improvementProcess efficiency improvementMetallurgyMartensite

The invention discloses tensile strength 800-MPa-class hot rolling complex phase steel and a production method thereof and belongs to the field of metal material and preparation thereof. The tensile strength 800-MPa-class hot rolling complex phase steel comprises the main components of 0.05%-0.09% of C, 0.10%-0.30% of Si, 1.40%-2.00% of Mn, 0.010%-0.050% of Al, 0-0.020% of P, 0-0.008% of S, 0.010%-0.070% of Nb, 0.08%-0.14% of Ti, 0.10%-0.25% of Mo, and the balance Fe and inevitable impurities. Through treatment of casting blank hot charging, hot continuous rolling and related process steps, yield strength is 700 MPa or above, tensile strength is 800 MPa or above, the hole expansion rate is larger than 60%, the microstructural type is a mixed structure composed of ferrite, granular bainiteand a small amount of island-shaped martensite, after the product is subjected to continuous pickling, product surface quality and performance are excellent, and the product is widely used for manufacturing automobile chassis structural parts, safety belt supports, bumpers and other parts.

Owner:MAANSHAN IRON & STEEL CO LTD

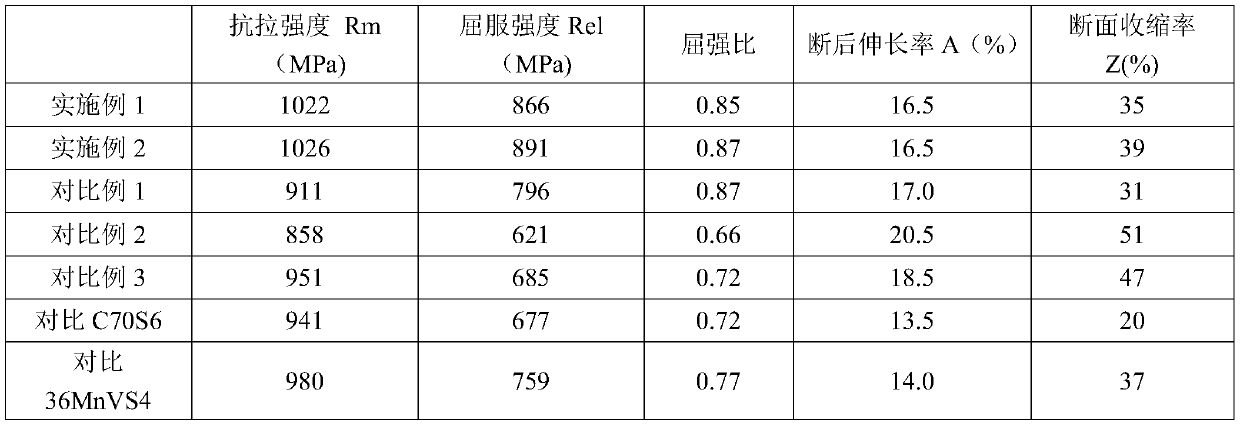

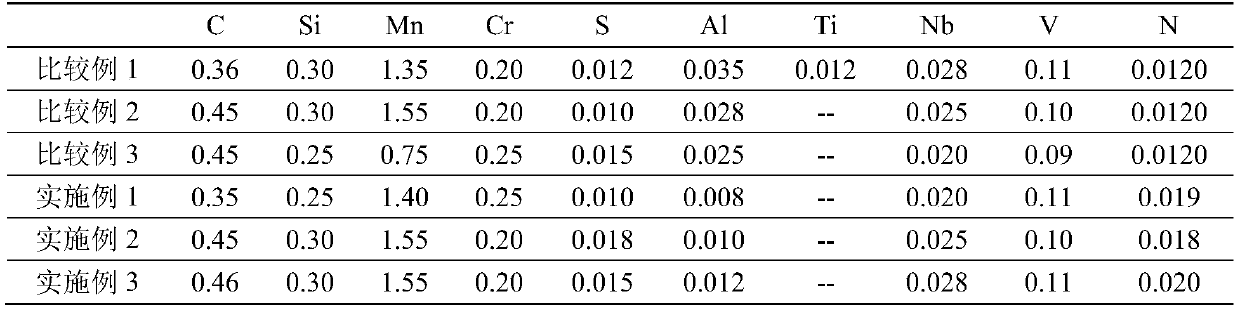

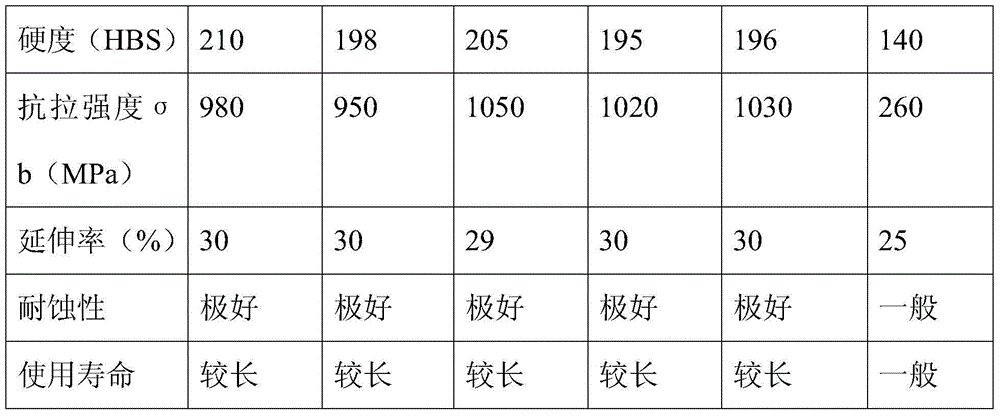

High-strength and high-yield-ratio non-quenched and tempered steel for automobile engine stretch-broken connecting rod and production method thereof

The invention discloses high-strength and high-yield-ratio non-quenched and tempered steel for an automobile engine stretch-broken connecting rod and a production method thereof. The steel comprises the following chemical components in percentage by weight, 0.40-0.50% of C, 0.40-0.60% of Si, 1.00-1.30% of Mn, 0.040-0.060% of S, 0.10-0.20% of V, 0.020-0.035% of Nb, 0.10-0.30% of Cr, 0.10-0.30% of Ni, 0.010-0.020% of N, and the balance Fe and impurity elements. Through the combination of the group distribution ratio and a controlled rolling and controlled cooling process, the mechanical propertyRel of the connecting rod material is greater than or equal to 850 MPa, the Rm is greater than or equal to 1000 MPa, and the yield ratio can reach more than 0.84, so that the light weight of an automobile engine is facilitated.

Owner:ZENITH STEEL GROUP CORP +1

Small-scale finish-rolled twisted steel and production method thereof

ActiveCN104328338AImprove distributionEvenly distributedManufacturing convertersChemical compositionRebar

The invention provides small-scale finish-rolled twisted steel and a production method thereof. The small-scale finish-rolled twisted steel comprises the following chemical components in percentage by mass: 0.40-0.50% of C, 1.5-1.8% of Si, 0.8-1.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.08-0.13% of V, 0.008-0.01% of Als and the balance of Fe and inevitable impurities. The production method comprises the following steps: desulfurizing molten iron, smelting in a converter, blowing argon, performing protective casting into a square blank of 200*200mm<2>, heating the square blank, rolling, performing controlled cooling after rolling, and performing air-cooling in a cooling bed. The finish-rolled twisted steel provided by the invention is stable in property, and the production method is simple and easy to operate.

Owner:武汉钢铁有限公司

High-strength and high-toughness cast magnesium alloy and preparation method thereof

The invention discloses high-strength and high-toughness cast magnesium alloy. The high-strength and high-toughness cast magnesium alloy is Mg-Bi-Ca-Zn alloy and composed of, by weight, 3.0-8.0% of Bi, 0.1-1.2% of Ca, 0.1-2.0% of Zn and the balance Mg. According to the invention, Bi serves as the main alloy element, lots of Mg3Bi2 phases are formed through the simple alloying way, few Ca elements and Zn elements are adopted for improving the strength of the alloy, the Ca elements effectively improve the morphology and distribution of the Mg3Bi2 phases so as to improve the plasticity of the alloy, and therefore the high-strength and high-toughness cast magnesium alloy can be developed for the Mg-Bi alloy series. The cast magnesium alloy is high in strength and plasticity, the tensile strength of the alloy with the components optimized reaches about 270 MPa, the yield strength of the alloy reaches about 145 MPa, and the ductility of the alloy reaches about 10%. Thus, the strength can be as high as that of rare earth magnesium alloy, and the ductility is high.

Owner:山东汇达蠕墨装备有限公司

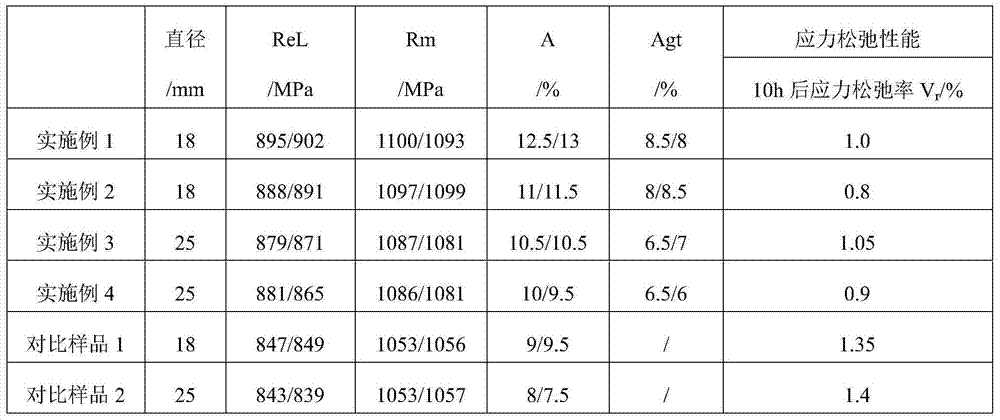

Hot-rolled round steel and preparation method thereof

ActiveCN111549282AMeet production requirementsMeet the process requirementsFurnace typesHeat treatment furnacesAustenite grainAssembly line

The invention relates to hot-rolled round steel and a preparation method thereof. After a steel billet is austenitized and heated, assembly line type rolling is carried out in four steps that descaling and first-time temperature holding are carried out; reciprocating cogging is carried out to obtain an intermediate square billet; head cutting and temperature holding before continuous rolling are carried out, specifically, the intermediate square billet is subjected to head cutting before entering a continuous mill, and secondary air cooling temperature holding is carried out, so that deformedaustenite grains are fully recrystallized, and meanwhile, carbonitrides of Nb and V are fully precipitated; continuous rolling and water passing after rolling are carried out, specifically, the intermediate square billet is rolled into a round steel bar, and the finish rolling temperature of the round steel is controlled to be higher than A<r>3; and the rolled round steel is taken out of the continuous mill and then cooled by passing through water, the structure enters a pseudo-pearlite area from an austenite non-recrystallization area, and the round steel rapidly passes through a ferrite precipitation interval to obtain as many fine lamellar pearlite structures as possible. In the round steel sawing process, due to phase change latent heat and core temperature return of the round steel, surface temperature returns to promote the carbonitrides of the Nb and the V which are not precipitated in time to be precipitated, and carbonitride grains precipitated in the low-temperature intervalare finer.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL +1

Annular joint and processing method

Owner:NINGBO HUI TONG MACHINE CONNECTION PARTS

900 MPa-stage high-cold-bending-property low-alloy high-strength steel plate and preparation method thereof

A 900 MPa-stage high-cold-bending-property low-alloy high-strength steel plate comprises the chemical components of, by weight, 0.05-0.1% of C, 0.2-0.6% of Si, 0.5-1.0% of Mn, 0.03-0.1% of Nb, 0.05-0.1% of Ti, 0.015% or the less of P, 0.008% or the less of S, 0.03-0.06% of Als and 0.005% or the less of N. The hot-rolling finish-rolling temperature is 880-910 DEG C, after rolling, cooling is conducted through a laminar flow cooling system till the temperature is 620-650 DEG C, and then reeling is conducted; the cold-rolling reduction rate is controlled to be 50-60%; and an annealing technologyis a continuous half-annealing method. According to the 900 MPa-stage high-cold-bending-property low-alloy high-strength steel plate, by matching low-carbon and Nb and Ti microalloying component design with reasonable rolling and half-annealing technological design, the steel plate precipitation strengthening effect is strengthened, and the high-cold-bending-property low-alloy high-strength steelplate with the welding and good cold-bending property is obtained.

Owner:HANDAN IRON & STEEL GROUP +1

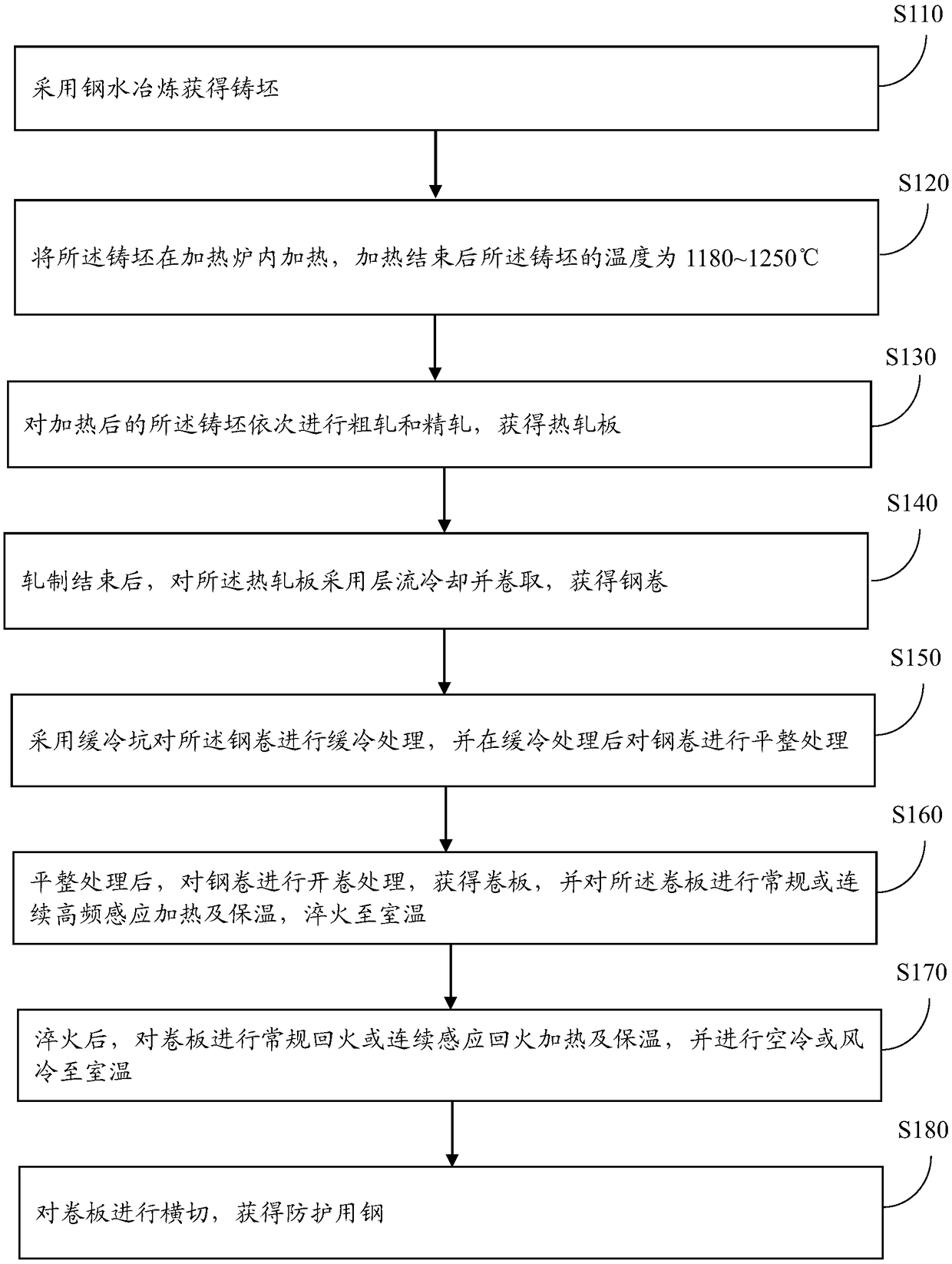

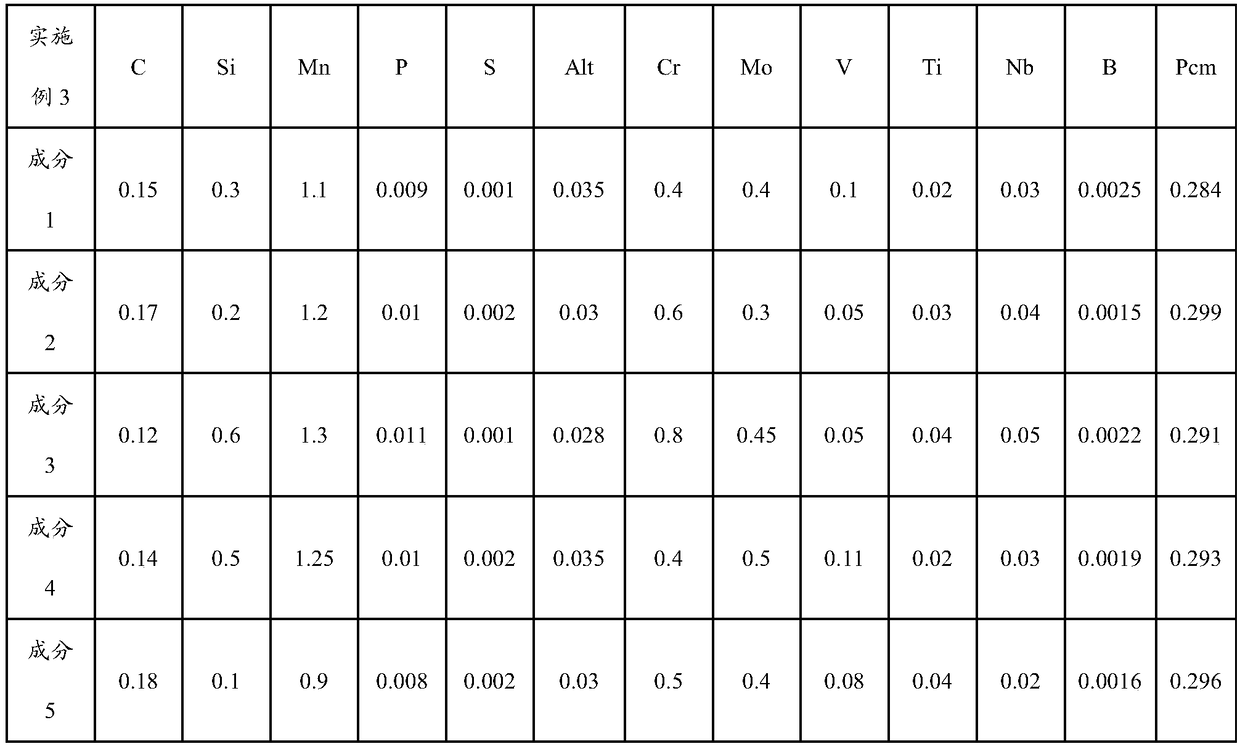

Protective steel and production method thereof

The invention discloses protective steel and a production method thereof. The protective steel is prepared from the following components in percentage by mass: 0.10-0.20% of C, 0.10-0.60% of Si, 0.8-1.65% of Mn, 0.02-0.05% of Nb, 0.3-0.8% of Mo, 0.05-0.15% of V, 0.01-0.05% of Ti, 0.01-0.06% of Al, 0.4-1.0% of Cr, 0.0015-0.0025% of B, no more than 0.02% of P, no more than 0.01% of S, no more than 0.008% of N, and the balance of Fe and unavoidable impurities. The problems that in the prior art, high-content C and high-content Mn are added into protective steel, Pcm is designed to be excessivelyhigh, consequently welding performance is lowered, and welding cold cracks and weld joint fatigue cracking are caused are solved, the technical problems of poor cold forming performance and poor low-temperature impact toughness are solved, and the technical effects that the protective steel has good cold forming performance and good low-temperature impact toughness, and safety performance of protected products is improved are achieved.

Owner:SHOUGANG CORPORATION

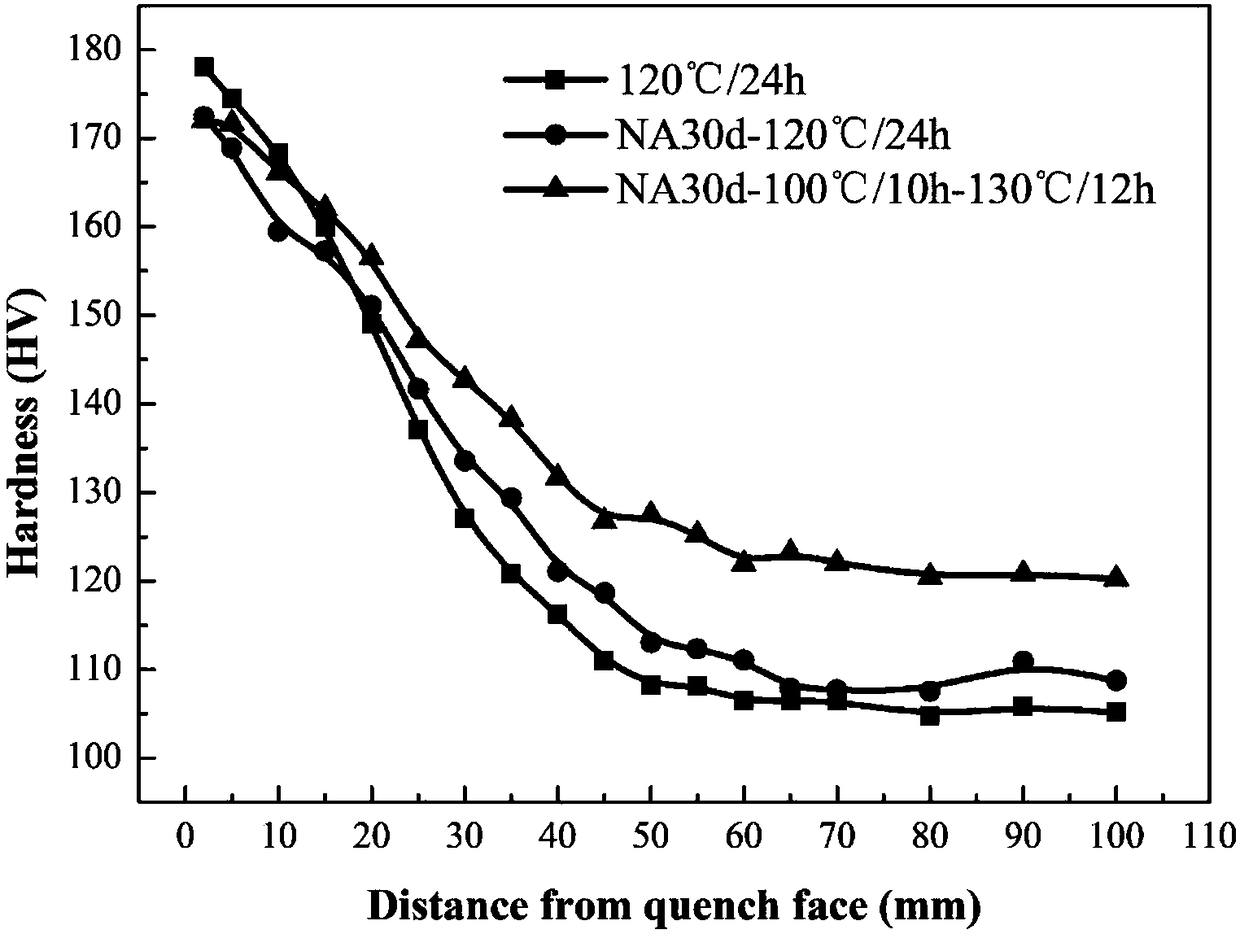

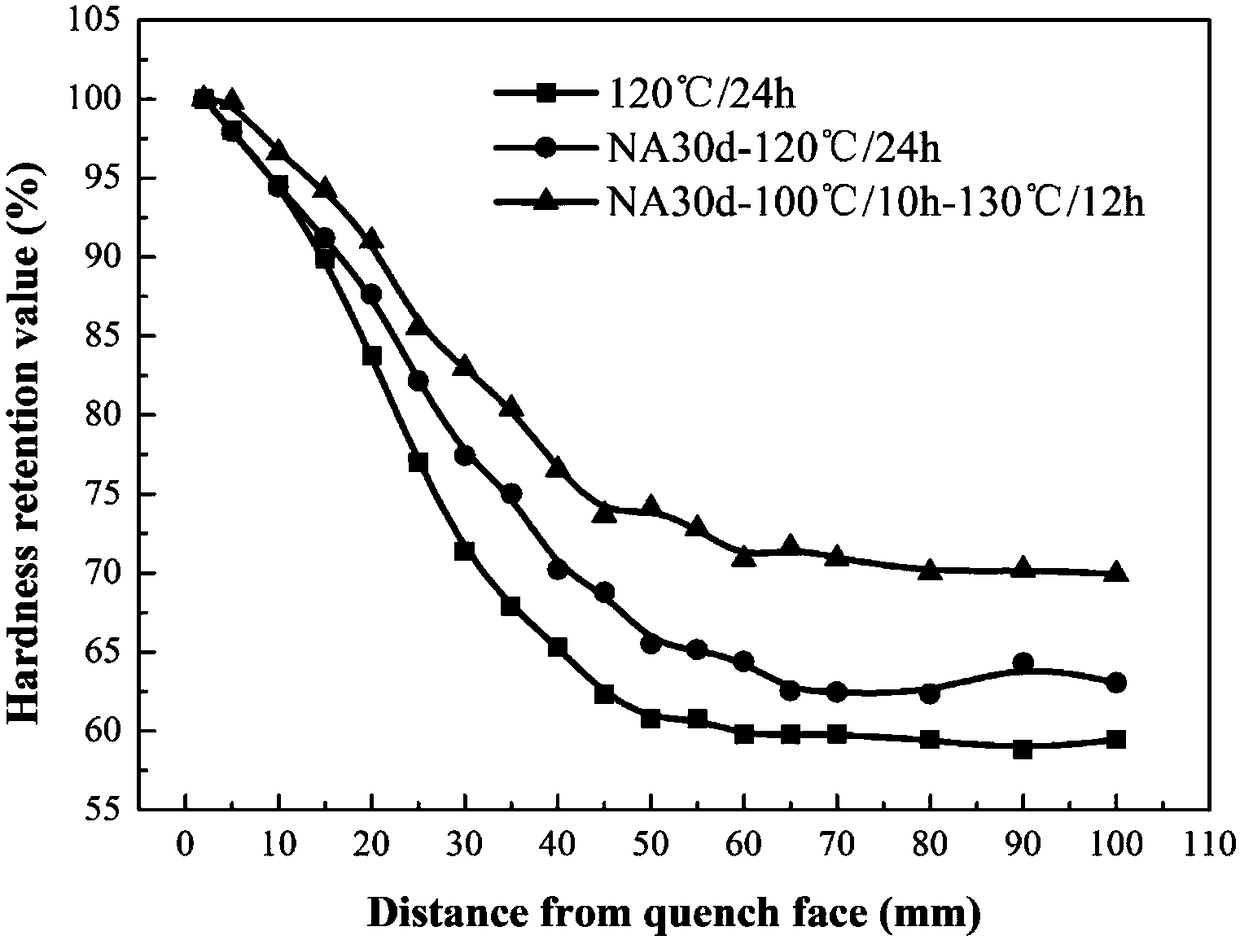

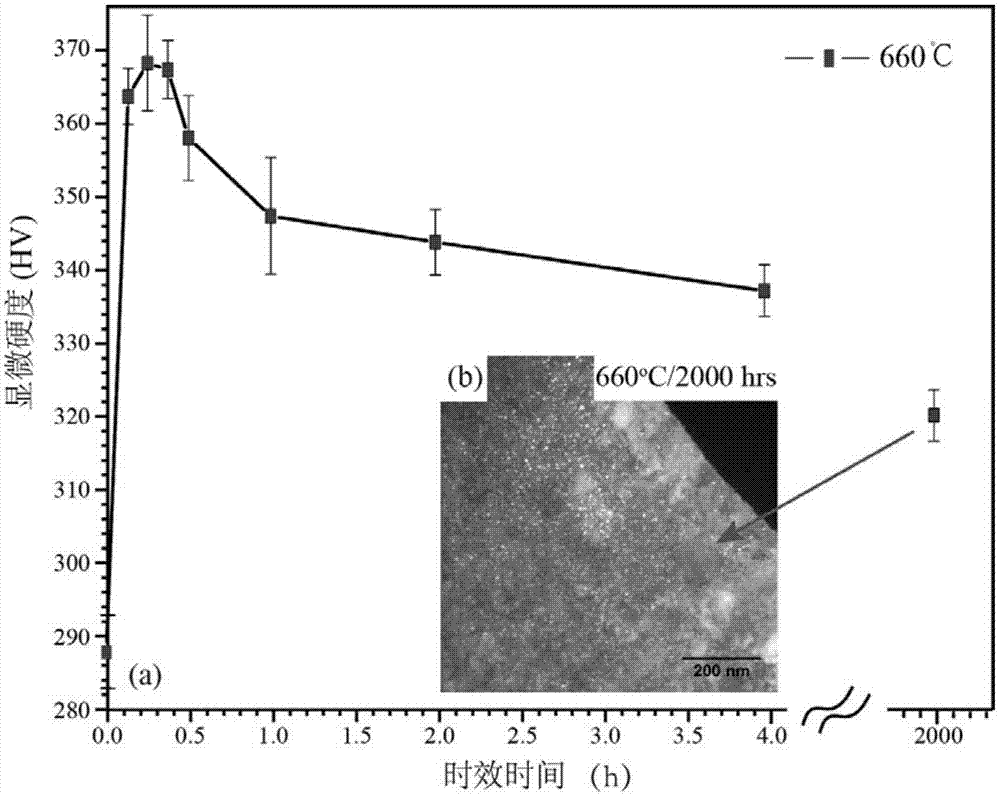

Ageing process for improving strength non-uniformity of quenched large-size 7-series aluminum alloy

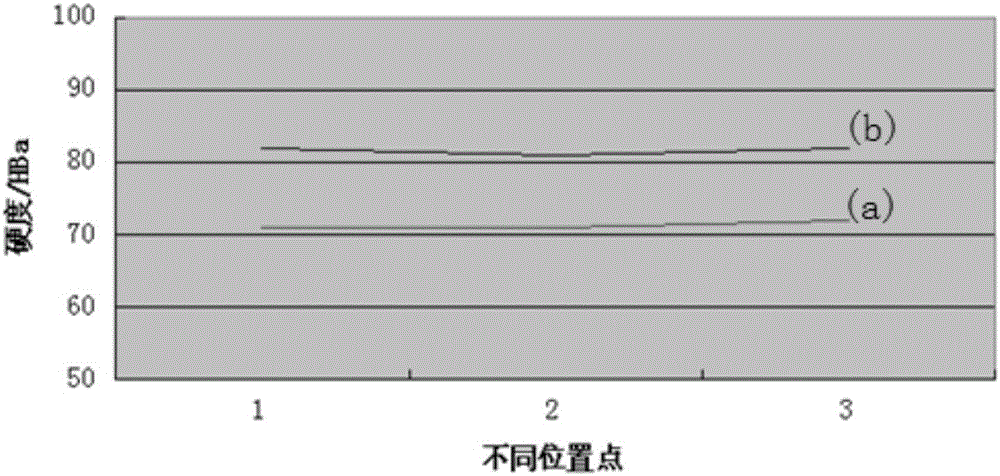

ActiveCN108265247AImprove precipitation strengthening effectDoes not significantly reduce surface propertiesThick plateHardness

The invention provides an ageing process for improving strength non-uniformity of quenched large-size 7-series aluminum alloy. According to the ageing process, an aluminum alloy thick plate which is subjected to solid-solution water-quenching treatment is subjected to natural ageing for 15-45 days and is then subjected to double-stage manual ageing treatment. The ageing process belongs to the technical field of preparation and thermal treatment of metals and alloy. By adopting a synergistic effect of natural ageing and subsequent double-stage manual ageing which are combined, the ageing process provided by the invention can effectively refine the size of a precipitated phase under a slow quenching state; thus the precipitation strengthening effect of the alloy under the slow quenching state; the hardness of a core part is improved by about 15% without remarkably reducing the surface performances of a large-size sample so that the strength non-uniformity, caused by quenching, of a large-size component can be effectively improved; compared with research results of formers, the ageing process provided by the invention shortens the natural ageing time by 94% to 98%, namely the naturalageing time is shortened from the original two years (730 days) to 15-45 days.

Owner:HUNAN UNIV

Cold-rolled steel sheet with 420 MPa grade yield strength and preparation method of steel sheet

ActiveCN106636898AImproved recrystallization kineticsGrain refinementChemical compositionSheet steel

The invention discloses a cold-rolled steel sheet with the 420 MPa grade yield strength and a preparation method of the steel sheet and belongs to the technical field of metallurgy. The steel sheet is prepared from components in percentage by mass as follows: 0.06%-0.09% of C, 0-0.2% of Si, 0.8%-1.0% of Mn, 0-0.02% of Ti, 0.01%-0.025% of Nb and the balance of Fe and inevitable impurity elements. The preparation method comprises steps as follows: (1) according to the ratio of the chemical components of the cold-rolled steel sheet, a steel ingot is obtained through smelting and is forged to form a slab; (2) heat preservation is performed on the slab, hot rolling is performed, and a hot-rolled sheet is prepared and is cooled to the proper temperature at a certain cooling rate for coiling; (3) the coiled hot-rolled sheet is pickled and then cold-rolled, and the cold-rolled sheet is prepared; (4) the cold-rolled sheet is subjected to continuous annealing treatment of low-temperature soaking and step cooling. According to the cold-rolled steel sheet, the microstructure mainly comprises ferrite, pearlite and cementite, the yield strength of the steel sheet ranges from 435 MPa to 450 MPa, the tensile strength ranges from 518 MPa to 548 MPa, and the ductility A80 ranges from 25.0% to 26.3%.

Owner:NORTHEASTERN UNIV LIAONING

Vanadium-chromium microalloying large-specification 500MPa ultra-fine grain corrosion-resisting anti-seismic steel bar and preparation method thereof

ActiveCN111519099AImprove precipitation strengthening effectImprove plastic toughnessProcess efficiency improvementAlloyRebar

The invention discloses a vanadium-chromium microalloying large-specification 500MPa ultra-fine grain corrosion-resisting anti-seismic steel bar and a preparation method thereof. The steel bar comprises, by weight percent, 0.21-0.25wt% of C, 0.45-0.55wt% of Si, 1.25-1.40wt% of Mn, 0.30-0.35wt% of Cr, 0.065-0.080wt% of V, not larger than 0.040wt% of S, not larger than 0.045wt% of P, not larger than0.0070wt% of O, 0.0165-0.0200wt% of N and the balance Fe and inevitable impurities. The preparation method of the steel bar comprises the procedures of molten steel smelting, deoxidization alloying,LF furnace refining, casting, steel blank heating and controlled rolling and controlled cooling. A certain amount of vanadium-containing pig iron is added into a tapping steel ladle to replace the expensive vanadium alloy, the V content of molten steel is increased, and the adding quantity of the vanadium alloy is reduced; in the deoxidization alloying process, a small quantity of silicon-nitrogenalloy is added, the nitrogen content in the molten steel is increased, and the proportion value of V / N in the steel is reduced, transferring of V from the solid solution state to a carbonitride precipitated phase in the rolling process is promoted, and the precipitation strength effect of the steel is obviously improved; and the preparation method is low in production cost and high in process applicability and controllability.

Owner:WUKUN STEEL

Low-temperature-resistant and lamellar-tearing-resistant super-thick steel plate and manufacturing method thereof

The invention discloses an extra-thick steel plate resistant to low temperature and lamellar tearing and a manufacturing method thereof. The chemical composition in steel is by weight percentage: C: 0.09% ~ 0.15%, Si: 0.15% ~ 0.45%, Mn: 1.05% ~ 1.45%, S≤0.003%, P≤0.010%, V: 0.06% ~ 0.08% , Als: 0.015% ~ 0.040%, N: 0.008% ~ 0.015%, Ni: 0.25% ~ 0.45%, the steel also contains one or one of Cr≤0.15%, Cu≤0.15%, Ti≤0.04% The above elements, the balance being Fe and unavoidable impurities. The production process of the steel plate is: die casting → billet rolling → finished product rolling → controlled cooling → normalizing treatment → weak cooling after being released from the furnace. The 180-250mm thick steel plate produced has excellent low temperature resistance and lamellar tear resistance in welded structures.

Owner:ANGANG STEEL CO LTD

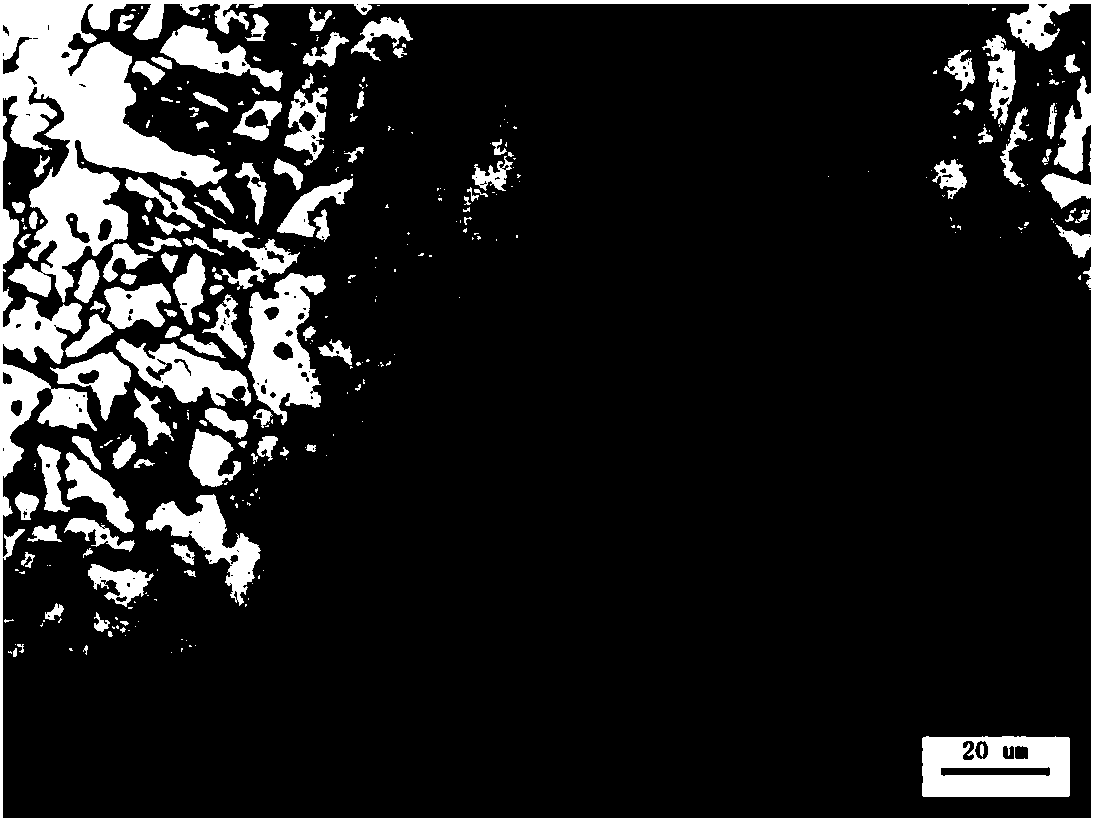

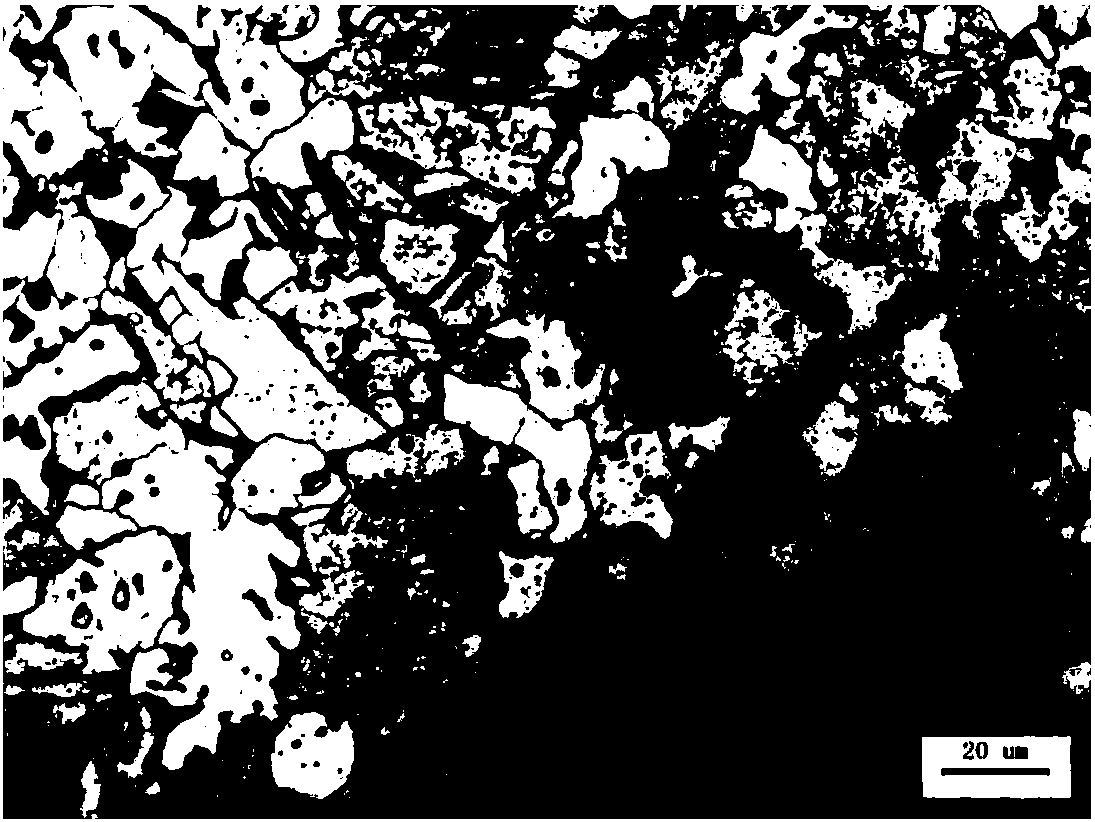

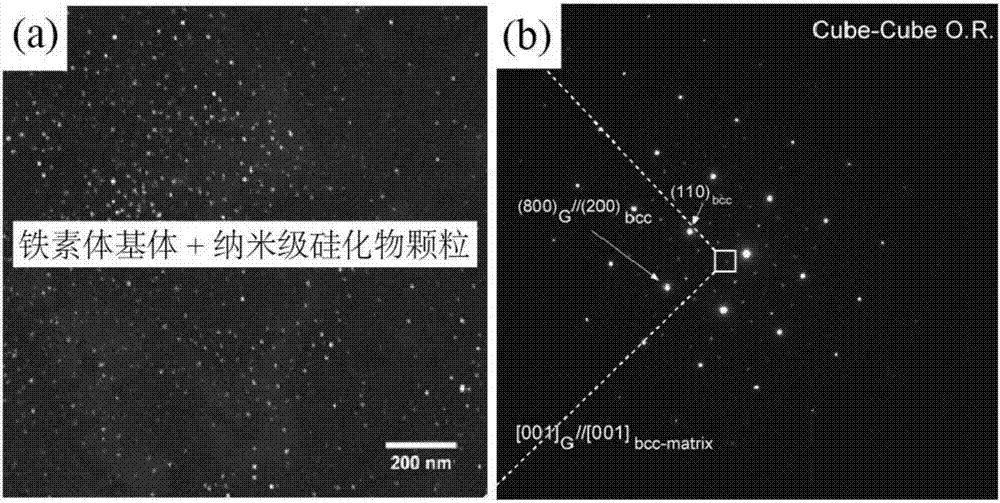

Ferrite high temperature steel

ActiveCN107326301AControllable shape and sizeAlloy heat treatment process is simpleAlloy elementChemical composition

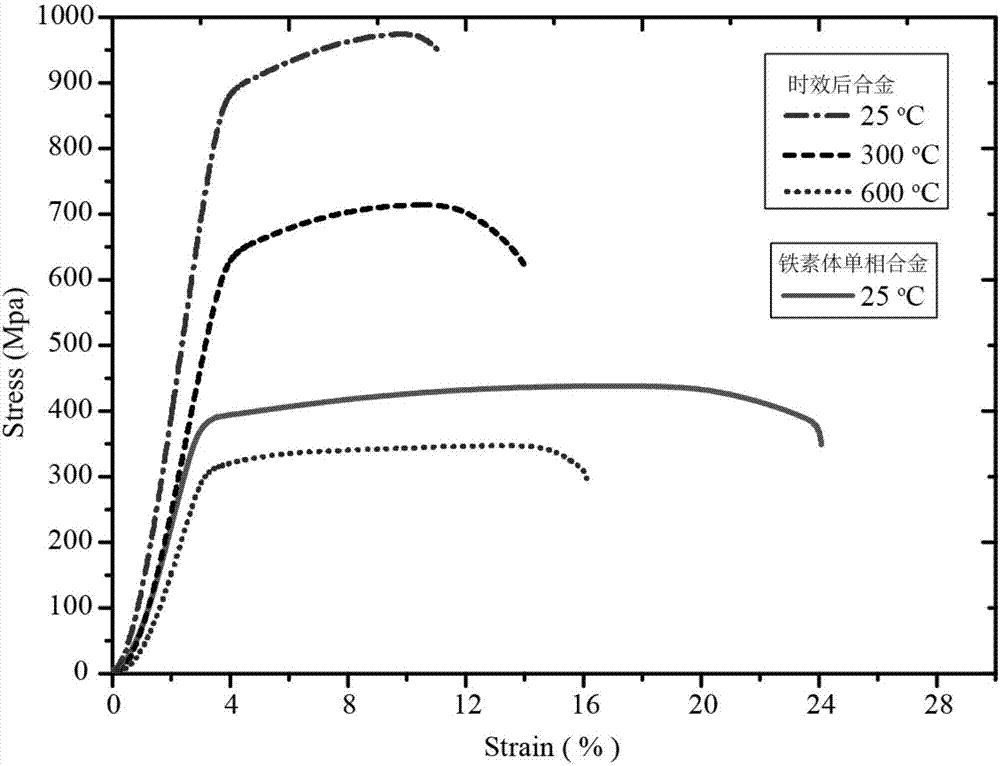

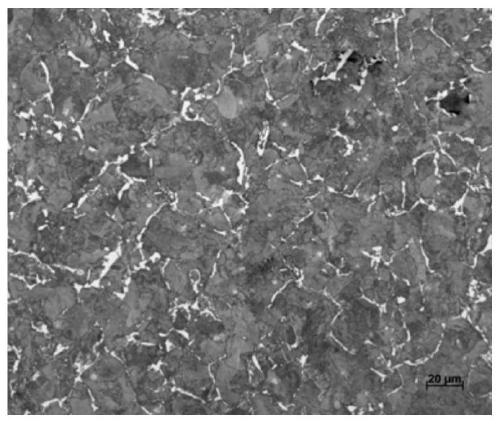

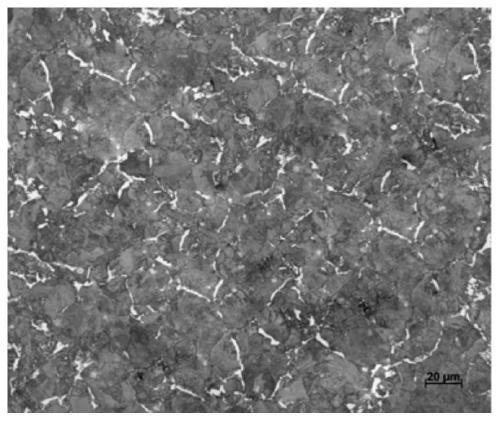

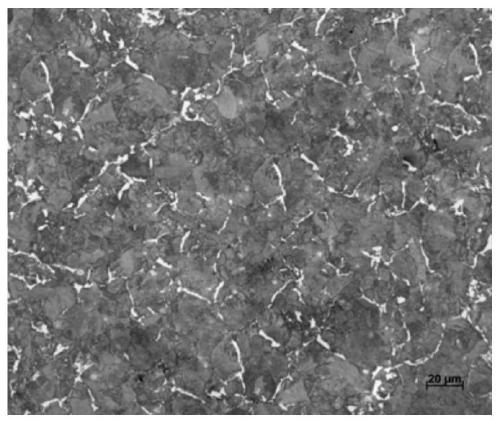

The invention discloses Fe-Cr-based ferrite high temperature steel. The components of the steel are composed of main elements including Fe and Cr, alloying elements including Ni, Mn, Si, Ti and Nb, microalloying elements including C and B and inevitable impurities. The high temperature steel comprises, by mass, of 65-75% of Fe, 18-25% of Cr, 1-5% of Ni, 0-2% of Mn, 2-4% of Si, 0.5-3% of Ti, 1-2.5 % of Nb, 0-0.05% of C and 0-0.08% of B, wherein the total mass percentage of Fe and Cr is 85-95%, the total mass percentage of Ni, Mn, Si, Ti and Nb is 7-13%, and the total mass percentage of C and B is 0-0.1%. A high temperature steel matrix in the technical scheme is a Fe-Cr-based ferrite, in the aging procedure, a spherical dispersedly-distributed coherent lattice nanoscale intermetallic compound Ni16M6Si7 (M=Ti, Nb) phase is dissolved out from the matrix to enable the strength of the steel to be obviously improved. The room-temperature tensile strength of the high temperature steel reaches 950 Mpa, and the instantaneous tensile strength under the high temperature of 600 DEG C is 300 Mpa or over.

Owner:XIAMEN UNIV

Medium-carbon wheel steel suitable for freight trains in alpine regions and method for producing wheels by using medium-carbon wheel steel

ActiveCN111270154AIncrease supersaturationImprove low temperature toughnessFurnace typesHeat treatment furnacesFreight trainsTempering

The invention provides medium-carbon wheel steel suitable for freight trains in alpine regions and a method for producing wheels by using the medium-carbon wheel steel. The medium-carbon wheel steel comprises the following components of 0.55% - 0.63% of C, 0.25% - 0.45% of Si, 0.65% - 0.90% of Mn, less than or equal to 0.030% of P, less than or equal to 0.025% of S, less than or equal to 0.10% ofV, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Ni and 0.0050% - 0.0100% of N, and the balance Fe and inevitable impurity elements. Compared with the prior art, according to the medium-carbon wheel steel suitable for the freight trains in the alpine regions and the method for producing the wheels by using the medium-carbon wheel steel, the N is used for generating precipitatessuch as MX nitride or carbonitride, so that the supersaturation degree of ferrite is improved, V(CN) particles are promoted to nucleate quickly, the particle spacing is reduced, and the precipitationcondition effect is improved; and according to the medium-carbon wheel steel suitable for the freight trains in the alpine regions and the method for producing the wheels by using the medium-carbon wheel steel, an ideal fine pearlite and ferrite (less than 4%) structure is obtained by adopting a circulating quenching and tempering process, so that the mechanical property level of rims is higher,and the fracture resistance of the wheels under a low-temperature service condition is enhanced.

Owner:MAANSHAN IRON & STEEL CO LTD

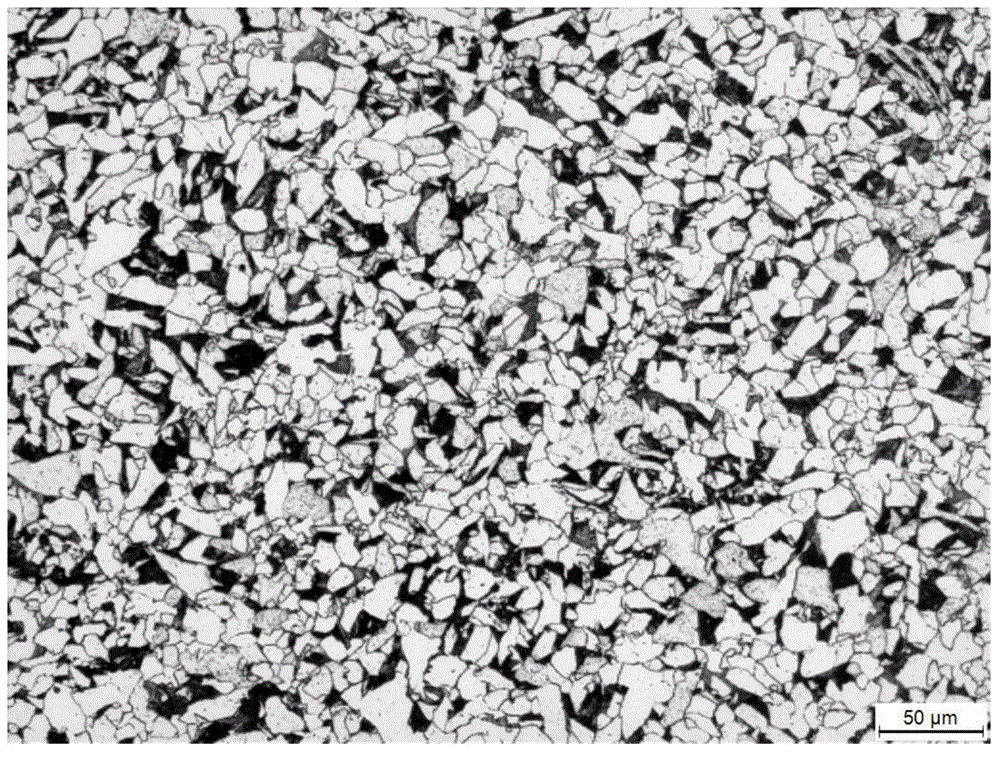

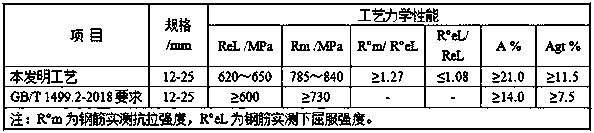

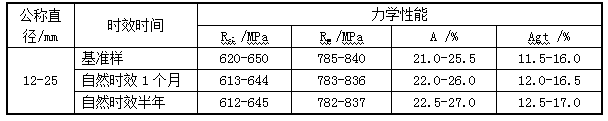

Ultra-fine grain high-strength and high-toughness 600MPa-grade anti-seismic steel bar and preparation method thereof

ActiveCN111455262AImprove precipitation strengthening effectHigh tensile strengthFurnace typesProcess efficiency improvementSteelmakingAlloy

The invention discloses an ultra-fine grain high-strength and high-toughness 600MPa-grade anti-seismic steel bar and a preparation method thereof. The steel bar comprises, by weight, 0.23 wt%-0.27 wt%of C, 0.45 wt%-0.57 wt% of Si, 1.42 wt%-1.55 wt% of Mn, 0.20 wt%-0.25 wt% of Cr, 0.012 wt%-0.017 wt% of Nb, 0.095 wt%-0.110 wt% of V, less than or equal to 0.040 wt% of S, less than or equal to 0.043wt% of P, less than or equal to 0.0070 wt% of O, 0.0240 wt%-0.0265 wt% of N and the balance Fe and inevitable impurities. The preparation method of the steel bar comprises the procedures of molten steel smelting, deoxidation alloying, molten steel argon station refining, molten steel casting, billet heating and billet controlled rolling and controlled cooling. According to the steel bar and the preparation method, a small amount of silicon-nitrogen alloy is added in the steel-making deoxidation alloying process, the nitrogen content in molten steel is increased, the V / N and Nb / N ratio value in steel is reduced, transfer of V and Nb from a solid solution state to a carbonitride precipitated phase in the rolling process is promoted, a large number of fine dispersed V (C, N) and Nb (C, N) precipitated phases are formed and precipitated, and the phase change temperature is reduced, so that the precipitation strengthening effect of the steel is obviously improved; and according to the method, the production cost is reduced, the anti-seismic property is improved, and the market competitiveness of the product is improved.

Owner:WUKUN STEEL

Preparation method for Cu-Ni-Si-Ma alloy strip

The invention provides a preparation method for a Cu-Ni-SI-Ma alloy strip. The method comprises the following steps that a copper source, a nickel source, a silicon source and a magnesium source serve as the raw materials and are sequentially subjected to melting, continuous casting, cooling and billet drawing to obtain a Cu-Ni-SI-Ma alloy rod billet; the Cu-Ni-Si-Ma alloy rod billet is directly subjected to continuous extrusion molding to obtain a Cu-Ni-Si-Mg alloy strip billet; and then rolling and ageing treatment are sequentially conducted to obtain the Cu-Ni-Si-Mg alloy strip. Embodiments show that the elongation, under the room temperature, of the Cu-Ni-Si-Mg alloy rod billet prepared through the preparation method is greater than 45%, and excellent plasticity is achieved; and melting and continuous casting in combination of cooling enforcement measures are adopted, continuous casting and fast solidification can be achieved, the solution strengthening and precipitation strengthening effects of alloy elements are effectively improved, and the method for continuous casting, continuous extruding, rolling and efficient molding of the Cu-Ni-Si-Mg alloy strip is provided.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

An extra-thick steel plate resistant to low temperature and lamellar tearing and its manufacturing method

The invention discloses a low-temperature-resistant and lamellar-tearing-resistant super-thick steel plate and a manufacturing method thereof. Steel is composed of chemical components of, by weight, 0.09-0.15% of C, 0.15-0.45% of Si, 1.05-1.45% of Mn, less than or equal to 0.003% of S, less than or equal to 0.010% of P, 0.06-0.08% of V, 0.015-0.040% of Als, 0.008-0.015% of N, 0.25-0.45% of Ni, oneor more elements of less than or equal to 0.15% of Cr, less than or equal to 0.15% of Cu and less than or equal to 0.04% of Ti, and the balance Fe and inevitable impurities. The production process ofthe steel plate comprises the steps of die casting, cogging rolling, finished product rolling, controlled cooling, normalizing treatment and slow cooling after furnace discharging. The produced thicksteel plate with the thickness being 180-250 mm has the good low temperature resistance and lamellar tearing resistance, and is suitable for welding structures.

Owner:ANGANG STEEL CO LTD

High-strength and heat-resisting rare earth aluminum alloy and preparing method thereof

InactiveCN111763861APoor high temperature performanceGood mechanical properties at room temperatureMaterials sciencePlastic property

The invention relates to a high-strength and heat-resisting rare earth aluminum alloy containing rare earth samarium and a preparing method of the high-strength and heat-resisting rare earth aluminumalloy and belongs to the technical field of alloys. The aluminum alloy comprises the following components including, by mass percent, 5%-6% of Zn, 2%-3% of Mg, 1%-2% of Cu, 0.1%-0.2% of Sm and the balance Al and inevitable impurities. Various second phases, uniform and fine microstructures and weak base plane textures are evenly distributed in the alloy, and therefore the alloy can have high strength and high plasticity. The invention further discloses a preparing method of the high-strength and heat-resisting rare earth aluminum alloy material, nano-order and micron-order second phases and grains with the size being relatively fine are evenly distributed in the tissue of the prepared aluminum alloy, and the mechanical performance of the aluminum alloy is obviously improved.

Owner:YANTAI NANSHAN UNIV

Large-thickness wear-resisting steel plate based on NQT process and having good -40 DEG C low-temperature toughness and preparing method

ActiveCN110157987AEnsure the uniformity of mechanical properties in the thickness directionImprove hardenabilityChemical compositionHardness

The invention discloses a large-thickness wear-resisting steel plate with good low-temperature toughness and a preparing method. The steel plate comprises, by weight percent, 0.16 to 0.18% of C, 0.20to 0.30% of Si, 1.15 to 1.30% of Mn, not larger than 0.010% of P, not larger than 0.002% of S, 0.010 to 0.020% of Nb, 0 to 0.05% of Cu, 0.40 to 0.60% of Cr, 0.45 to 0.60% of Mo, 0.95 to 1.20% of Ni, 0.025 to 0.040% of V, 0.001 to 0.0025% of B, larger than or equal to 0.060% of Alt, 0.002 to 0.004% of Ca, and the balance Fe and trace impurities. The hardenability index of steel is larger than or equal to 140, the wear-resisting index is larger than or equal to 0.59, the steel plate thicknesses ranges from 80 to 100 mm, the NQT process is adopted, the large-thickness wear-resisting steel plate with good -40 DEG C low-temperature toughness is excellent in mechanical property, the steel plate surface hardness ranges from 330 HBW to 380 HBW, the hardness average value in the thickness directionis not lower than the surface hardness by 90%, and -40 DEG C impact energy at the 1 / 4 thickness is 60 to 80 J.

Owner:贝斯山钢(山东)钢板有限公司 +1

Aluminum alloy heat radiator profile as well as application and on-line quenching process thereof

ActiveCN106834984AAvoid deformationPrevent precipitationFurnace typesHeat treatment furnacesHardnessIngot

The invention provides an aluminum alloy heat radiator profile as well as application and an on-line quenching process thereof, and relates to the technical field of aluminum alloy processing. The on-line quenching process of the aluminum alloy heat radiator profile comprises the following steps: under conditions that the heating temperature of a mold is 480-520 DEG C and the temperature of an extrusion cylinder is 430-460 DEG C, extruding aluminum alloy ingots, and blowing the bottom of an aluminum alloy heat radiator profile by utilizinga blowing device, wherein the aluminum alloy heat radiator profile is made in an extrusion mode, the air speed of the bottom of the aluminum alloy heat radiator profile is 40-50m / s, and the air speeds of the top and two sides of the aluminum alloy heat radiator profile are all 0m / s. By adopting the on-line quenching process of the aluminum alloy heat radiator profile provided by the invention, hardness requirements of the bottom of the profile can be ensured, and meanwhile profile tooth pieces can be prevented from deformation.

Owner:SHANDONG NANSHAN ALUMINUM +2

High-steel-grade corrosion-resistant sleeve and preparation method thereof

The invention discloses a high-steel-grade corrosion-resistant sleeve and a preparation method thereof. The high-steel-grade corrosion-resistant sleeve comprises a sleeve body; the sleeve body comprises the following components of, by mass, 0.27%-0.32% of C, 0.15%-0.35% of Si, 0.40%-0.55% of Mn, 0-0.012% of P, 0-0.003% of S, 0.45%-0.60% of Cr, 0-0.10% of Ni, 0-0.10% of Cu, 0.82%-0.92% of Mo, 0.05%-0.09% of V, 0.02%-0.06% of Nb, 0.01-0.04% of Al, 0-0.002% of H, 0-0.004% of O, 0-0.008% of N, and the balance iron and unavoidable impurities, and the total mass is 100%. The high-steel-grade corrosion-resistant sleeve can reach the C110 steel grade, not only has good corrosion resistance, but also has good mechanical properties, and conforms to API standard requirements.

Owner:JIANGSU CHANGBAO PLS STEEL TUBE

Preparation method of high-strength and high-conductivity copper-silver alloy wire

The invention discloses a preparation method of a high-strength and high-conductivity copper-silver alloy wire. The alloy mainly comprises 0.2 to 8.0 percent by weight of Ag, not more than 0.1 percentof impurities and the balance of Cu. The preparation method sequentially comprises the steps of vacuum melting, vacuum continuous casting, aging and multi-pass drawing. By means of the technology, the content of solid solution Ag atoms in the alloy can be well controlled, and meanwhile, nano Ag is separated out, so that the dislocation density of the alloy is improved, and the alloy obtains the maximum separation strengthening and dislocation strengthening effects. Compared with a traditional method that solid solution is conducted firstly and then aging is conducted, the preparation method provided by the invention has the advantages that the mechanical property of the Cu-Ag alloy is guaranteed, meanwhile, higher electrical conductivity can be obtained, the mechanical property and the electrical conductivity of the prepared copper-silver alloy wire are well matched, the technological process is shortened, and the production cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

Hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and preparation method thereof

ActiveCN114525452AGuaranteed Yield StrengthGuaranteed tensile strengthHot-dipping/immersion processesProcess efficiency improvementAlloyContinuous annealing

The invention discloses hot-dip galvanized low-alloy high-strength steel with yield strength of 700Mpa and a preparation method of the hot-dip galvanized low-alloy high-strength steel. The hot-dip galvanized low-alloy high-strength steel comprises the following chemical components in percentage by weight: 0.07-0.12% of C; 0.2 to 0.5 percent of Si; mn: 1.1 to 1.5%; 0.02% to 0.06% of Nb; 0.06% to 0.12% of Ti; less than or equal to 0.020% of P; s is less than or equal to 0.012%; the content of Als is 0.02 to 0.06 percent; n is less than or equal to 0.006%, and the balance is Fe and inevitable impurities. The preparation method comprises the procedures of smelting, hot rolling, cold rolling and hot galvanizing. Through reasonable design of low-carbon, Nb and Ti microalloying components, hot rolling, cold rolling reduction rate and a hot dipping continuous annealing process are matched, a certain amount of temper mill extension is used, the precipitation strengthening effect of a steel plate is strengthened, and the hot-dip galvanized low-alloy high-strength steel which is uniform in structure, stable in mechanical performance, good in cold bending performance and high in corrosion resistance is obtained.

Owner:HANDAN IRON & STEEL GROUP +1

High nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method

ActiveCN111020393AImprove precipitation strengthening effectHigh tensile strengthFurnace typesManufacturing convertersSteelmakingRebar

The invention discloses a high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method. In the steelmaking converter steel tapping process and the ladle furnace (LF) refining process, a certain amount of vanadium pig iron is added to replace an expensive vanadium alloy, so that the molten steel V content is increased; and in the steelmaking deoxidation alloying process, a high nitrogen-vanadium alloy and appropriate amount of silicon-nitrogen alloys are added, and molten steel is subjected to LF refining and nitrogen-blowing treatment, so that the nitrogen content in the molten steel is increased, a V / N matching ratio in steel is remarkably reduced, and a steel precipitation strength effect is remarkably improved. According to the high nitrogen-vanadium microalloying large-scale anti-seismic reinforcing steel bar preparation method provided by the invention, through the integrated innovation of chemical composition design, converter smelting, deoxidation alloying, LF refining, continuous casting, a rolled steel heating schedule, rolling temperature and a controlled cooling technology, a produced reinforcing steel bar has the advantages of excellent and stable process mechanical property, fine and uniform microscopic structure, good ductility and toughness, low strain timeliness, excellent anti-seismic property and the like, the production cost is reduced, the anti-seismic property is improved, and the market competitiveness of products is improved.

Owner:WUKUN STEEL

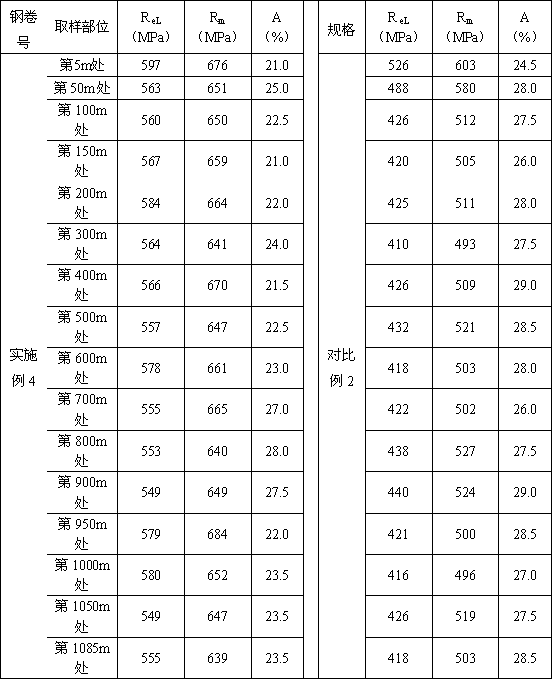

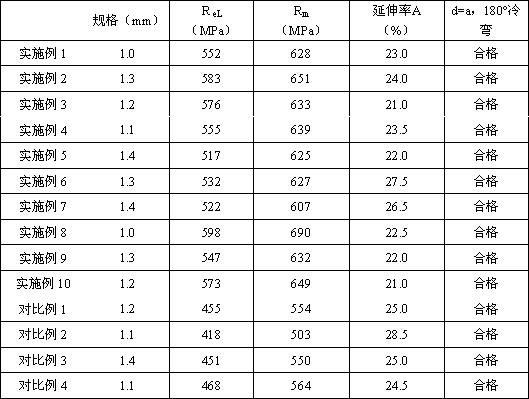

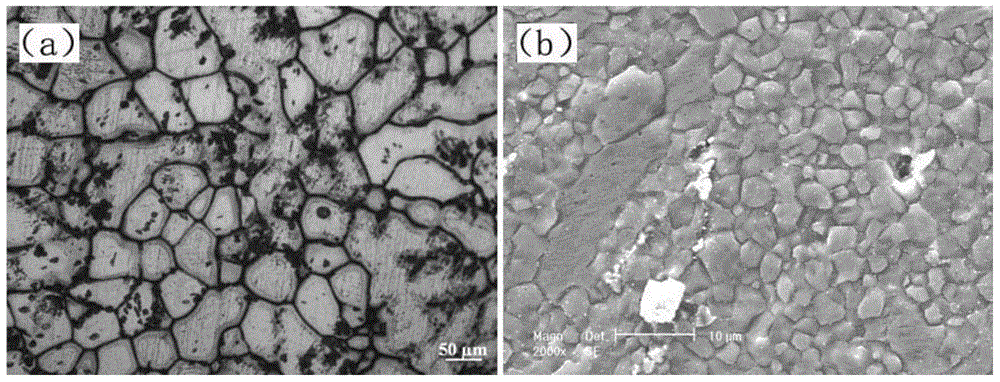

Production method for inline increase in precipitation toughening effect of ti microalloyed hot-rolled high-strength steel

ActiveUS20200232054A1Improve precipitation strengthening effectLow costWork treatment devicesFurnace typesLaminar coolingIngot

There is provided a production method for on-line improving precipitation strengthening effect of Ti microalloyed hot-rolled high-strength steel, comprising: casting a molten steel with microalloying element Ti added to obtain an ingot; after heating the ingot, subjecting it to rough rolling, finish rolling, laminar cooling and coiling to obtain a hot-rolled coil; after unloading the coil, covering the coil on-line with an insulating enclosure and moving it into a steel coil warehouse along with a transport chain; after a specified period of on-line insulating time, removing the coil from the insulating enclosure, and cooling it to room temperature in air, wherein the microalloying element Ti has a content of ≥0.03 wt %; the coiling is performed at a temperature of 500-700° C.; said covering on-line with an insulating enclosure means each hot-rolled coil is individually covered with an independent, closed insulating enclosure unit within 60 minutes after unloading; the on-line insulating time is ≥60 minutes. The method of the present disclosure is characterized by low cost and high efficiency, and is not affected by surroundings.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com