900 MPa-stage high-cold-bending-property low-alloy high-strength steel plate and preparation method thereof

A high-strength steel plate and low-alloy technology, applied in the field of automotive plate rolling, can solve the problems of not meeting the lightweight requirements of the automotive industry, less research and development, and low performance of high cold bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

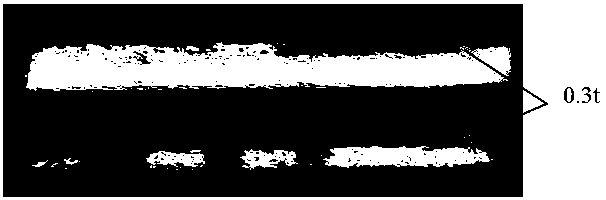

Image

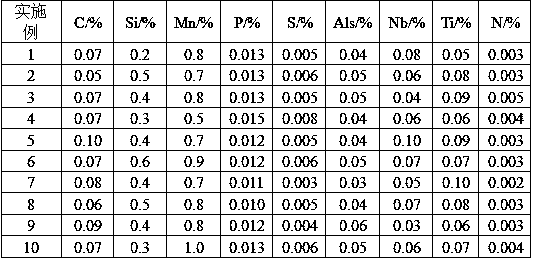

Examples

preparation example Construction

[0030] A method for preparing a 900MPa grade high cold bending performance low alloy high strength steel plate comprising the following steps:

[0031] (1) Smelting: Converter smelting, LF+RH duplex, slabs are obtained after continuous casting;

[0032] (2) Hot rolling: the final rolling temperature is controlled at 880-910°C, and after rolling, it is cooled to 620-650°C by a laminar cooling system for coiling;

[0033] (3) Cold rolling: the reduction rate is controlled at 50-60%;

[0034] (4) Annealing: the annealing method adopts continuous annealing;

[0035] The annealing process is a continuous semi-annealing method. The steel plate is heated to 580-630°C at a heating rate of 1-3°C / s, kept for 100-150s, and then slowly cooled to 400-470°C at a cooling rate of 2-4°C / s. ℃, then rapidly cooled to 250-300°C at a cooling rate of 10-20°C / s, and overaged for 250-400s, with a flat elongation of 0.3-0.7%.

[0036] The present invention adopts low-carbon and reasonable compositi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com