High-strength wrought magnesium alloy and preparation method thereof

A deformed magnesium alloy, high-strength technology, applied in the field of light metal materials, can solve the problems of high cost and insufficient strength, and achieve the effect of increasing strength, improving mechanical properties, and enhancing the effect of precipitation strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

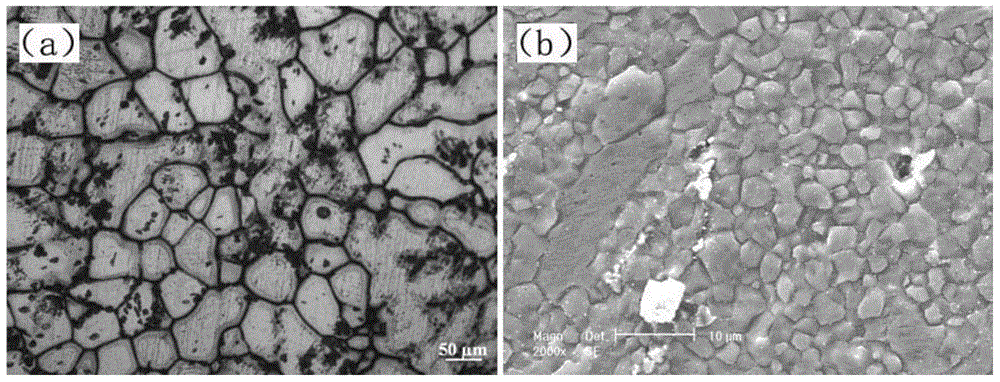

[0027] A cube ingot with a side length of 200 mm and a height of 150 mm was obtained by metal mold gravity casting. After chemical analysis, its chemical composition is: Mg-2.0Zn-0.8Gd-0.7Ca-0.5Mn. Its as-cast structure is as figure 1 As shown in (a), the as-cast grain size is 50-100 microns.

[0028] The alloy ingot was subjected to homogenization treatment at 420° C. for 16 hours; after treatment, it was cut into billets for extrusion with a diameter of 50 mm. The billet for extrusion was kept at 380° C. for 2 hours, put into an extrusion cylinder for extrusion, and an extruded rod with a diameter of 12 mm was obtained. The microstructure of the extruded rod is as figure 1 (b); After extrusion, the grains are refined to 2-5 microns. According to the Hall-Petch relationship, the grain refinement will increase the strength of the alloy. The mechanical properties were tested according to the national standard GB / T228-2002. The tensile strength was 418MPa, the yield strength...

Embodiment 2

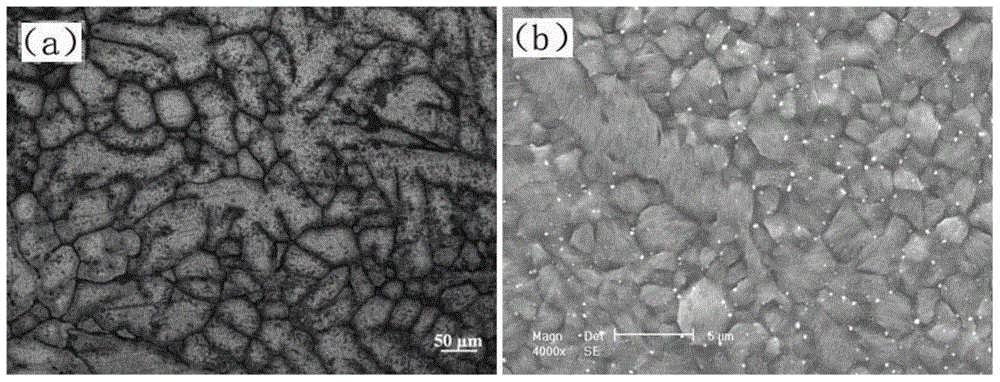

[0030] A cube ingot with a side length of 200 mm and a height of 150 mm was obtained by metal mold gravity casting. After chemical analysis, its chemical composition is: Mg-3.0Zn-0.2Gd-2.0Ca-0.2Mn-0.3Zr. Its as-cast structure is as figure 2 As shown in (a), the as-cast grain size is 50-100 microns, due to the increase of Zn content, dendrites are formed, and more second phases are produced.

[0031]The alloy ingot was subjected to homogenization treatment at 400°C for 12 hours; after treatment, it was cut into billets for extrusion with a diameter of 50 mm. The billet for extrusion was kept at 380° C. for 2 hours, put into an extrusion cylinder for extrusion, and an extruded rod with a diameter of 12 mm was obtained. The microstructure of the extruded rod is as figure 2 (b); After extrusion, the grains are refined to 1-5 microns, and a lot of fine particle precipitates are produced, and the grain refinement and precipitation strengthening further improve the strength. Th...

Embodiment 3

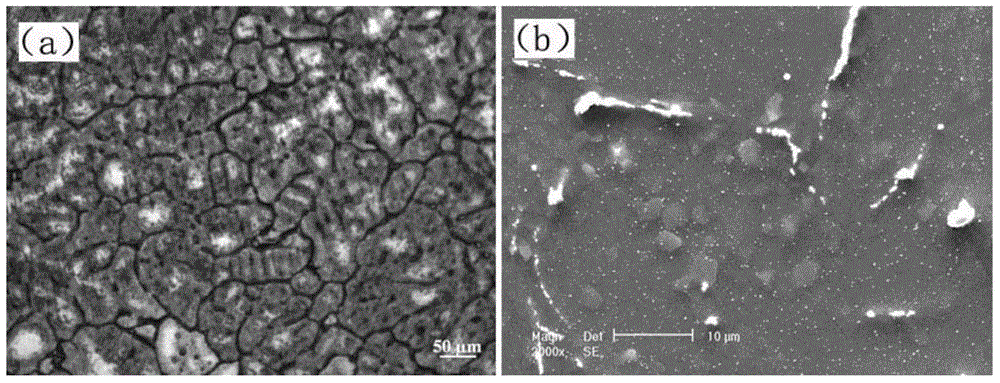

[0033] A cube ingot with a side length of 200 mm and a height of 150 mm was obtained by metal mold gravity casting. After chemical analysis, its chemical composition is: Mg-4.1Zn-3Y-0.2Ca-2.0Mn. Its as-cast structure is as image 3 As shown in (a), the as-cast grain size is 50-100 microns, and due to the continuous increase of Zn content, the number of dendrites is more, and the number of second phases also increases.

[0034] The alloy ingot was subjected to homogenization treatment at 380° C. for 12 hours; after treatment, it was cut into billets for extrusion with a diameter of 50 mm. The billet for extrusion was kept at 380° C. for 2 hours, put into an extrusion cylinder for extrusion, and an extruded rod with a diameter of 12 mm was obtained. The microstructure of the extruded rod is as image 3 (b); After extrusion, the grains are refined to 1-5 microns, and a lot of fine grain precipitates are produced, and there are also some coarse second phases. The grain refineme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com