High-strength and high-toughness cast magnesium alloy and preparation method thereof

A technology for casting magnesium alloys and magnesium alloys, which is applied in the field of low-cost non-rare earth type high-strength and toughness casting magnesium alloys and their preparation, can solve the problems of limiting the popularization and application of alloys, increasing the cost of alloys, etc., so as to improve the morphology and distribution, and save energy. , the effect of improving plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

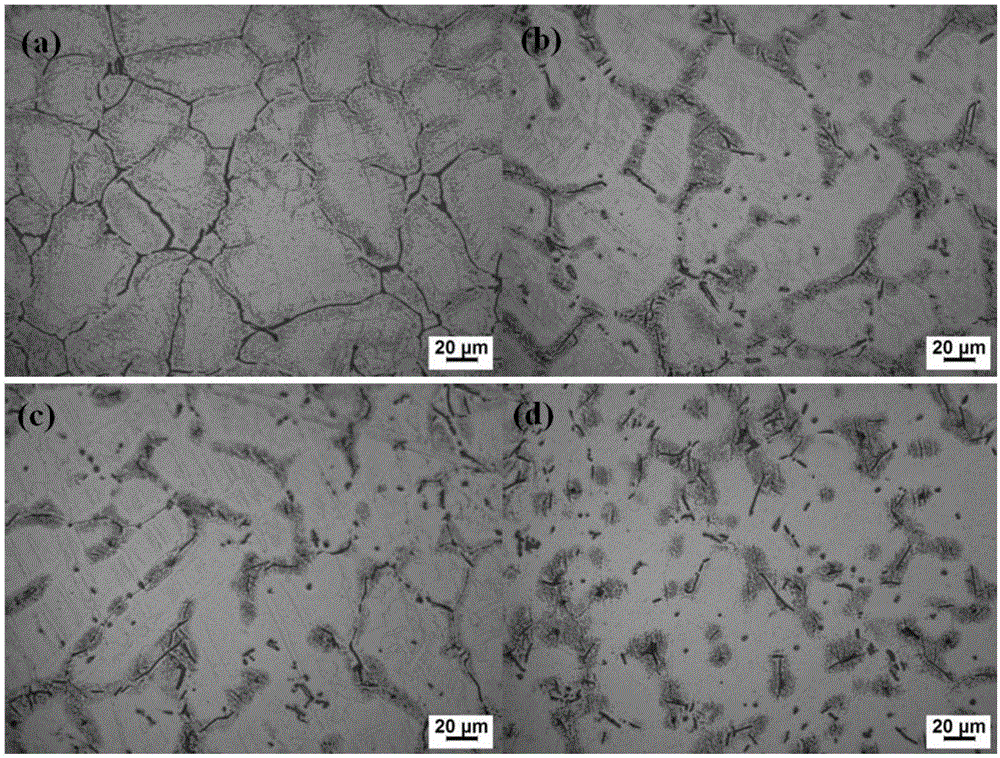

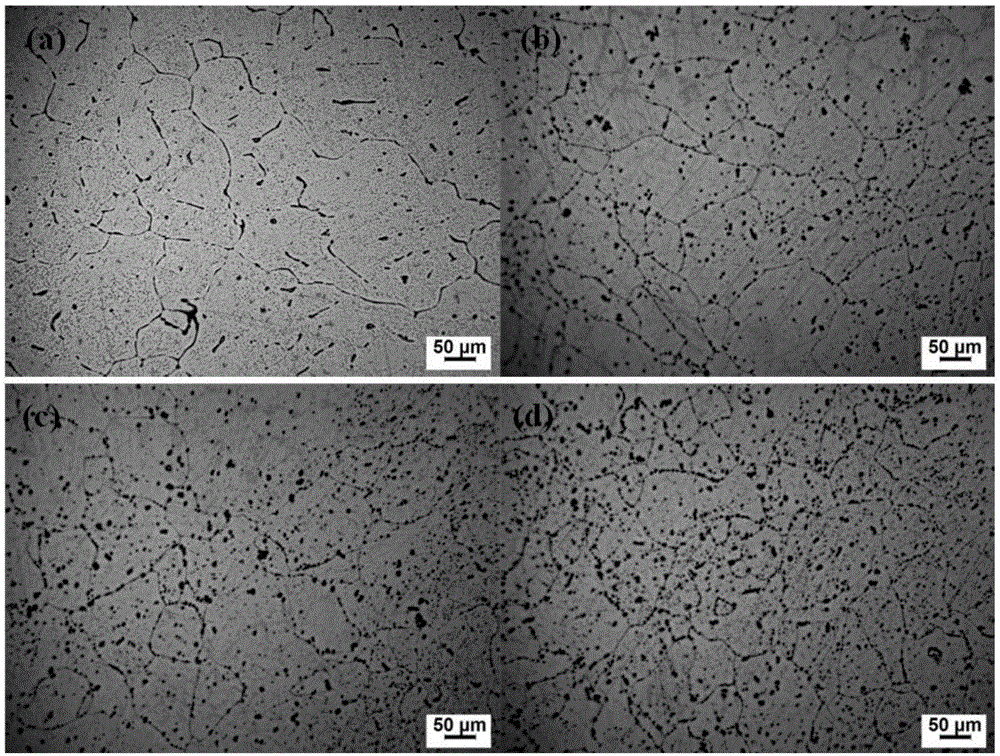

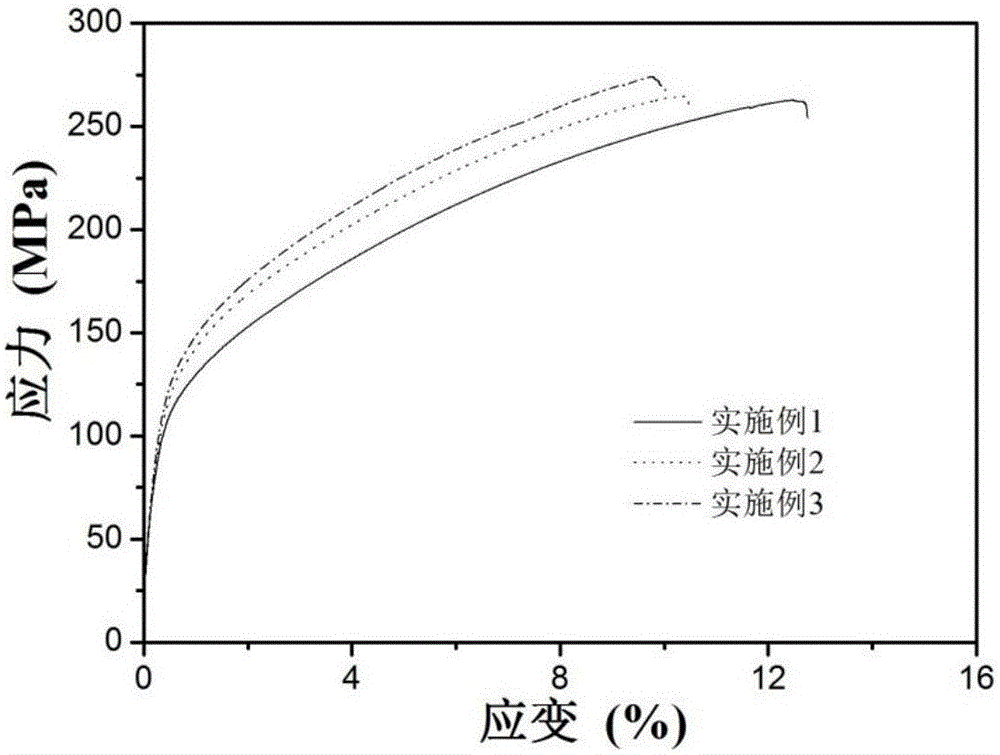

Embodiment 1

[0037] (1) Take raw material by the mass percent of alloy Mg-4Bi-0.3Ca-1.0Zn (wt%): pure Bi, pure Zn, Mg-20Ca, all the other are Mg (every 1000 grams of target alloys can be made of 15 grams of Mg-20Ca , 10g grams of Zn, 40 grams of Bi and 935 grams of Mg formulated). And do a good job of surface treatment of raw materials (such as removal of dirt, scale, etc.).

[0038] (2) First, clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, heat slowly, and the heating rate is 20-40°C / min, and maintain the set furnace temperature;

[0039] (3) After all the pure magnesium ingots are melted, respectively add pure Bi, pure Zn and Mg-20Ca intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep the temperature for 5-10 Minutes, then mechanically stirred for 3-5 minutes, then filled with argon gas for refining...

Embodiment 2

[0044] (1) Take raw material by the mass percent of alloy (Mg-6.0Bi-0.5Ca-1.0Zn): pure Bi, pure Zn, Mg-20Ca, all the other are Mg; And do the raw material surface treatment (as removing dirt, oxide skin, etc.).

[0045] (2) First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, and slowly heat the heating rate to 20-40°C / min , and maintain the set furnace temperature;

[0046] (3) After all the pure magnesium ingots are melted, add pure Bi, pure Zn and Mg-20Ca intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep the temperature for 5-10 Minutes, then mechanically stirred for 3-5 minutes, then filled with argon gas for refining and degassing, then adjusted the furnace temperature to the pouring temperature of 720°C, stood for 2-10 minutes, and poured to obtain the cast alloy. The whole process...

Embodiment 3

[0051] (1) Take raw material by the mass percent of alloy (Mg-7.0Bi-0.7Ca-1.0Zn): pure Bi, pure Zn, Mg-20Ca, all the other are Mg; And do the raw material surface treatment (as removing dirt, oxide skin, etc.).

[0052] (2) First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, set the furnace temperature to 720°C, and slowly heat the heating rate to 20-40°C / min , and maintain the set furnace temperature;

[0053] (3) After all the pure magnesium ingots are melted, add pure Bi, pure Zn and Mg-20Ca intermediate alloys preheated to about 200°C to the magnesium melt, raise the furnace temperature to 730°C, and keep the temperature for 5-10 Minutes, then mechanically stirred for 3-5 minutes, then filled with argon gas for refining and degassing, then adjusted the furnace temperature to the pouring temperature of 720°C, stood for 2-10 minutes, and poured to obtain the cast alloy. The whole process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com