Small-scale finish-rolled twisted steel and production method thereof

A technology of finishing thread and production method, which is applied in the manufacture of converters, etc., can solve the problems of insufficient self-tempering, complex process, and large fluctuations in product performance, and achieve improved precipitation strengthening effect, simple process, and microalloy distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

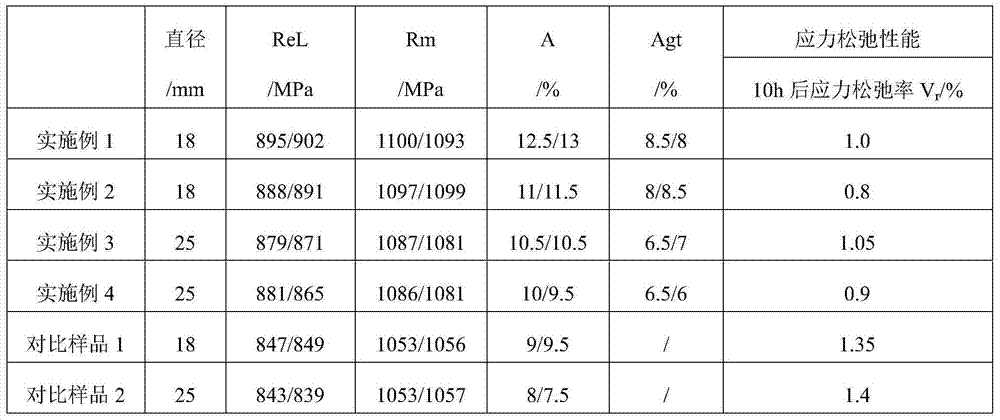

Examples

Embodiment 1

[0026] Prepare a finish-rolled rebar with a diameter of 18mm. According to the steel composition requirements, the chemical composition of molten steel is: C: 0.45%, Si: 1.67%, Mn: 0.86%, P: 0.034%, S: 0.027%, V: 0.083 %, Als: 0.0081%;

[0027] Its preparation method comprises the following steps in turn:

[0028] It includes the steps of molten iron desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling.

[0029] (1) Desulfurization of the molten iron, controlling the sulfur content of the molten iron leaving the station S≤0.030%;

[0030] (2) Converter top-bottom blowing, the amount of steel scrap charged accounts for 10% of the total charge; the converter adopts top-bottom combined blowing, the end point adopts high-drawing supplementary blowing process, and the number of point blowing times is ≤ 2 times; the final slag alkalinity The target is 2.88; the control target o...

Embodiment 2

[0038] Prepare a finish-rolled rebar with a diameter of 18mm. According to the steel composition requirements, the chemical composition of molten steel is: C: 0.40%, Si: 1.8%, Mn: 0.92%, P: 0.027%, S: 0.021%, V: 0.94 %, Als: 0.008%;

[0039] Its preparation method comprises the following steps in turn:

[0040] It includes the steps of molten iron desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling, and is characterized in that:

[0041] (1) Desulfurization of the molten iron, controlling the sulfur content of the molten iron leaving the station S≤0.030%;

[0042] (2) Converter top-bottom blowing, the amount of steel scrap charged accounts for 13% of the total charge; the converter adopts top-bottom compound blowing, the end point adopts high-drawing supplementary blowing process, and the number of point blowing times is ≤ 2 times; the final slag alkalinity The target is...

Embodiment 3

[0050] Prepare a finish-rolled threaded steel bar with a diameter of 25mm. According to the steel composition requirements, the chemical composition of molten steel is: C: 0.42%, Si: 1.5%, Mn: 0.96%, P: 0.021%, S: 0.020%, V: 0.117 %, Als0.009%;

[0051] Its preparation method comprises the following steps in turn:

[0052] It includes the steps of molten iron desulfurization, converter smelting, argon blowing, continuous casting, billet heating, rolling, post-rolling controlled cooling, and cooling bed air cooling, and is characterized in that:

[0053] (1) Desulfurization of the molten iron, controlling the sulfur content of the molten iron leaving the station S≤0.020%;

[0054] (2) Converter top-bottom blowing, the amount of steel scrap charged accounts for 15% of the total charge; the converter adopts top-bottom compound blowing, the end point adopts high-drawing supplementary blowing process, and the number of point blowing times is ≤ 2 times; the final slag alkalinity T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com