V-N microalloyed Q550 grade medium plate and preparation method thereof

A technology for micro-alloying and thick steel plates, applied in the field of medium and thick plate manufacturing, can solve the problems of complex preparation process and large amount of alloy, and achieve the effects of increasing the solid solubility product, improving the strength and toughness, and good low-temperature impact toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

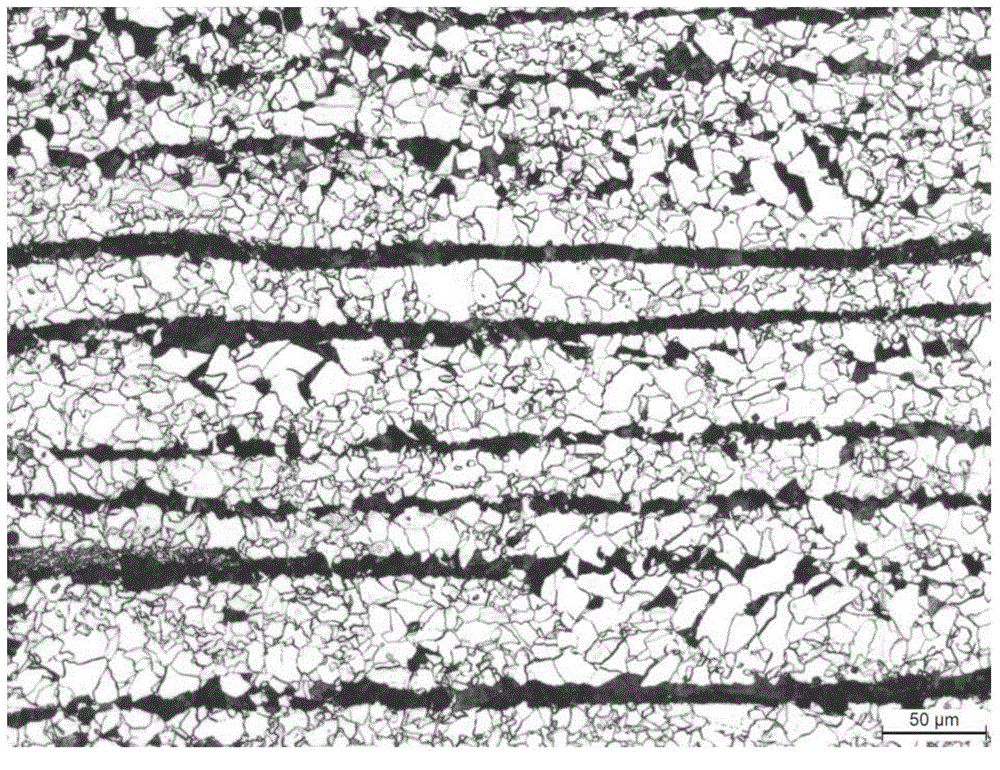

[0028] A V-N micro-alloyed Q550D grade medium-thick steel plate with a thickness of 50mm, its chemical composition by weight percentage is: C: 0.12%, Mn: 1.90%, Si: 0.20%, S: 0.005%, P: 0.003%, Al : 0.01%, V: 0.11%, N: 0.018%, the balance is Fe and other unavoidable impurities; the structure is fine-grained ferrite and pearlite.

[0029] Its preparation method is as follows:

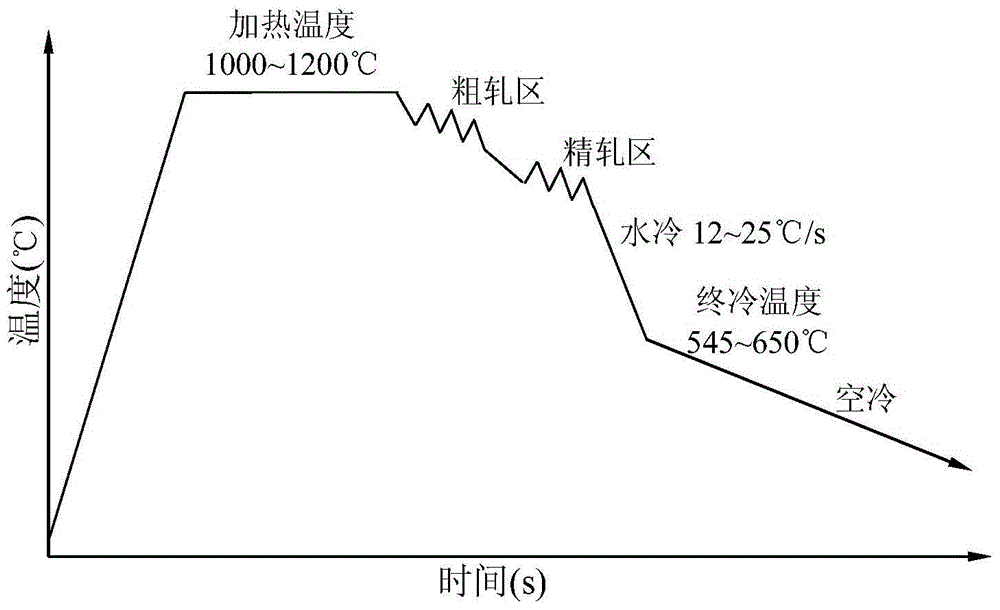

[0030] The continuous casting slab with a thickness of 220mm of the above components was heated to 1200°C with the furnace and held for 3 hours, and then hot-rolled into a hot-rolled plate with a thickness of 50mm. The starting and finishing temperatures of the rough rolling stage were 1150°C and 1020°C respectively ℃, the start rolling temperature and finish rolling temperature in the finish rolling stage are 925°C and 845°C respectively, the rough rolling stage passes through 5 passes of rolling, the total reduction rate is 55.9%, and the finish rolling stage passes through 5 passes of rolling, The to...

Embodiment 2

[0034] A V-N micro-alloyed Q550E grade plate with a thickness of 30mm, its chemical composition by weight percentage is: C: 0.10%, Mn: 1.20%, Si: 0.10%, S: 0.002%, P: 0.01%, Al : 0.04%, V: 0.15%, N: 0.01%, the balance is Fe and other unavoidable impurities; the structure is fine-grained ferrite, pearlite and acicular ferrite.

[0035] Its preparation method is as follows:

[0036] The slab with the thickness of 140mm of the above components was heated to 1100°C with the furnace and held for 4 hours, and then hot-rolled into a hot-rolled plate with a thickness of 30mm. The starting and finishing temperatures of the rough rolling stage were 1080°C and 990°C respectively. The starting and finishing temperatures of the finish rolling stage are 920°C and 837°C respectively. The rough rolling stage has been rolled for 5 passes, and the total reduction rate is 41.4%. The finish rolling stage has been rolled for 7 passes. The down rate was 37.1%;

[0037] After the hot rolling, the ...

Embodiment 3

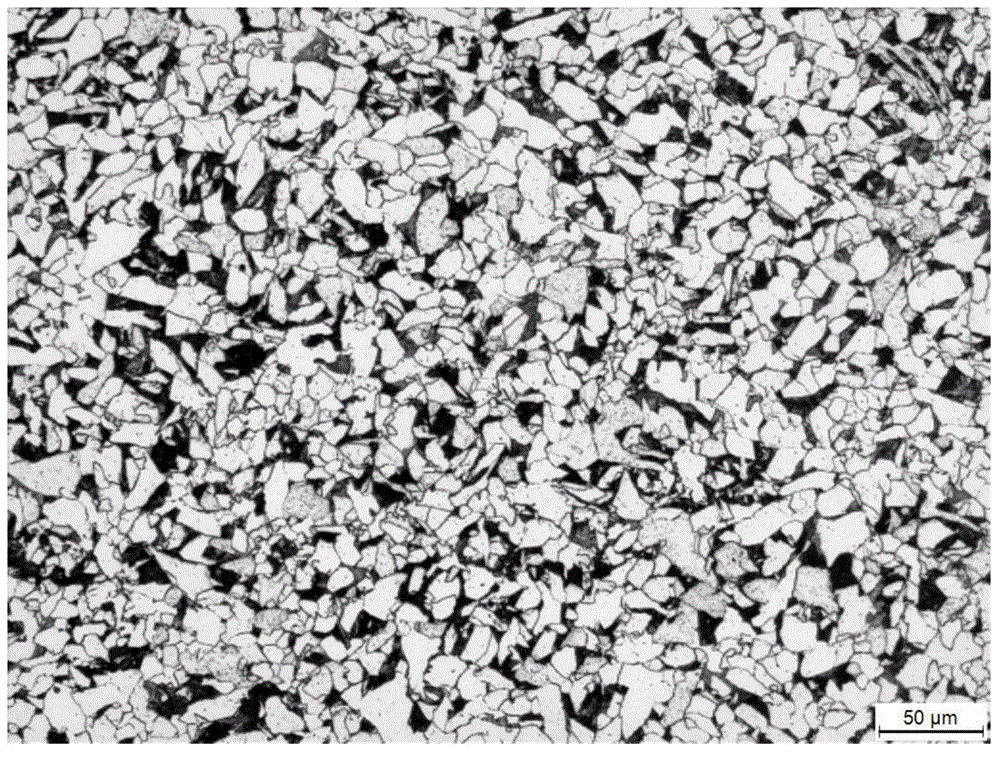

[0040] A V-N micro-alloyed Q550E grade plate with a thickness of 20mm, its chemical composition by weight percentage is: C: 0.06%, Mn: 2.00%, Si: 0.50%, S: 0.01%, P: 0.006%, Al : 0.05%, V: 0.06%, N: 0.02%, the balance is Fe and other unavoidable impurities; the structure is fine-grained ferrite, pearlite and acicular ferrite.

[0041] Its preparation method is as follows:

[0042] The slab with the thickness of 120mm of the above components was heated to 1000°C with the furnace and held for 4 hours, and then hot-rolled into a hot-rolled plate with a thickness of 20mm. The starting and finishing temperatures of the rough rolling stage were 1030°C and 980°C respectively. The starting and finishing temperatures of the finish rolling stage are 908°C and 820°C, respectively. The rough rolling stage has been rolled for 5 passes, and the total reduction ratio is 58.3%. The down rate is 25%;

[0043] After hot rolling, water-cooled to 545°C at a cooling rate of 25°C / s, and then air-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com