800MPa grade low-welding crack sensitive tempering type hydroelectric steel plate

A sensitive quenching and tempering technology with low welding cracks, applied in the field of metallurgy, can solve problems such as plasticity index and low temperature impact performance gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

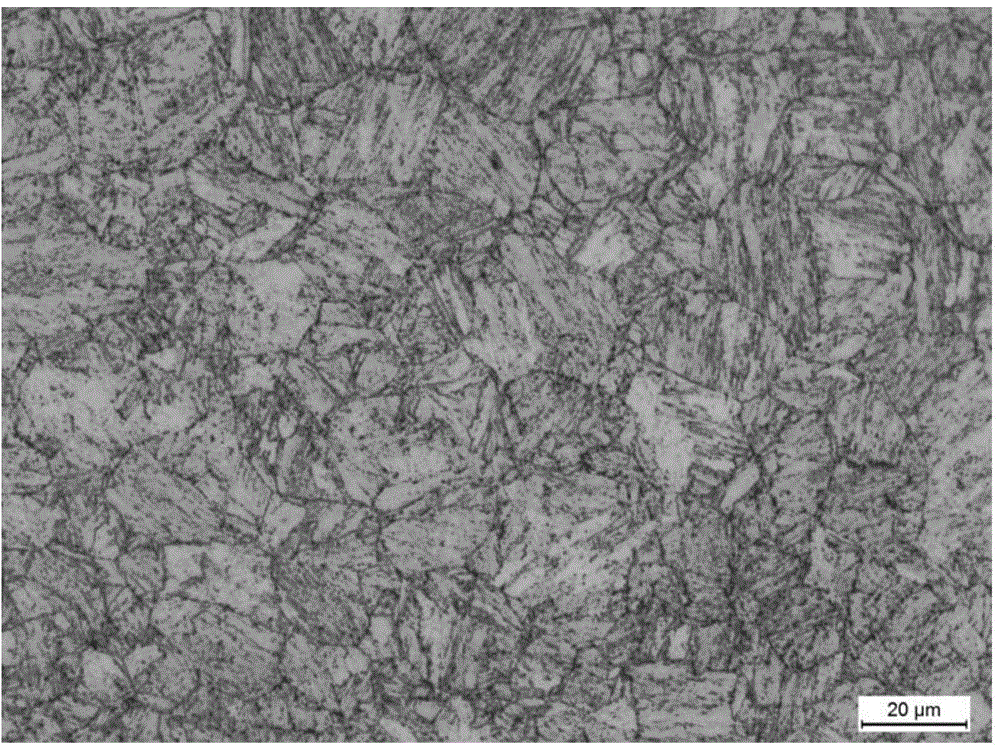

[0034] The composition of the steel in Examples 1-3 is consistent, and the steelmaking, continuous casting, forging slab heating and rolling processes are consistent, the difference lies in the subsequent quenching and tempering heat treatment process system, the specific process is as follows:

[0035] ⑴Steelmaking: A furnace of steel was smelted, and its actual chemical composition (% by weight) is, C: 0.1%, Si: 0.28%, Mn: 1.38%, Al: 0.04%, Cr: 0.48%, Ni: 0.44% , Mo: 0.38%, Nb: 0.02%, V: 0.04%, Ti: 0.014%, Cu: 0.25%, S: 0.0004%, P: 0.009%, N≤0.0060%, H≤0.00030%, B: 0.001% , the balance being Fe. Casting into a continuous casting billet with a specification of 320mm×2280mm×2100mm; the billet has undergone thermal inspection, stack cooling for 48 hours, and billet surface inspection before entering the furnace. The billet surface quality is good, and there is no grinding billet.

[0036] (2) Billet heating and rolling: The billet is heated and homogenized in two stages and th...

Embodiment 4

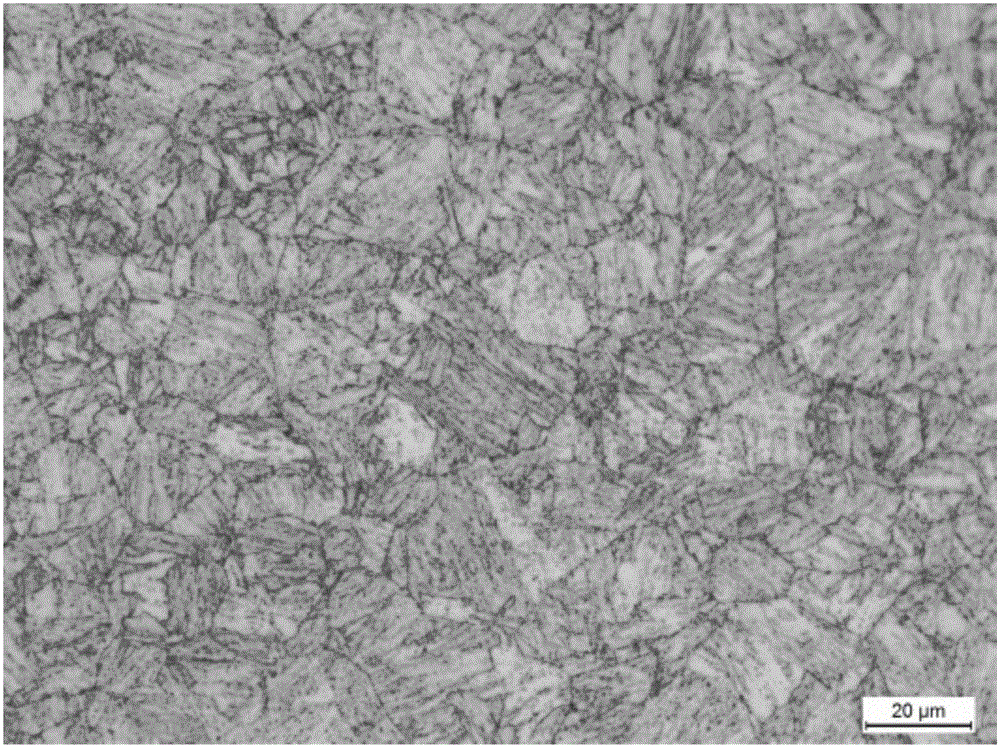

[0043]This embodiment is an 800MPa grade low welding crack sensitivity quenched and tempered steel plate for hydropower. The chemical composition of the steel plate is: C: 0.09%, Si: 0.24%, Mn: 0.7%, P: 0.013%, S : 0.002%, Nb: 0.035%, Ti: 0.012%, Ni: 0.30%, Alt: 0.020%, V: 0.035%, Cr: 0.25%, Mo: 0.25%, Cu: 0.15%, N: 0.0060%, H : 0.00030%, B: 0.0008%, and the balance is Fe.

[0044] The preparation method of the present embodiment steel plate, concrete steps are as follows:

[0045] (1) Smelt molten steel according to the set chemical composition and cast it into a slab with a thickness of 315mm; the chemical composition of the slab by weight percentage is: C: 0.09%, Si: 0.24%, Mn: 0.7%, P: 0.013%, S: 0.002%, Nb: 0.035%, Ti: 0.012%, Ni: 0.30%, Alt: 0.020%, V: 0.035%, Cr: 0.25%, Mo: 0.25%, Cu: 0.15%, N: 0.0060%, H: 0.00030%, B: 0.0008%, and the balance is Fe.

[0046] (2) Rough rolling is carried out after the billet is heated and homogenized in two stages. In the first stage...

Embodiment 5

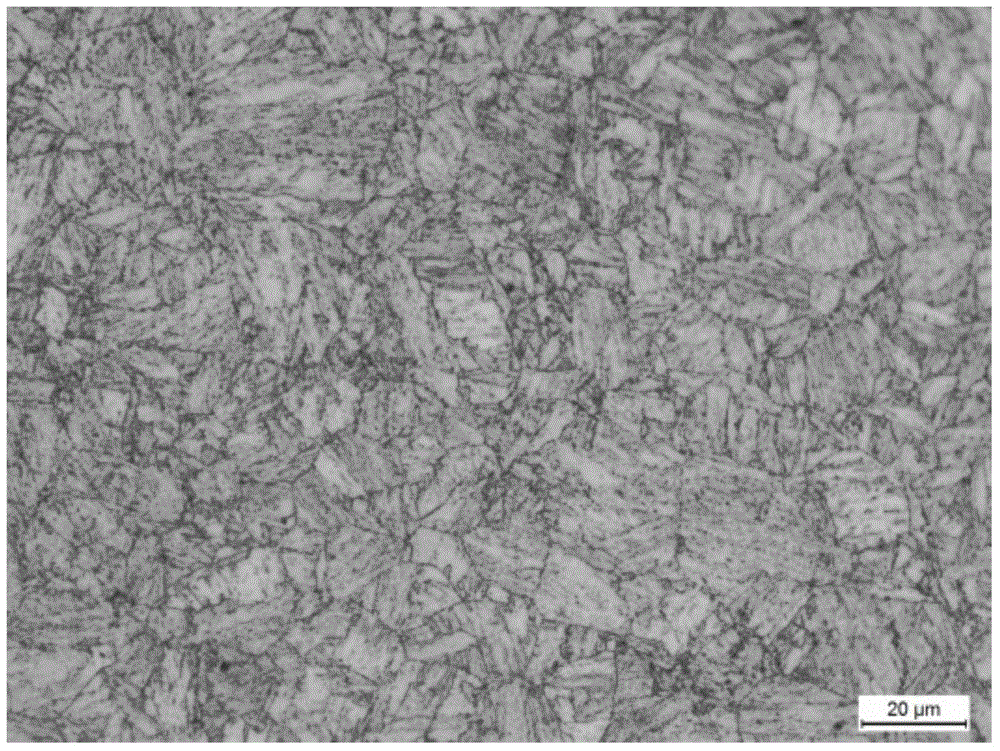

[0051] This embodiment is an 800MPa grade low welding crack sensitivity quenched and tempered steel plate for hydropower. The chemical composition of the steel plate is: C: 0.11%, Si: 0.28%, Mn: 0.9%, P: 0.01%, S : 0.001%, Nb: 0.015%, Ti: 0.016%, Ni: 0.40%, Alt: 0.050%, V: 0.040%, Cr: 0.45%, Mo: 0.35%, Cu: 0.20%, N: 0.0020%, H : 0.00010%, B: 0.001%, and the balance is Fe.

[0052] The preparation method of the present embodiment steel plate, concrete steps are as follows:

[0053] (1) Smelt molten steel according to the set chemical composition and cast it into a slab with a thickness of 320mm; the chemical composition of the slab by weight percentage is: C: 0.11%, Si: 0.28%, Mn: 0.9%, P: 0.01%, S: 0.001%, Nb: 0.015%, Ti: 0.016%, Ni: 0.40%, Alt: 0.050%, V: 0.040%, Cr: 0.45%, Mo: 0.35%, Cu: 0.20%, N: 0.0020%, H: 0.00010%, B: 0.001%, and the balance is Fe.

[0054] (2) Rough rolling is carried out after the billet is heated and homogenized in two stages. In the first stage, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com