Method of submerged-arc welding of thick sheet S355NL for low-temperature wind tower

A welding method, submerged arc welding technology, applied in welding medium, welding equipment, welding equipment, etc., can solve the problems of no preheating, no heat treatment, etc., to achieve simple welding operation, excellent mechanical properties, excellent low temperature impact toughness and The effect of safety reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

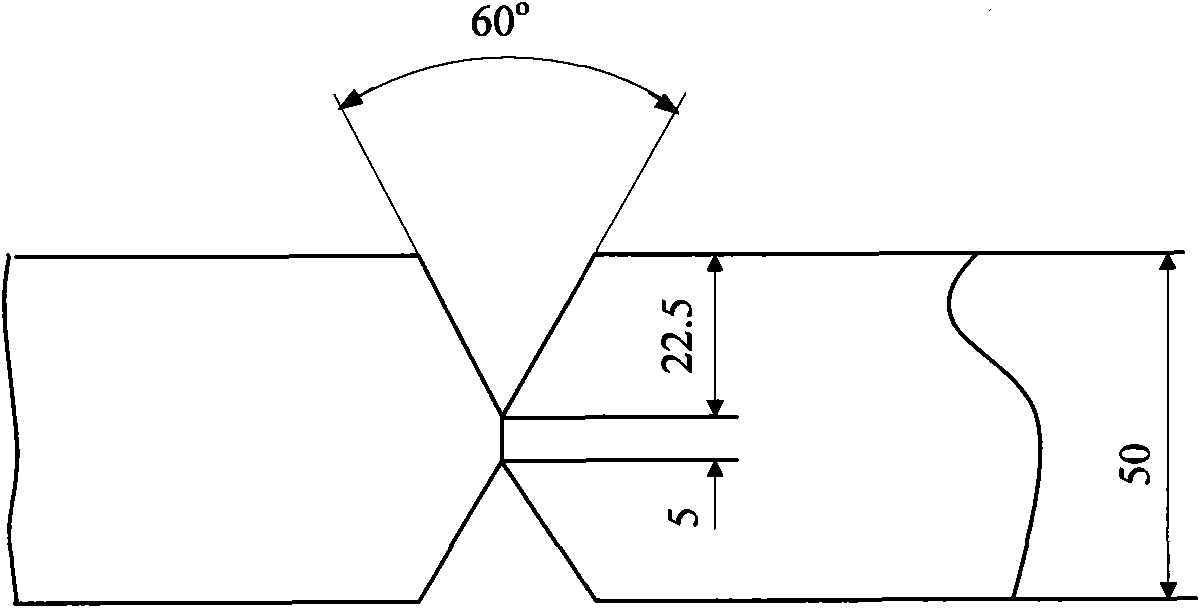

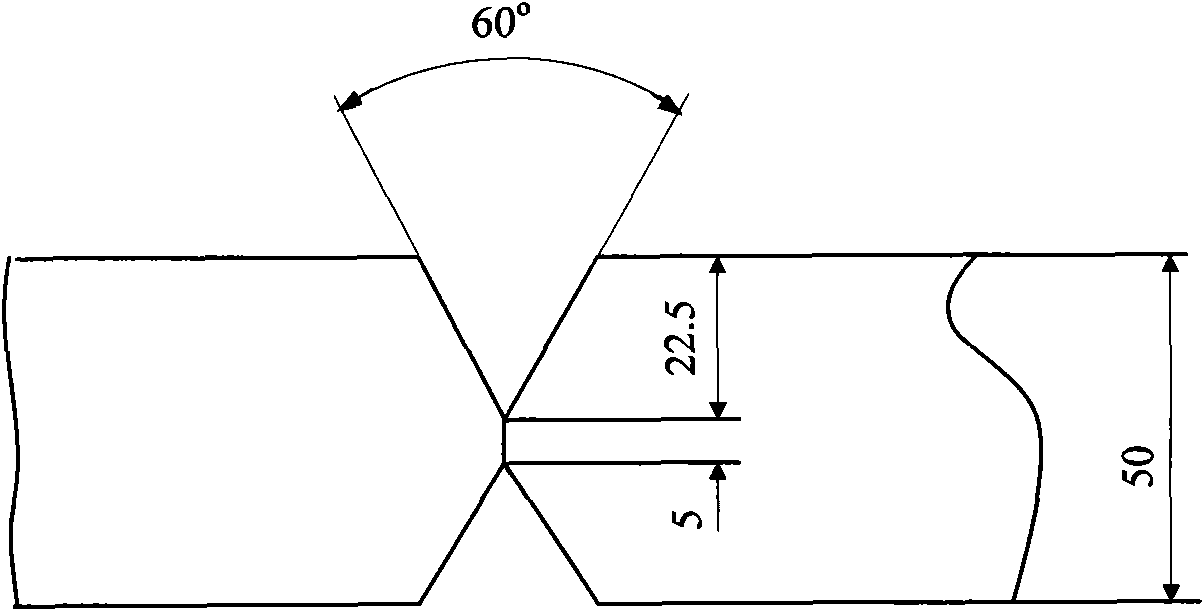

[0030] A kind of low-temperature wind tower of the present invention uses thick plate S355NL submerged arc welding method, comprises the following steps:

[0031] The steel plate S355NL for low-temperature wind tower with a strength of ≥490MPa produced by thermomechanical controlled rolling and controlled cooling process (TMCP) + normalizing, and the combination of plate thickness is 50mm+50mm. The size of the test plate is 600mm×400mm×32mm; the chemical composition and weight percentage of the selected S355NL low temperature wind tower steel meet: C: 0.10~0.14%, Mn: 1.30~1.45%, Si: 0.20~0.30%, P: ≤0.013%, S: ≤0.005%, Nb: 0.020~0.030%, V: 0.04~0.05%, Ti: ≤0.03%, Ni: 0.20~0.30%, Cr: ≤0.08%, Mo: ≤0.08%, remainder The amount is Fe and unavoidable impurities; the carbon equivalent of steel Ceq≤0.42%.

[0032] Select matching welding materials:

[0033] Welding wire BHM-6, the wire diameter is Φ4mm, its chemical composition and weight percentage are: C: 0.12%, Mn: 1.87%, Si: 0.01%,...

Embodiment 2

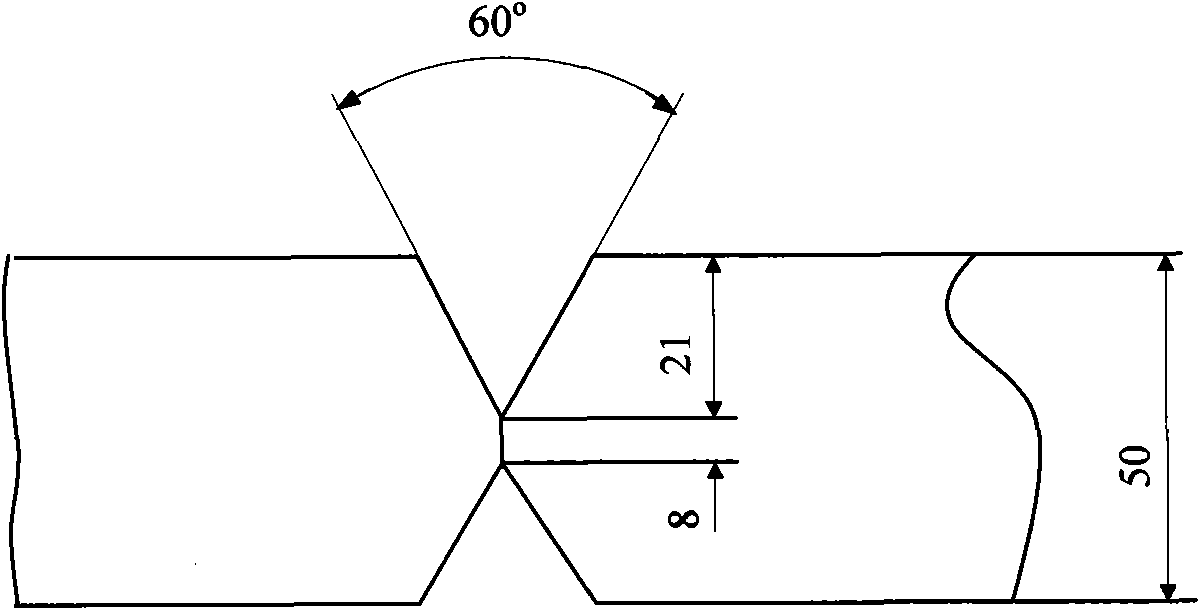

[0039] Another kind of low-temperature wind tower of the present invention uses thick plate S355NL submerged arc welding method, comprising the following steps:

[0040] The low-temperature wind tower steel plate S355NL with a strength of ≥490MPa is produced by thermomechanical controlled rolling and controlled cold rolling process (TMCP) + normalizing, and the combination of thick plates is 50mm+50mm. The size of the test plate is 600mm×400mm×50mm; the chemical composition and weight percentage of the selected S355NL low temperature wind tower steel meet: C: 0.10~0.14%, Mn: 1.30~1.45%, Si: 0.20~0.30%, P: ≤0.013%, S: ≤0.005%, Nb: 0.020~0.030%, V: 0.04~0.05%, Ti: ≤0.03%, Ni: 0.20~0.30%, Cr: ≤0.08%, Mo: ≤0.08%, remainder The amount is Fe and unavoidable impurities; the carbon equivalent of steel Ceq≤0.42%.

[0041] Select matching welding materials:

[0042] Welding wire BHM-6, the wire diameter is Φ4mm, its chemical composition and weight percentage are: C: 0.12%, Mn: 1.87%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com