High-strength and high-yield-ratio non-quenched and tempered steel for automobile engine stretch-broken connecting rod and production method thereof

An automotive engine, high yield-strength ratio technology, applied in temperature control and other directions, can solve the problems of reducing C content, difficulty in adding rare earth, low fatigue performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

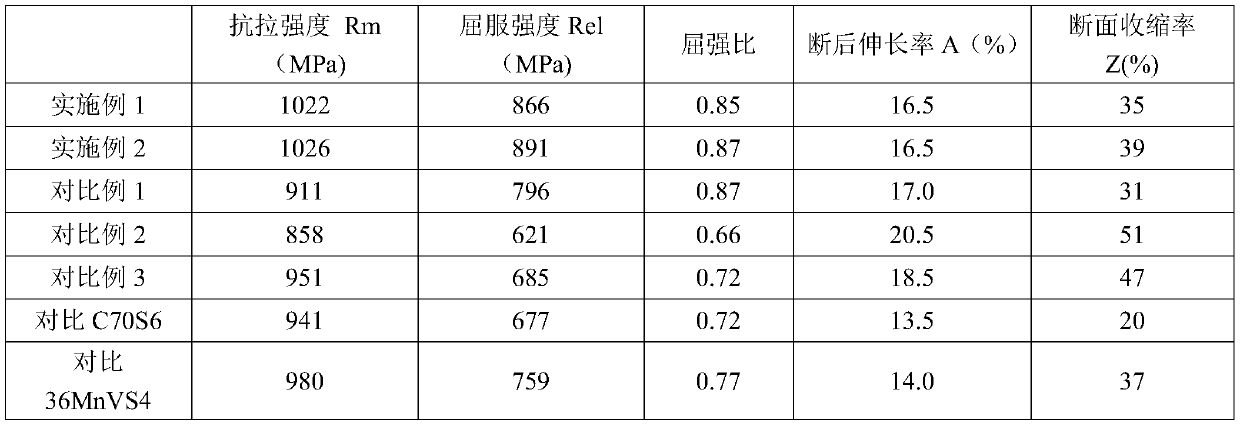

Examples

Embodiment 1

[0043] A high-strength, high-yield-ratio non-quenched and tempered steel for automotive engine breakable connecting rods and a production method thereof. The chemical composition of the steel is calculated by weight percentage: C 0.45%, Si 0.56%, Mn 1.23%, S 0.049%, V 0.15%, Nb 0.029%, Cr 0.20%, Ni 0.13%, N 0.016%, the rest are Fe and impurity elements.

[0044] The initial smelting end point C is 0.20%, to prevent molten steel from peroxidation, and slag is strictly prohibited; during the tapping process, deoxidizer, alloy, recarburizer, and slag are added in sequence; LF refining is fine-tuned to maintain the reducing atmosphere in the furnace, and the slag alkalinity is 2.5. Bottom-blowing argon gas stirring, uniform temperature and composition, and promoting the removal of non-metallic inclusions in the steel to ensure the purity of molten steel; the Mn content at the end of LF is 1.08%, leaving a suitable margin for adjusting the Mn and N content after vacuum.

[0045] Du...

Embodiment 2

[0050] A high-strength, high-yield-ratio non-quenched and tempered steel for automotive engine connecting rods and a production method thereof. The chemical composition of the steel is calculated by weight percentage: C 0.47%, Si 0.54%, Mn 1.25%, S 0.047%, V 0.14%, Nb 0.030%, Cr 0.21%, Ni 0.15%, N 0.016%, the rest are Fe and impurity elements.

[0051] The initial smelting end point C is 0.21%, to prevent molten steel from peroxidation, and slag removal is strictly prohibited; during the tapping process, deoxidizer, alloy, carburizer, and slag are added in sequence; LF refining carries out fine-tuning of the composition to maintain the reducing atmosphere in the furnace, and the slag alkalinity is 2.3, Bottom-blowing argon gas stirring, uniform temperature and composition, and promoting the removal of non-metallic inclusions in the steel to ensure the purity of molten steel; the Mn content at the end of LF is 1.08%, leaving a suitable margin for adjusting the Mn and N content a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com