Patents

Literature

32results about How to "Good self-fluxing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laser cladding repair process for cross shafts

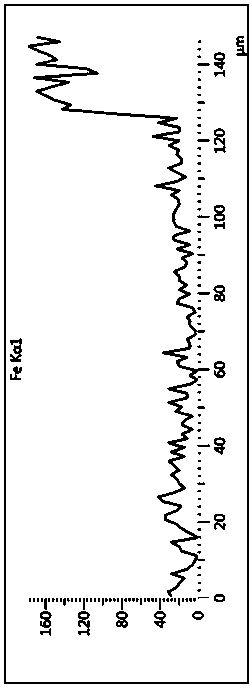

InactiveCN102828181AImprove wettabilityImprove wear resistanceMetallic material coating processesOptoelectronicsHardness

The invention relates to a laser cladding repair process for cross shafts. The process comprises the following steps of: A. carrying out treatment on the surface of the cross shaft, and carrying out failure analysis; B. carrying out 80-150 DEG C overall preheating on the cross shaft; C. according to failure analysis results of the cross shaft, optimizing process parameters, and carrying out laser cladding, wherein adopted alloy powder comprises the following components in percentage by weight: less than or equal to 0.1% of C, 10-13% of Cr, 1.5-2.5% of B, 1-2% of Si, 0.5-1.2% of Mo, 8-12% of Mn, 6-12% of W, 5-15% of TiO2, and the balance of Fe; and D. carrying out detection. According to the laser cladding repair process for the cross shafts, disclosed by the invention, through carrying out the laser cladding on the surface of the cross shaft, the size of the cross shaft can meet the application requirements, and the hardness and the wear resistance of the cross shaft subjected to repair exceed the original hardness and the original wear resistance of the cross shaft.

Owner:DANYANG HONGTU LASER TECH

Rare earth and Ni based alloy powder material

The invention discloses a rare earth and Ni based alloy powder material to improve the abrasion and corrosion resistances of the material and prolong the service lives of parts. The material comprises 1.0-1.4wt% of C, 3.0-3.6wt% of B, 3.8-4.0wt% of Si, 16.5-18.5wt% of Cr, 3.0-4.0wt% of Fe, 1.0-2.0wt% of Cu, 1.0-2.0wt% of Mo, 0.2-0.3wt% of Nb, 0.2-0.3wt% of Y, and the balance Ni.

Owner:兰州理工合金粉末有限责任公司

Method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles

InactiveCN101580939AImprove processing qualityImprove coating qualityMolten spray coatingHeat inorganic powder coatingSurface engineeringHardness

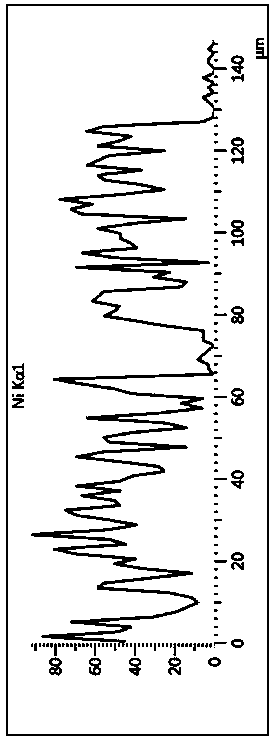

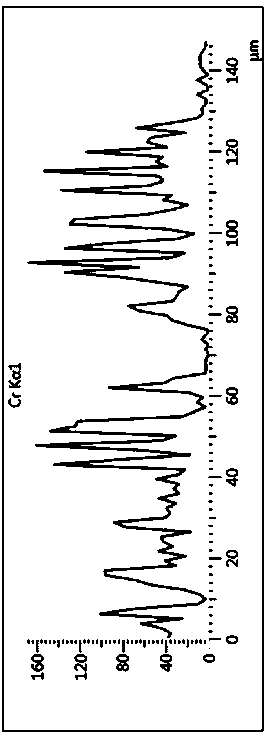

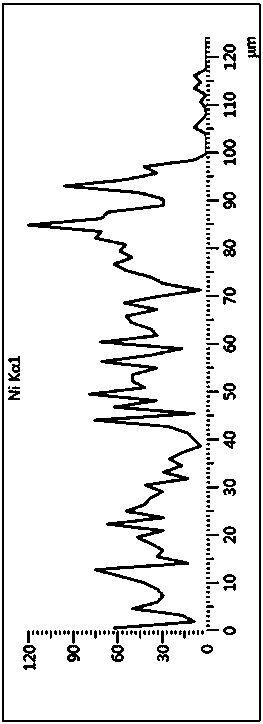

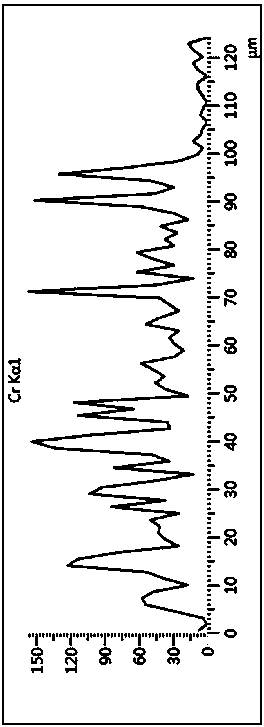

The invention relates to surface engineering technique in technical fields such as design materials, electrical power, metallurgy, machine and the like, in particular to a method for preparing metallic matrix composite coating reinforced by tungsten carbide ceramics particles. The metallic matrix composite coating reinforced with tungsten carbide ceramics particles (WCP / NiCrBSi) is prepared on the surface of mild steel base material based on the characteristics of high hardness, wear resistance, erosion resistance of the tungsten carbide ceramics material and fine self-fluxing nature, wettability and plasma spraying technology of the NiCrBSi alloy, and the property of wear and tarnish resistance is improved. The technique process of preparing WCP / NiCrBSi composite material coating is as follows: coating design; sifting dusty spray; mixing the powder according to certain ratio; superficial treatment of base material; controlling plasma spraying parameter; preparing WCP / NiCrBSi coating.

Owner:JILIN UNIV

Gear laser cladding repair process beneficial to improve hardness and wear resistance

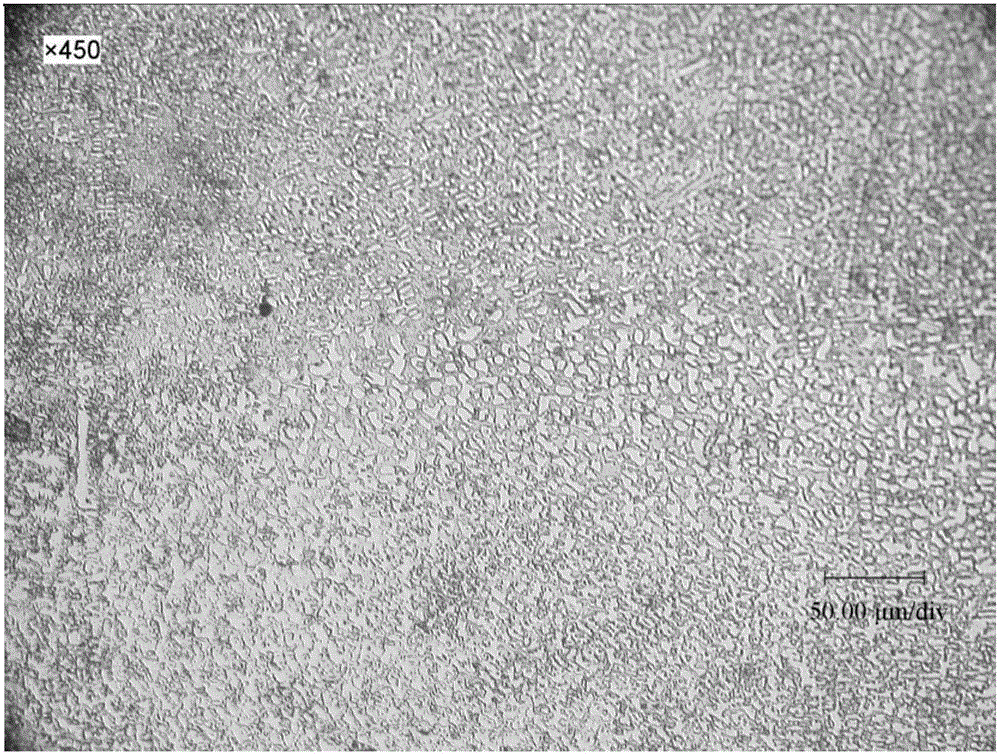

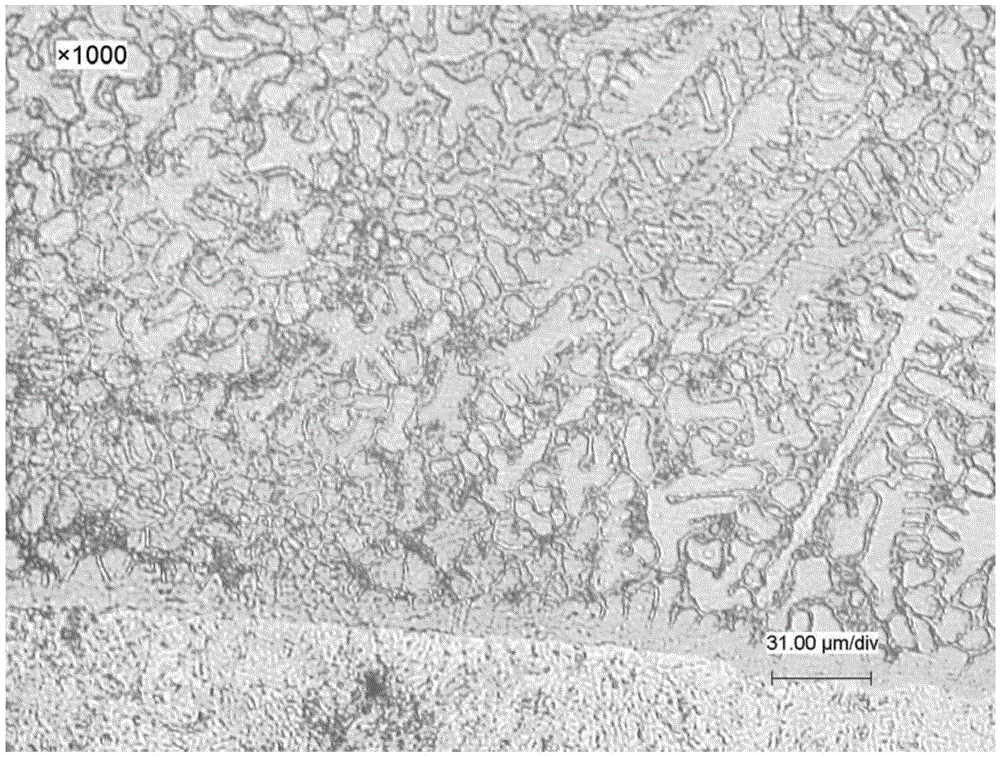

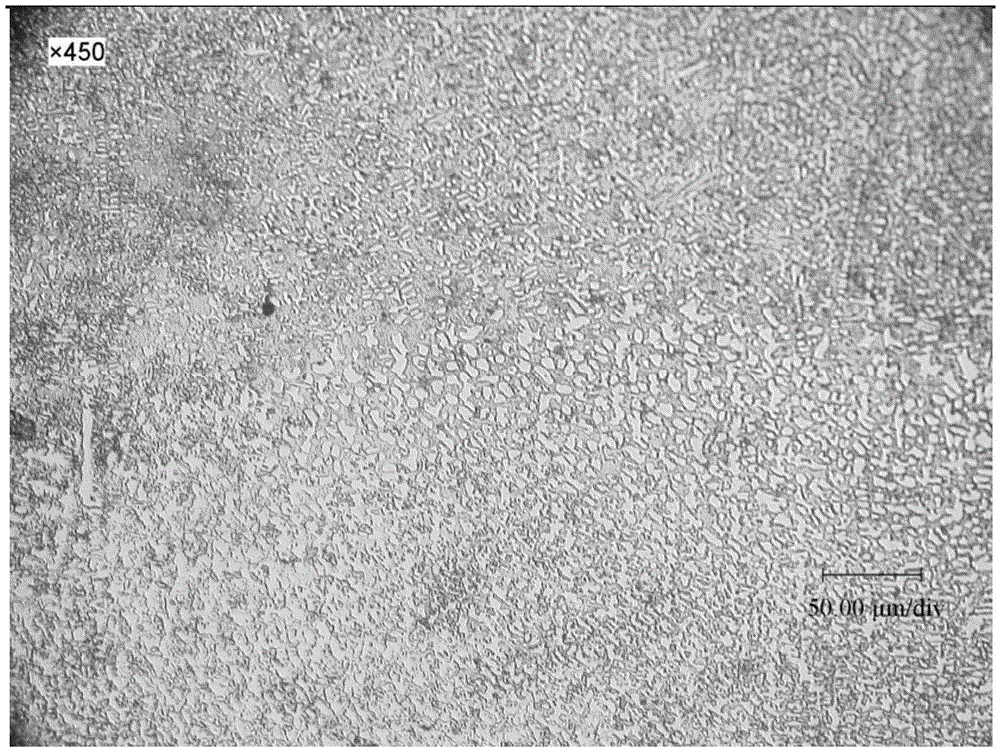

ActiveCN103668176AGood self-fluxingIncrease contentMetallic material coating processesGear wheelAlloy

The invention relates to a gear laser repair process which comprises the following steps: A. treating the surface of a gear, and performing failure analysis on the gear; B, integrally preheating the gear at 80-120 DEG C, and locally preheating the to-be-repaired part of the gear at 180-220 DEG C at the same time; C, optimizing process parameters according to the failure analysis result of gear, performing layer-by-layer laser cladding, wherein the thickness of each cladding layer is less than or equal to 0.4 mm, the edge of the next cladding layer is extended outwards from the edge of the previous cladding layer by 4-6mm, and the used alloy powder comprises the following components in percentage by weight: no more than 0.5% of C, 38-52% of Cr, 1.5-2.5% of B, 0.5-1.5% of Si and the balance of Fe; and D, detecting. According to the gear laser repair process, the surface of the gear is subjected to laser cladding, so that the size meets the use requirements, and the hardness and wear resistance of the repaired gear exceed the original properties.

Owner:XINJIANG HUIXIANG LASER TECH

Laser repairing technology for aluminum foil roll crack

InactiveCN102677047AImprove tissue uniformityAvoid it happening againMetallic material coating processesLaser beam welding apparatusAlcladOptoelectronics

The invention relates to a laser repairing technology for an aluminum foil roll crack. The laser repairing technology for the aluminum foil roll crack comprises the following steps: A, cleaning up a roll; B, preheating the roll at a low temperature; C, optimizing technical parameters, and performing laser cladding on polished and cleaned pits on the roll, wherein in the process, the roll is vibrated, the temperature of the roll is kept to be 180-250 DEG C until the pits are filled, a cladding layer is higher than the roll surface, and used alloy powder comprises the following components by weight percent: 10-15% of Cr, 1-2% of B, 0.5-1.5% of Si and Fe in balancing amount; and D. detecting. The laser repairing technology for the aluminum foil roll crack can perform laser cladding on the roll crack and can effectively fill a very deep crack to making the deep crack meet a using requirement; the structural uniformity of the cladding layer is good; and the fusion rate of the cladding layer and a matrix is high.

Owner:DANYANG HONGTU LASER TECH

Nickel-chrome-molybdenum-tungsten alloy powder for plasma surfacing

InactiveCN102828138AImprove corrosion resistanceExtended service lifeMolten spray coatingPlasma welding apparatusTungsten alloyMolybdenum

The invention discloses nickel-chrome-molybdenum-tungsten alloy powder for plasma surfacing. The nickel-chrome-molybdenum-tungsten alloy powder comprises the following components in percentage by weight: 1.3 to 1.6 percent of C, 3.2 to 3.8 percent of B, 3.8 to 4.5 percent of Si, 22 to 28 percent of Cr, 3.0 to 5.0 percent of Fe, 3.0 to 5.0 percent of Mo, 1.0 to 3.0 percent of W and the balance of Ni.

Owner:兰州理工合金粉末有限责任公司

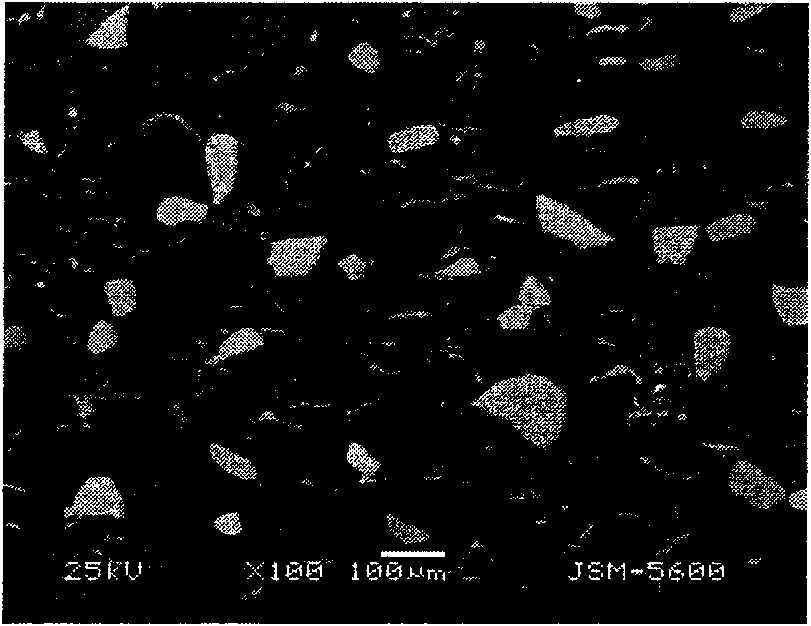

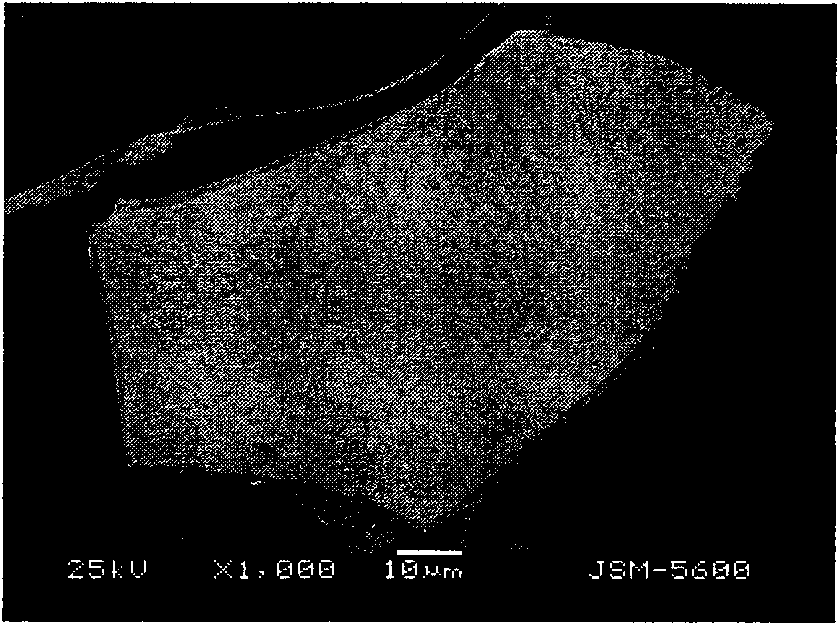

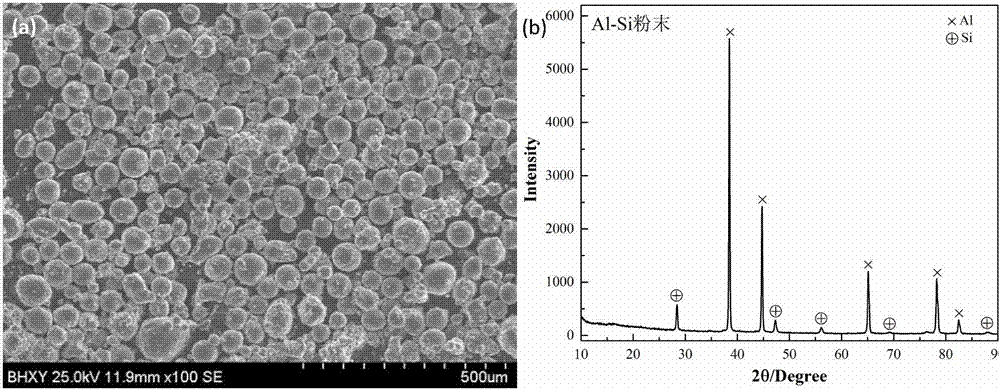

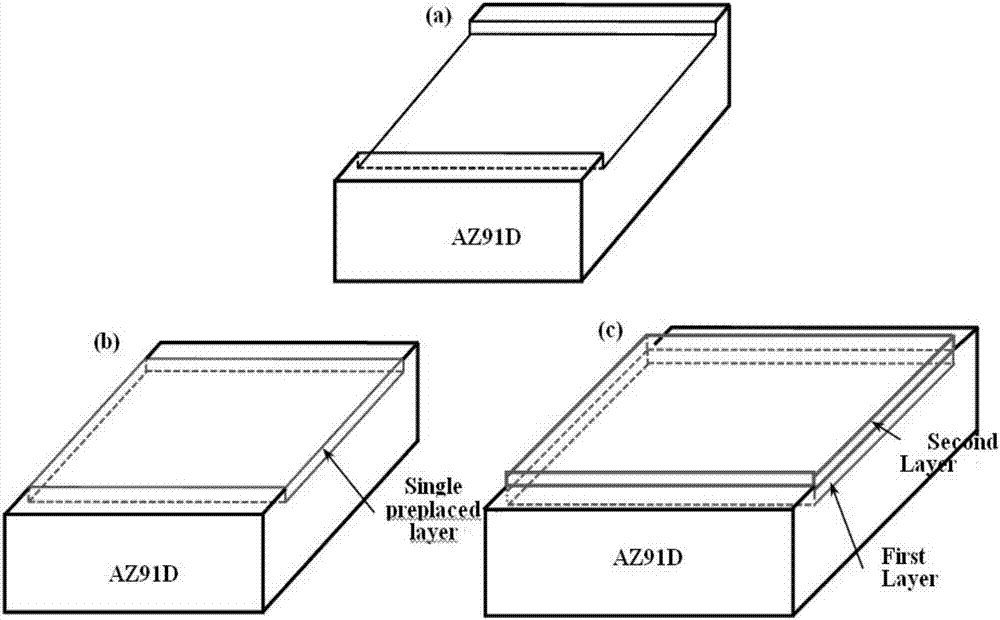

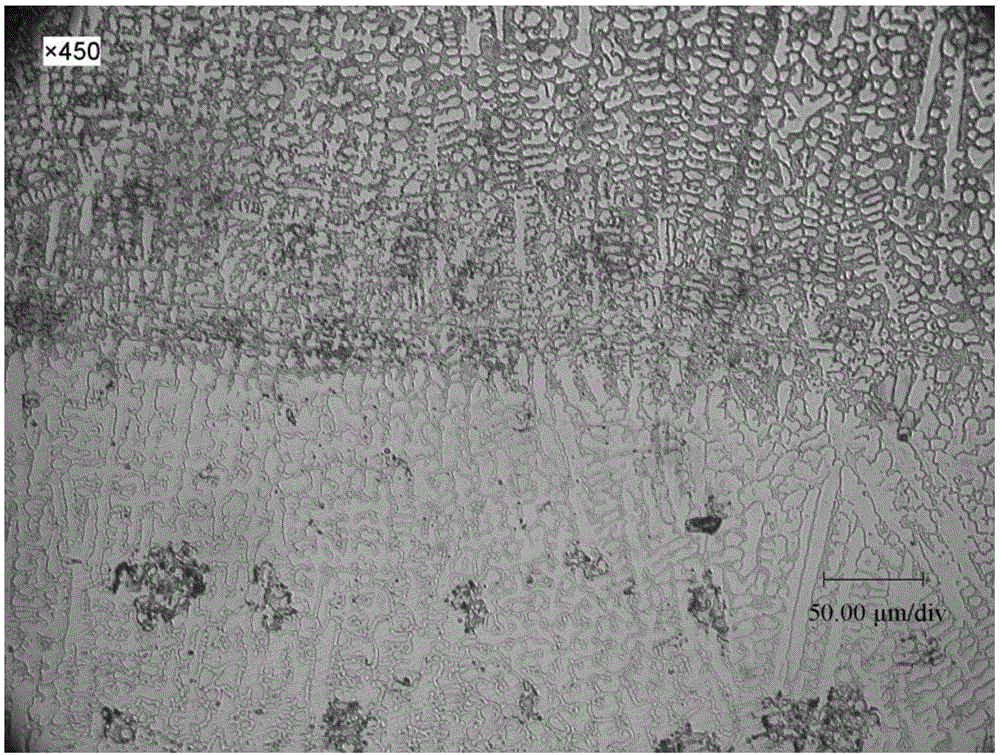

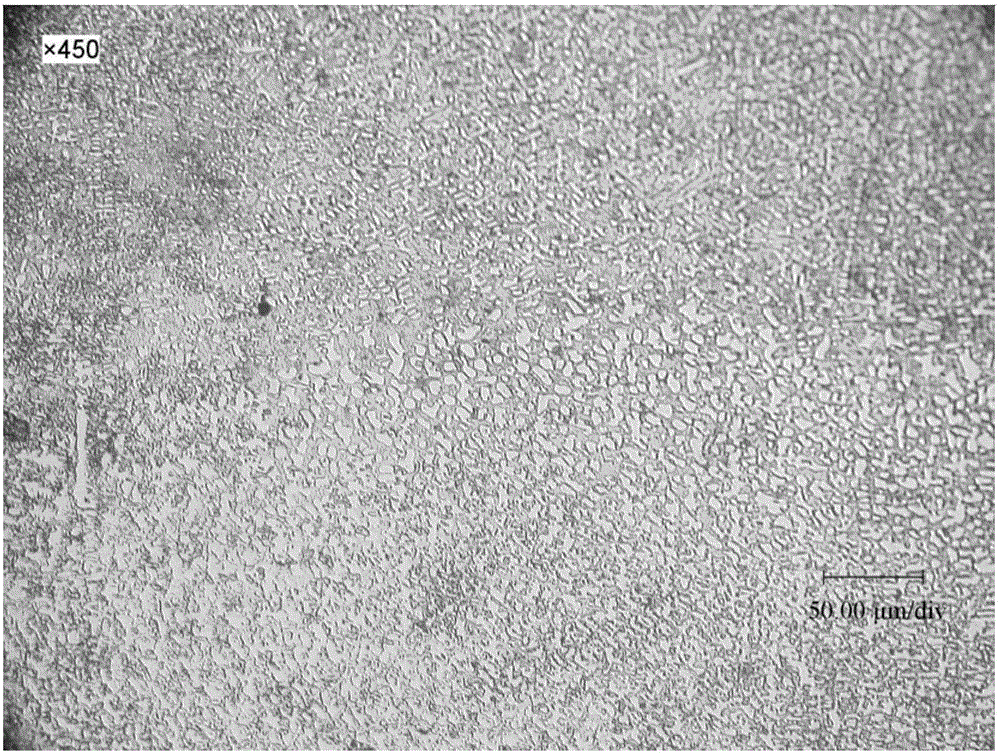

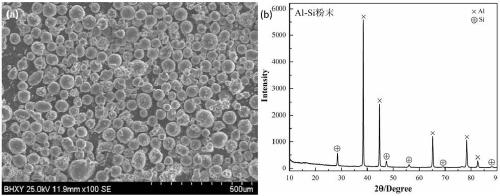

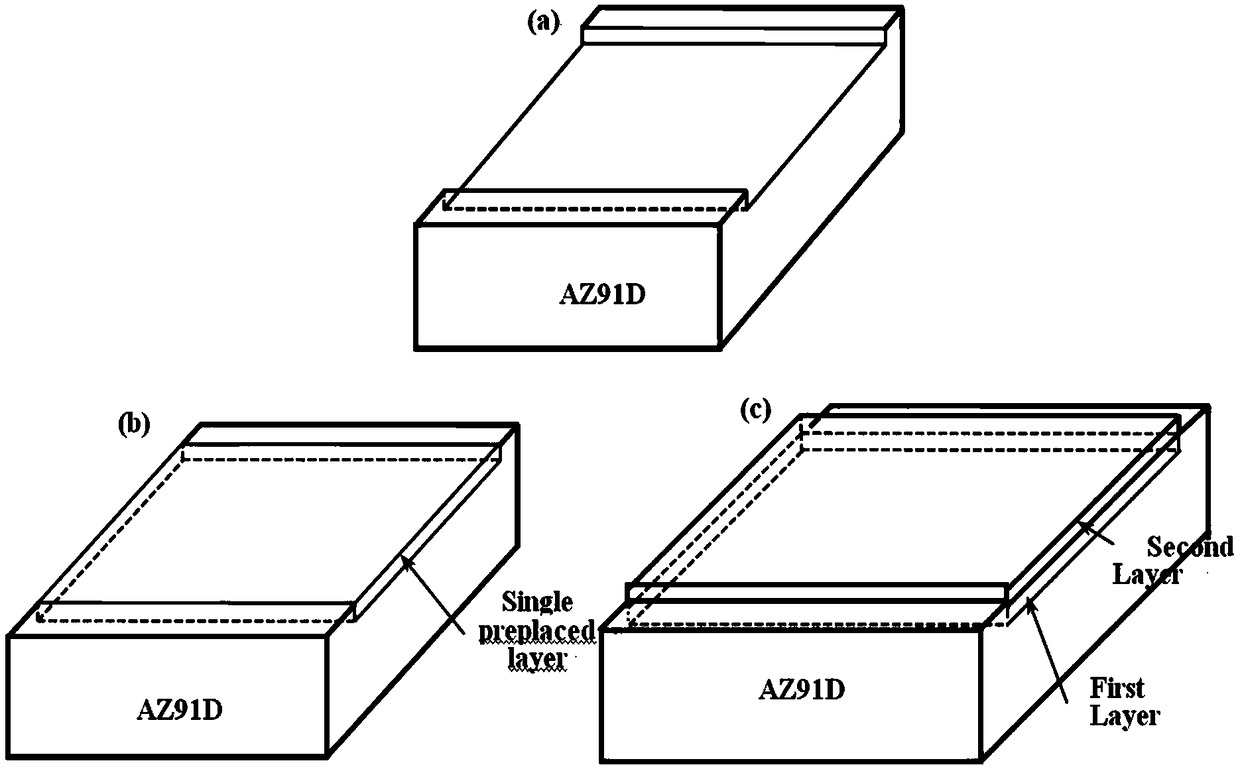

Aluminum oxide modified gradient laser cladding layer and preparation method thereof

ActiveCN107012463AReduce excessive oxidation and burning lossAvoid destructionMetallic material coating processesCorrosion resistantCorrosion current density

The invention discloses an aluminum oxide modified gradient laser cladding layer and a preparation method thereof. Magnesium alloy serves as base material, Al-Si alloy powder serves as a first precoated layer, the mixed powder of nickel-based self-melting alloy powder and Al2O3 serves as a second precoated layer, and the aluminum oxide modified gradient laser cladding layer is formed through laser cladding. The corrosion potential of the Al2O3 modified gradient laser cladding layer is about -1.1 V and is similar to that of a Ni35, Al-Si / Ni35 cladding layer, the corrosion current density is large in difference and is about 1 / 15-1 / 2 that of the base material, and a good corrosion resistant effect is achieved. The aluminum oxide modified gradient laser cladding layer and the preparation method thereof can be used for surface strengthening and modification of magnesium alloy parts in the industrial field, the application range of magnesium alloy in corrosion resistant occasions is extended, and wide application prospects are achieved.

Owner:SHANDONG UNIV

Wear-resistant ceramic roller and preparation method thereof

InactiveCN111575568AReasonable structural designImprove wear resistanceMetallic material coating processesPolyvinyl alcoholAdhesive

The invention discloses a wear-resistant ceramic roller and a preparation method thereof. The ceramic roller comprises a roller core and a wear-resistant layer from inside to outside, and the roller core is prepared from the following components of, in parts by mass, 70 to 80 parts of ceramic particles, 20 to 30 parts of a metal matrix, 15 to 20 parts of active elements and 1 to 5 parts of an adhesive, wherein the ceramic particles are prepared from the following components of, in parts by mass, 80 to 85 parts of Al2O3, 10 to 15 parts of ZrO2 and 1 to 5 parts of polyvinyl alcohol; the metal matrix is prepared from the following components of, in parts by mass, 20 to 15 parts of Cr, 2.0 to 2.5 parts of C, 1.0 to 2.2 parts of Ni, 1.0 to 1.5 parts of Mo, 0.5 to 1.0 part of Mn, 0.2 to 0.6 partof Si, 0 to 0.1 part of P, 0 to 0.05 part of S and the balance of Fe; and the wear-resistant layer is prepared from the following components of, in parts by mass, 85 to 95 parts of Fe55 powder and 5to 15 parts of TiC particles. According to the wear-resistant ceramic roller and the preparation method thereof, the formula is reasonable, the preparation method is simple, the cost is low, the yieldis high, large-scale batch production is easy to realize, and the prepared ceramic roller has the advantages of good wear resistance, long service life and wide application prospect.

Owner:徐州华焰特种陶瓷有限公司

Preparation method of nickel alloy 200-micrometer coating containing titanium boride

The invention discloses a preparation method of a nickel alloy 200-micrometer coating containing titanium boride. The method comprises the steps that firstly, heat treatment is carried out on the surface of a metal workpiece; then, various kinds of raw material powder are taken to prepare alloy powder according to the proportion; and finally, a plasma spraying method is adopted to spray an alloy layer on the surface of the workpiece. The method has the advantages that the method is simple, raw materials are easy to obtain, the comprehensive performance is good, and the application is wide.

Owner:SHENYANG LIGONG UNIV

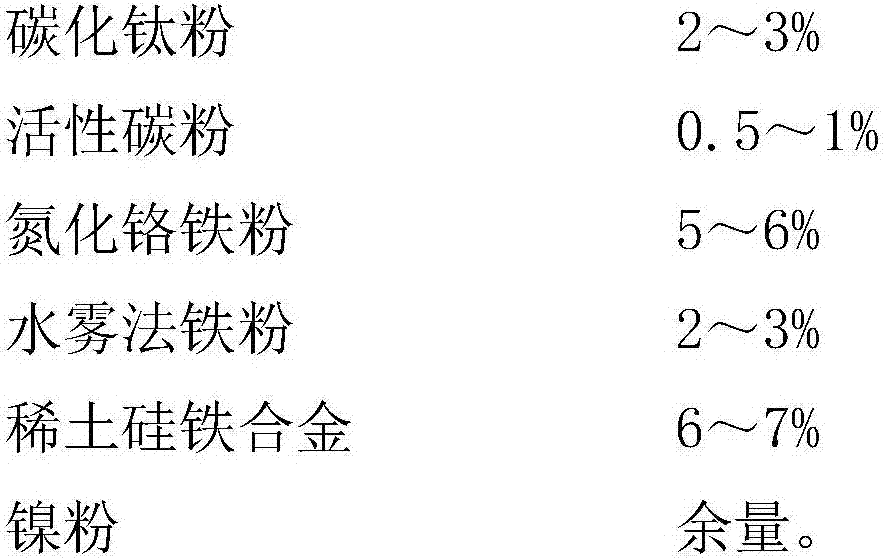

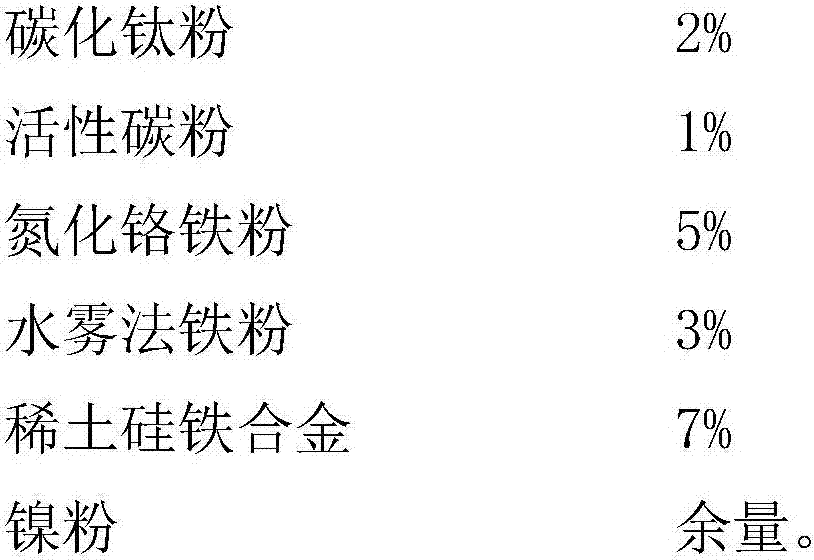

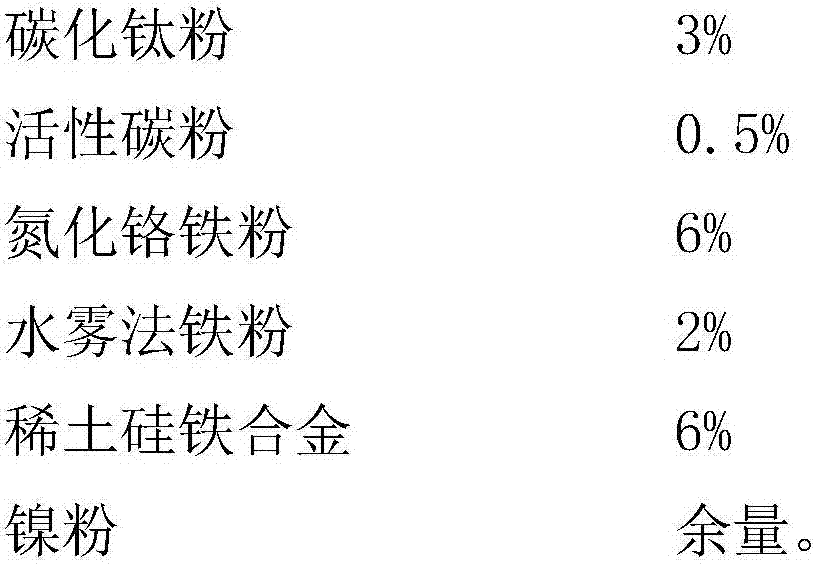

Self-fluxing nickel base alloy powder for repairing valve seats and welding technology thereof

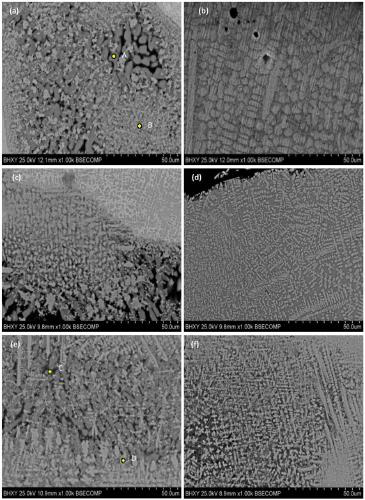

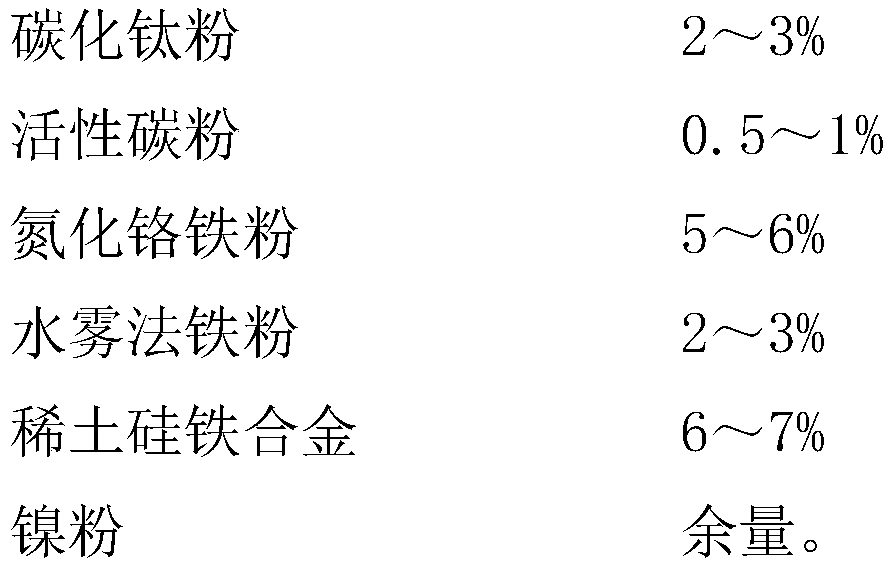

ActiveCN107335890AGood self-fluxingLow melting pointPlasma welding apparatusWelding/cutting media/materialsFerrosiliconRare earth

The invention relates to a self-fluxing nickel base alloy powder for repairing a valve seat and awelding technology of self-fluxing nickel base alloy powder for repairing the valve seat. The self-fluxing nickel base alloy powder for repairing valve seat is prepared from, by mass, 2-3% of titanium carbide powder, 0.5-1% of activated carbon powder; 5-6% of nitrogen containing ferrochromium powder, 2-3% of water mist iron powder, 6-7% of rare earth ferrosilicon alloy and the balance nickel powder. The self-fluxing nickel base alloy powder has low melting point and good self-fluxing nature. Therefore, the self-fluxing nickel base alloy powder is suitable for spray welding hard face alloy. The spray welding layer has good abrasive resisting property, good corrosion resisting property, good heat resisting property and good oxidation resisting property. A welding layer is formed on the surface of a workpiece by an oxygen-acetylene one-step or two-step method for spray welding. Apart from achieving the restoring of the size of a valve seat, the surface properties of the valve seat are also further improved. Therefore, the service life of the valve seat is extended.

Owner:安徽鼎恒再制造产业技术研究院有限公司

Laser cladding repairing process of valve seat with high hardness and less deformation

ActiveCN103668036AImprove corrosion resistanceImprove wear resistanceMolten spray coatingLaser beam welding apparatusHardnessAlloy

The invention relates to a laser cladding repairing process of a valve seat. The process comprises the following steps: A, treating the surface of the valve seat, and carrying out failure analysis on the valve seat; B, optimizing the technical parameters for laser cladding according to the failure analysis results of the valve seat, wherein the alloy powder adopted comprises the following components in percentage by weight: 0.5-1% of C, 19-23% of Cr, 1.5-2% of B, 1-3% of Si, 0.05-0.5% of Mo, 0.05-0.5% of Mn, 7-9% of W, 2.5-4% of Ni and the balance of C; and C, detecting. According to the laser cladding repairing process of the valve seat, laser cladding is carried out on the surface of the valve seat, so that the size of the valve seat is recovered to meet the using demands, and the corrosion resistance and wear resistance of the repaired valve seat exceed the original performances.

Owner:临沂人才数字科技集团有限公司

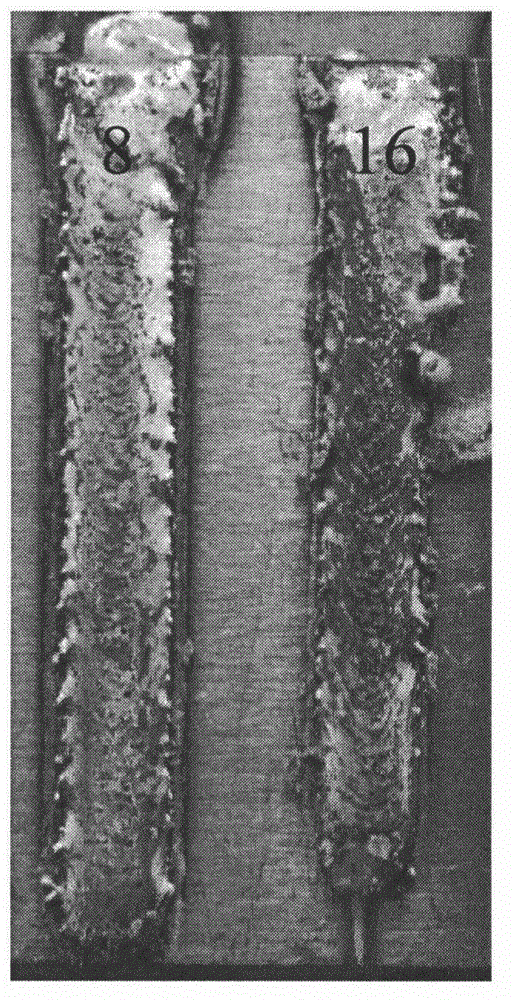

Preparation method for nickel-based glass fiber composite material based on laser cladding

InactiveCN104451663AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesShielding gasOptoelectronics

The invention discloses a laser cladding coating method for iron-based titanium carbide. The method is characterized by comprising the following steps: 1, selecting 45# steel as a cladding substrate, polishing to be smooth and clean by 600-mesh sand paper, thoroughly removing oil stains and rust on the surface of the substrate by an acetone solution; 2, drying nickel-based powder in a drying machine at 120 DEG C for 60 minutes; 3, arranging glass fibers on the substrate, and prearranging nickel-based powder on the surface of the 45# steel substrate, wherein the powder is 1-5 mm in thickness; 4, cladding by a high-power semiconductor laser device, wherein the laser power is 3,000 W. The selected and used optical spot is 2-8 mm in width, the focal length is 370 mm, the scanning speed is 8 mm / s or 16 mm / s, and argon gas is adopted as protection gas.

Owner:TIANJIN POLYTECHNIC UNIV

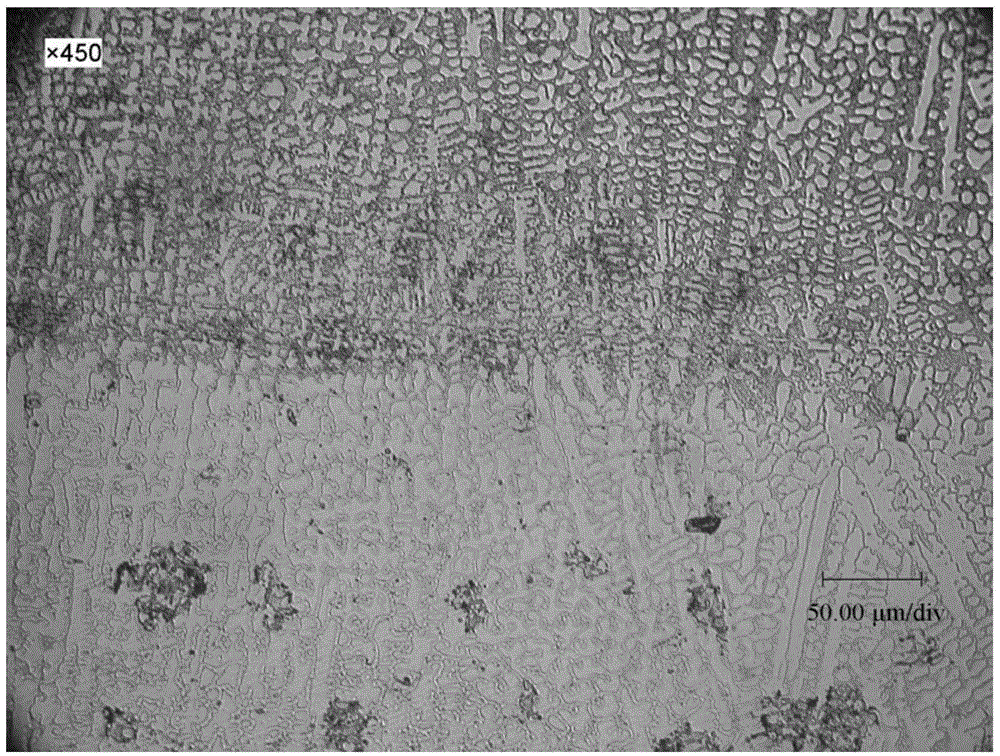

Laser repairing method for allowing roller surface of hot roller to have good thermal hardness after repairing

InactiveCN106567065APositive effectSmall amount of deformationMetallic material coating processesAlloyHardness

The invention relates to a laser repairing method for allowing the roller surface of a hot roller to have good thermal hardness after repairing. A transitional alloy layer, an intermediate alloy layer and a surface alloy layer are arranged on the surface of the hot roller in a laser cladding mode from inside one by one. The alloy powder adopted by the transitional alloy layer comprises, by mass, 0.21%-0.31% of C, 3.2%-3.6% of Si, 1.0%-1.1% of B, 2.2%-2.6% of Fe, 7%-8% of Cr and the balance Ni. The alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4%-0.5% of C, 3.8%-4.3% of Si, 11.2%-11.93% of B, 2.5%-3.2% of Fe, 10%-12% of Cr and the balance Ni. The alloy powder adopted by the surface alloy layer comprises, by mass, 0.05%-0.1% of C, 3.2%-3.6% of Si, 2%-4% of Fe, 16%-19% of Cr, 27%-30% of Mo and the balance Co. The surface of the hot roller repaired by using the laser repairing method for the hot roller has good abrasion resistance, corrosion resistance and thermal hardness, toughness and strength are taken into account in the interior, and the effect of laser cladding is good.

Owner:DANYANG HONGTU LASER TECH

A nickel-based self-fluxing hardfacing flux-cored welding wire for plasma surfacing

InactiveCN106271208BGood self-fluxingReduce manufacturing costPlasma welding apparatusWelding/cutting media/materialsIron powderHardness

The invention belongs to the field of welding materials, and particularly relates to a nickel-based self-fluxing hard-facing flux-cored wire for plasma surfacing. The flux-cored wire comprises all elemental components including, by weight, 0.3% to 1.0% of carbon, 14% to 19% of chromium, 3.5% to 5.0% of silicon, 3.0% to 4.5% of boron, 0% to 6% of iron and the balance nickel. The wire is prepared through the following method: a certain amount of chromium powder, boron powder, nickel powder and silicon and iron powder are weighed and sufficiently stirred to be evenly mixed, a Ni80Cr20 stainless steel strip bent into a U shape is filled with the mixed powder, curling and opening sealing are carried out, the strip is drawn down to the diameter of 2.0 stage by stage through a wire drawing machine, and the flux-cored wire is obtained. The nickel-based self-fluxing hard-facing flux-cored wire has the beneficial effects of being low in production cost, good in self-fluxing, high in surfacing efficiency, high in cladding rate and the like, and is suitable for plasma surfacing; a surfacing layer is large in combination strength and high in hardness and has the extremely high hard-faced wear resistance, abrasive particle wear resistance and erosive wear resistance properties.

Owner:WUHAN UNIV OF TECH

High-temperature-resistant abrasion-resistant remelting nickel-based composite coating for fire grate segment of garbage incinerator and preparation of high-temperature-resistant abrasion-resistant remelting nickel-based composite coating

ActiveCN111876717AQuality improvementImprove wear resistanceMolten spray coatingIncinerator apparatusSpray coatingAlloy

The invention relates to a high-temperature-resistant abrasion-resistant remelting nickel-based composite coating for a fire grate segment of a garbage incinerator. The high-temperature-resistant abrasion-resistant remelting nickel-based composite coating is a remelting nickel-based self-fluxing alloy-based aluminum oxide particle reinforced composite coating. The coating is cladded on the surfaceof the fire grate segment and is metallurgically bonded with the surface of a fire grate segment base body. The invention also relates to the preparation method of the coating. The method comprises the following steps: firstly, pressing and coating high-heat-release nano thermite on the surface of the fire grate segment, then spraying a nickel-based self-fluxing alloy material, preparing the nickel-based self-fluxing alloy-based composite coating on the surface of the fire grate segment through a self-propagating reaction caused by spraying, enabling a spraying coating to be in metallurgicalbonding with a thermite reaction product and the base body, finally, remelting a self-fluxing alloy layer sprayed on the surface through an induction coil or oxyacetylene flames, and obtaining the compact abrasion-resistant coating. The coating prepared through the method is compact in structure, smooth in surface, high in interface bonding strength with the base body, good in high-temperature abrasion resistance, suitable for curved surface automatic surfacing and capable of achieving industrial batch production.

Owner:JIANGSU KEHUAN INNOVATIVE MATERIAL CO LTD +1

Low roller deformation hot roller laser repair method

InactiveCN106567071APositive effectSmall amount of deformationMetallic material coating processesAlloyUltimate tensile strength

The present invention relates to a low roller deformation hot roller laser repair method, wherein a transition alloy layer, an intermediate alloy layer and a surface alloy layer are sequentially subjected to laser cladding on the surface of a hot roller from the inner layer, the components of the alley powder used by the transition alloy layer comprise, by mass, 0.2-0.3% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance of Ni, the components of the alley powder used by the intermediate alloy layer comprise, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance of Ni, and the components of the alley powder used by the surface alloy layer comprise, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo, and the balance of Co. According to the present invention, the hot roller repaired by using the hot roller laser repair method of the present invention has good abrasion resistance, good corrosion resistance and good thermal rigidity of the surface, has good toughness and good strength of the internal, and has good laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

A hot roller laser restoration method capable of prolonging the service lifetime of a hot roller

InactiveCN106567064APositive effectSmall amount of deformationMetallic material coating processesRestoration methodWear resistance

The invention relates to a hot roller laser restoration method capable of prolonging the service lifetime of a hot roller. A transitional alloy layer, a middle alloy layer and a surface alloy layer are cladded with laser layer by layer from the inside on the surface of the hot roller. Alloy powder adopted by the transitional alloy layer includes components by mass: 0.12-0.19% of C, 3.2-3.6% of Si, 1.2-1.8% of B, 2.2-2.6% of Fe, and 7-8% of Cr, with the balance being Ni. Alloy powder adopted by the middle alloy layer includes components by mass: 0.4-0.5 % of C, 3.8-4.3% of Si, 12-13% of B, 2.5-3.2% of Fe, and 10-12% of Cr, with the balance being Ni. Alloy powder adopted by the surface alloy layer includes components by mass: 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr and 27-30% of Mo, with the balance being Co. The surface of the hot roller restored by the method has good wear resistance, corrosion resistance and hot hardness, both toughness and strength of the inside of the hot roller are taken into account, and laser cladding effects are good.

Owner:DANYANG HONGTU LASER TECH

Laser repairing method of hot roll good in laser cladding effect

InactiveCN106567069APositive effectSmall amount of deformationSuperimposed coating processToughnessRepair method

The invention relates to a laser repairing method of a hot roll good in laser cladding effect. The surface of the hot roll is laser-cladded with a transition alloy layer, an intermediate alloy layer and a surface alloy layer from the inside layer by layer; alloy powder adopted by the transition alloy layer comprises, by mass, 0.21-0.31% of C, 3.2-3.6% of Si, 1.0-1.1% of B, 2.2-2.6% of Fe, 7-8% of Cr and the balance Ni; alloy powder adopted by the intermediate alloy layer comprises, by mass, 0.4-0.5% of C, 3.8-4.3% of Si, 11.2-11.93% of B, 2.5-3.2% of Fe, 10-12% of Cr and the balance Ni; and alloy powder adopted by the surface alloy layer comprises, by mass, 0.05-0.1% of C, 3.0-3.16% of Si, 2-4% of Fe, 16-19% of Cr, 27-30% of Mo and the balance Co. The hot roll repaired by the laser repairing method of the hot roll good in laser cladding effect has good abrasion resistance, corrosion resistance and hot hardness in surface, integrates toughness and strength inside, and is good in laser cladding effect.

Owner:DANYANG HONGTU LASER TECH

Rare earth-nickel base alloy powder material

The invention discloses a rare-earth nickel-based alloy powder material. The components are: C: 1.2-1.4%; B: 3.2-3.6%; Si: 3.5-4.0%; Cr: 16.0-18.5%. ; Fe: 3.2-4.0%; Cu: 1.5-2.0%; Mo: 1.2-2.0%; Nb: 0.2-0.3%; Y: 0.2-0.3%, Co: 0.3-0.5%, W: 0.3-0.4%, Ti: 0.1-0.3%, the balance being Ni. The invention improves the wear resistance and corrosion resistance of materials and prolongs the service life of parts.

Owner:罗旭

A kind of aluminum oxide modified gradient laser cladding layer and preparation method thereof

ActiveCN107012463BImprove surface corrosion resistanceImprove corrosion resistanceMetallic material coating processesCorrosion current densityCorrosion resistant

The invention discloses an aluminum oxide modified gradient laser cladding layer and a preparation method thereof. Magnesium alloy serves as base material, Al-Si alloy powder serves as a first precoated layer, the mixed powder of nickel-based self-melting alloy powder and Al2O3 serves as a second precoated layer, and the aluminum oxide modified gradient laser cladding layer is formed through laser cladding. The corrosion potential of the Al2O3 modified gradient laser cladding layer is about -1.1 V and is similar to that of a Ni35, Al-Si / Ni35 cladding layer, the corrosion current density is large in difference and is about 1 / 15-1 / 2 that of the base material, and a good corrosion resistant effect is achieved. The aluminum oxide modified gradient laser cladding layer and the preparation method thereof can be used for surface strengthening and modification of magnesium alloy parts in the industrial field, the application range of magnesium alloy in corrosion resistant occasions is extended, and wide application prospects are achieved.

Owner:SHANDONG UNIV

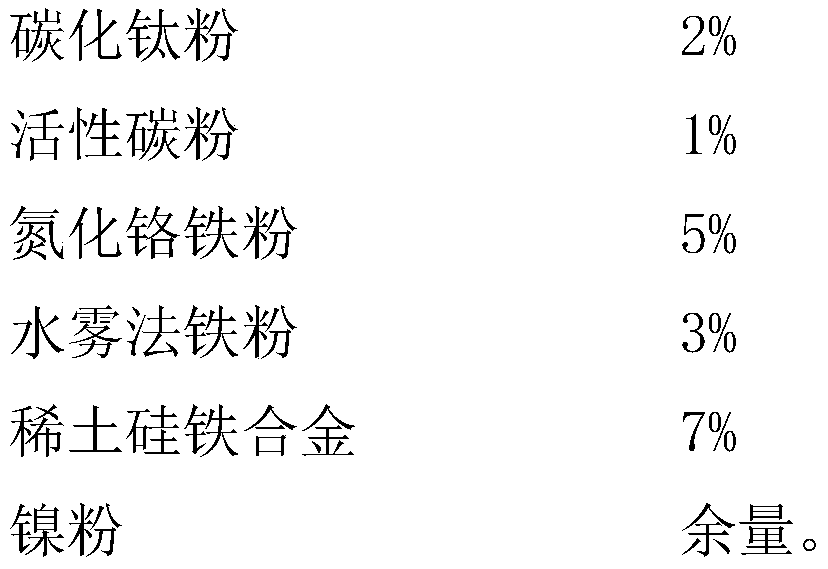

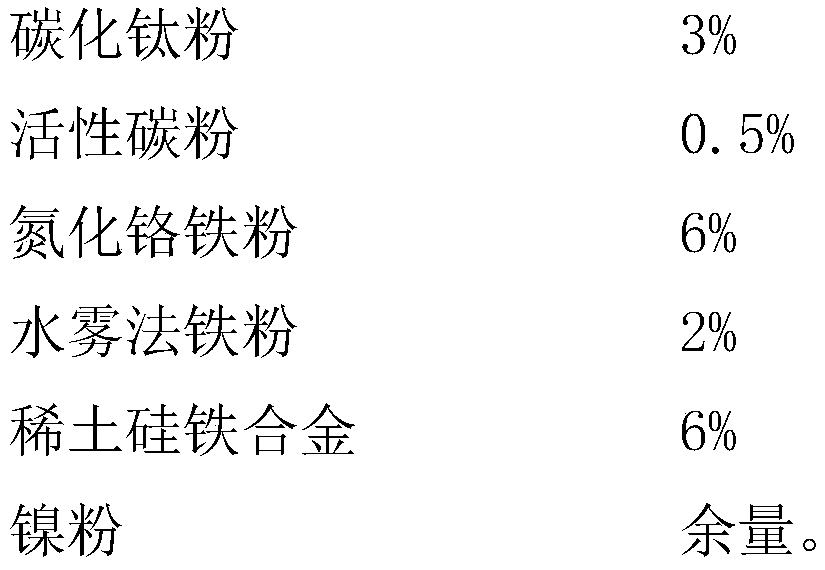

Nickel-based self-fluxing alloy powder for valve seat repair and its welding process

ActiveCN107335890BGood self-fluxingLow melting pointPlasma welding apparatusWelding/cutting media/materialsRare earthFerrosilicon

The invention relates to nickel-based self-fluxing alloy powder for valve seat repair and its welding process, comprising the following components in mass percentage: 2-3% of titanium carbide powder, 0.5-1% of active carbon powder, and 5-5% of ferrochromium nitride powder 6%, water mist iron powder 2-3%, rare earth ferrosilicon alloy 6-7%, nickel powder balance. The nickel-based self-fluxing alloy powder of the invention has low melting point and excellent self-fluxing property, and is suitable for spray welding hard surface alloy, and the spray welding layer has excellent performances of wear resistance, corrosion resistance, heat resistance and oxidation resistance. Oxygen-acetylene one-step or two-step spray welding is used to form a welding layer on the surface of the workpiece. While the size of the valve seat is repaired, the surface performance of the valve seat is further improved, and the service life of the valve seat is extended.

Owner:安徽鼎恒再制造产业技术研究院有限公司

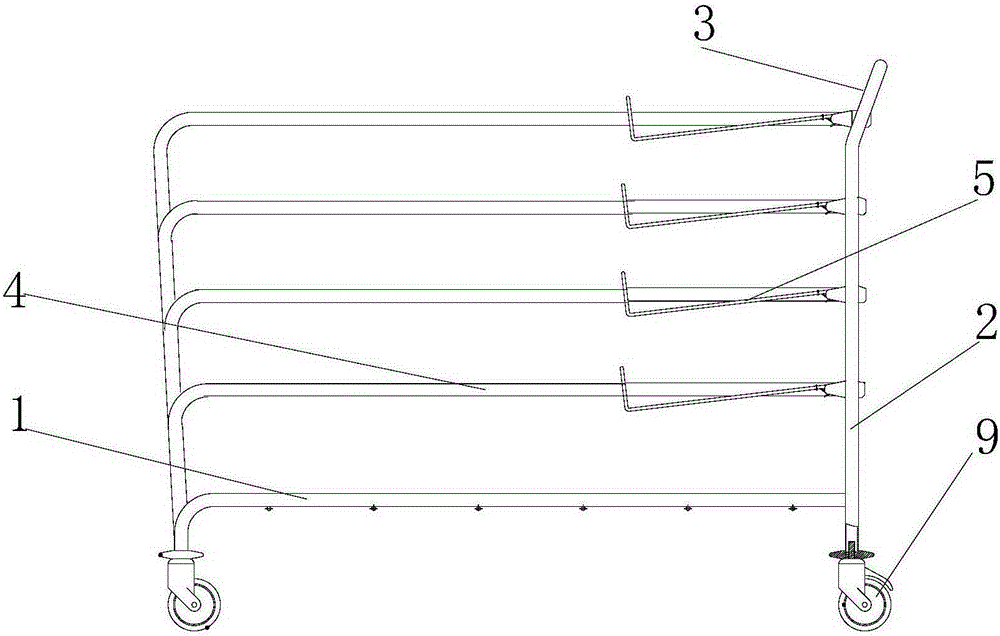

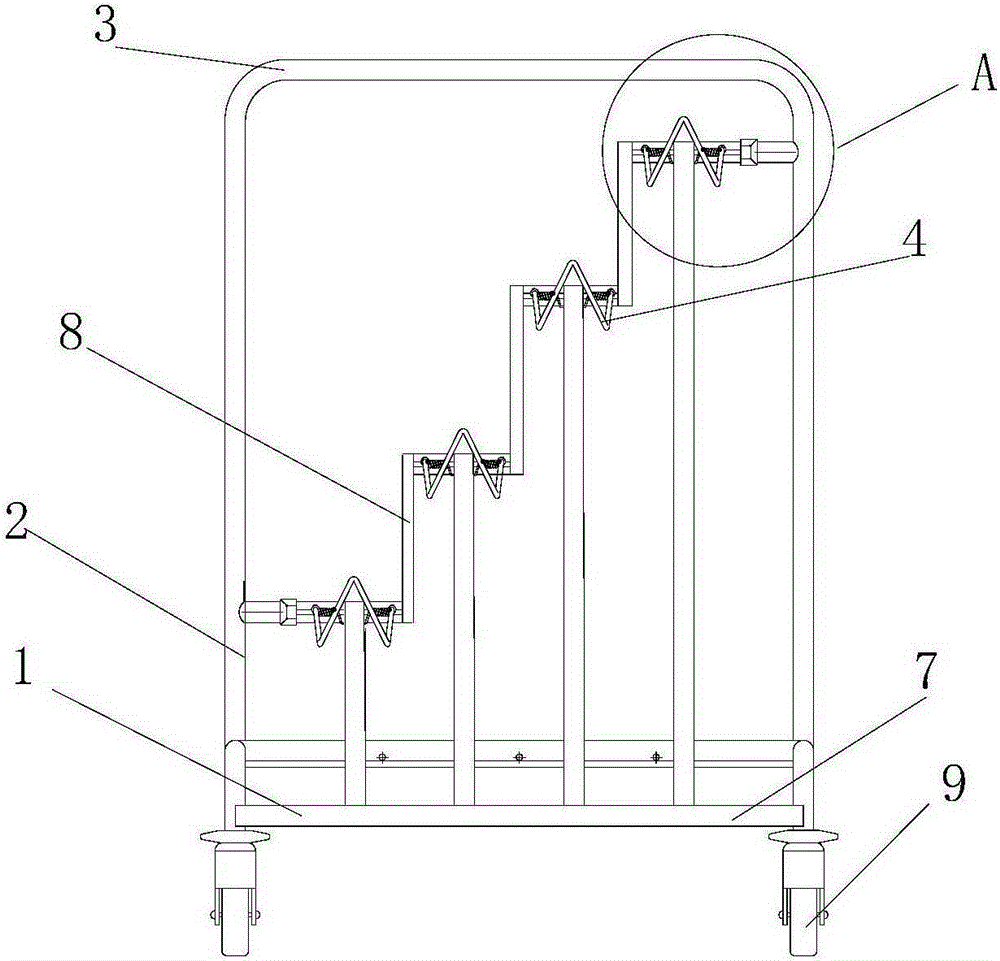

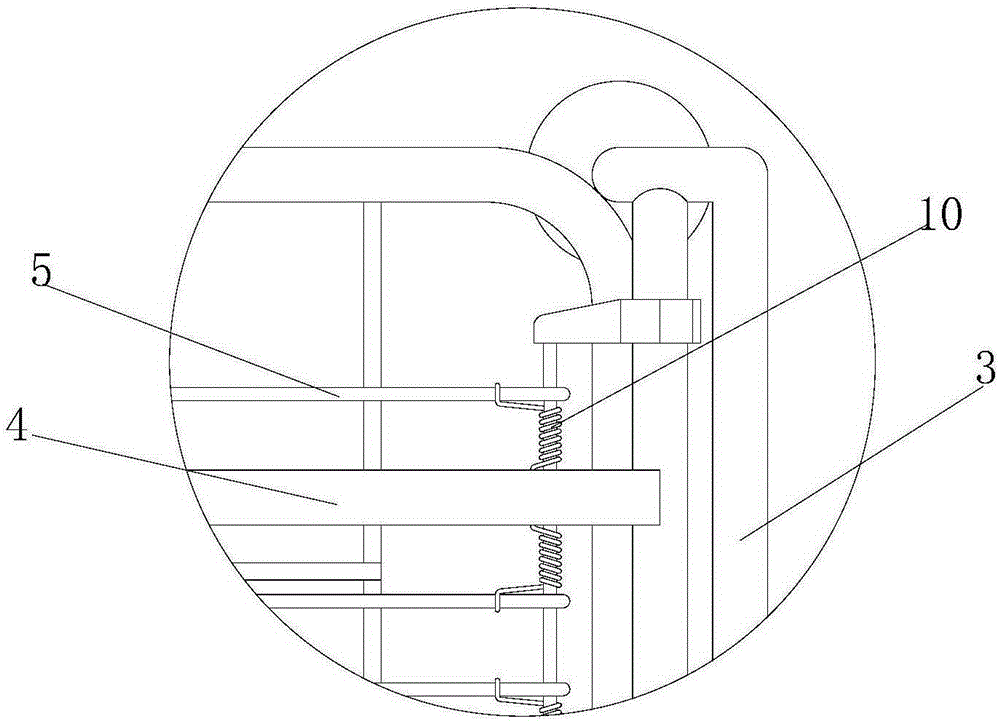

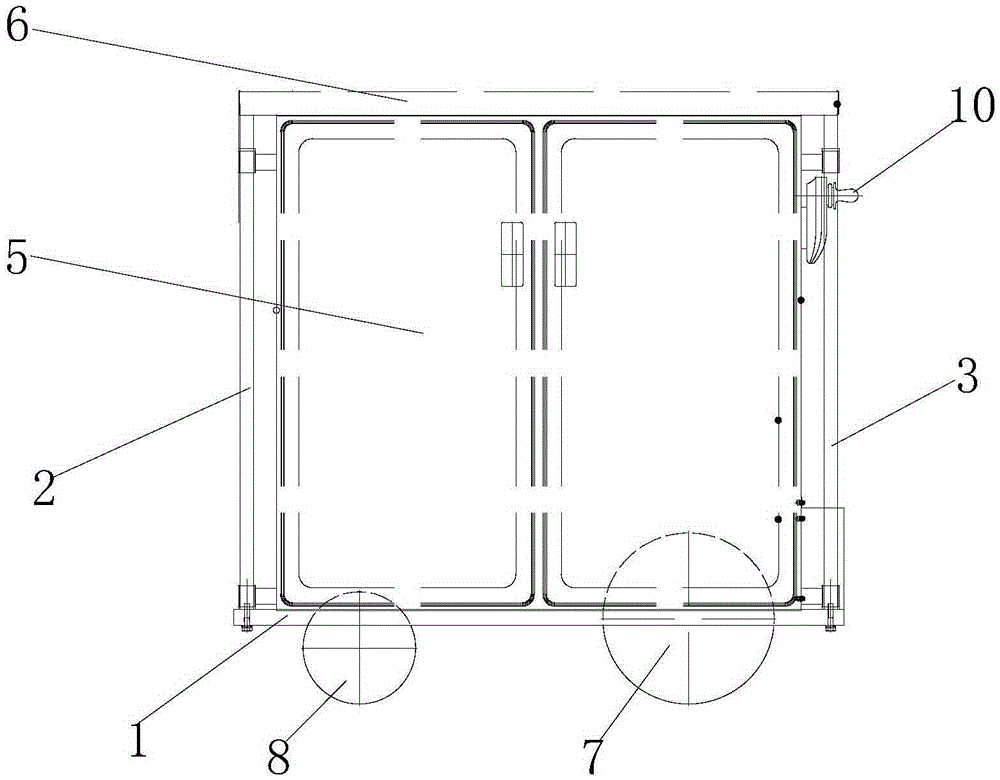

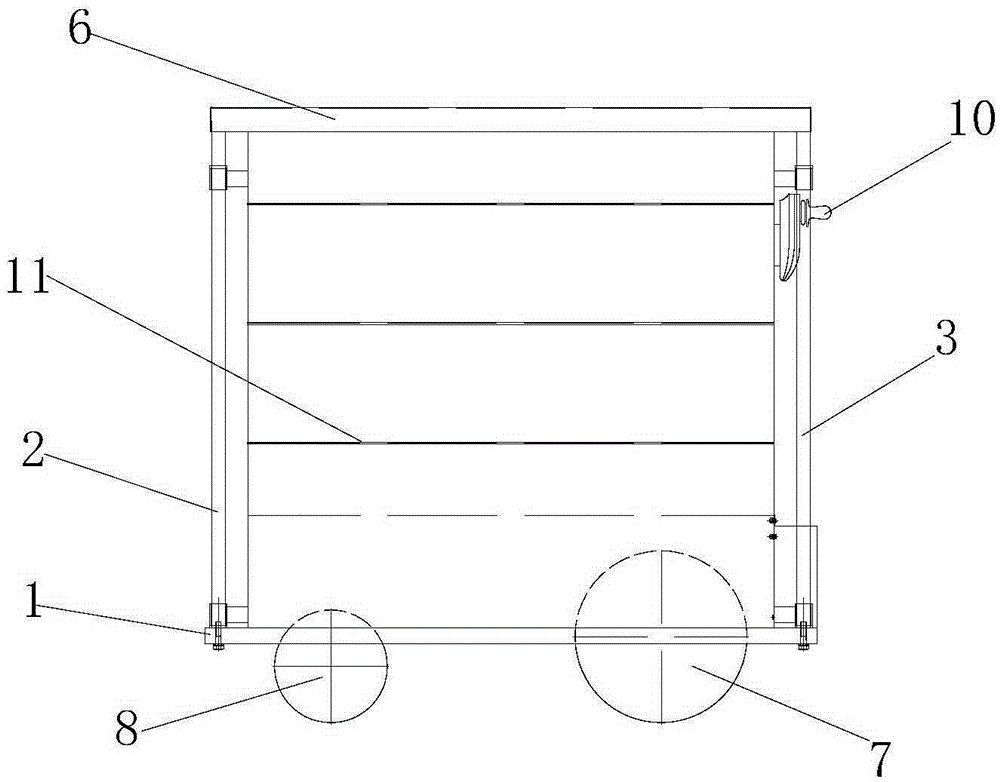

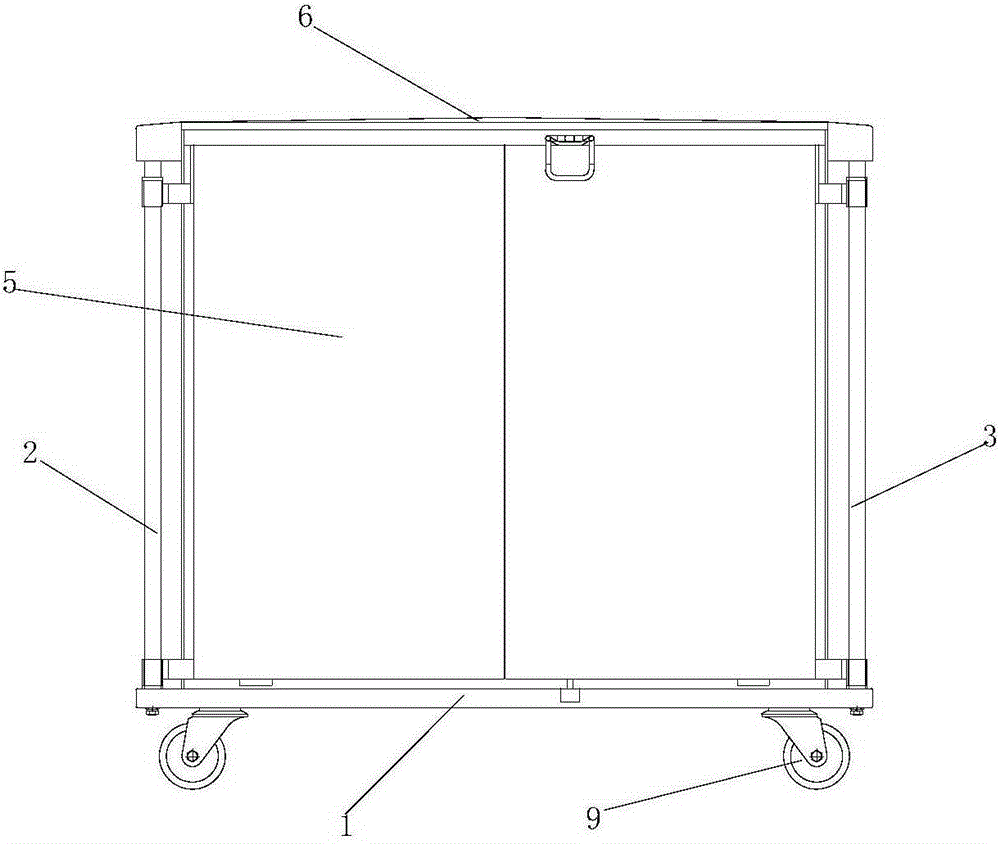

Wrapping cloth storage and transportation trolley and maintenance method thereof

InactiveCN106551769ASmall amount of deformationSuitable for noise control requirementsMetallic material coating processesNursing accommodationCoatingBreathing

The invention relates to a wrapping cloth storage and transportation trolley and a maintenance method thereof. The wrapping cloth storage and transportation trolley comprises an underframe, a trolley body arranged on the underframe, a push handle arranged on the rear side of the trolley body, a plurality of wrapping cloth pipes which are arranged on the trolley body and distributed in a stepped mode, wrapping cloth clamps arranged at the tail ends of the wrapping cloth pipes, and trundles which are arranged at the four ends of the underframe and provided with brakes. The tail ends of every two adjacent wrapping cloth pipes are connected through an inverted L-shaped connecting support. The wrapping cloth pipes are distributed in the stepped mode, so that aired wrapping cloth receives sunshine by a larger area, ventilation is facilitated, and the airing effect is remarkably improved. The wrapping cloth pipes are square pipes so that the wrapping cloth pipes and the wrapping cloth clamps can be matched more firmly and reliably. The trundles are arranged at the four ends, and thus transportation of the wrapping cloth is facilitated. The surfaces of the underframe, the trolley body, the push handle, fence assemblies, the wrapping cloth pipes, a lower transverse bracket and the inverted L-shaped connecting supports are coated with Teflon coatings, so that firmness and durability are achieved, dust is not liable to adhere to the surfaces, and cleaning and disinfection are easy.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

A kind of preparation method of nickel alloy 200um coating

The invention discloses a preparation method of a nickel alloy 200-micrometer coating. The method comprises the steps that firstly, heat treatment is carried out on the surface of a workpiece; then, various kinds of metal powder are taken out, are used for preparing alloy powder according to the proportion and are evenly stirred; and finally, a plasma spraying method is adopted to spray an alloy layer on the surface of the workpiece. The method has the advantages that the method is simple, raw materials are easy to obtain, the comprehensive performance is good, and the application is wide.

Owner:SHENYANG LIGONG UNIV

A kind of preparation method of nickel alloy 200um coating containing titanium boride

The invention discloses a preparation method of a nickel alloy 200-micrometer coating containing titanium boride. The method comprises the steps that firstly, heat treatment is carried out on the surface of a metal workpiece; then, various kinds of raw material powder are taken to prepare alloy powder according to the proportion; and finally, a plasma spraying method is adopted to spray an alloy layer on the surface of the workpiece. The method has the advantages that the method is simple, raw materials are easy to obtain, the comprehensive performance is good, and the application is wide.

Owner:沈阳维瓴科技有限公司

Nickel-based self-fusing alloy powder for remanufacturing glass mold and welding process of nickel-based self-fusing alloy powder

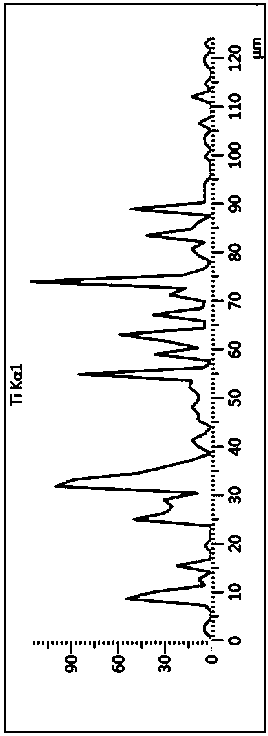

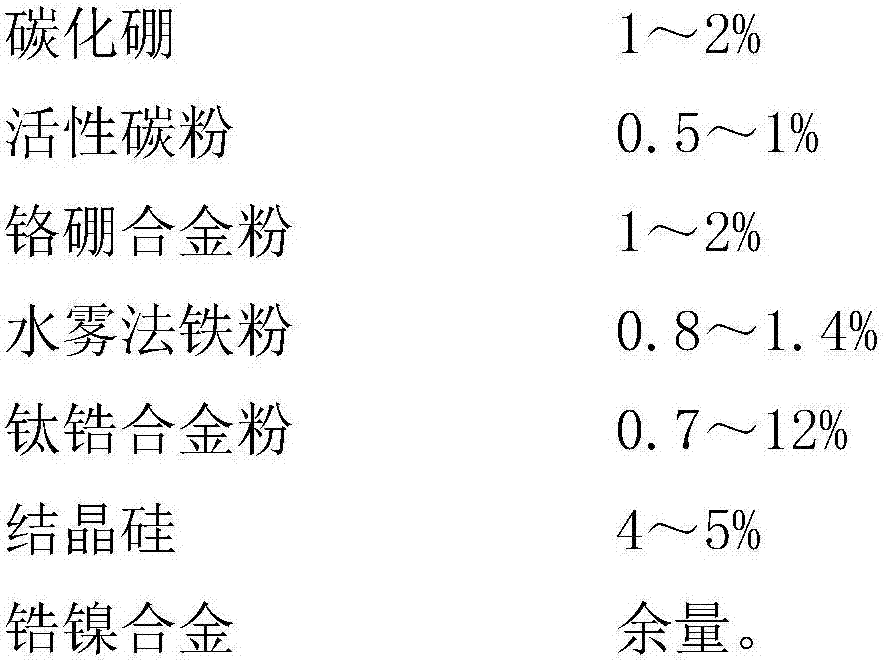

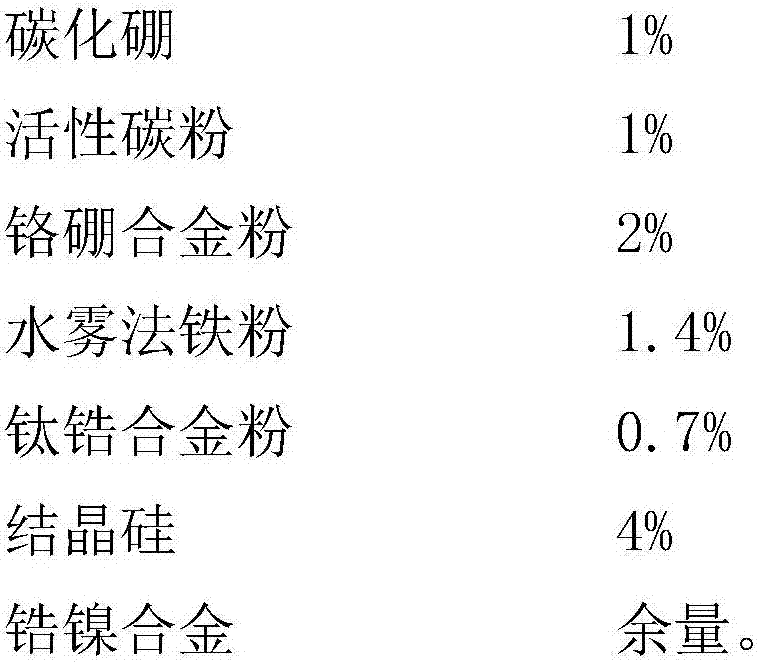

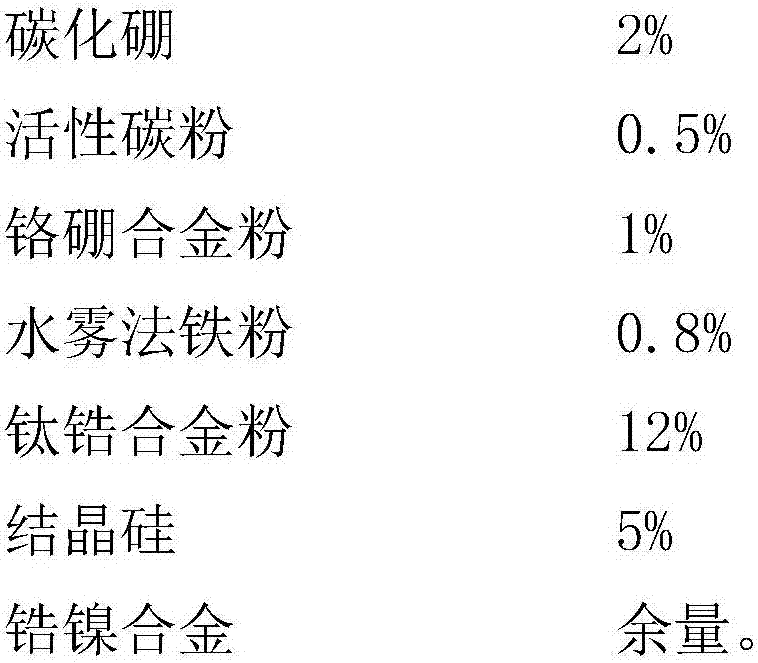

InactiveCN107574400AGood self-fluxingLow melting pointMolten spray coatingGas flame welding apparatusTitanium zirconiumBoron carbide

The invention relates to nickel-based self-fusing alloy powder for remanufacturing a glass mold and a welding process of the nickel-based self-fusing alloy powder. The nickel-based self-fusing alloy powder comprises, by mass percentage, 1-2% of boron carbide, 0.5-1% of activated carbon powder, 1-2% of chromium-boron alloy powder, 0.8-1.4% of water mist method iron powder, 0.7-12% of titanium-zirconium alloy powder, 4-5% of crystal silicon and the balance a zirconium-nickel alloy. The nickel-based self-fusing alloy powder is low in fusing point, excellent in self-fusing performance and suitablefor being used for conducting spray-welding on a hard-face alloy; and a spray-welding layer is excellent in abrasion resistance, corrosion resistance, heat resistance and oxidation resistance. The nickel-based self-fusing alloy powder is used for repairing and pre-protecting the glass mold, a plastic forming mold, a shaft sleeve, an iron casting and machine tool guide rails. By means of the nickel-based self-fusing alloy powder, dimension repair of the glass mold is achieved, and meanwhile, performance of the glass mold is further improved; and thus, the service life of the glass mold is prolonged.

Owner:WUHU DINGHAN REMFR TECH

Laser cladding repair process of thin-walled sleeve favorable for reducing build-up welding stress and deformation

InactiveCN103668175AUniform force on the circumferenceControl deformationMetallic material coating processesLaser beam welding apparatusOptoelectronicsAlloy

The invention relates to a laser repair process of a thin-walled sleeve. The laser repair process comprises the following steps: A) performing treatment on the surface of the thin-walled sleeve, and performing failure analysis; B) fixing an inner hole of the thin-walled sleeve by using a tool; C) performing laser cladding, and cooling other parts except the part to be repaired during laser cladding, wherein the adopted alloy powder comprises the following components in percentage by weight: not more than 0.03% of C, 18%-22% of Cr, 0.5%-1.2% of Si,10%-15% of Ni, 2.0%-3.0% of Mo, 1.0%-2.0% of Mn, 1.0%-2.0% of W and the balance of Fe; D) detecting; E) assembling and simultaneously dismantling the tool. According to the laser repair process of the thin-walled sleeve, the laser cladding can be performed on the surface of the thin-walled sleeve, so that the size of the thin-walled sleeve can be restored to meet the using requirements, the deformation of the product after repair is very small, and the hardness and corrosion resistance of the thin-walled sleeve after repair exceed the original properties.

Owner:佛山市矢量钢材加工有限公司

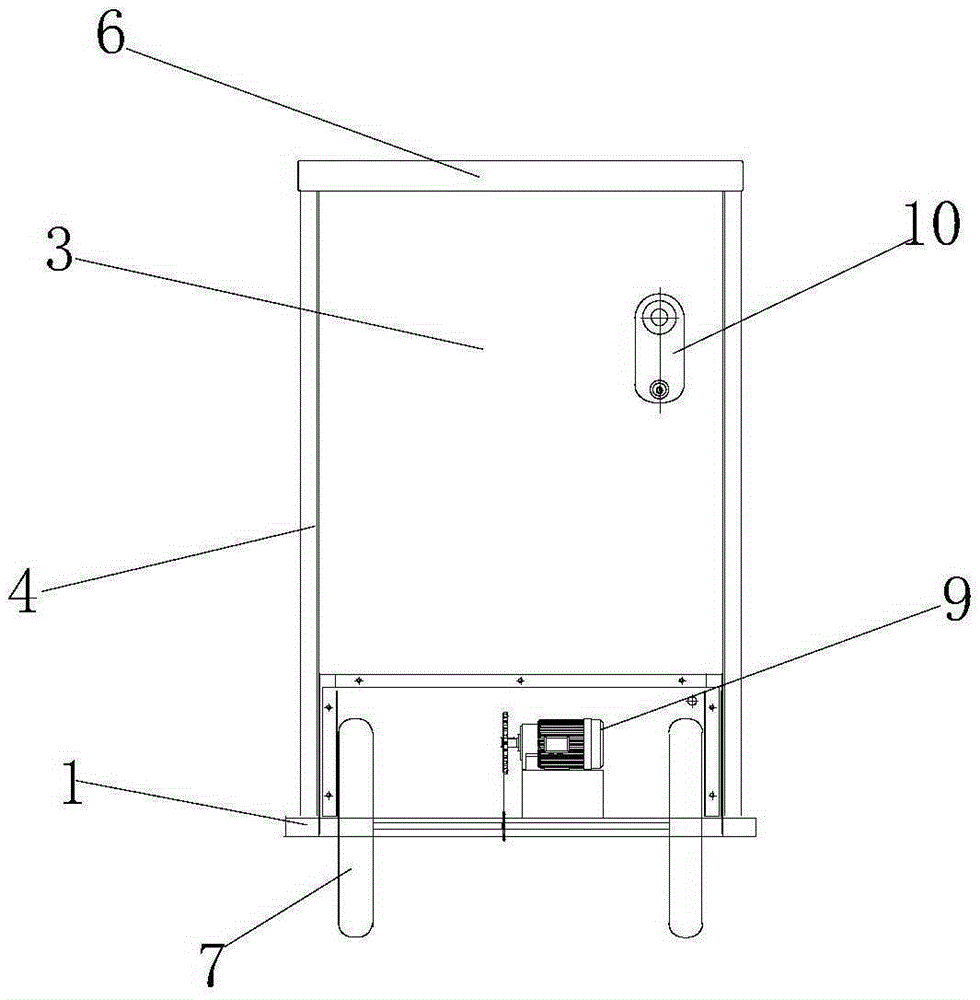

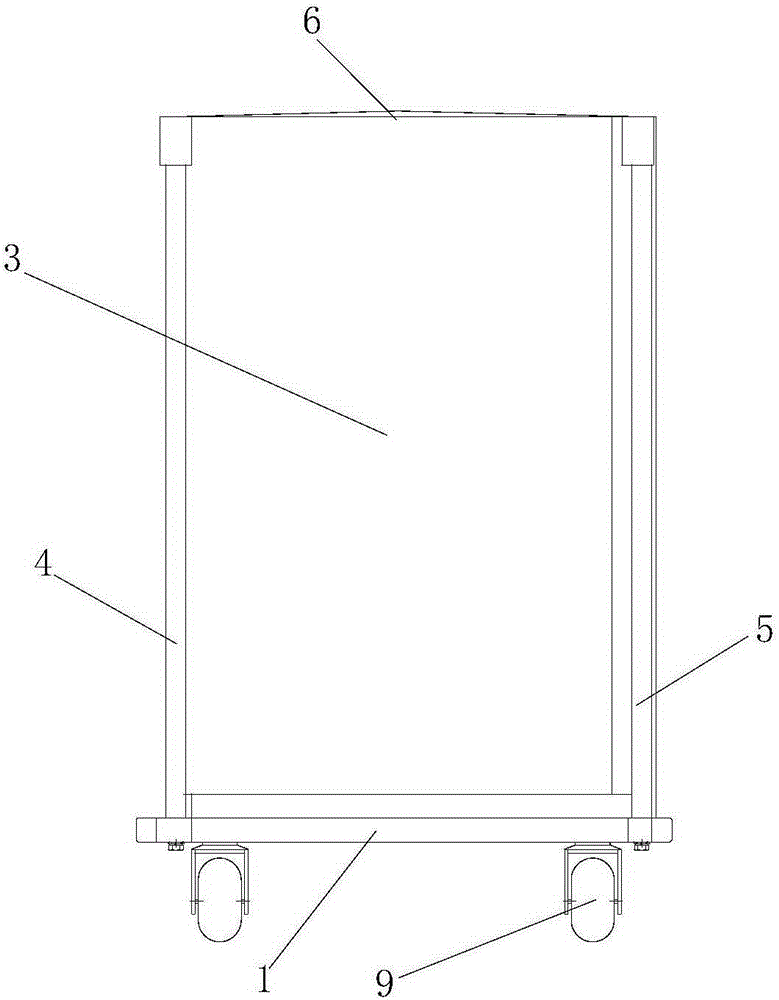

Sealed distributing and collecting trolley and maintaining method thereof

InactiveCN106553672AEasy to cleanEasy to disinfectMetallic material coating processesHand carts with multiple axesDrive wheelEngineering

The invention relates to a sealed distributing and collecting trolley and a maintaining method thereof. The trolley comprises a left side plate assembly, a right side plate assembly, a back plate, a double door assembly and a top cover assembly, wherein the left side plate assembly, the right side plate assembly, the back plate and the double door assembly are arranged on the four sides of a bottom plate assembly, the top cover assembly is arranged on the tops of the left side plate assembly, the right side plate assembly, the back plate and the double door assembly, and a sealed box body is jointly formed by the left side plate assembly, the right side plate assembly, the back plate, the double door assembly and the top cover assembly. The inner side face of the sealed box body is coated with a Teflon coating. Inner partition plates with the height capable of being freely adjusted are arranged in the sealed box body and made of stainless steel with the surface coated with the Teflon coating, dust staining is not likely to happen, and cleaning is easy. Multiple drive wheels connected with a motor driving system are arranged at the bottom of the right side of the bottom plate assembly. Multiple driven wheels are arranged at the bottom of the left side of the bottom plate assembly. A waterproof direct current motor is selected as a motor of the motor driving system, whole trolley cleaning and disinfecting are convenient, sanitation safety of equipment is ensured, the motor is used for driving the sealed distributing and collecting trolley, original manpower driving is replaced, and the labor intensity of medical workers is greatly lowered.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

High temperature resistant and anti-abrasion remelting nickel-based composite material coating for waste incinerator grate sheets and preparation method thereof

ActiveCN111876717BQuality improvementImprove wear resistanceMolten spray coatingIncinerator apparatusAlloyThermite

The invention relates to a high-temperature-resistant, abrasion-resistant remelting nickel-based composite material coating for the grate sheets of a waste incinerator, which is a remelting nickel-based self-fluxing alloy-based alumina particle-reinforced composite material coating; the coating is clad on the furnace The surface of the grate sheet is metallurgically combined with the surface of the grate sheet substrate. The invention also relates to a method for preparing the above-mentioned coating. The method firstly press-coats a high-exothermic nano-thermite on the surface of the grate sheet, and then sprays a nickel-based self-fluxing alloy material. The surface of the sheet is made of a nickel-based self-fluxing alloy-based composite material coating, so that the sprayed layer forms a metallurgical bond with the thermite reaction product and the matrix. Finally, the self-fluxing alloy layer sprayed on the surface is remelted with an induction coil or an oxyacetylene flame. , to obtain a dense anti-abrasion coating. The coating prepared by the method has dense structure and smooth surface, high bonding strength between the coating and the substrate interface, and good high temperature abrasion resistance, which is suitable for automatic surfacing of curved surfaces and can be industrialized and mass produced.

Owner:JIANGSU KEHUAN INNOVATIVE MATERIAL CO LTD +1

Laser cladding repair process for gears with improved hardness and wear resistance

ActiveCN103668176BGood self-fluxingIncrease contentMetallic material coating processesEngineeringHardness

The invention relates to a laser cladding repair process for gear, which comprises the following steps: (A) treating the surface of the valve seat and performing failure analysis on the valve seat; (B) integrally preheating the gear at 80-120 DEG C and locally preheating the portion to be repaired of the gear at 80-220 DEG C at the same time; (C) optimizing technological parameter according to the failure analysis result of the gear, and performing laser cladding on the valve seat layer by layer, the thickness of each cladding layer is less than or equal to 0.4 mm, the edge of the later cladding layer extends out of the edge of the former cladding layer by 4 mm to 6 mm, the powdered alloy adopted is prepared from the following components in percentage by weight: less than or equal to 0.5% of carbon, 38-52% of chromium, 1.5-2.5% of boron, 0.5-1.5% of silicon and the balance of ferrum; and (D) performing detection. The surface of the gear is subjected to laser cladding through the laser repair process for gear, so that the size of the valve seat is recovered to operating requirement, and the hardness and abrasive resistance of the valve seat repaired exceed its original performance.

Owner:XINJIANG HUIXIANG LASER TECH

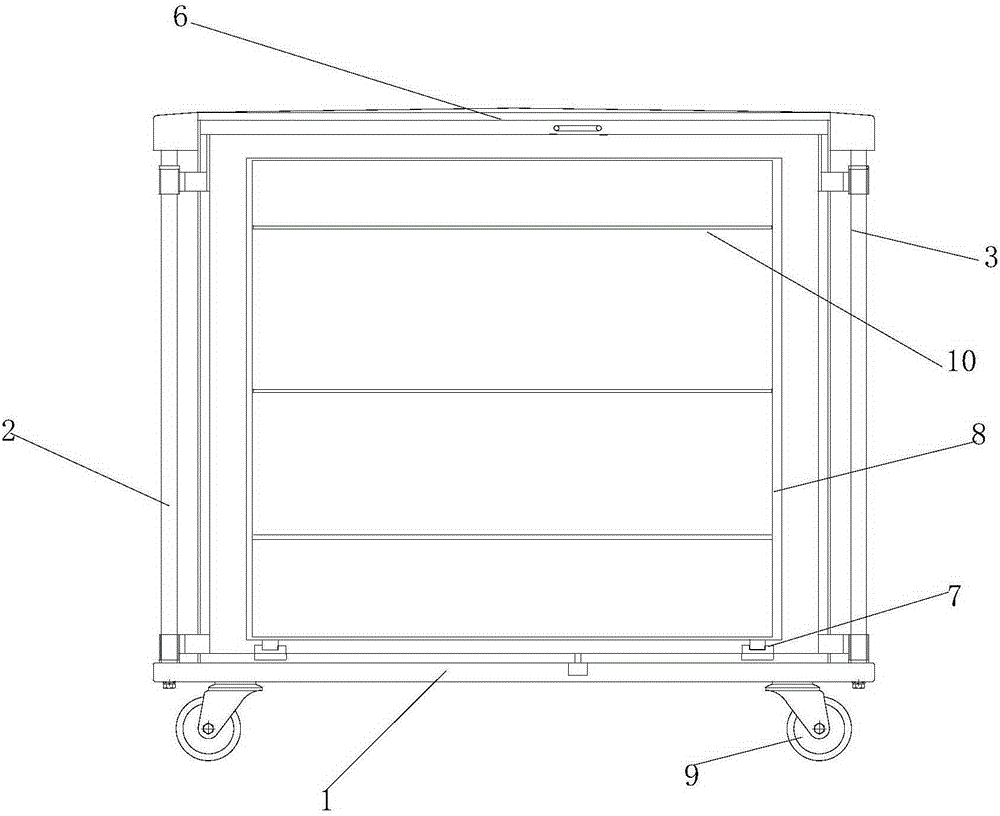

Medical sealed distributing and collecting trolley and maintaining method thereof

InactiveCN106553673AEasy to convertAvoid secondary pollutionMetallic material coating processesHand carts with multiple axesEngineeringCross infection

The invention relates to a medical sealed distributing and collecting trolley and a maintaining method thereof. The medical sealed distributing and collecting trolley comprises a sealed box body, and the sealed box body is formed by a left side plate assembly, a right side plate assembly, a back plate and a double door assembly which are arranged on the four sides of a bottom plate assembly. The sealed box body is internally further provided with a sliding rail and an inner container with one face opened. The inner container slides on the sliding rail in a matched manner. Multiple medical silence trundles with brakes are arranged at the bottom of the bottom plate assembly. The inner container is internally provided with inner partition plates with the adjustable height, flexible adjustment can be conducted according to the size of actually-conveyed objects, and the inner container can be detached. The inner container and the inner partition plates are made of stainless steel with the surface coated with a Teflon coating, dust staining is not likely to happen, cleaning and disinfecting are easy, and bacterium breeding is avoided. The inner container can be freely drawn out to be replaced, switching between clean object distributing and dirt object collecting is facilitated, cross infection is avoided, and using is convenient and flexible.

Owner:WANSHENG PRECISION MACHINERY JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com