Patents

Literature

105results about How to "Improve surface corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

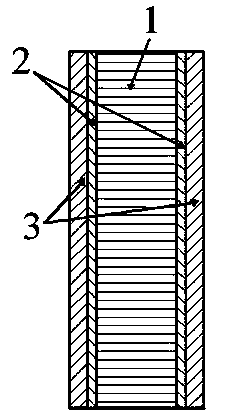

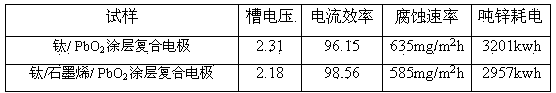

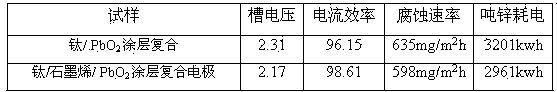

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

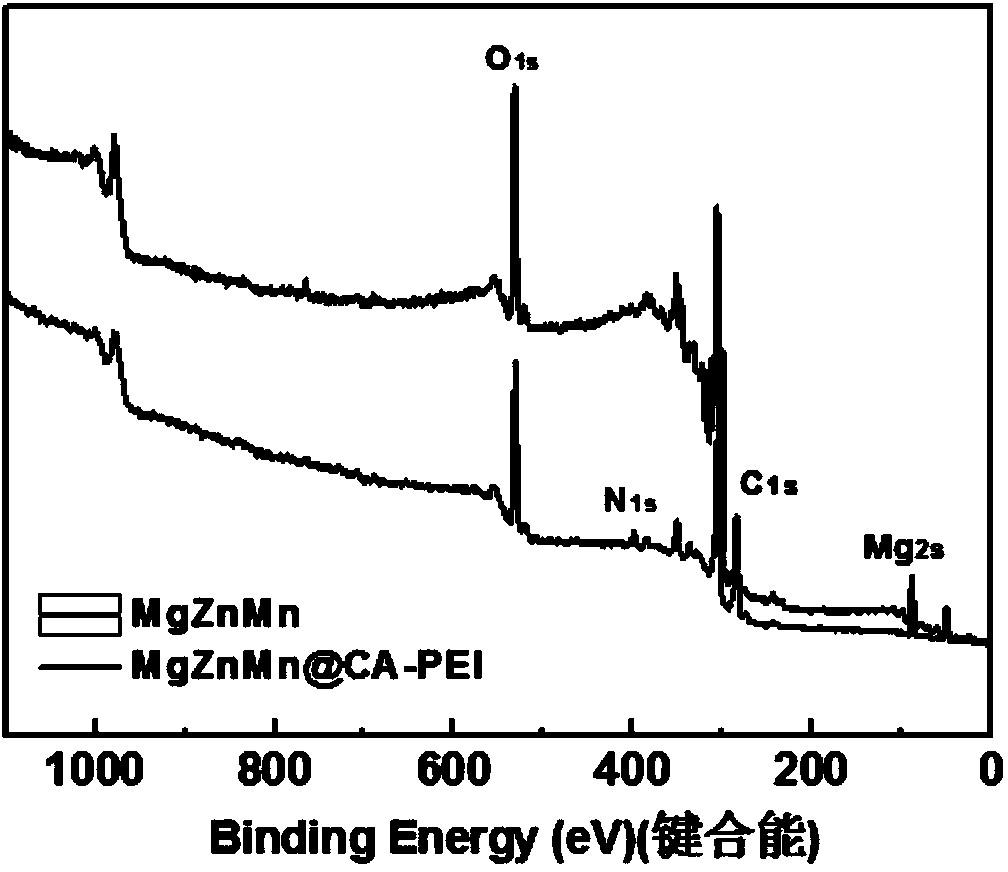

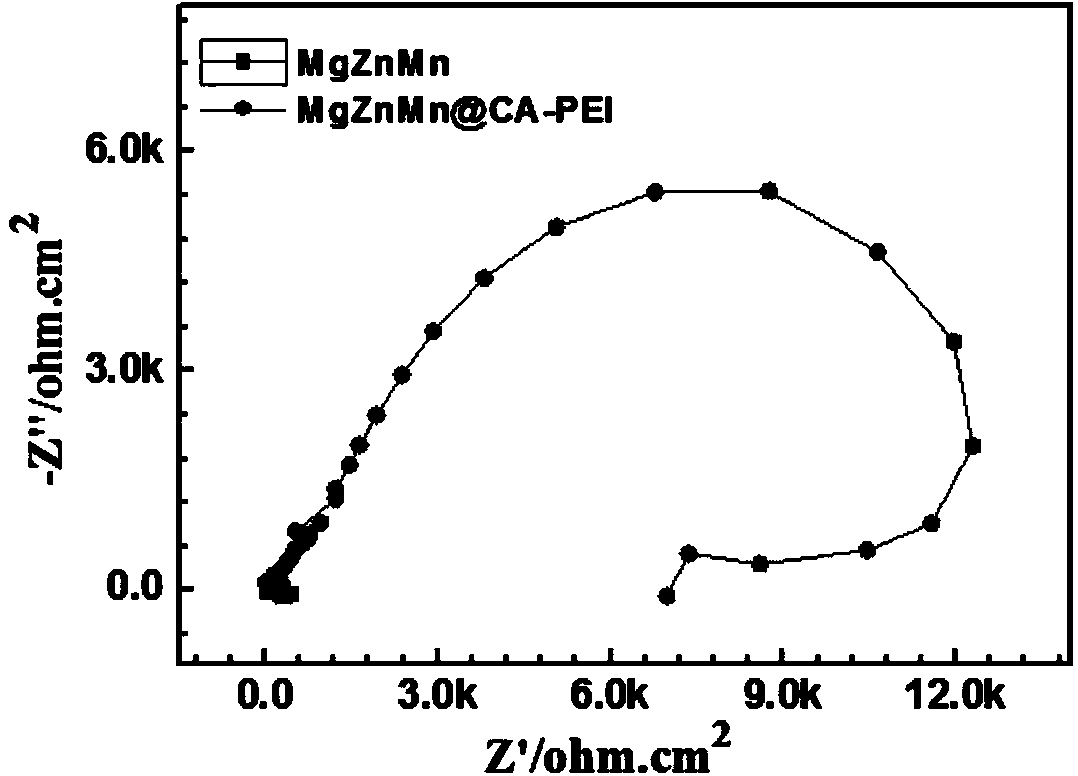

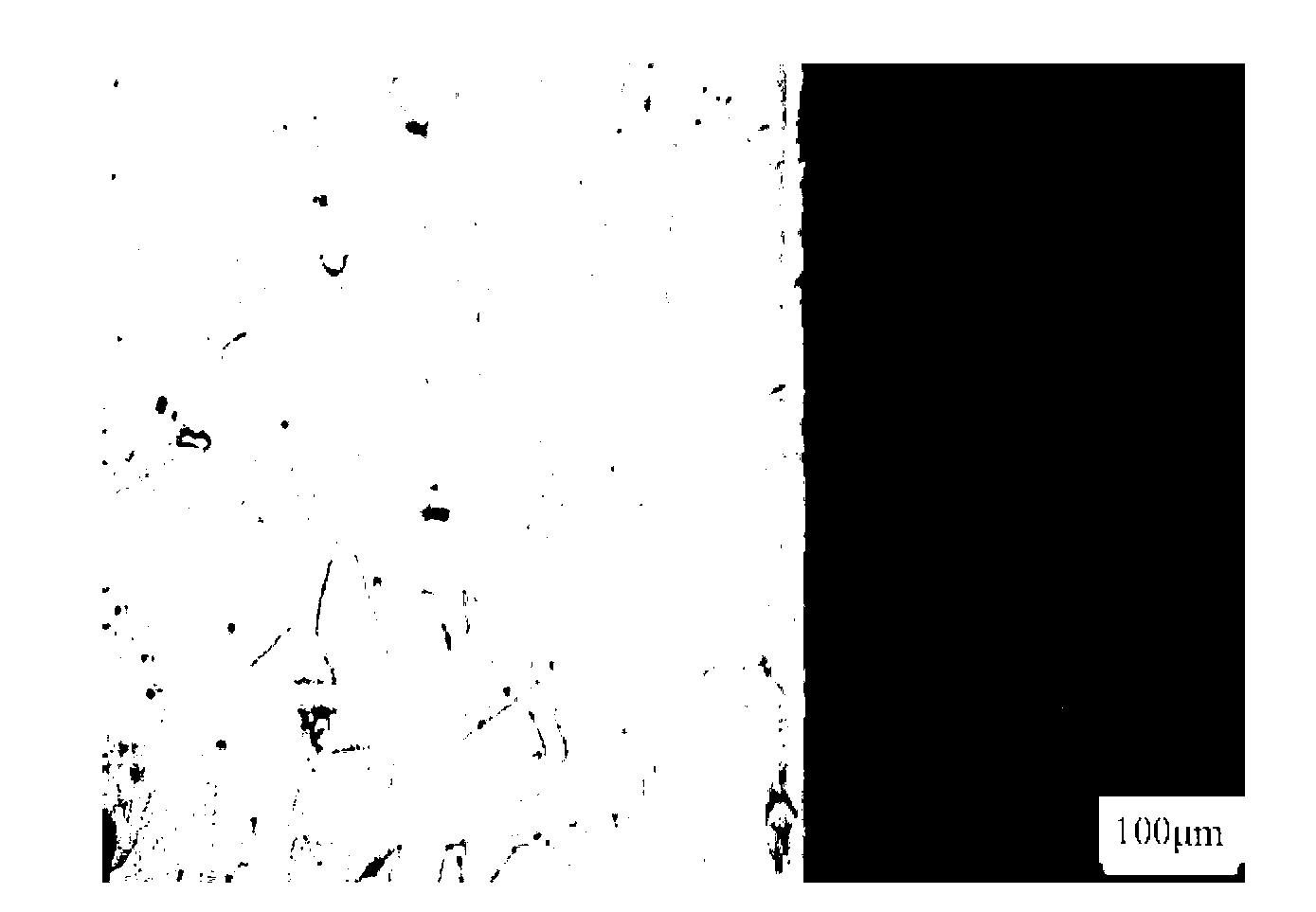

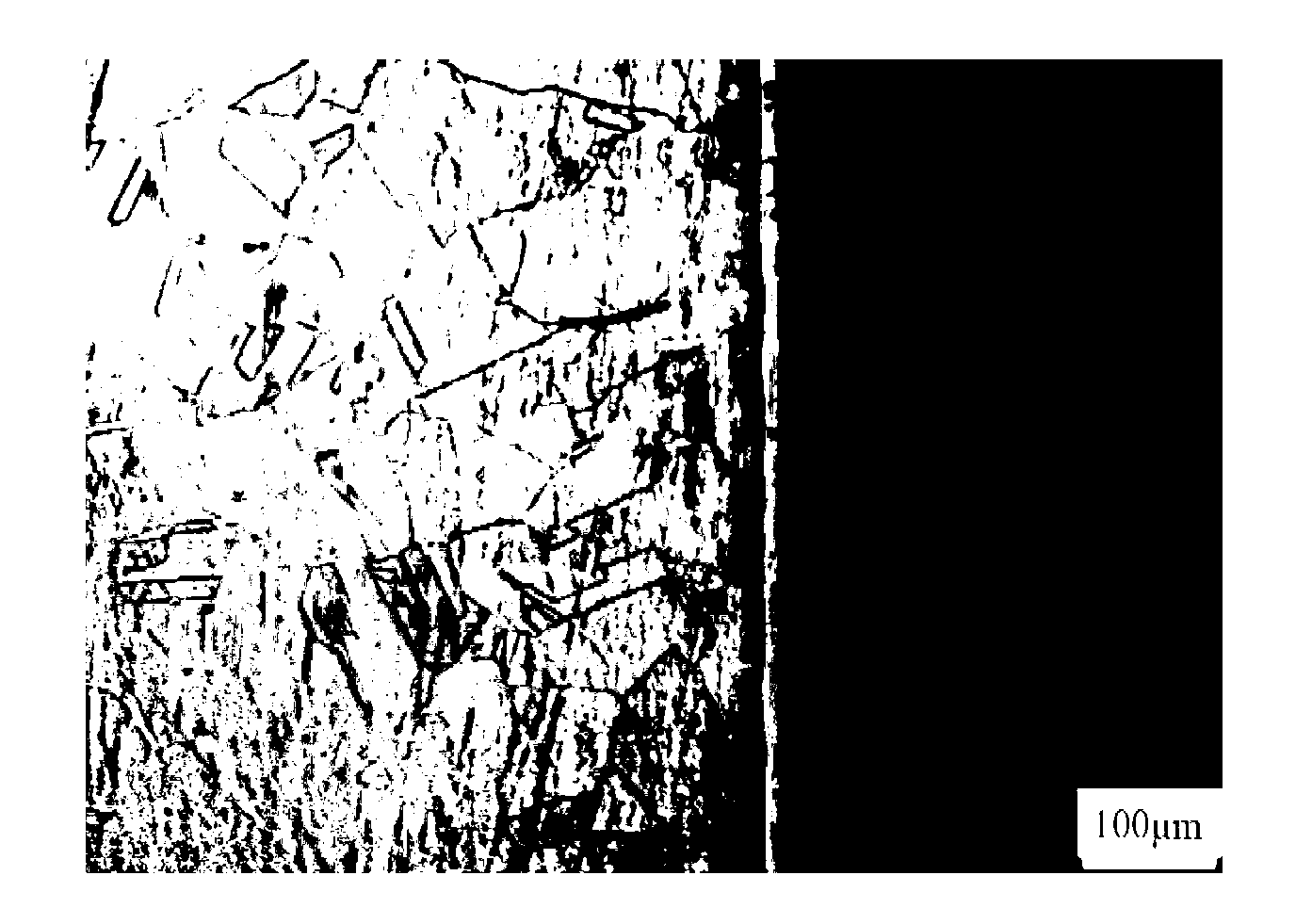

Modification method for improving corrosion resistance and surface functionalization of biomedical magnesium-based metal material

InactiveCN104195535AHigh research and application valuePassive Surface Electrode PotentialMetallic material coating processesSurface functionEndothelial Cell Growth Factor

The invention discloses a modification method for improving corrosion resistance and surface functionalization of a biomedical magnesium-based metal material. The modification method for improving corrosion resistance and surface functionalization of the biomedical magnesium-based metal material comprises the following steps: preparing a Tris-buffer solution with a pH value of 7-12, adding a compound which has a certain concentration and is of a phenolic hydroxyl structure or also adding a compound which has a certain concentration and is of a multi-amino structure. The modification method for improving corrosion resistance and surface functionalization of the biomedical magnesium-based metal material is mild in reaction conditions, simple and easy to operate, relatively low in cost and favorable for after-treatment. The magnesium-based metal material prepared by the method and treated with modified coating has relatively excellent corrosion resistance; by virtue of introduction of different components, a plurality of reactive functional groups can be successfully introduced into the prepared material; the prepared material can be used for subsequent fixation of biological molecules (such as heparin, endothelial cell growth factor VEGF, various types of biological function protein and the like) or introduction of biological functions, is capable of exerting the corresponding biological functions and provides a novel research model for application of magnesium and magnesium alloys to cardiovascular materials.

Owner:SOUTHWEST JIAOTONG UNIV

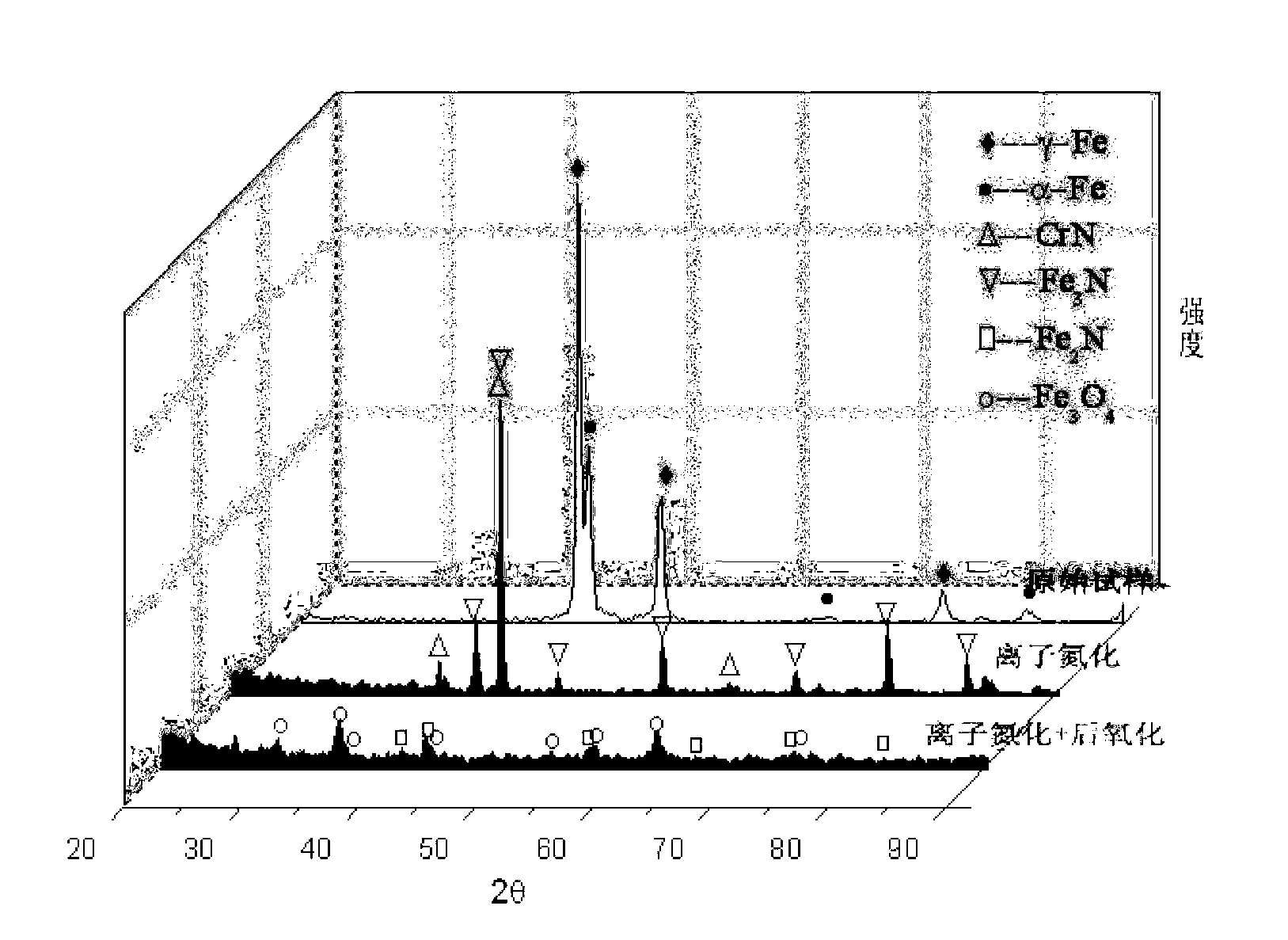

Treatment process of composite surface of austenitic stainless steel

ActiveCN103014599AHigh hardnessImprove surface wear resistanceSolid state diffusion coatingNitrogen gasAustenite

The invention belongs to the technical field of metal surface modification, and in particular relates to a treatment process of a composite surface of an austenitic stainless steel. The process mainly comprises the following steps: 1) washing the surface of a workpiece, and removing the oil stain and impurities on the surface of the workpiece; 2) putting the stainless steel workpiece into an ion nitriding furnace after being cooled down, introducing dried hydrogen, building up of luminance and heating up, after reaching a certain temperature, introducing nitrogen, adjusting the ratio of the nitrogen to the hydrogen and the pressure in the furnace, and subsequently starting to time; and 3) after nitriding for a certain time, stopping introducing the nitrogen, introducing dried air and keeping the temperature for a certain time. Not only is the surface abrasion resistance of the stainless steel treated by using the treatment process improved, but also the excellent corrosion resistance of the stainless steel self is maintained.

Owner:CHANGZHOU UNIV

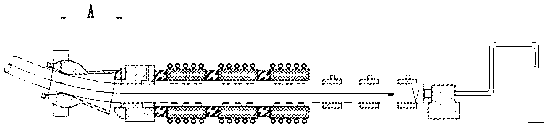

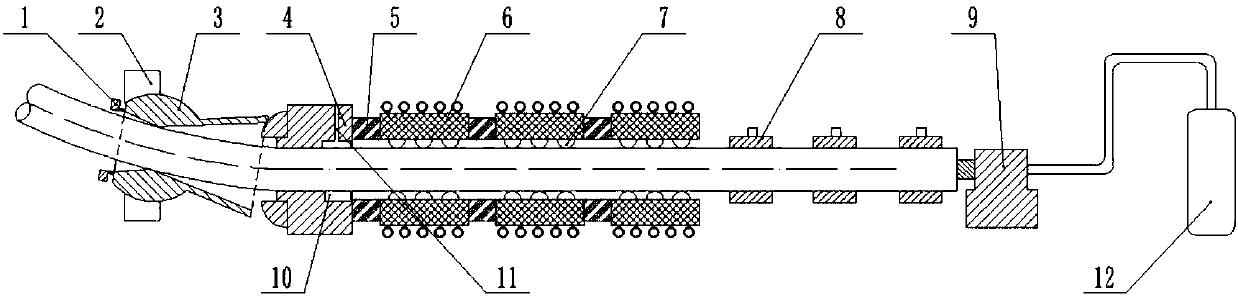

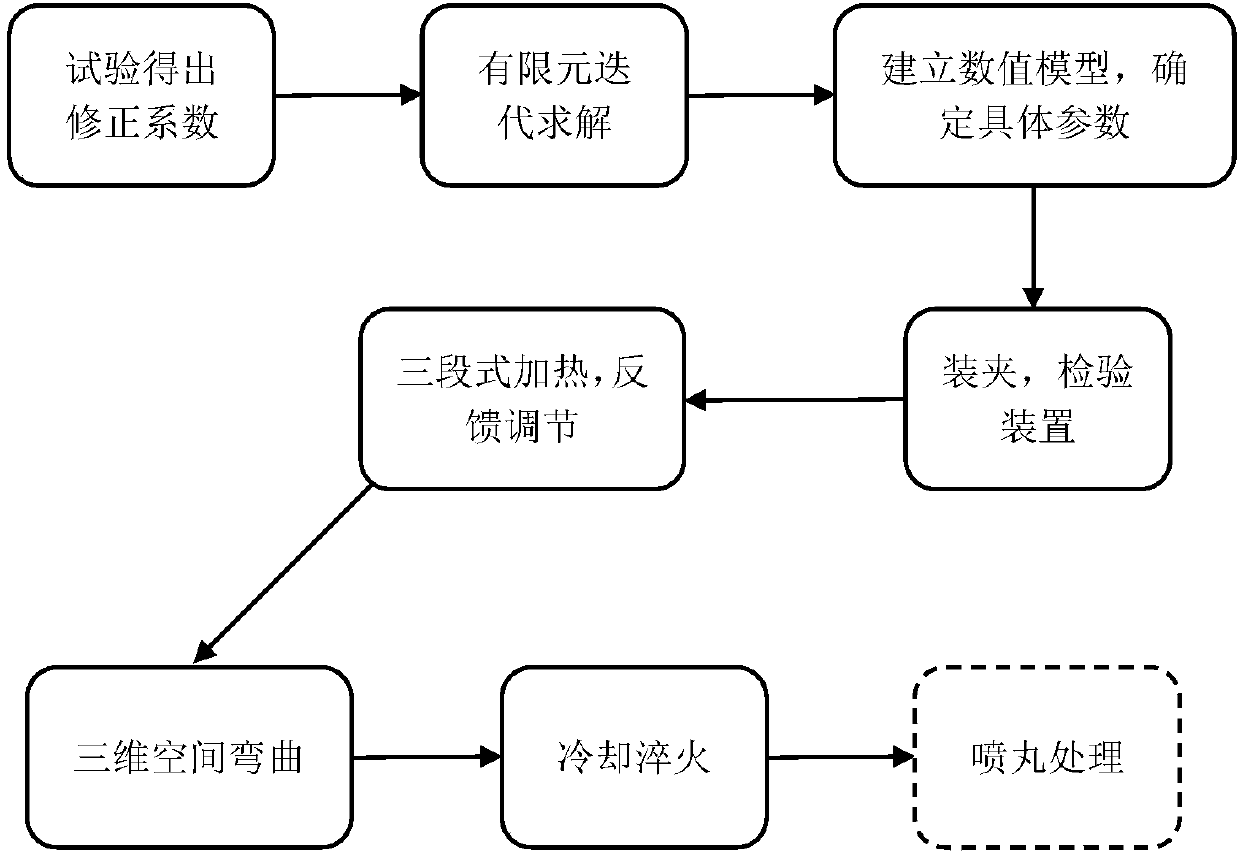

Martensite steel 3D free-bending forming device and method

ActiveCN107755490AIncrease productivityRealization of free bending pipeShaping toolsMetal-working feeding devicesNuclear powerMartensite

The invention discloses a martensite steel 3D free-bending forming device and method and belongs to the technical field of advanced manufacturing and plastic forming. Firstly, based on relative parameters of the forming performance of a pipe material, a corresponding correction factor of the material is obtained through repeated iterative calculation, and an initial model is corrected; after the using situations of parts are tested and calibrated, a three-stage type induction heating device and sensors are matched to achieve precise temperature-control heating; the three-dimensional space of abending mould rotates to extrude the front end of the pipe material to enable the front end of the pipe material to be in a bent shape with the complicated space; and the quenching process is conducted through an annular water-cooling spraying head and accordingly is rapid and uniform. The martensite steel 3D free-bending forming technical problem is solved, and high-temperature free-bending forming under the three-dimensional space is achieved; by means of a rapid quenching system, the strength of 1400 MPa or above is obtained, formation coordinated control of an ultrahigh-strength steel 3Dfree-bending member is achieved; and thus the martensite steel 3D free-bending forming device and method have important engineering application value in the fields of aerospace, rail transportation, automobiles and nuclear power.

Owner:NANJING INST OF TECH +1

Continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel

ActiveCN103243339AAvoid intergranular corrosionSpeed up the formation of passivation filmHydrofluoric acidConcentration ratio

A continuous annealing and acid washing method for medium-chromium ultrapure ferrite stainless steel comprises the process flow of cold rolling, annealing heat treatment, acid washing, final water washing, drying, flattening and packaging, and is characterized in that in the acid washing process flow, the acid washing solution is prepared from 120-150g / L of 65% nitric acid, 2-4g / L of 40% hydrofluoric acid and water. According to the invention, in the chemical acid washing stage, reasonable concentration ratio of nitric acid to hydrofluoric acid is adopted and proper acid washing speed is controlled to carry out acid washing on medium-chromium ferrite stainless steel. As a result, on one hand, the performance of a medium-chromium ferrite stainless steel passivation film is obviously improved, and the corrosion resistance of the surface of a medium-chromium ferrite stainless steel 2B board is significantly improved, and on the other hand, the process flow of the existing production factory is not needed to be changed, a special passivation treatment procedure is not needed, and the production cost is significantly lowered.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Chromium-free passivation solution

InactiveCN102409330AImprove corrosion resistancePH value is stableMetallic material coating processesChromium freeInorganic salts

The invention discloses a chromium-free passivation solution, which has the pH value 1-5 and consists of rare-earth salt, inorganic salt, boric acid, nitric acid and water serving as raw materials. In the chromium-free passivation solution, the content of the rare earth salt is 1-15 g / L, the content of the inorganic salt is 3-30 g / L, the content of the boric acid is 0.1-3 g / L, and the content of the nitric acid is 3-30 ml / L; the rare earth salt is a mixture of vanadate and cerium slat in the weight ratio 1:(1.33-6.5); and the inorganic salt is sodium chloride or potassium chloride. The chromium-free passivation solution has the advantages of good passivation effect, low application cost, high production efficiency, stable performance, difficulty in deteriorating and long storage time.

Owner:WEIFANG UNIVERSITY

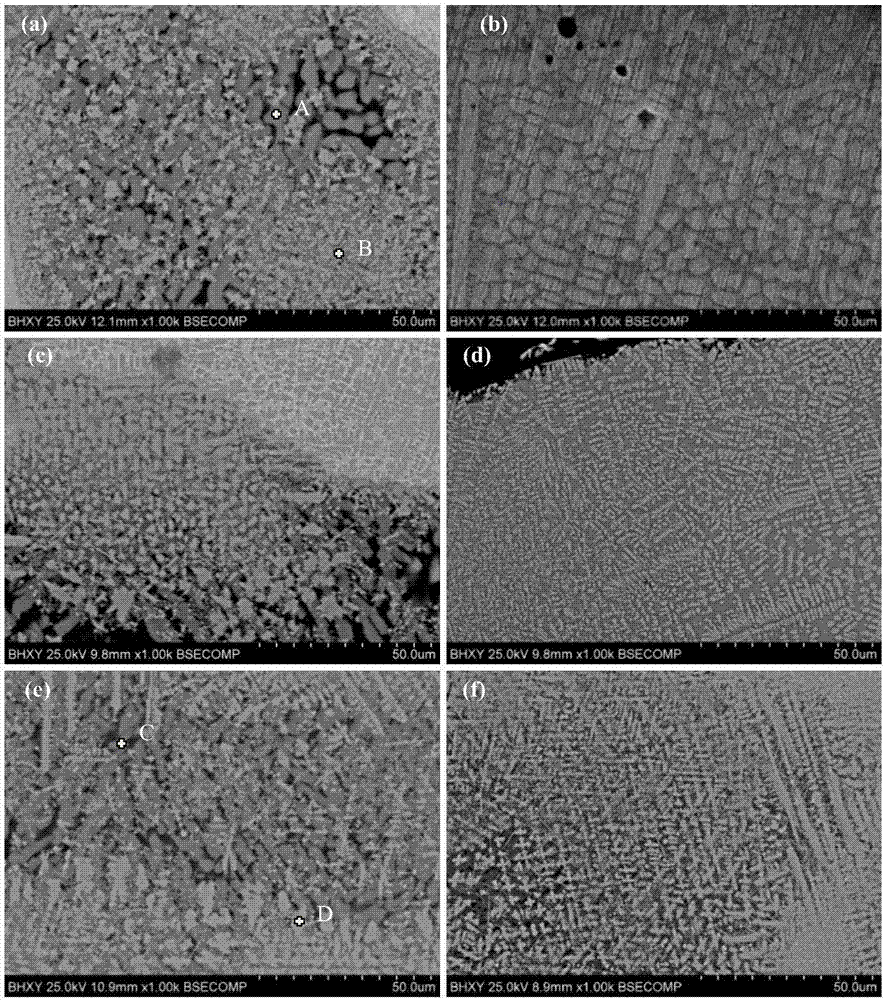

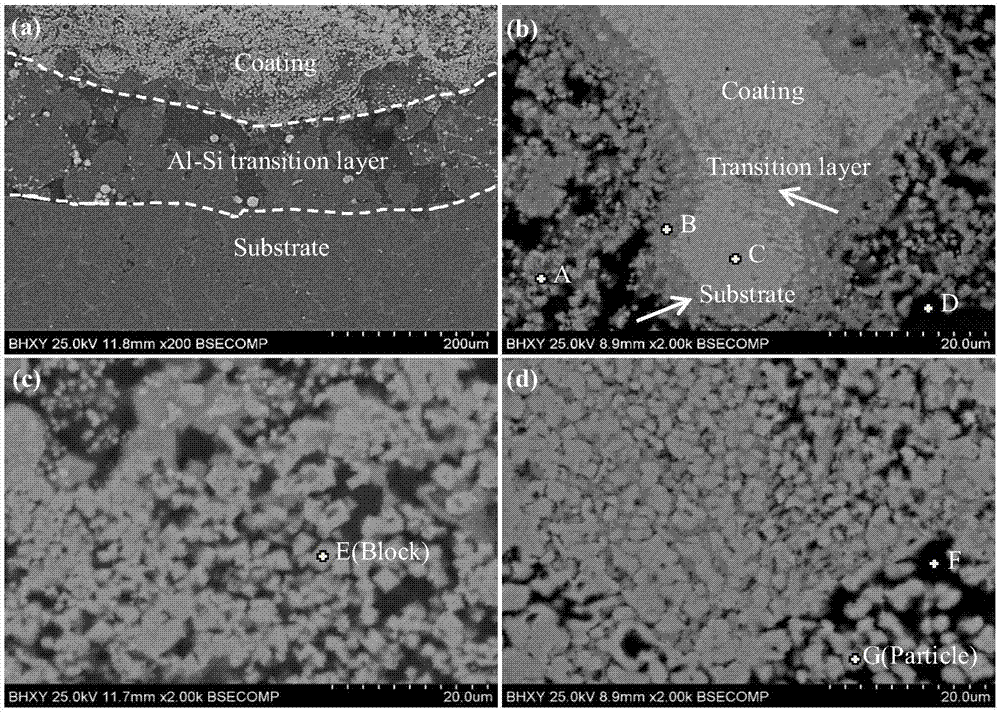

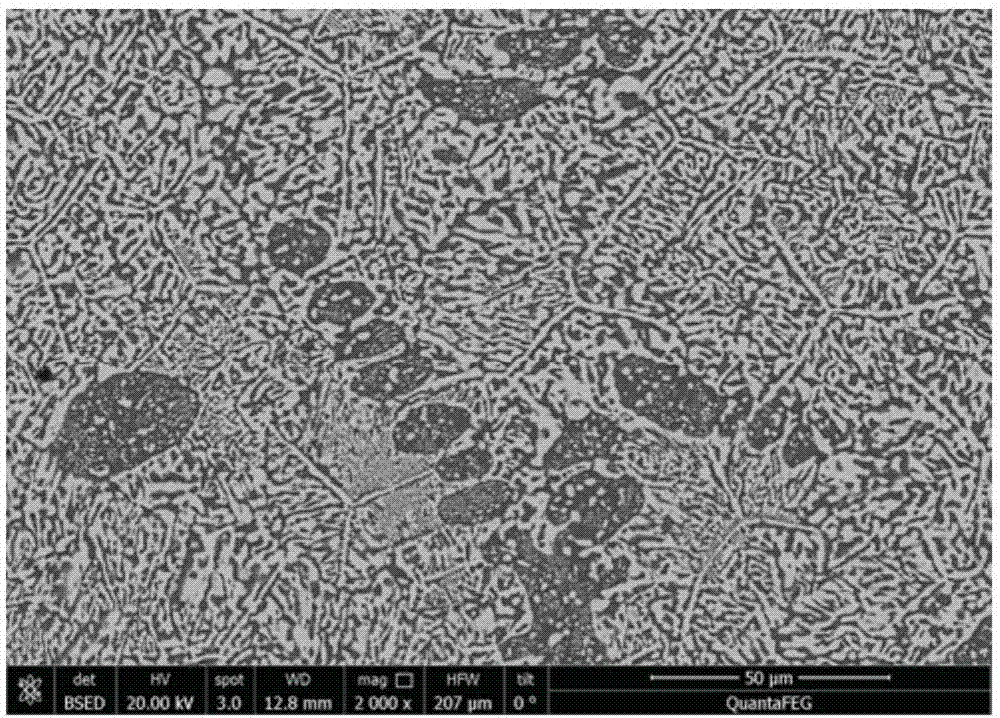

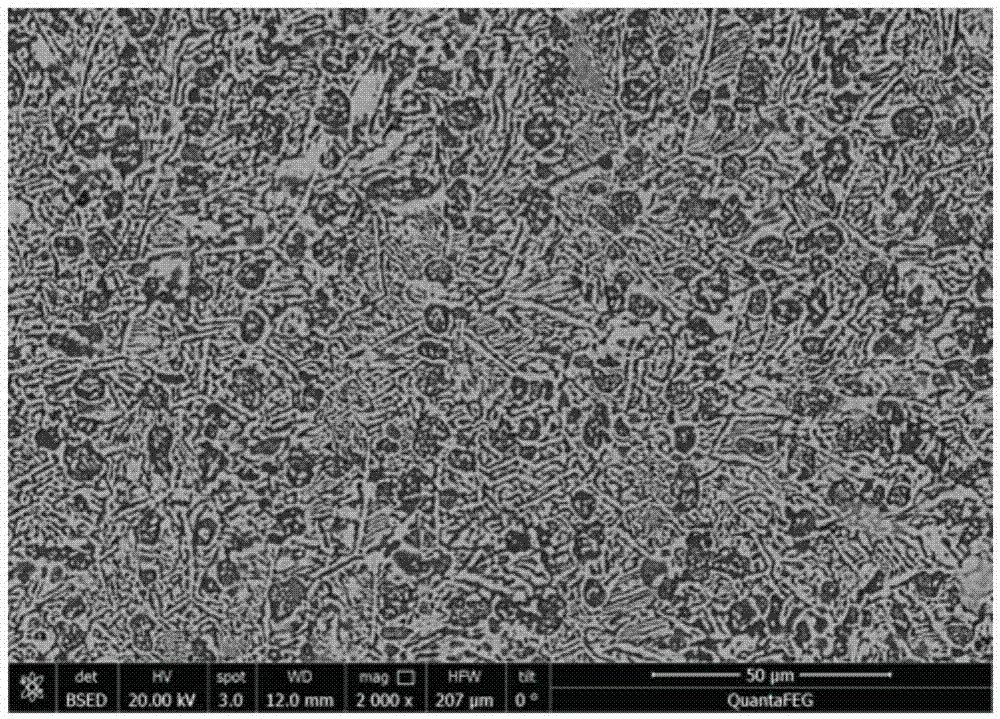

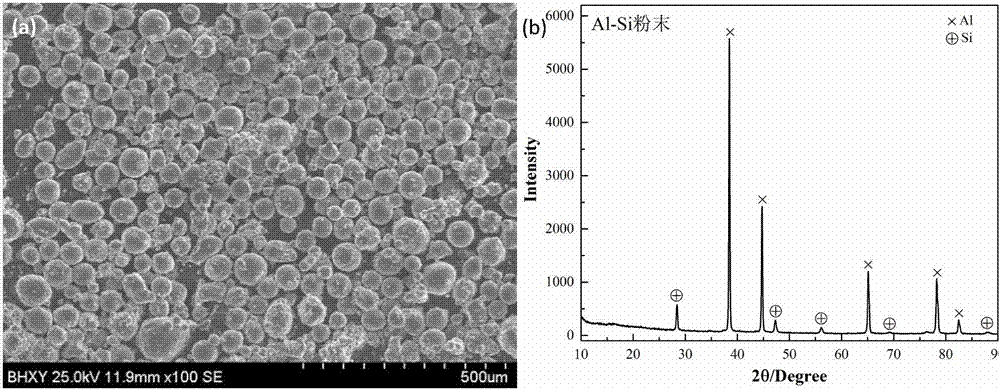

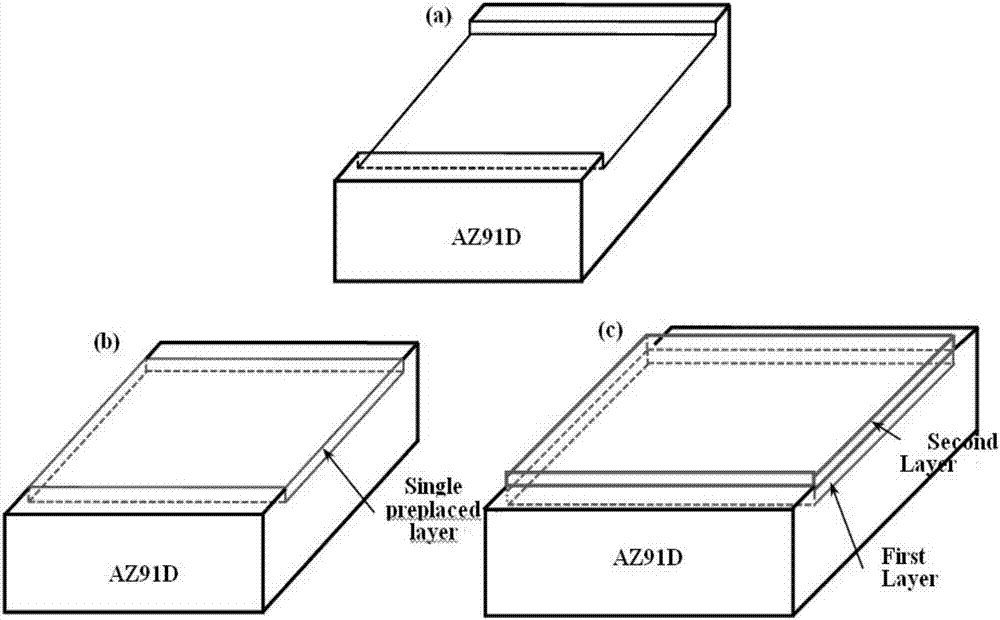

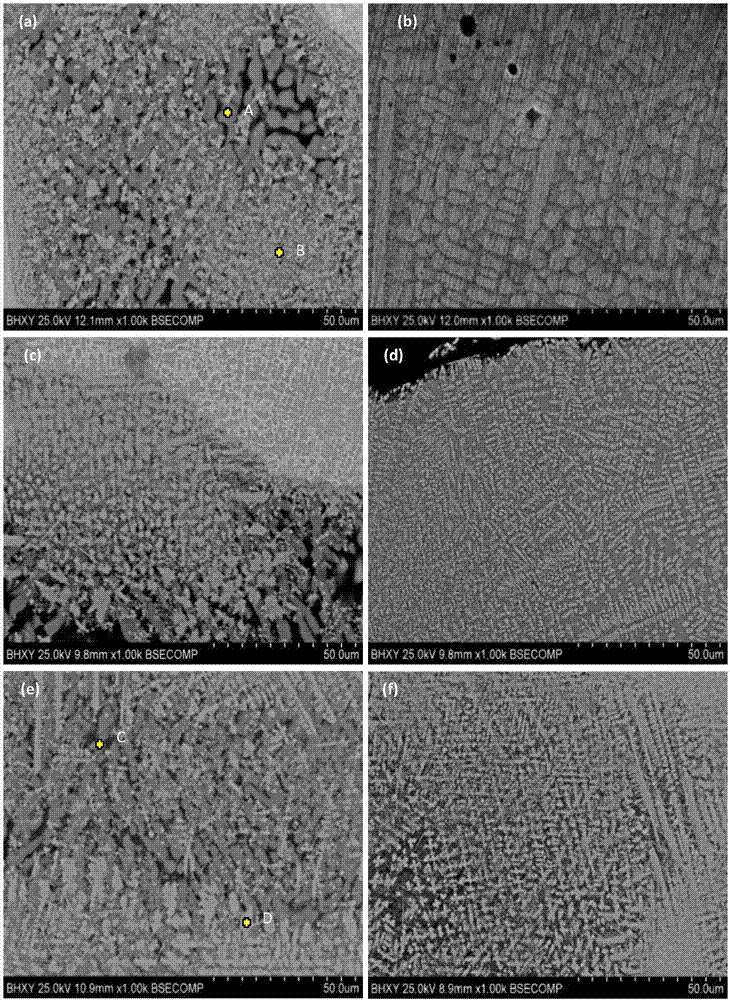

Magnesium alloy surface gradient laser cladding layer and preparation technology thereof

ActiveCN106967975AImprove corrosion resistanceReduce dilutionMetallic material coating processesSurface gradientMaterials science

The invention discloses a magnesium alloy surface gradient laser cladding layer and a preparation technology thereof. The preparation technology includes the steps that a mixture of Al-Si eutectic alloy powder and a binder is coated on the surface of a magnesium alloy base material at first; then a mixture of Ni-Cr-B-Si series nickel-base self-fusing alloy and a binder is coated after drying is completed; and a gradient preset coating can be formed after drying is completed. The gradient preset coating is treated by the adoption of a laser cladding technology, the prepared cladding layer and the base material achieve metallurgical bonding, the Ni-Cr-B-Si series nickel-base self-fusing alloy and the magnesium alloy base material can be well combined together, the effect that the property of the base material is improved can be guaranteed, and meanwhile the impact on the property of the cladding layer due to excessive dilution of the base material can be avoided. The magnesium alloy surface gradient laser cladding layer can be used for surface strengthening and modification of magnesium alloy parts in the industrial field, the application range of magnesium alloy at anti-corrosion places is widened, and the application prospects are broad.

Owner:SHANDONG UNIV

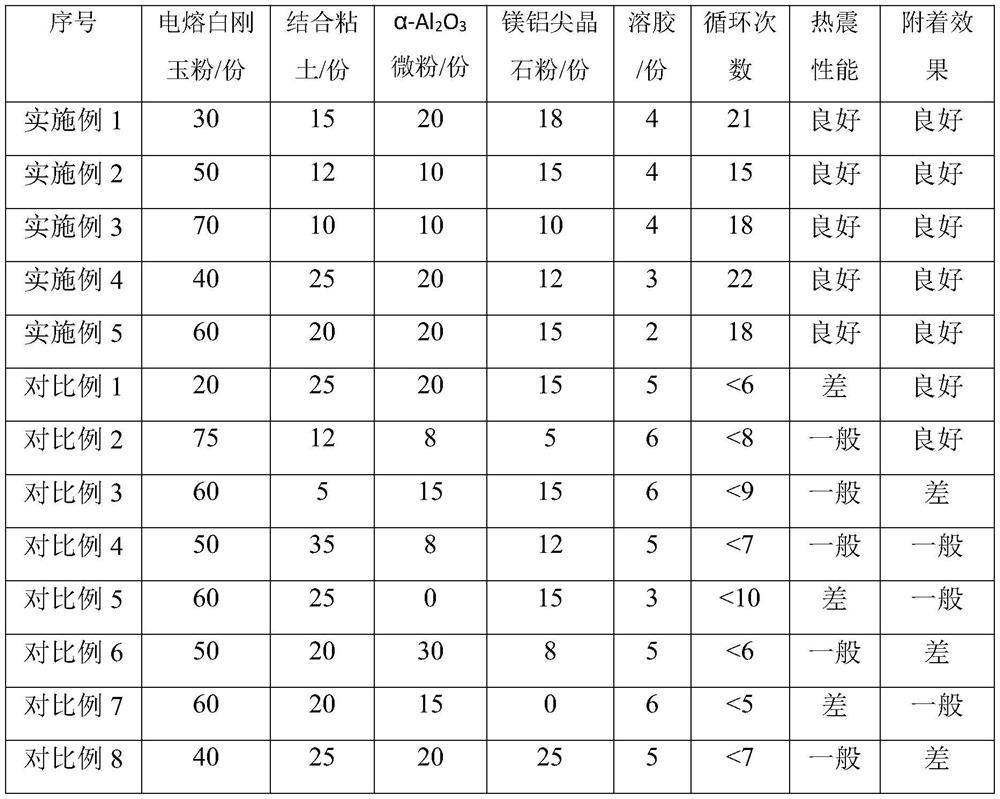

Waste sagger repairing coating and use method thereof

The invention provides waste sagger repairing coating and a use method thereof. The waste sagger repairing coating is prepared from the following raw material components in parts by weight: 30 to 70 parts of fused white corundum powder, 1 to 10 parts of mullite powder, 8 to 30 parts of binding clay, 0 to 5 parts of spodumene, 1 to 5 parts of zirconium oxide, 5 to 25 parts of alpha-Al2O3 micro powder, 1 to 20 parts of magnesium aluminate spinel powder, 2 to 8 parts of sol, 1 to 5 parts of a binding agent, 0.1 to 1 part of a water reducing agent and 16 to 22 parts of water. The using method of the waste sagger repairing coating comprises the steps of preparing the repairing coating, polishing a waste sagger and repairing the waste sagger to obtain a regenerated new sagger. The repaired waste saggar not only can be put into use again, but also is high in strength, high in corrosion resistance and good in thermal shock resistance. The recycling rate of the waste saggars is increased, and the problems of stacking difficulty and environmental pollution are reduced to a great extent.

Owner:CENT SOUTH UNIV

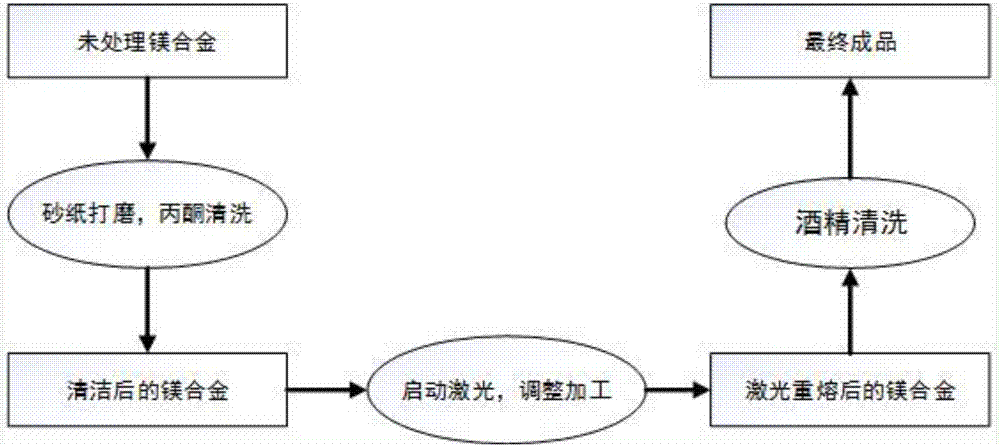

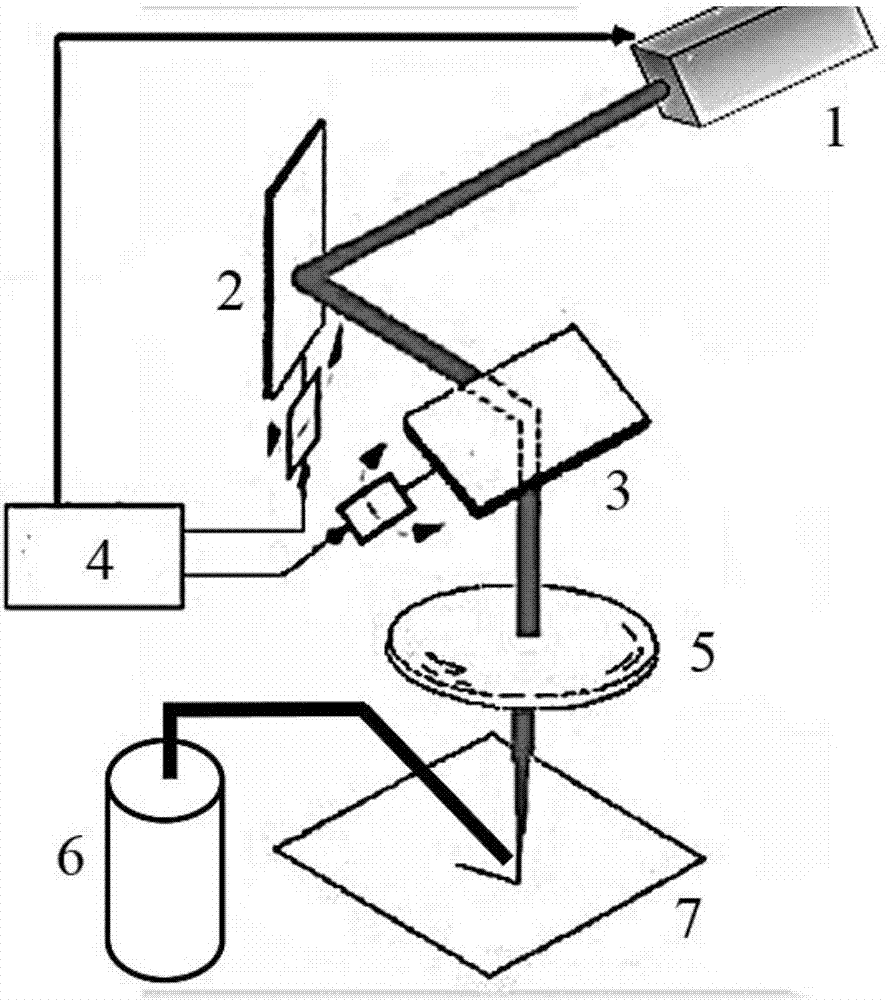

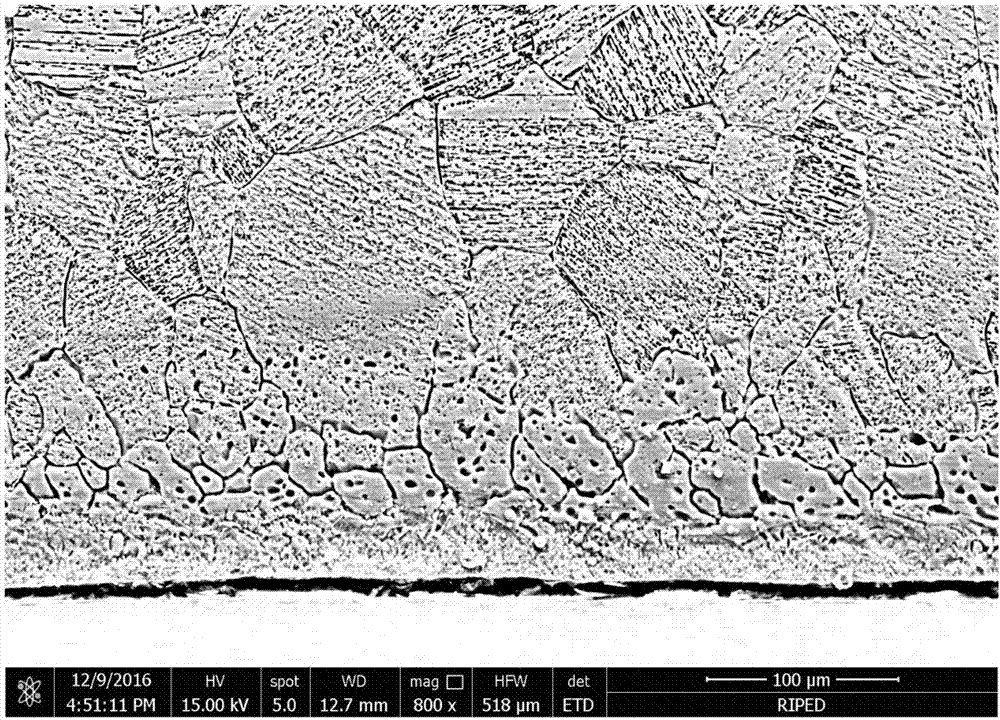

Method for improving corrosion resistance of magnesium alloy surface through short-pulse laser

The invention relates to a method for improving corrosion resistance of the magnesium alloy surface through a short-pulse laser. The method comprises the steps that (1), a magnesium alloy material is subjected to sand papering to remove an oxidation layer and then subjected to acetone cleaning to remove oil; (2), the cleaned magnesium material is placed on a worktable of a nanosecond laser machining system, laser parameters are set, the laser machining system is started, the laser is made to scan on the surface of the magnesium alloy material in a certain speed through galvanometer scanning, and a remelting layer is obtained on the surface of the magnesium alloy material; and (3), the machined metal material is cleaned simply. According to the method for improving corrosion resistance of the magnesium alloy surface through the short-pulse laser, a laser direct writing system is utilized, and by changing the laser parameters such as the frequency, the scanning speed and the power, the fused depth, the area and the like of the metal surface can be controlled precisely; a chemical reagent does not need to be added additionally, so that environment protecting is achieved; arbitrary set of a machining area can be achieved; the machining speed is higher, and the production efficiency is improved; and the short-pulse laser with the low power is used, so that the situation that metal matrix performance remains unchanged is facilitated.

Owner:BEIHANG UNIV

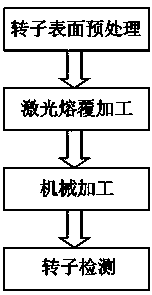

Repair process of screw rod compressor rotor

The invention provides a repair process of a screw rod compressor rotor. The repair process comprises the following processing steps of (a) rotor surface pretreatment, (b) laser cladding processing, (c) mechanical processing and (d) rotor detection. The invention discloses the repair process of the screw rod compressor rotor. The repair process has the advantages that the implementation is simple and convenient, the repair cost is low, the screw rod compressor rotor treated by the repair process has higher intensity and better surface corrosion resistance and wear resistance, in addition, the rotor gap is small, and the surface is smooth and cannot be easily contaminated.

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

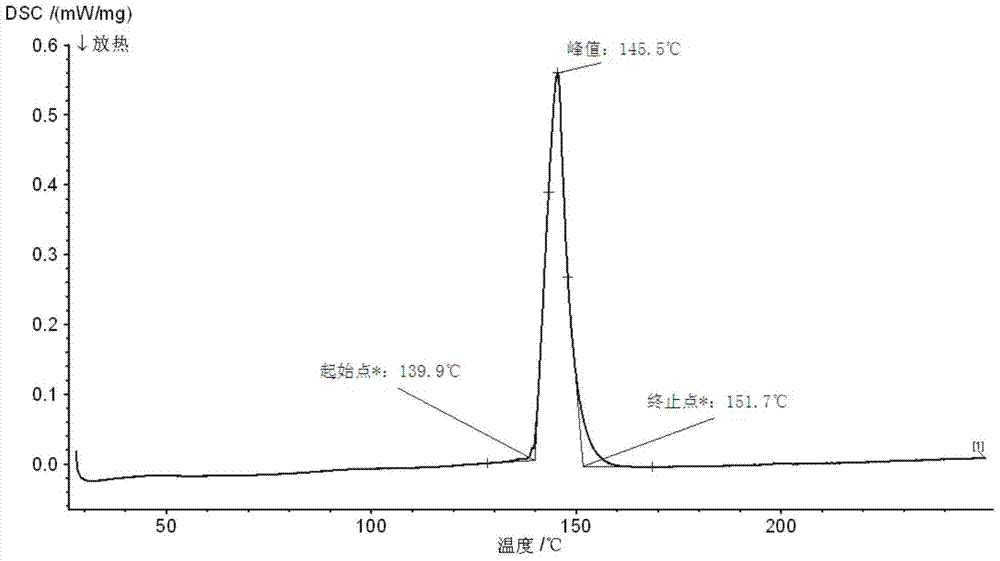

Low-temperature Ge-containing Sn-Bi solder used for photovoltaic solder strip and preparation method thereof

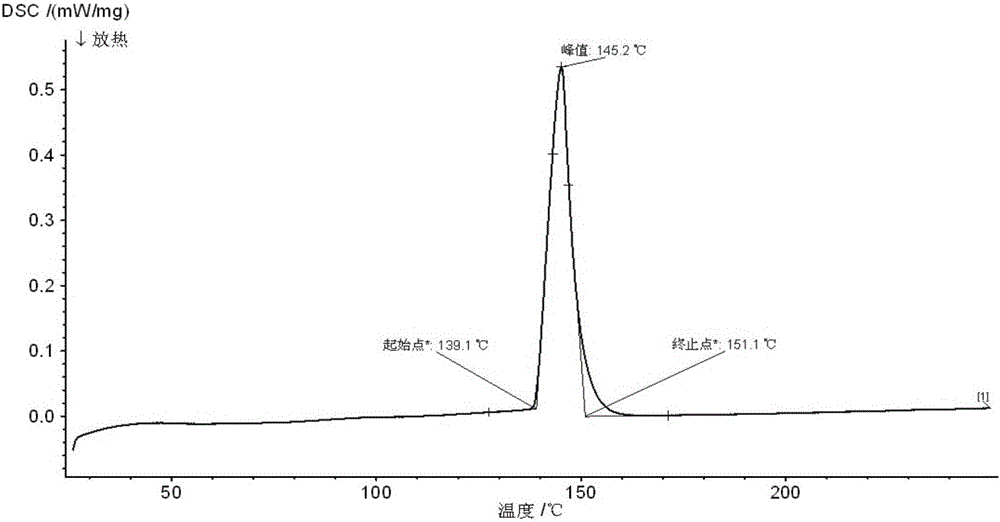

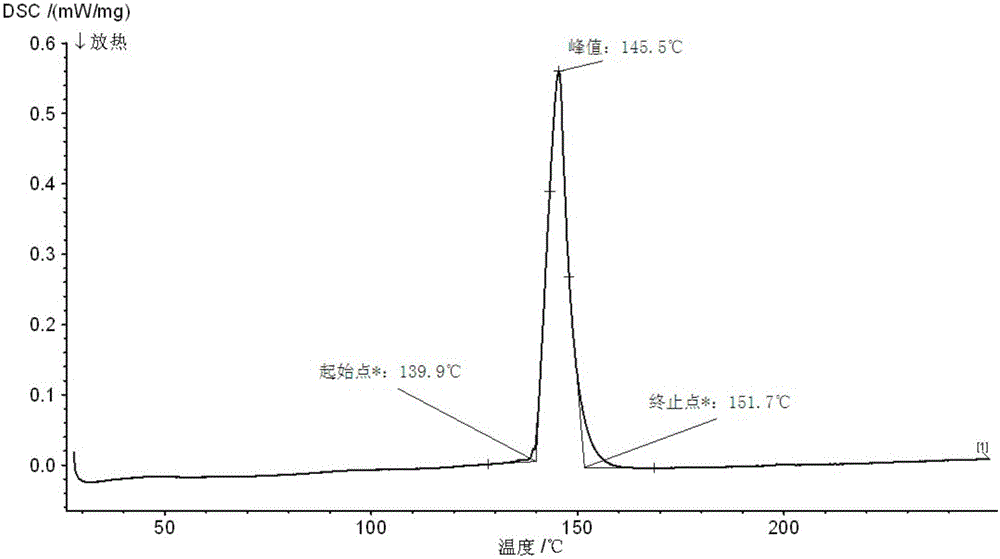

InactiveCN107262957AImprove mechanical propertiesAccelerated corrosionWelding/cutting media/materialsSoldering mediaTrace elementAlloy

The invention discloses low-temperature Ge-containing Sn-Bi solder used for a photovoltaic solder strip. The low-temperature Ge-containing Sn-Bi solder used for the photovoltaic solder strip comprises, by weight, 35%-52% of Bi, 0.025%-0.1% of Ge, and the balance Sn. The invention further discloses a preparation method of the low-temperature Ge-containing Sn-Bi solder used for the photovoltaic solder strip. According to the low-temperature Ge-containing Sn-Bi solder used for the photovoltaic solder strip, by controlling the content of the key element Bi and adding the trace element Ge, grains are refined, and the corrosion resistance of Sn-Bi alloy is improved; and the melting point of the solder is low, and the wettability of the solder is good, so that it is ensured that a copper strip is effectively wetted by the solder, and traditional Sn-Pb solder can be replaced by the low-temperature Ge-containing Sn-Bi solder.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS +1

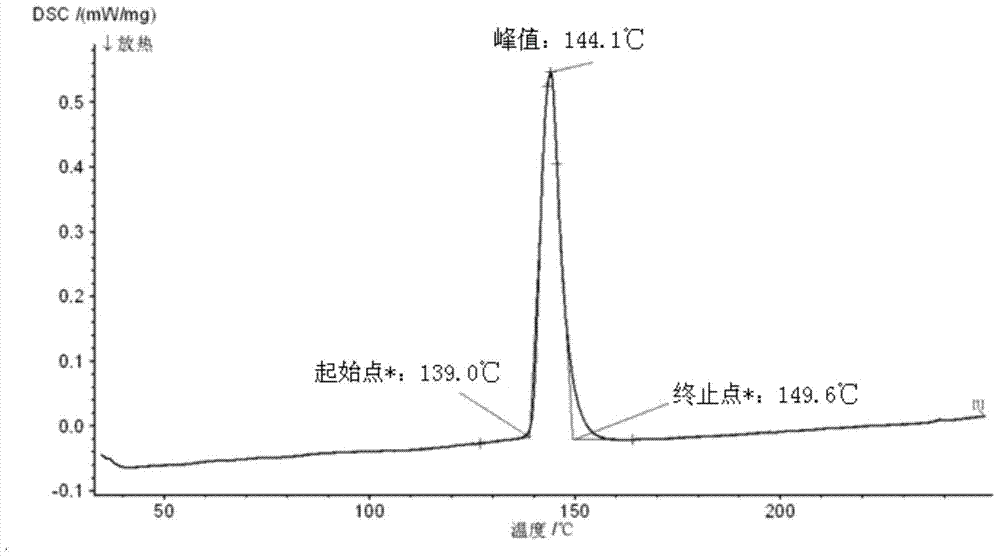

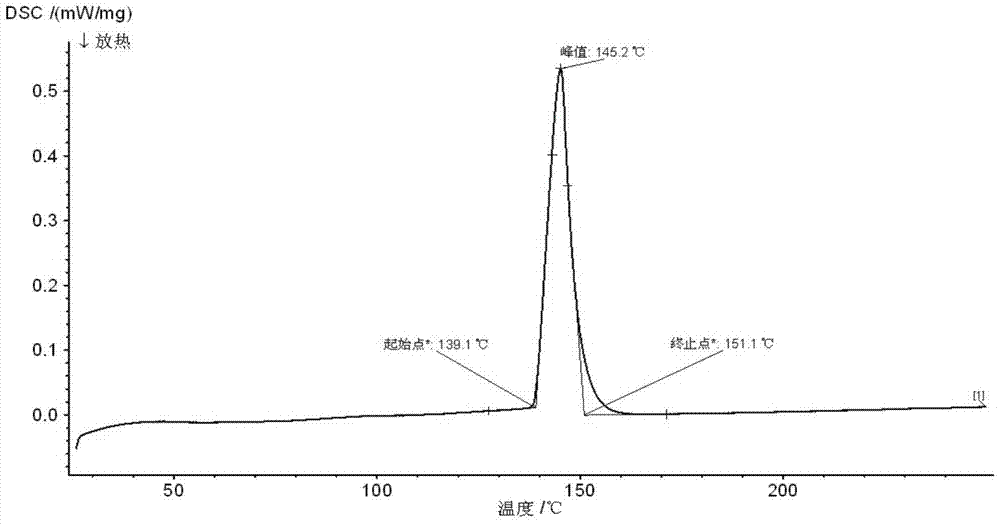

Corrosion-resistant low-temperature solder for photovoltaic solder strip and preparation method of corrosion-resistant low-temperature solder

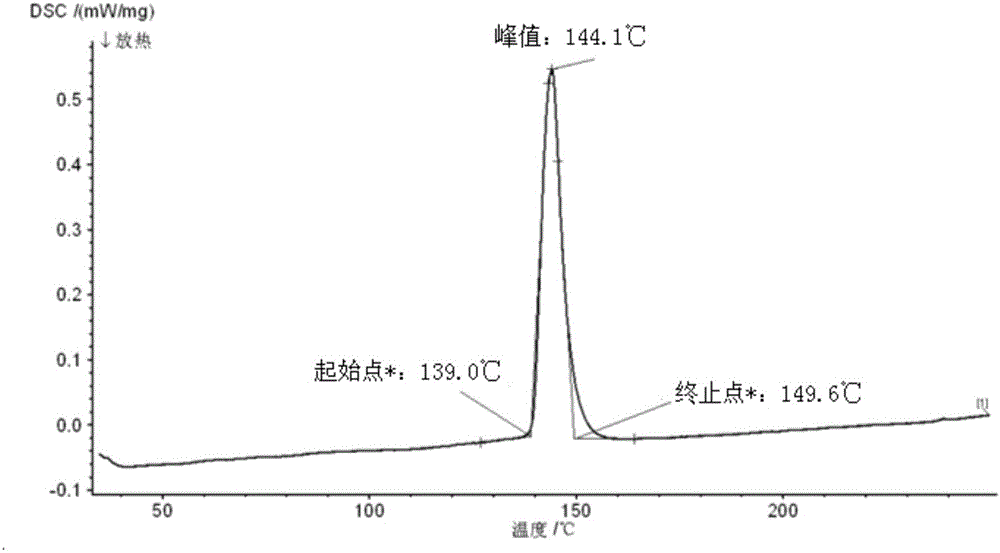

ActiveCN105014254ALow melting pointImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaDip solderingPorous carbon

The invention discloses corrosion-resistant low-temperature solder for a photovoltaic solder strip and a preparation method of the corrosion-resistant low-temperature solder. The solder comprises, by weight, 55%-60% of Bi, 0-0.01% of Sb, 0-0.0005% of Al, 0-0.0005% of Zn and the balance tin. The method comprises the following steps that a proper amount of the tin and bismuth is heated to 280 DEG C to 300 DEG C, and mixed melt is obtained; a proper amount of bismuth chloride is added to cover the surface of the mixed melt, then heat preservation is carried out, temperature is reduced to below 180 DEG C after stirring of 15-20 minutes, and molten solder is obtained; and finally the molten solder is filtered through porous carbon, the filtered molten solder is cast, and the corrosion-resistant low-temperature solder is obtained. According to the solder, the content of the key component Bi is controlled, it is measured that the melting point is close to 139 DEG C, the temperature difference of a solid phase and a liquid phase is only about 12 DEG C, and the phenomenon of segregation can be effectively avoided in dip soldering and other welding processes with the high cooling rate; the content of impurities is controlled to be low, so that the melting point of the prepared solder is low, and the corrosion resistance of the prepared solder is high.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS +1

Stainless steel surface treatment process

InactiveCN106238299AImprove surface corrosion resistanceStrong metal texturePretreated surfacesCoatingsSand blastingFilm-coated tablet

A stainless steel surface treatment process comprises the following steps of a, cleaning, wherein the surface of a stainless steel workpiece is cleaned, and grease on the surface of the workpiece is removed; b, sand blasting, wherein the cleaned surface of the workpiece is subjected to sand blasting; c, spraying, wherein one or two layers of glue are evenly sprayed to the surface of the stainless steel workpiece; d, sintering, wherein the stainless steel workpiece sprayed with the glue is placed in an oven to be sintered, and a stainless steel non-stick layer is formed; e, coloring, wherein the stainless steel workpiece is subjected to coloring treatment after being subjected to anodic oxidation treatment; f, film coating, wherein the surface of the stainless steel workpiece obtained after coloring is finished is coated with a fingerprint-resistant coating, and a fingerprint-resistant film is formed; and g, drying, wherein the stainless steel workpiece coated with the fingerprint-resistant coating is dried.

Owner:江苏华力金属材料有限公司

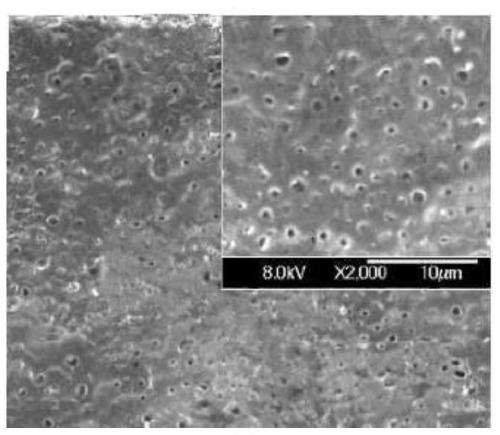

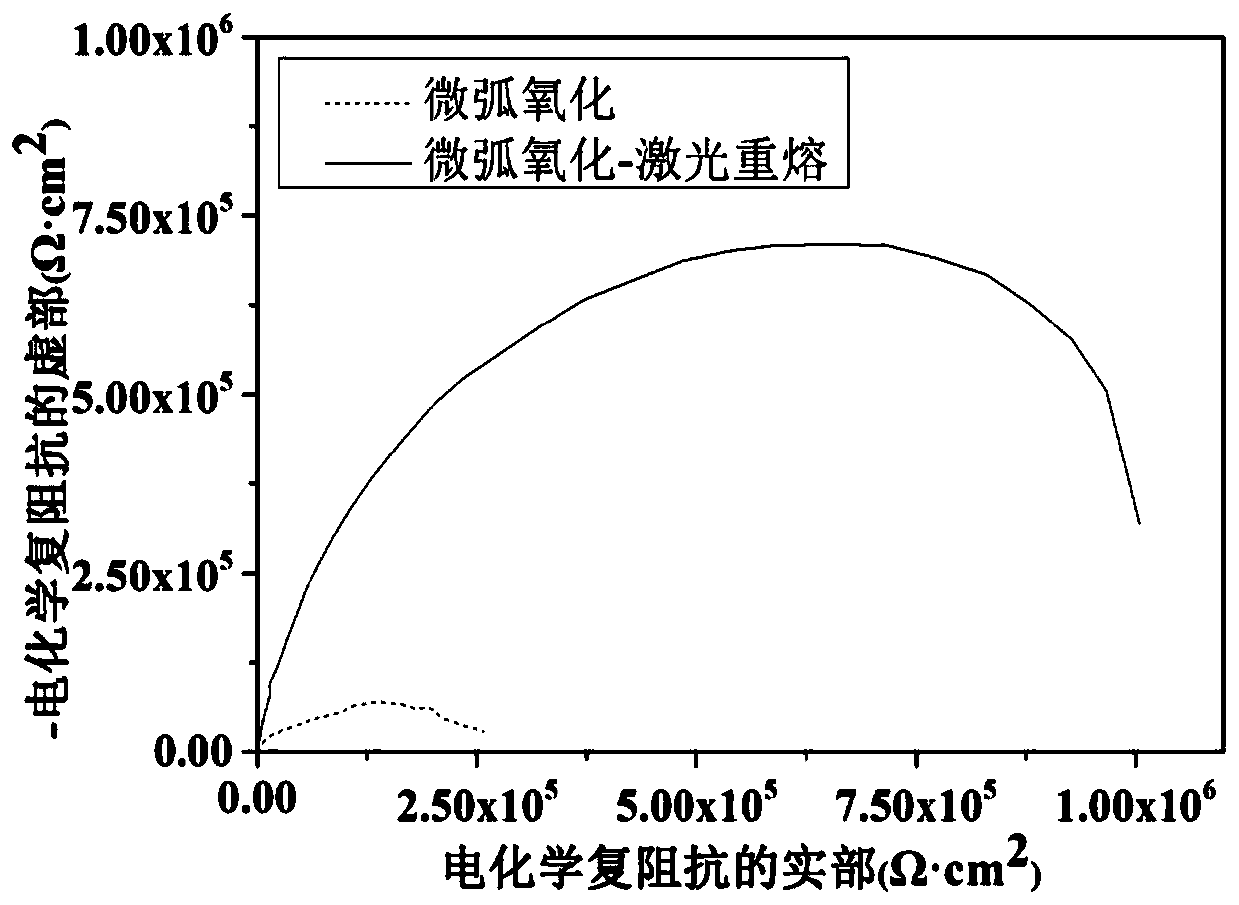

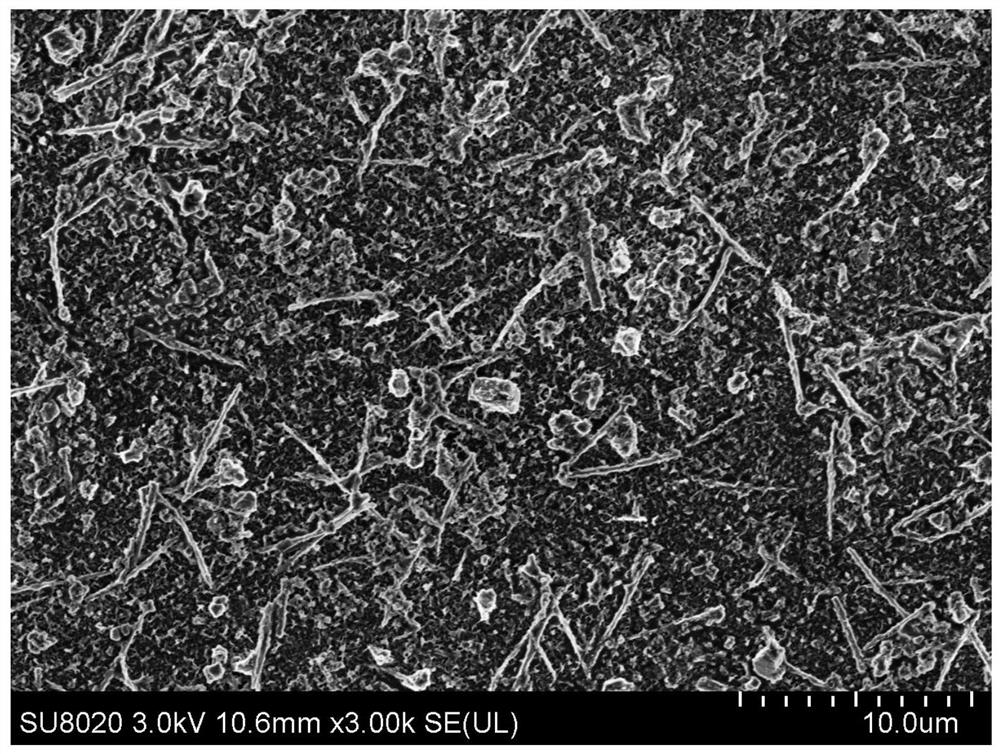

Method for improving corrosion resistance of surface of magnesium alloy on basis of micro-arc oxidation and laser remelting

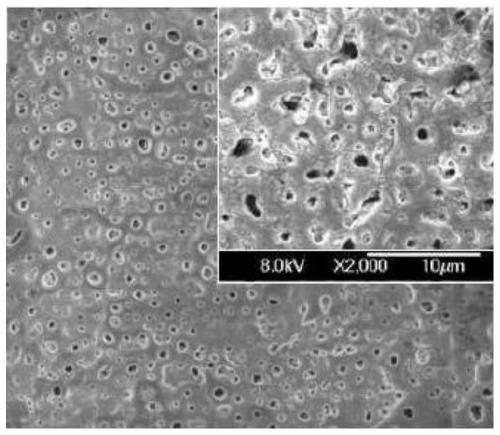

InactiveCN110079850AImprove surface corrosion resistanceImprove corrosion resistanceAnodisationLiquid surface applicatorsEnvironmental resistanceMicro arc oxidation

The invention discloses a method for improving corrosion resistance of the surface of magnesium alloy on the basis of micro-arc oxidation and laser remelting. Firstly, after micro-arc oxidation treatment is conducted on the surface of the magnesium alloy, a layer of ceramic film is obtained, the film layer is prefilled with a thin layer of graphene oxide particles through ultrasonic oscillating, then microcracks and holes of the ceramic film are filled with molten graphene oxide particles effectively through laser remelting technology, and thus corrosion resistance of the surface of the magnesium alloy is improved greatly. The method is environmentally friendly in process and high in repeatability, and a novel way is developed for improving the corrosion resistance of the surface of the magnesium alloy.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

Preparation method of hollow slab beam for bridge

ActiveCN104924449AEasy to useExtended service lifeCeramic shaping apparatusBuilding reinforcementsRebar corrosionBasalt fiber

The invention discloses a preparation method of a hollow slab beam for a bridge. A basalt fiber reinforcement cage replaces a reinforcement cage and serves as a framework of the hollow slab beam, the problem of reinforcement corrosion is solved, and the mechanical property, the physical property and high-temperature stability of the hollow slab beam are improved. Basalt fiber reinforcements are connected into a stereoscopic basalt fiber reinforcement cage framework by a basalt fiber connecting ring, basalt fiber connectors do not deform or collapse and are simple in structure, convenient and rapid, binding or welding is omitted, connectors made of second materials are not led in, practicability of the basalt fiber reinforcement cage is improved, the service performance of the hollow slab beam is improved, and the service life of the hollow slab beam is prolonged.

Owner:山东聚源玄武岩纤维股份有限公司

Method of machining special passivated stainless steel surface

ActiveCN103100562AReduce manufacturing costThe production process is simple and controllableWork treatment devicesMetallic material coating processesFurnace temperatureHydrogen Nitrate

Owner:NINGBO BAOXIN STAINLESS STEEL

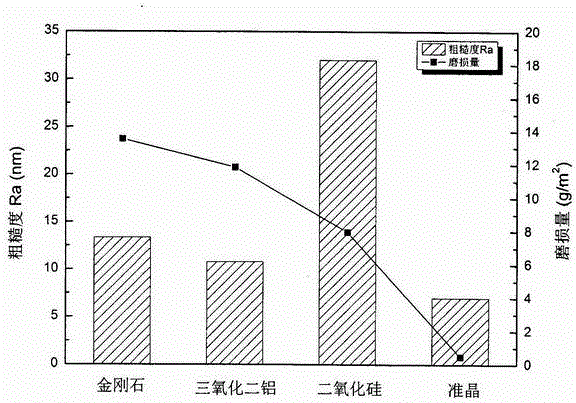

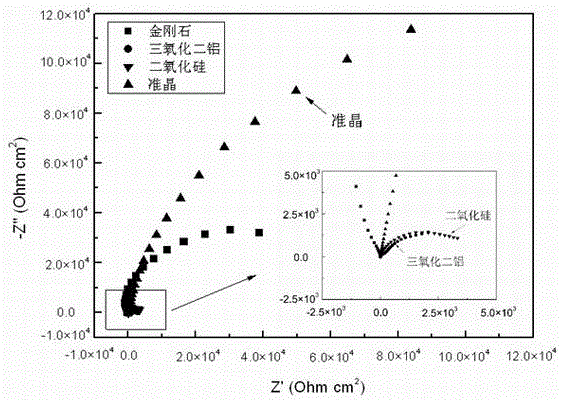

Low-wear abrasive capable of improving corrosion resistance capability of stainless steel surface and preparation method of low-wear abrasive

InactiveCN105154004AImprove surface corrosion resistanceHigh hardness ratioOther chemical processesSurface corrosionQuasicrystal

The invention discloses a low-wear abrasive capable of improving corrosion resistance capability of the stainless steel surface and a preparation method of the low-wear abrasive and belongs to the technical field of grinding and polishing finish machining for stainless steel surface machining. The low-wear abrasive capable of improving the corrosion resistance capability of the stainless steel surface forms a quasicrystal and approximates and comprises components as follows: Al-(Li,Cu,Fe,Co,Cr,V,Mn,Ru,Re,Os), TiZrNi, (Zn / Cd)-Mg-(Y,Yb,Gd,Tb,Dy,Ho,Er,Sc) and Cd-(Ca,Y,Gd,Tb,Tm,Ho,Dy,Er,Yb), and the content of the quasicrystal and the approximates is larger than 50%. The abrasive is used for grinding and polishing the stainless steel surface and also can realize low-wear polishing and finish machining of stainless steel and rapidly improve the surface corrosion resistance capability.

Owner:DALIAN UNIV OF TECH

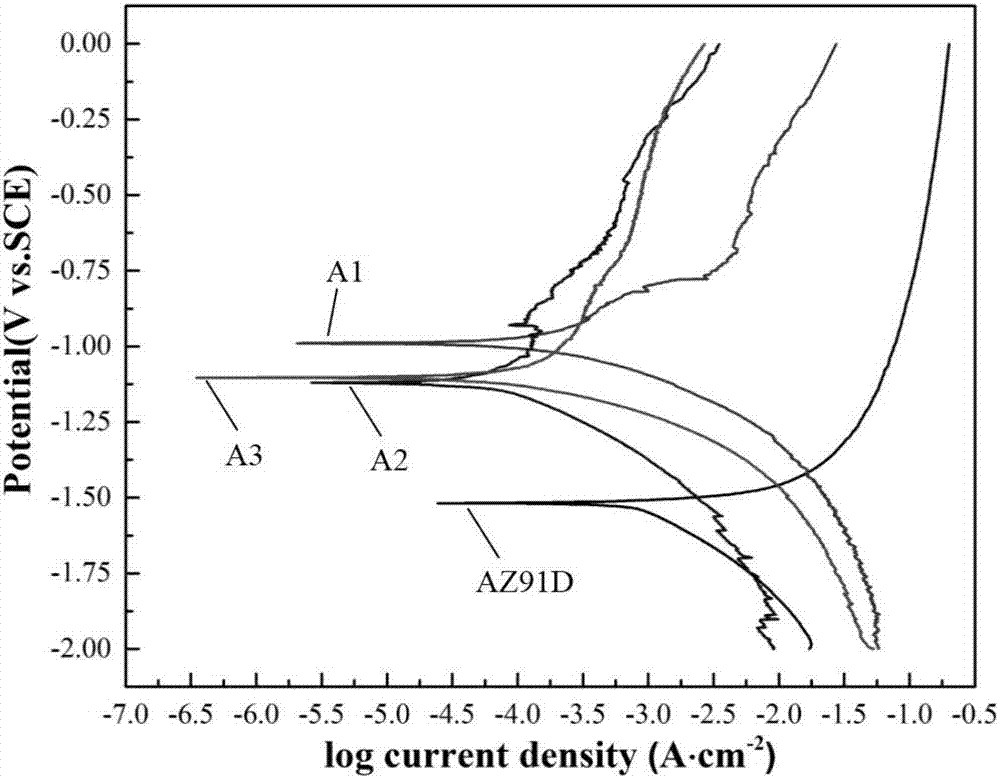

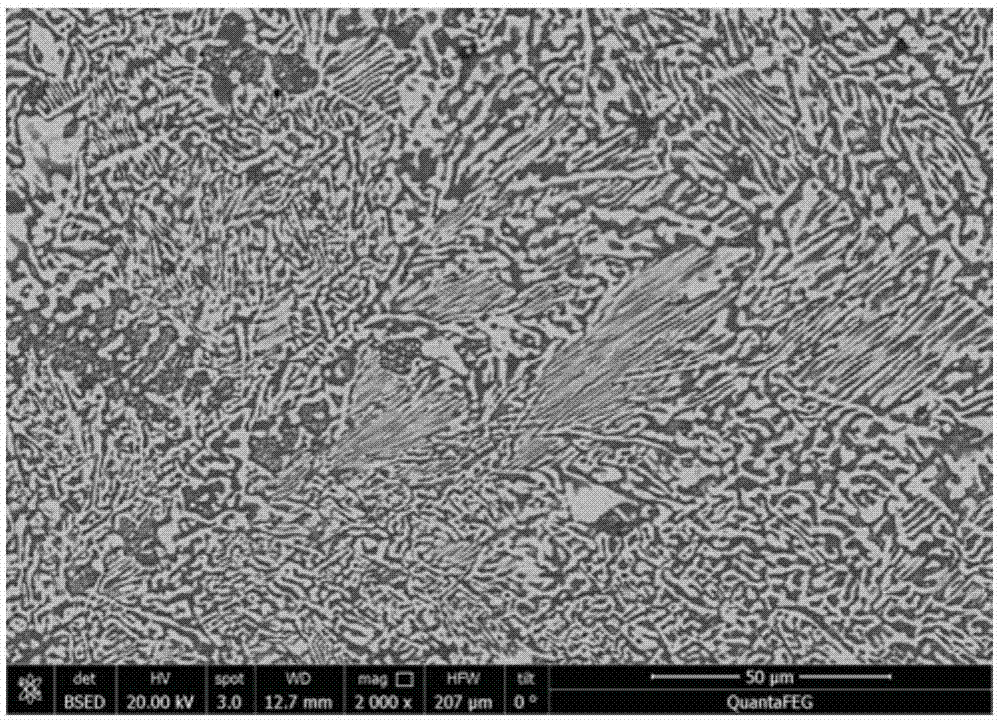

Aluminum oxide modified gradient laser cladding layer and preparation method thereof

ActiveCN107012463AReduce excessive oxidation and burning lossAvoid destructionMetallic material coating processesCorrosion resistantCorrosion current density

The invention discloses an aluminum oxide modified gradient laser cladding layer and a preparation method thereof. Magnesium alloy serves as base material, Al-Si alloy powder serves as a first precoated layer, the mixed powder of nickel-based self-melting alloy powder and Al2O3 serves as a second precoated layer, and the aluminum oxide modified gradient laser cladding layer is formed through laser cladding. The corrosion potential of the Al2O3 modified gradient laser cladding layer is about -1.1 V and is similar to that of a Ni35, Al-Si / Ni35 cladding layer, the corrosion current density is large in difference and is about 1 / 15-1 / 2 that of the base material, and a good corrosion resistant effect is achieved. The aluminum oxide modified gradient laser cladding layer and the preparation method thereof can be used for surface strengthening and modification of magnesium alloy parts in the industrial field, the application range of magnesium alloy in corrosion resistant occasions is extended, and wide application prospects are achieved.

Owner:SHANDONG UNIV

Preparation method of modified glass fiber

The invention discloses a preparation method of a modified glass fiber, and relates to the technical field of high performance fibers. The preparation method comprises following steps: (1) adding glass fibers in a rare earth solution, and processing glass fibers in an ultrasonic field; (2) blending the glass fibers with nano diatomite to modify the glass fibers; and (3) adding the glass fibers into a coupling agent solution so as to process the glass fibers. According to the preparation method, the glass fibers are modified, and the toughness, surface wear resistance, and surface compatibilityof glass fibers are effectively enhanced.

Owner:安徽兴乐健身器材有限公司

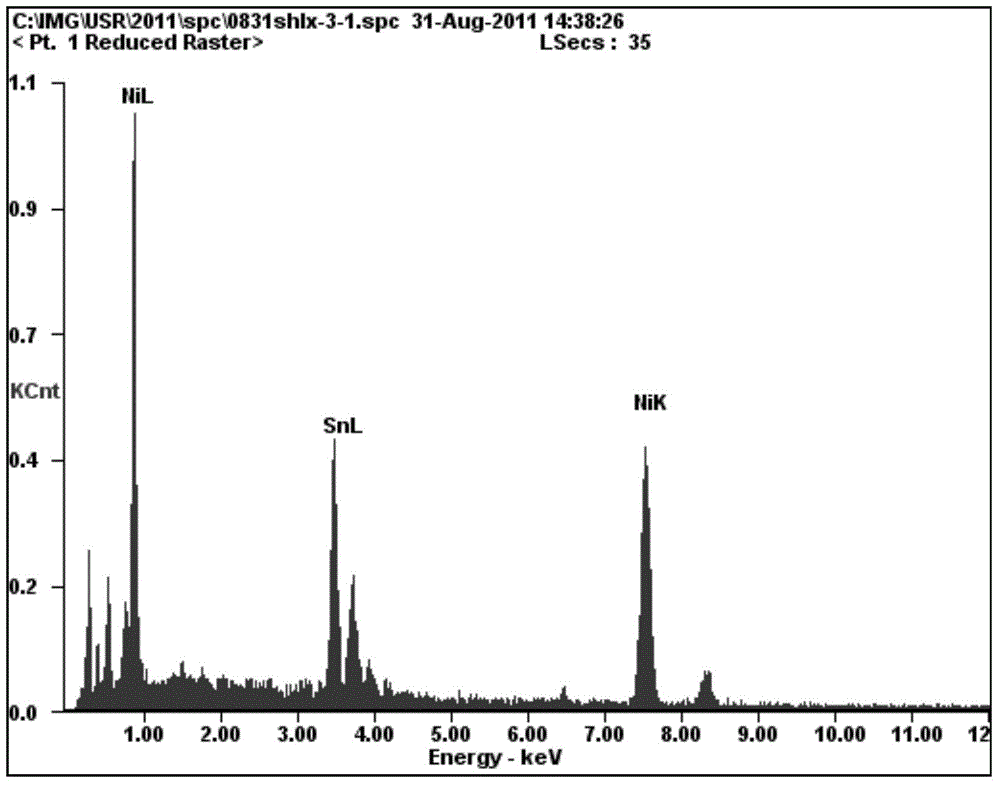

Rare earth permanent magnet with multilayer composite electroplated coating and composite electroplating method thereof

ActiveCN104630852AImprove corrosion resistanceUniform appearancePermanent magnetsMagnetic materialsNickel electroplatingTechnetium stannous pyrophosphate

The invention provides a rare earth permanent magnet with a multilayer composite electroplated coating and a composite electroplating method thereof. The rare earth permanent magnet includes a rare earth permanent magnet body, a first layer of nickel coating, a second layer of copper coating, a third layer of nickel coating and a fourth layer. An electroplating solution includes: 40-60g / L stannous pyrophosphate, 30-45g / L nickel chloride, 250-320g / L potassium pyrophosphate, and 20g / L glycine. The composite electroplated coating not only can play an anti-corrosion role of conventional electroplated nickel, but also has certain protection effect on the eyes of inspectors, and the uniform appearance and black and shiny color can reach certain decorative effect.

Owner:TIANJIN SANHUAN LUCKY NEW MATERIAL CO LTD +1

High-strength aluminum alloy profile for brake chamber and processing technology of high-strength aluminum alloy profile

ActiveCN114672684AImprove corrosion resistanceImprove wear resistanceAnodisationElectrolytic agentSilumin

According to the high-strength aluminum alloy profile for the brake chamber and the machining technology of the high-strength aluminum alloy profile, ZL205A is selected to be made into an aluminum alloy body, the microstructure of the aluminum alloy is improved by limiting the type and content of the added alterant and matching with a proper solid solution aging heat treatment method, and then the normal-temperature and high-temperature mechanical properties of the alloy are improved; rare earth Sc and rare earth La are added into the alloy for modification treatment, and an aluminum alloy body is treated by using an ion nitriding technology, so that the hardness, wear resistance and fatigue resistance of the aluminum alloy body are remarkably improved, and the aluminum alloy body is uniform and compact in structure and gentle in hardness gradient; the impurity removal and purification capacity is enhanced by limiting a refining agent and a rotary blowing degassing and purification treatment process, and the precision of the aluminum alloy is effectively improved; the components and content of the electrolyte are limited, anodic oxidation is carried out on the surface of the aluminum alloy body, and the composite nano cerium oxide is introduced, so that the corrosion resistance of the surface of the aluminum alloy body is improved, and meanwhile, the service life of the aluminum alloy profile is greatly prolonged.

Owner:江苏恒鑫正宏科技有限公司

Processing technology for automobile hub surface

InactiveCN106835171AImprove scratch resistanceExtend your lifeFurnace typesHeat treatment furnacesLaser processingEngineering

The invention discloses a processing technology for the automobile hub surface. The processing technology comprises the steps of (1) oil stain removing; (2) alkaline cleaning; (3) water cleaning; (4) electrolytic polishing; (5) laser processing; (6) pickling; and (7) water cleaning. The processing technology for the automobile hub surface is simple, the corrosion resistant capacity of the automobile hub surface is improved greatly, the surface can prevent oil stains, the process is simple, and energy consumption is low.

Owner:安徽世强机械制造有限公司

Corrosion-resistant mullite refractory brick and preparation method thereof

InactiveCN107954726AImprove surface corrosion resistanceReduce porosityCeramicwareBrickPolyvinyl alcohol

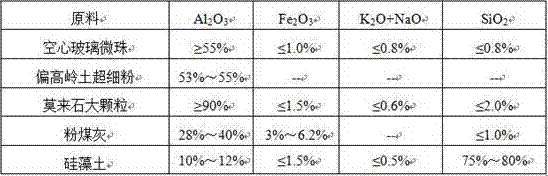

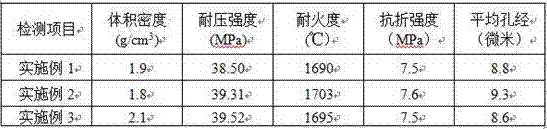

The invention provides a corrosion-resistant mullite refractory brick which comprises a refractory brick base and a high-temperature-resistant coating sprayed on the surface of the refractory brick base. The refractory brick base is prepared from the following raw materials: 27-31% of mullite large granule, 15-25% of hollow glass microsphere, 3-5% of metakaolin ultrafine powder, 10-18% of titaniumwhite, 0.5-1.5% of polyvinyl alcohol water solution, 5-10% of fly ash, 5-10% of diatomite, 6-11% of calcium carbonate and the balance of paper pulp water. The high-temperature-resistant coating is prepared from the following raw materials: 20-35% of polysiloxane, 30-38% of polyborosilazane, 3-10% of Mo powder and the balance of ethanol. The invention also provides a preparation method of the corrosion-resistant mullite refractory brick. The method is nitrogen in steps, and can easily implement automatic production.

Owner:HENAN HAINADE NEW MATERIAL CO LTD

Low-carbon nickel-chromium-molybdenum-niobium alloy stainless-steel seamless pipe

InactiveCN103215473AImprove surface corrosion resistanceSuperior Performance StandardsRigid pipesManganeseAcid washing

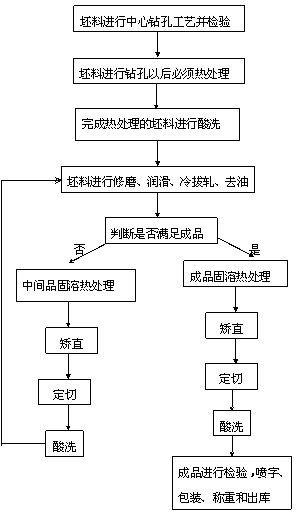

The invention discloses a low-carbon nickel-chromium-molybdenum-niobium alloy stainless-steel seamless pipe. The stainless-steel seamless pipe contains the following ingredients in percentage by weight: 58% of nickel, 20%-23% of chromium, 8%-10% of molybdenum, 3.15%-4.15% of niobium, 5% of iron, 0.4 of aluminum, 0.4 of titanium, 0.1% of carbon, 0.5% of manganese, 0.5% of silicon, 1% of cobalt, 0.015% of phosphorus and 0.015% of sulfur. The stainless-steel seamless pipe is produced by the steps of: (1) drilling a hole in the center of a blank and inspecting the blank; (2) heat-treating the blank after hole drilling; (3) acid-washing the blank after heat treatment; (4) coping, lubricating, cold drawing and rolling, and deoiling the acid-washed blank; (5) judging whether a finished product requirement is met, if so, implementing solid solution heat treatment, straightening, stationary cutting and acid washing on a finished product; (6) if not, implementing solid solution heat treatment, straightening, stationary cutting and acid washing on an intermediate product, and repeating the step (4); and (7) inspecting the finished product, spraying words, packaging and weighing the finished product, and delivering the finished product out from a warehouse. According to the stainless-steel seamless pipe, the corrosion resisting performance of the surface is enhanced, the performance standard is optimized, the manufacturing cost is lowered and the production process is simple.

Owner:SUZHOU BEST METAL PROD

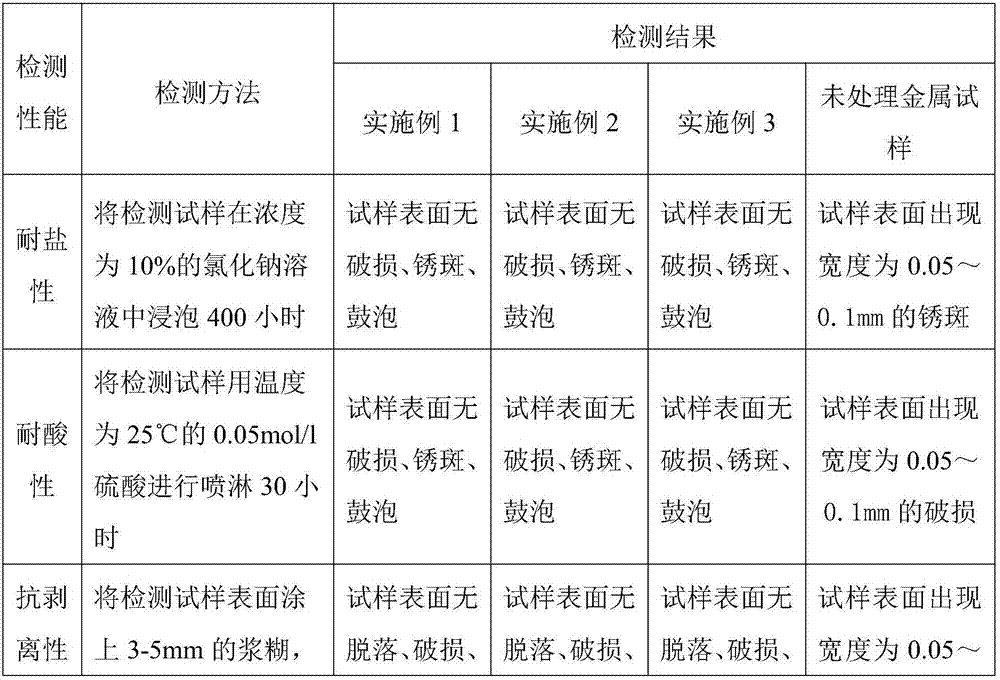

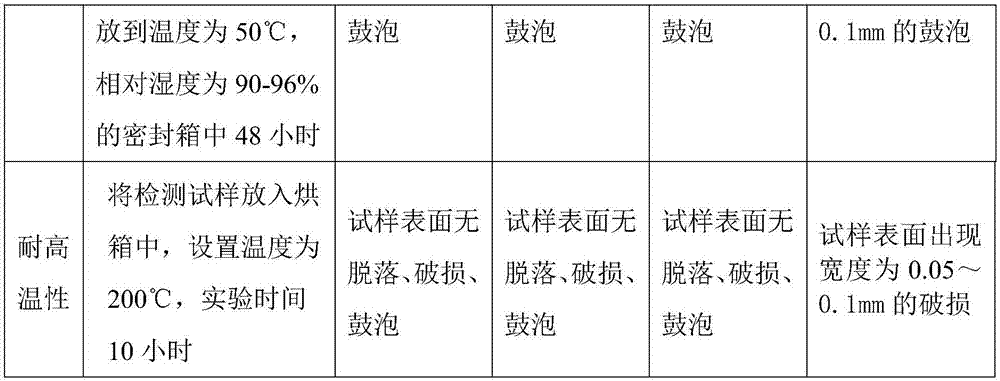

Surface treatment technique for metal material

InactiveCN107245716AImprove surface corrosion resistanceImprove insulation performanceSuperimposed coating processPolyvinyl chlorideMetallic materials

The invention provides a surface treatment technique for a metal material. The surface treatment technique comprises the following steps: (1), the surface of the metal material is ground, polished, cleaned and dried for pretreatment; (2), the surface of the metal material which is treated in the step (1) is subjected to micro-processing, and a micro groove is formed; the surface of the metal material is cladded with PVC microparticle powder, so that the micro groove is filled with the PVC microparticle powder; the surface of the metal material is struck by an ultrasonic striking head; (3), the surface of the metal material which is treated in the step (2) is further subjected to micro-processing, and a micro groove is formed; the position of the micro groove is staggered with the position of the micro groove in the step (2); the surface of the metal material is cladded with nano-ceramic powder, so that the micro groove is filled with the nano-ceramic powder; the surface of the metal material is subjected to laser shot blasting treatment; and (4), the surface of the metal material which is treated in the step (3) is subjected to anti-corrosion protection. The surface treatment technique has the advantages that while the surface performance of the material is improved, the anti-fatigue capability is enhanced; and the service life of the material is prolonged.

Owner:合肥聪亨新型建材科技有限公司

Preparation method of high-strength Si3N4/SiC composite ceramics

The invention discloses a preparation method of high-strength Si3N4 / SiC composite ceramics; and the preparation method comprises the following steps of: (a) using SiC powder as a main material; adding 10-15 % of Si powder, 2.2-2.7 % of Al2O3, 0.6-0.8 % of Fe2O3, 2.5-3.0 % of Y2O3 and 0.5-1.2 % of CeO2 to the main material; (b) wetly rolling a mixed powder obtained in the step (a) in a ball mill for 4-6 h; drying and granulating the mixed powder; and dryly pressing the mixed powder for molding; and (c) nitriding and sintering the mixed powder at 1500-1600 DEG C so as to obtain the Si3N4 / SiC composite ceramics. The Vickers hardness of the composite ceramic material prepared by the method disclosed by the invention can reach 2.185 GPa, the heat bending strength of the composite ceramic material can reach 420 MPa, and the breaking tenacity of the composite ceramic material reaches 12 MPa*m1 / 2; and the corrosion resistance of the surface of the composite ceramic material is enhanced.

Owner:NANJING DADI REFRIGERATION FOOD

Corrosion-resistant steel passivation method for high-purity pipe

ActiveCN113106220APromote preferential oxidationImprove surface corrosion resistanceMetallic material coating processesElectrolysisWorking environment

The invention belongs to the technical field of stainless steel pipe corrosion prevention, and particularly relates to a corrosion-resistant steel passivation method for a high-purity pipe. The 0Cr15Ni10MnMoWTiAlSc corrosion-resistant steel passivation method for the high-purity pipe includes the steps of pre-passivating treatment, bright annealing treatment, electrolytic treatment and solution passivating treatment. According to the disclosed corrosion-resistant steel passivation method for the high-purity pipe, a 0Cr15Ni10MnMoWTiAlSc alloy product has good inspiration permeation prevention characteristic and dusty corrosion resistance, and the service life of the alloy product is longer than the service life of an alloy for a 0Cr15Ni10MnMoWTiAlSc ultra-pure pipe subjected to common passivation treatment by more than 0.5 times under the working environment of same high-purity special gas.

Owner:湖州合创金属材料有限公司

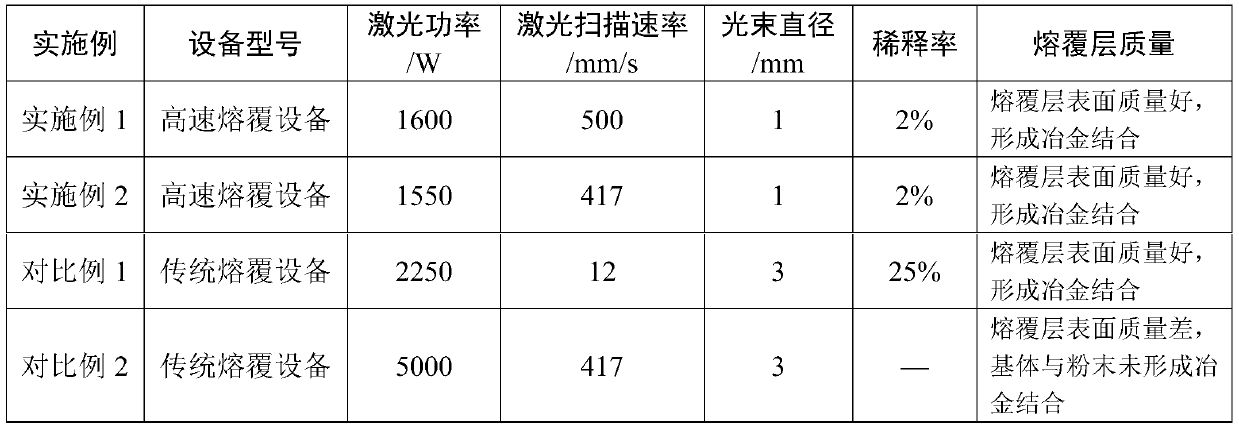

Ultra-high-speed laser cladding iron-based metal powder, and preparation method and application thereof

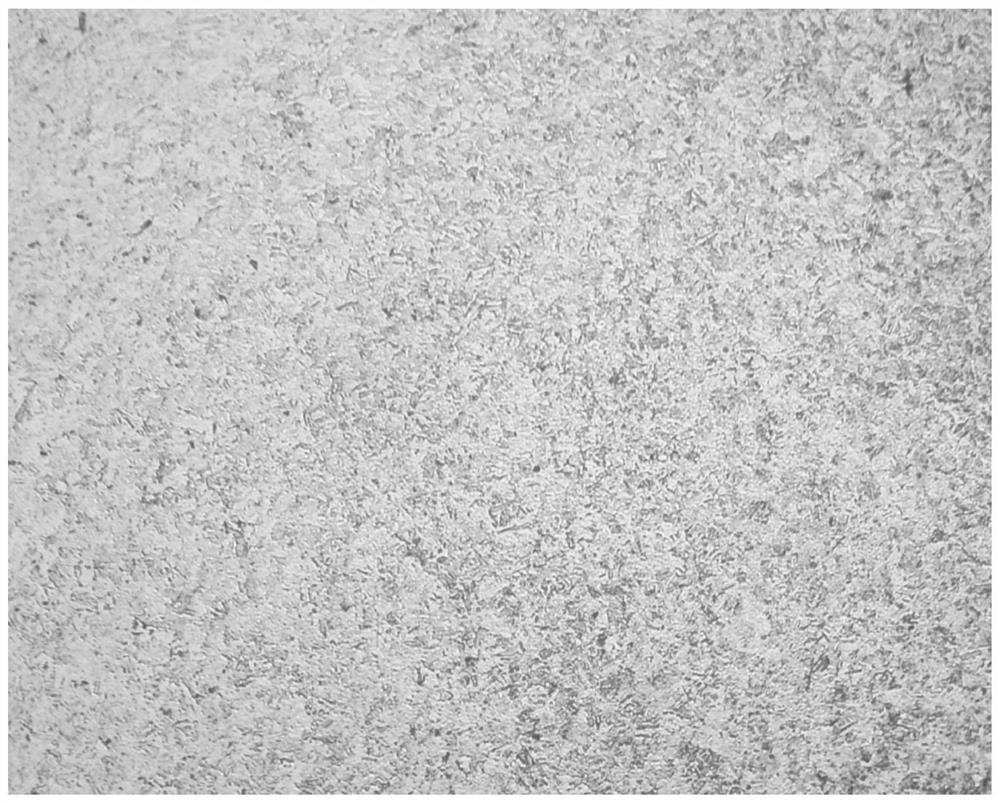

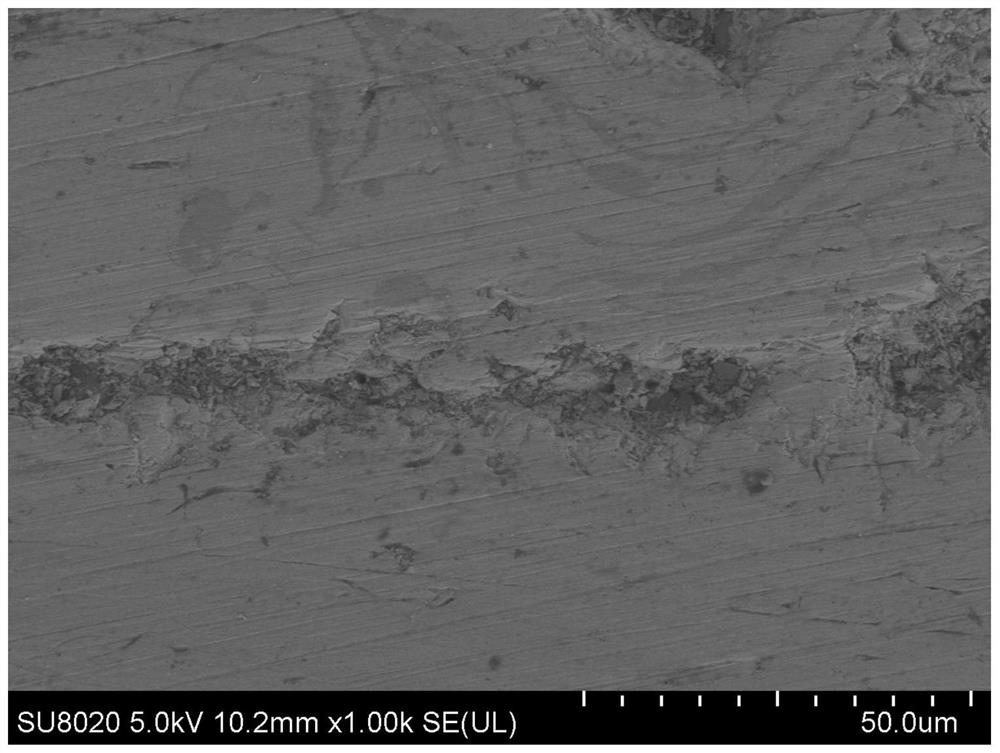

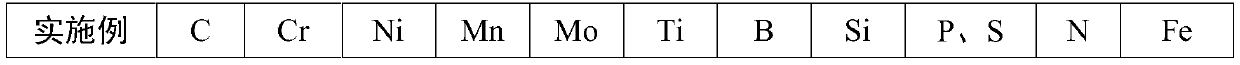

ActiveCN111074268AImprove surface corrosion resistanceEvenly distributedTransportation and packagingMetallic material coating processesUltra high speedChemical composition

The invention provides ultra-high-speed laser cladding iron-based metal powder, and a preparation method and application thereof. The iron-based metal powder comprises the following chemical components of, in percentage by mass, 0.6 %-1.0% of C, 17.0 %-20.0 % of Cr, 5.0 %-6.5 % of Ni, 2.0 %-4.0 % of Mn, 1.0 %-1.5 % of Mo, 4.0 %-6.0 % of Ti, 1.0 %-1.5 % of B, 0.08 %-0.15 % of N, less than or equalto 0.5% of Si, less than or equal to 0.030% of P, less than or equal to 0.030% of S and the balance Fe and inevitable impurities. According to the metal powder, the particle size is 15-65 microns andthe fluidity is 16-20 s / 50g. The invention further provides the application method of the metal powder. According to the application method, by adopting an super-high-speed laser cladding technology,and matching different processes, a shaft part base body surface is strengthened and repaired.

Owner:中机新材料研究院(郑州)有限公司

Anticorrosion, insulation and wear-resisting treatment method for oil pipeline surface

ActiveCN104726873BHigh surface hardnessImprove bindingSolid state diffusion coatingChemical vapor deposition coatingCarbon filmSurface cleaning

The invention provides an anti-corrosive insulated wear-resistant treatment method for a petroleum pipeline surface. The method comprises the following steps: 1 carrying out surface gas nitriding treatment; 2 carrying out surface electrolytic polishing treatment in an electrolytic polishing pond; 3 carrying out surface cleaning treatment in an ultrasonic cleaning tank; 4 carrying out surface argon ion bombardment cleaning treatment in chemical vapor deposition equipment; and 5 carrying out vapor deposition on a diamond-like carbon film which is 1-10micron thick in the chemical vapor deposition equipment. Through the technical scheme provided by the invention, the hardness of a dense anti-corrosive insulated protection film formed on the petroleum pipeline surface is 2,000-3,000HV; the electrical resistivity is greater than 2*10<9>ohm.cm; the film deposition process can be carried out below 500 DEG C; the mechanical property of the material of a petroleum pipeline workpiece can be well reserved; meanwhile, the film which is not greater than 10 microns can cover the inner surface and the outer surface of the workpiece; the anti-corrosive, wear-resistant and insulating properties of the part surfaces of screw threads and flanges of the petroleum pipeline are greatly improved; and the process is simple and easy to popularize.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Corrosion-resistant low-temperature solder for photovoltaic ribbon and preparation method thereof

ActiveCN105014254BImprove surface corrosion resistanceLow melting pointWelding/cutting media/materialsSoldering mediaDip solderingPorous carbon

The invention discloses corrosion-resistant low-temperature solder for a photovoltaic solder strip and a preparation method of the corrosion-resistant low-temperature solder. The solder comprises, by weight, 55%-60% of Bi, 0-0.01% of Sb, 0-0.0005% of Al, 0-0.0005% of Zn and the balance tin. The method comprises the following steps that a proper amount of the tin and bismuth is heated to 280 DEG C to 300 DEG C, and mixed melt is obtained; a proper amount of bismuth chloride is added to cover the surface of the mixed melt, then heat preservation is carried out, temperature is reduced to below 180 DEG C after stirring of 15-20 minutes, and molten solder is obtained; and finally the molten solder is filtered through porous carbon, the filtered molten solder is cast, and the corrosion-resistant low-temperature solder is obtained. According to the solder, the content of the key component Bi is controlled, it is measured that the melting point is close to 139 DEG C, the temperature difference of a solid phase and a liquid phase is only about 12 DEG C, and the phenomenon of segregation can be effectively avoided in dip soldering and other welding processes with the high cooling rate; the content of impurities is controlled to be low, so that the melting point of the prepared solder is low, and the corrosion resistance of the prepared solder is high.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com