Magnesium alloy surface gradient laser cladding layer and preparation technology thereof

A preparation process, laser cladding technology, applied in metal material coating process, coating, etc., can solve the problem of reducing the enhancement effect of magnesium alloy surface corrosion resistance, excessive dilution rate of substrate to cladding layer, physical properties Large differences and other problems, to achieve the effect of reducing dilution, enhancing corrosion resistance, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] 1. Use volume ratio water glass: H 2 The solution of O=1:3 is used as a binder, and the binder is mixed with Ni35 powder to make a paste or paste, and at the same time, the binder is mixed with Al-Si eutectic alloy powder to make a paste or paste shape.

[0073] 2. First cut the AZ91D magnesium alloy sheet into blocks with a DK77-40 electric discharge CNC wire cutting machine, and then use a milling machine to mill out grooves on the surface of the block AZ91D magnesium alloy. Use 180# sandpaper to polish the surface of the groove to remove the oxide skin on the surface of the groove. First coat the Al-Si eutectic alloy powder prepared into a paste or paste in the groove, control the thickness of the coating to 0.5mm, place it in a cool place to dry naturally, and then apply the prepared paste or paste Ni35 The powder is coated in the groove, and the thickness of the coating is controlled to 0.8mm, and then placed in a cool place to dry naturally.

[0074] 3. Adopt T...

Embodiment 2

[0076] This embodiment is the same as Embodiment 1, except that the parameters of the laser cladding treatment are as shown in Table 1, and sample B2 is obtained.

Embodiment 3

[0078] This embodiment is the same as Embodiment 1, except that the parameters of the laser cladding treatment are as shown in Table 1, and sample B3 is obtained.

[0079] Table 1 Laser cladding pre-coating powder ratio and process parameters

[0080]

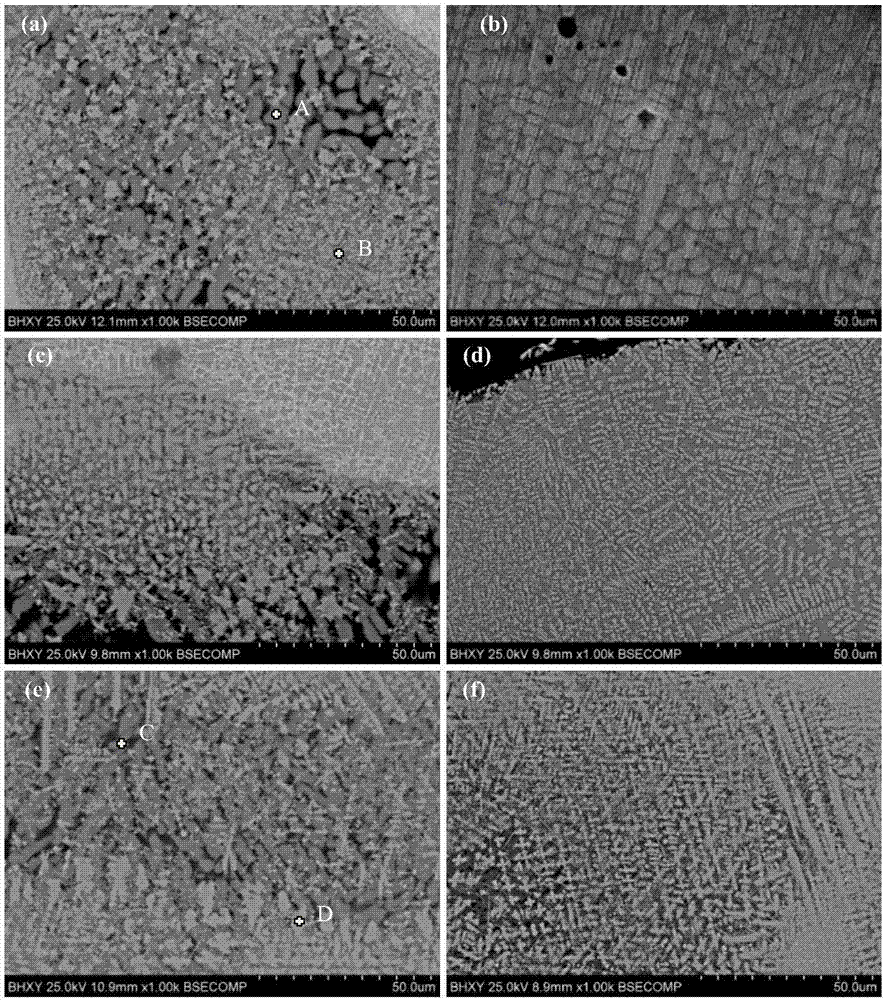

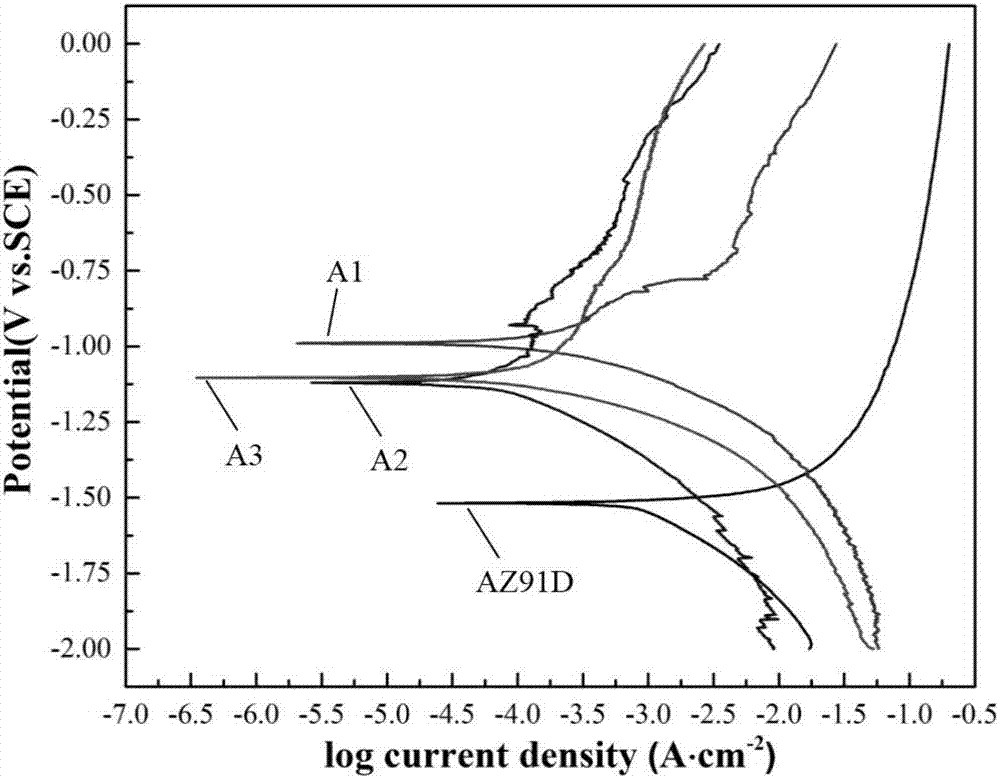

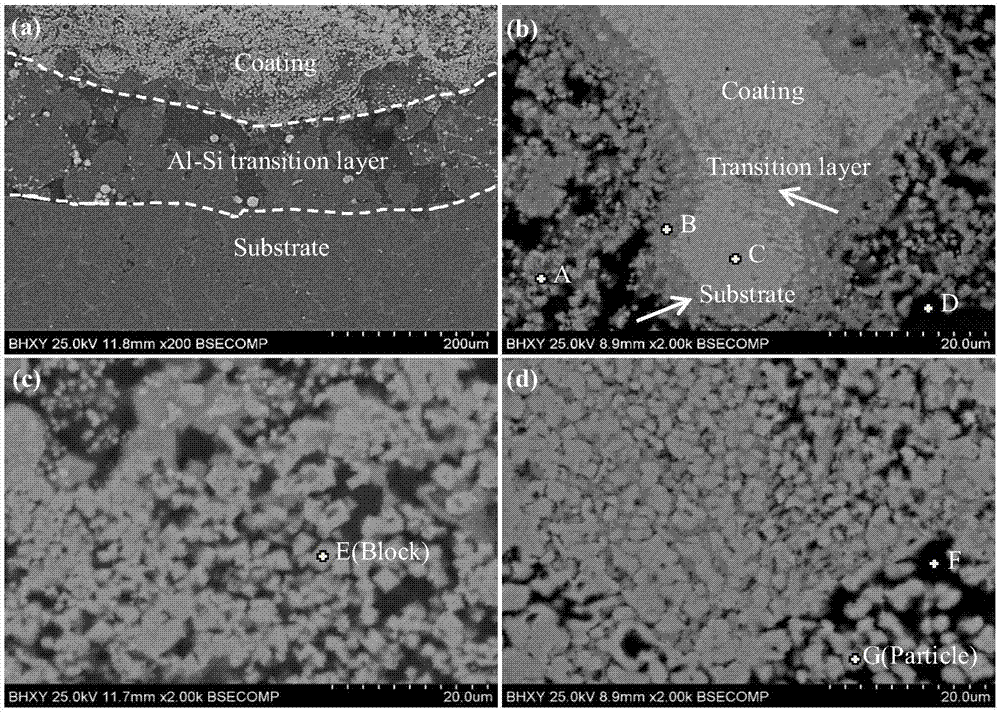

[0081] Metallographic sample preparation is carried out to the sample prepared by comparative examples 1~3, embodiment 1~3

[0082] The clad samples were cut along the direction perpendicular to the scanning speed, ground and polished for follow-up observation. After mounting the cut sample with XQ-2B mounting machine, use 180#, 360#, 720# water sandpaper and 400#, 600#, 1000# metallographic sandpaper to polish, until the cross section only shows Tiny scratches distributed in the same direction.

[0083] The polished sample was polished with a polishing machine, and a 2.5 μm diamond polishing agent was used in the polishing process to obtain a sample with a shiny surface and almost no scratches. Clean the sample with alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com