Repair process of screw rod compressor rotor

A screw compressor and rotor technology, applied in the field of compressors, can solve the problems of screw rotor corrosion, low repair timeliness, screw compressor rotor scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

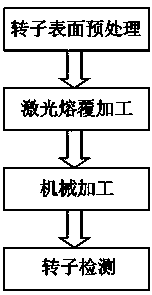

[0016] The specific implementation steps are as follows:

[0017] a) Rotor surface pretreatment, the specific process is: first, clean and polish the corrosion fatigue layer, spiral surface and end surface corrosion of the male and female rotor body to remove the fatigue layer; then according to the size and shaft diameter surface damage, the male and female The diameter of the rotor support shaft, the shaft diameter of the synchronous gear, and the shaft diameter of the seal are rough-turned; then the rotor is subjected to a comprehensive non-destructive inspection; finally, a special cleaning agent is used to clean the surface of the rotor.

[0018] b) Laser cladding processing, laser cladding processing includes the following steps: 1) Configure laser cladding metal powder; according to the composition and actual working conditions of the rotor, the composition and mass ratio of the laser cladding metal powder configured are: manganese 55%, 15% chromium, 13% nickel, and 17%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com