Waste sagger repairing coating and use method thereof

A technology for repairing paint and saggers, which is applied in the field of recycling waste saggers, can solve the problems of shortening the service life of recycled saggers, affecting the quality of recycled saggers, and not mentioning harmful metals, etc., and achieves strong oxidation resistance and corrosion resistance , Good thermal shock stability, and the effect of reducing the difficulty of stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

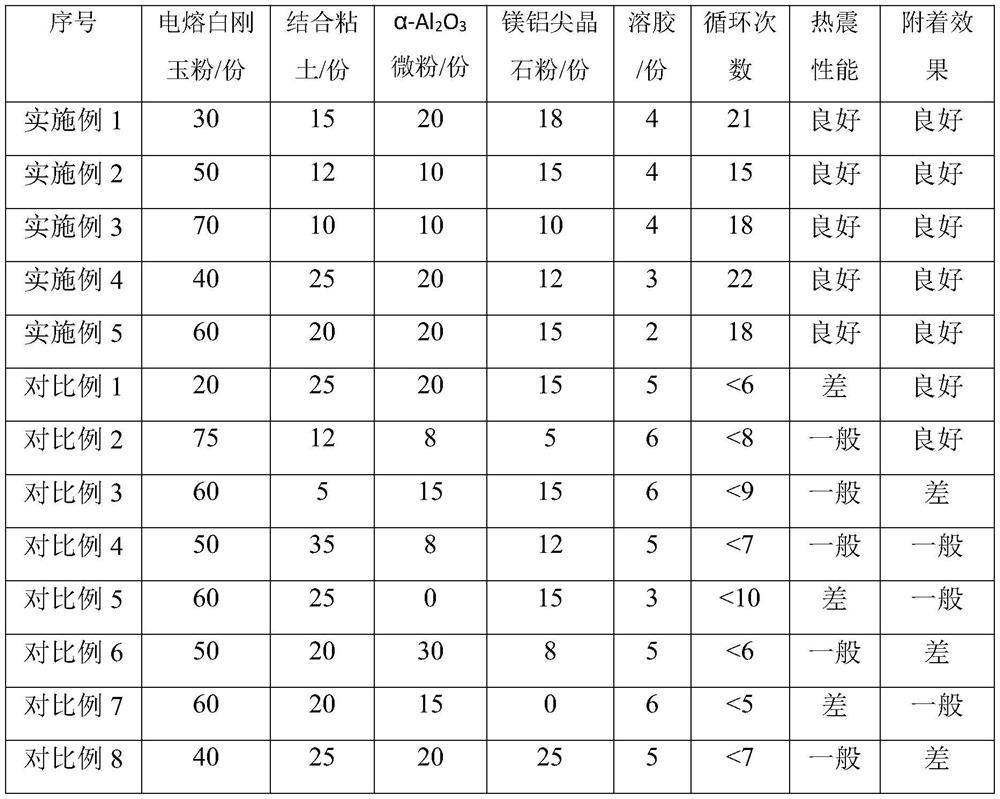

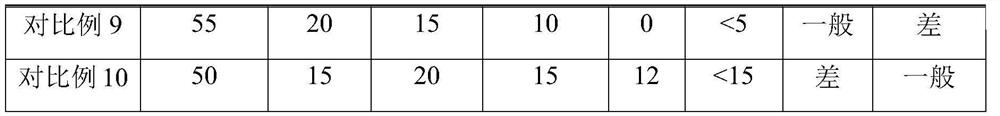

Examples

Embodiment 1

[0029] A paint for repairing waste saggers, comprising the following raw material components in parts by weight: fused white corundum powder (fused white corundum powder is made of industrial alumina powder, which is smelted at a high temperature above 2000°C in an electric arc and then cooled. 30 parts, 5 parts of mullite powder, 15 parts of bonded clay (the particle size is 325 mesh, and the production site is Guangxi), spodumene 3 parts, 4 parts of zirconia, α-Al 2 o 3 20 parts of fine powder, 18 parts of magnesium aluminum spinel powder, 4 parts of sol, 5 parts of binder, 0.3 part of water reducing agent and 18 parts of water.

[0030] The binder is 2 parts of dextrin, 1 part of U.S. rubber powder and 2 parts of polyurethane, wherein the model of U.S. rubber powder is TH-2008.

[0031] The sol is aluminum sol.

[0032] The water reducer is sodium tripolyphosphate.

[0033] The particle size of the fused white corundum powder is 300 mesh, the particle size of the mullit...

Embodiment 2

[0046] The difference from Example 1 is that the waste sagger restoration paint includes the following raw material components in parts by weight: 50 parts of fused white corundum powder, 4 parts of mullite powder, 12 parts of bonded clay, and 4 parts of spodumene , 2 parts of zirconia, α-Al 2 o 3 10 parts of fine powder, 15 parts of magnesium aluminum spinel powder, 4 parts of sol, 4 parts of binder, 0.5 part of water reducing agent and 16 parts of water.

[0047] The binder is 1 part of starch, 1 part of U.S. rubber powder and 2 parts of polyurethane, wherein the model of U.S. rubber powder is TH-2008.

[0048] The sol is silica sol.

[0049] The water reducer is sodium polyacrylate.

[0050] The particle size of the fused white corundum powder is 200 mesh.

[0051] In the step of preparing the repair paint, the stirring rate to obtain the repair paint is 1000r / min, and the stirring time is 20min.

[0052] In the step of repairing the waste saggar, the firing temperatur...

Embodiment 3

[0054] The difference from Example 1 is that the waste sagger restoration paint includes the following raw material components in parts by weight: 70 parts of fused white corundum powder, 3 parts of mullite powder, 10 parts of bonded clay, and 2 parts of spodumene , 2 parts of zirconia, α-Al 2 o 3 10 parts of fine powder, 10 parts of magnesium aluminum spinel powder, 4 parts of binder, 0.4 part of water reducing agent and 20 parts of water.

[0055] The binder is 1 part of dextrin, 2 parts of U.S. rubber powder and 1 part of polyacrylamine, wherein the model of U.S. rubber powder is TH-2008.

[0056] The water reducer is sodium hexametaphosphate.

[0057] The particle size of the fused white corundum powder is 100 mesh.

[0058] In the step of preparing the repair paint, the stirring speed for obtaining the mixed powder is 1000 r / min, and the stirring time is 2.5 hours.

[0059] In the step of preparing the repair paint, the stirring rate to obtain the repair paint is 1100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com