Rare earth permanent magnet with multilayer composite electroplated coating and composite electroplating method thereof

A rare earth permanent magnet, multi-layer composite technology, used in the manufacture of permanent magnets, magnetic objects, permanent magnets, etc., can solve problems such as adverse effects on eyes, and achieve uniform appearance, improved corrosion resistance, and black and bright colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

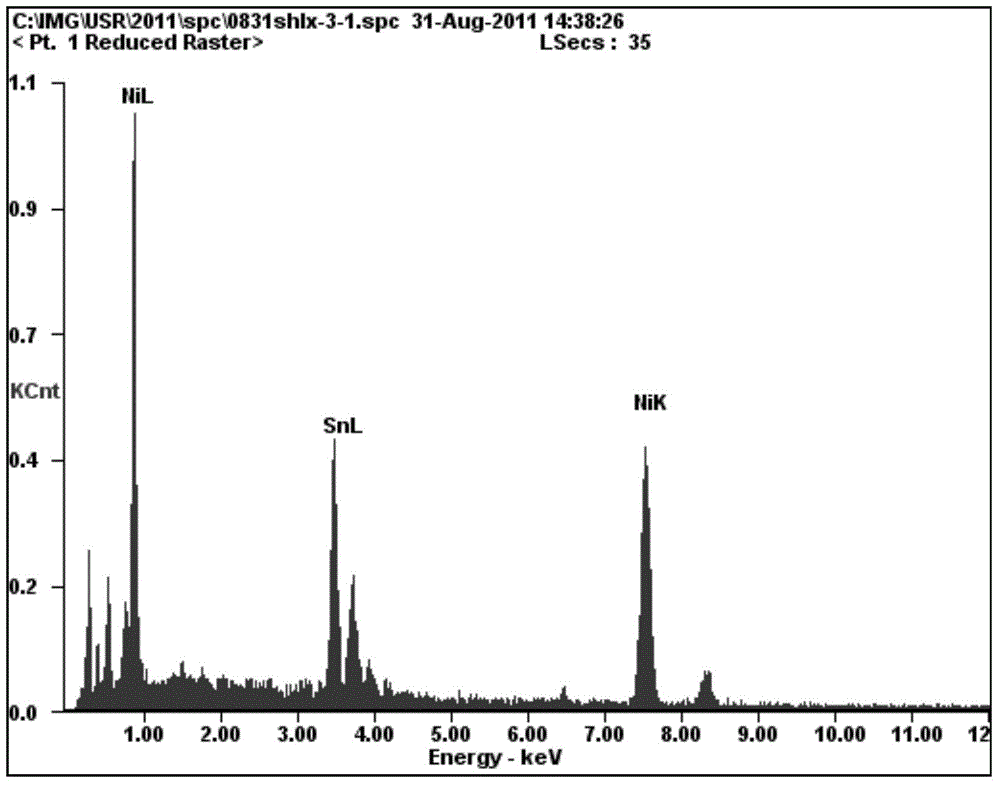

Image

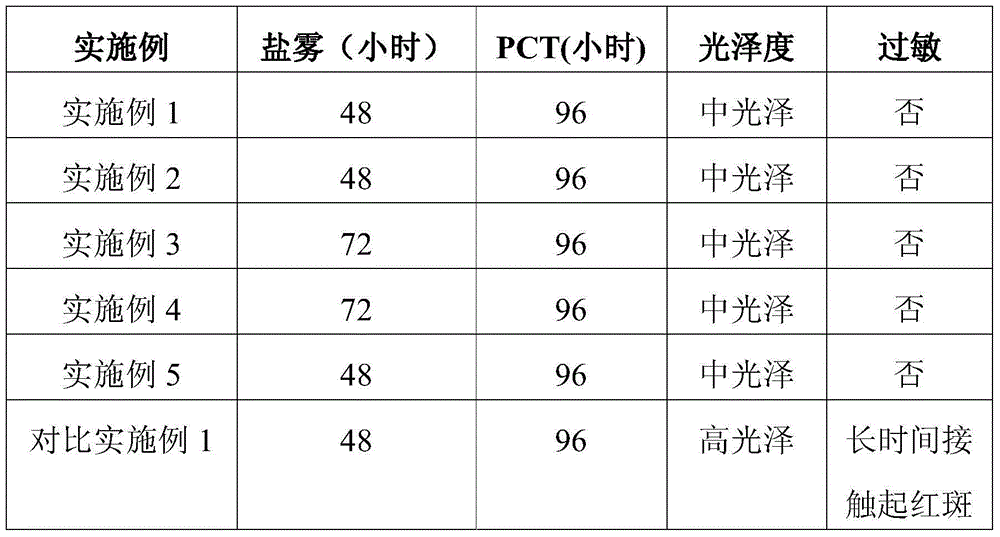

Examples

Embodiment 1

[0017] Will 2.3 kilograms of sintered NdFeB permanent magnet materials were first polished in a vibration mill for 2 hours. After degreasing and degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter, pickling in 1% nitric acid to remove surface oxides, washing with water, electroplating the first layer of nickel coating, electroplating nickel is ordinary electroplating Watt nickel, the formula of the electroplating solution is as follows: nickel sulfate 275 g / l, nickel chloride 30 g / l, boric acid 40 g / l, pH 3.5, temperature 60°C, nickel concentration 2.0 mol / l, nickel plating thickness 5 microns .

[0018] Then wash with water, and use electroplating copper pyrophosphate to electroplate the second layer of copper coating. 55°C, the coating thickness is 7 microns.

[0019] Next, use the bright nickel electroplating solution to electroplate the third layer of nickel coating. The formula of the bright nickel plating solution is as ...

Embodiment 2

[0022] Will 2.3 kilograms of sintered NdFeB permanent magnet materials were first polished in a vibration mill for 2 hours. After degreasing and degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter, pickling in 1% nitric acid to remove surface oxides, washing with water, electroplating the first layer of nickel coating, electroplating nickel is ordinary electroplating Watt nickel, the formula of the electroplating solution is as follows: nickel sulfate 150 g / l, nickel chloride 20 g / l, boric acid 40 g / l, pH 4.5, temperature 35°C, nickel concentration 1.0 mol / l, nickel plating thickness 3 microns .

[0023] Then wash with water, and use electroplating copper pyrophosphate to electroplate the second layer of copper coating. 60°C, coating thickness 10 microns.

[0024] Next, use the bright nickel electroplating solution to electroplate the third layer of nickel coating. The formula of the bright nickel plating solution is as follow...

Embodiment 3

[0027] Will 2.3 kilograms of sintered NdFeB permanent magnet materials were first polished in a vibration mill for 2 hours. After degreasing and degreasing with sodium phosphate 20g / liter, sodium carbonate 10g / liter, sodium hydroxide 10g / liter, pickling in 1% nitric acid to remove surface oxides, washing with water, electroplating the first layer of nickel coating, electroplating nickel is ordinary electroplating Watt nickel, the formula of the electroplating solution is as follows: nickel sulfate 200 g / l, nickel chloride 30 g / l, boric acid 40 g / l, pH 3.5, temperature 55°C, nickel concentration 1.5 mol / l, nickel plating thickness 4 microns .

[0028]Then wash with water, and use electroplating copper pyrophosphate to electroplate the second layer of copper coating. 55°C, the coating thickness is 10 microns.

[0029] Then, the third layer of nickel coating is electroplated with a semi-bright nickel plating solution. The formula of the semi-bright nickel plating solution is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com