Ultra-high-speed laser cladding iron-based metal powder, and preparation method and application thereof

A laser cladding and iron-based metal technology, which is applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of restricting the popularization and application of laser cladding technology, low energy utilization rate, and slow cladding rate, etc. problems, to achieve the effect of smooth surface, improved service life, and good powder aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preferably, a powder preparation method is provided, which is characterized in that the method is as follows: raw material components are alloyed and proportioned, and then vacuum smelted, and the vacuum degree of the smelting chamber is 10 -1 ~10 -2 Pa, using gas atomization method to make powder, powder spraying gas argon pressure 1.2~3.8MPa, particle size screening after collecting powder, screening metal powder in the particle size range of 15~65μm, to obtain iron-based metal for ultra-high-speed laser cladding powder.

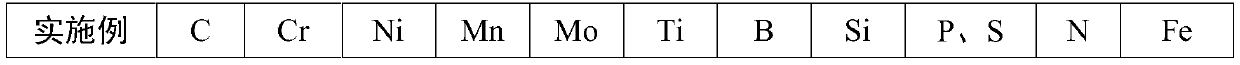

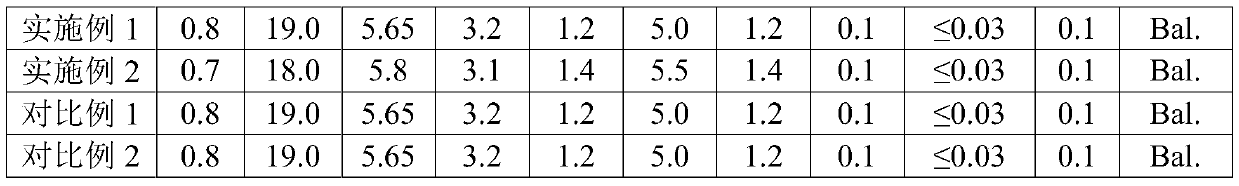

[0034] Preferably, an iron-based metal powder is provided, the mass fraction of each element is: C 0.8%, Cr 19.0%, Ni 5.65%, Mn 3.2%, Mo 1.2%, Ti 5.0%, B 1.2%, N 0.09 %, Si≤0.5%, P≤0.030%, S≤0.030%, the balance is Fe and unavoidable impurities.

[0035] The particle size of the metal powder is: 15 ~ 65μm, fluidity: 18s / 50g, sphericity ≥ 91%, D 50 = 32 μm.

[0036] Preferably, the powder has an oxygen content of 160 ppm. Hollow flour rate <1%. ...

Embodiment 2

[0044] Preferably, a powder preparation method is provided, which is characterized in that the method is as follows: raw material components are alloyed and proportioned, and then vacuum smelted, and the vacuum degree of the smelting chamber is 10 -1 ~10 -2 Pa, adopt the gas atomization method to make powder, the argon gas pressure of the powder spraying gas is 1.2~3.8MPa, after collecting the powder, carry out particle size screening, and screen the metal powder with a particle size range of 15~65μm to obtain the iron-based metal for ultra-high-speed laser cladding powder.

[0045]Preferably, an iron-based metal powder is provided, the mass fraction of each element is: C 0.7%, Cr 18.0%, Ni 5.8%, Mn 3.1%, Mo 1.4%, Ti 5.5%, B 1.2%, N 0.09 %, Si≤0.5%, P≤0.030%, S≤0.030%, the balance is Fe and unavoidable impurities.

[0046] The particle size of the metal powder is: 15~65μm, fluidity: 18s / 50g, sphericity ≥ 95%, D 50 = 34 μm.

[0047] Preferably, the powder has an oxygen cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com