Surface treatment technique for metal material

A metal material and surface treatment technology, applied in the direction of metal material coating process, superimposed layer plating, coating, etc., can solve the problems of insufficient mechanical bonding force, weak interface bonding force, and reduced service life, so as to improve Effects of surface properties, surface roughness reduction, and service life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

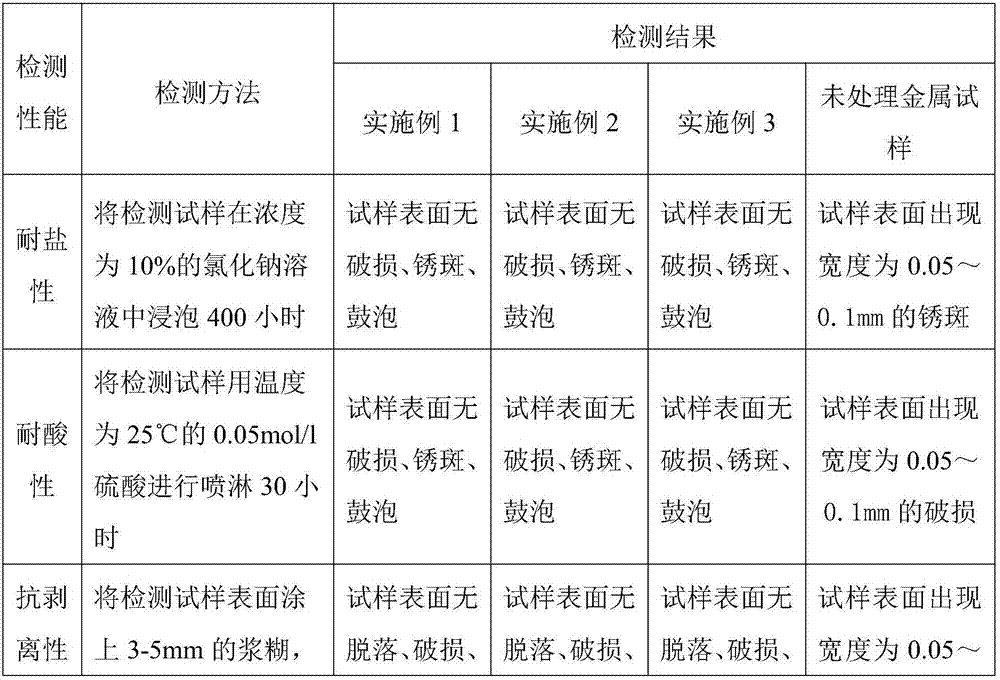

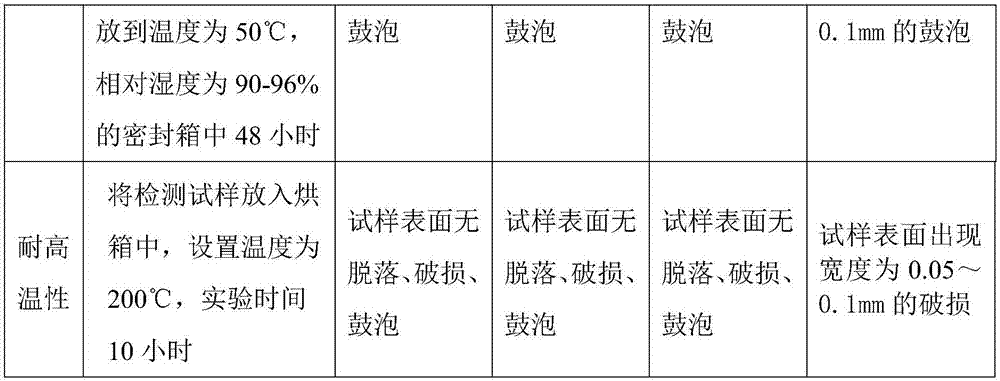

Examples

Embodiment 1

[0021] A metal material surface treatment process, comprising the following steps:

[0022] (1) Grinding, polishing, cleaning and drying the surface of the metal material;

[0023] (2) Carry out micro-modeling on the surface of the metal material processed through step (1) to process micro-grooves; coat the polyvinyl chloride micro-particle powder on the surface of the metal material, so that the polyvinyl chloride micro-particle powder is filled in the micro-grooves Among them: impact the surface of the metal material with an ultrasonic impact head, so that the polyvinyl chloride micro-particle powder and the metal in the micro-groove are mixed and refined to nanometer;

[0024] (3) Carry out micro-modeling again on the metal material surface that is processed through step (2), process micro-grooves, the position of micro-grooves and micro-grooves in step (2) is staggered; Coat nano ceramics on the metal material surface Powder, so that the nano-ceramic powder is filled in t...

Embodiment 2

[0034] A metal material surface treatment process, comprising the following steps:

[0035] (1) Grinding, polishing, cleaning and drying the surface of the metal material;

[0036] (2) Carry out micro-modeling on the surface of the metal material processed through step (1) to process micro-grooves; coat the polyvinyl chloride micro-particle powder on the surface of the metal material, so that the polyvinyl chloride micro-particle powder is filled in the micro-grooves Among them: impact the surface of the metal material with an ultrasonic impact head, so that the polyvinyl chloride micro-particle powder and the metal in the micro-groove are mixed and refined to nanometer;

[0037] (3) Carry out micro-modeling again on the metal material surface that is processed through step (2), process micro-grooves, the position of micro-grooves and micro-grooves in step (2) is staggered; Coat nano ceramics on the metal material surface Powder, so that the nano-ceramic powder is filled in t...

Embodiment 3

[0047] A metal material surface treatment process, comprising the following steps:

[0048] (1) Grinding, polishing, cleaning and drying the surface of the metal material;

[0049] (2) Carry out micro-modeling on the surface of the metal material processed through step (1) to process micro-grooves; coat the polyvinyl chloride micro-particle powder on the surface of the metal material, so that the polyvinyl chloride micro-particle powder is filled in the micro-grooves Among them: impact the surface of the metal material with an ultrasonic impact head, so that the polyvinyl chloride micro-particle powder and the metal in the micro-groove are mixed and refined to nanometer;

[0050](3) Carry out micro-modeling again on the metal material surface that is processed through step (2), process micro-grooves, the position of micro-grooves and micro-grooves in step (2) is staggered; Coat nano ceramics on the metal material surface Powder, so that the nano-ceramic powder is filled in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com